Full-process design optimization method for special screwed joint oil casing for shale gas

A special thread and optimization method technology, applied in design optimization/simulation, special data processing applications, geometric CAD, etc., can solve problems such as high cost, few special thread products, long cycle, etc., to reduce test cost and shorten test cycle , The effect of ensuring the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the drawings:

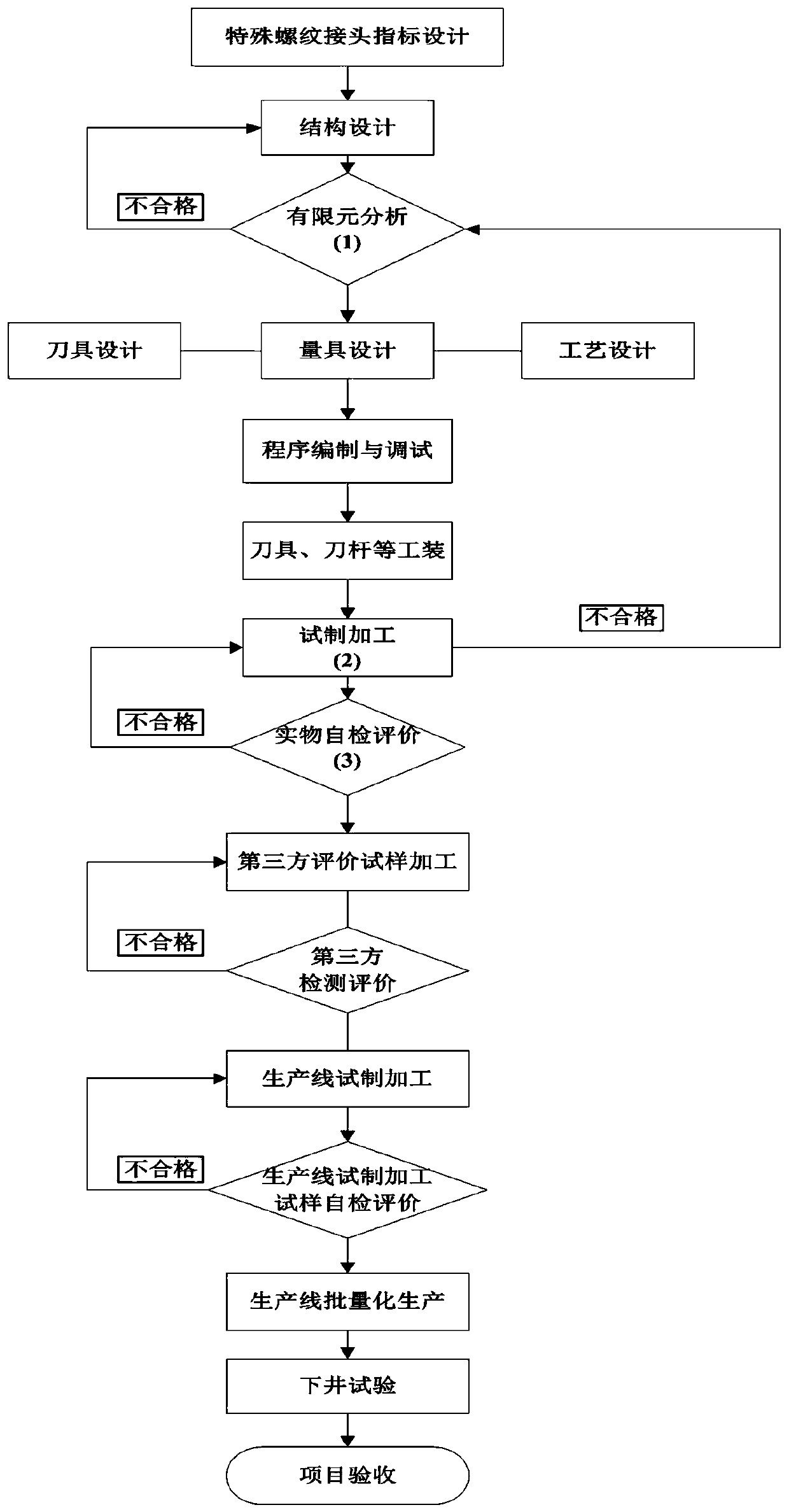

[0023] figure 1 Design optimization methods for the whole process of specific threaded joint tubing and casing for specific shale gas, including:

[0024] Step 1: Determine the performance indicators of the special threaded joint tubing and casing. According to the actual well conditions of the shale gas well in the oil field, determine the performance indicators of the special threaded joint tubing and casing, including: adaptable specifications, material parameters, trial well depth and dogleg degree;

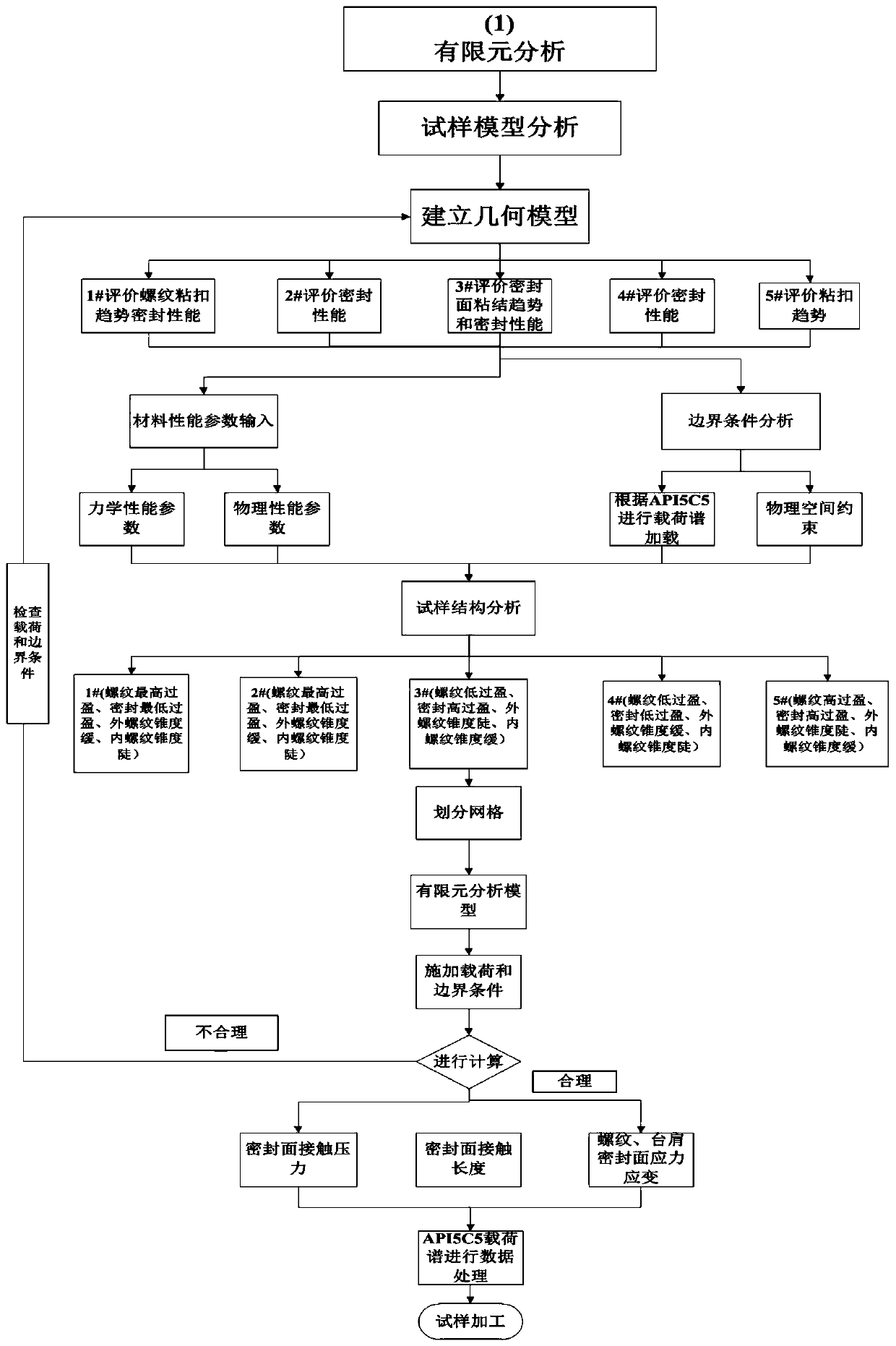

[0025] Step 2: Establish a geometric model, construct a unique constitutive equation, and use the airtight criterion of "contact pressure weighted index + minimum contact length" for finite element simulation calculation analysis.

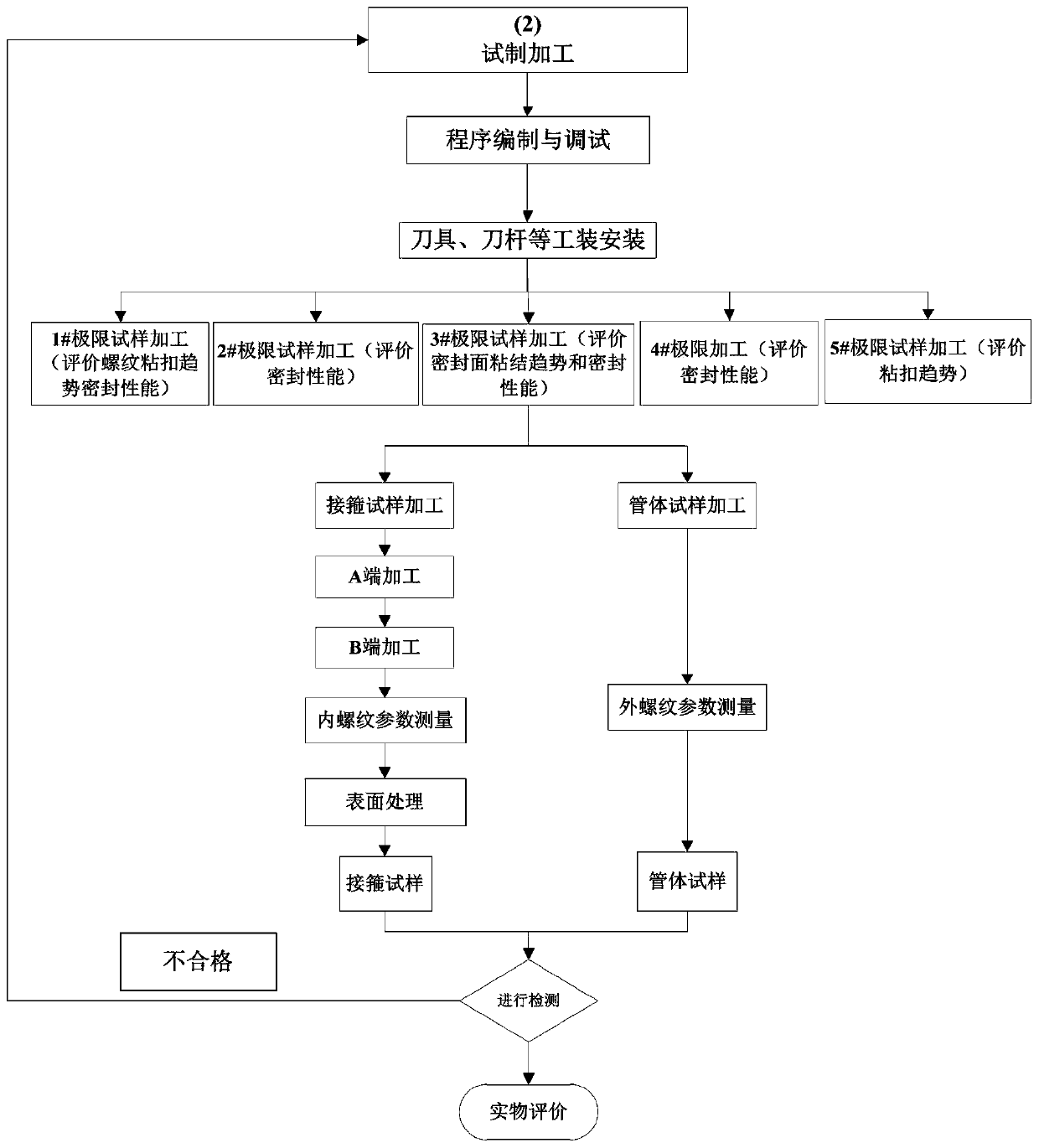

[0026] Such as figure 2 As shown, the geometric modeling software is used to perform parametric geometric modeling of the special threaded joint tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com