Patents

Literature

90results about How to "Omit structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

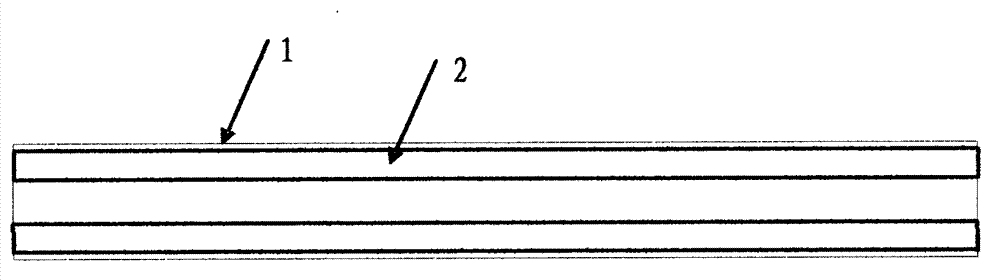

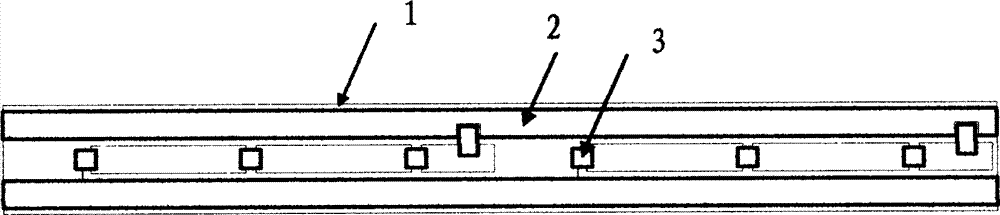

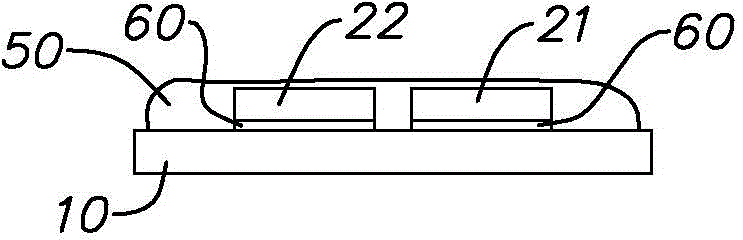

Integrated flip type LED illuminating assembly

InactiveCN102927483AImprove cooling effectOmit structurePoint-like light sourceElectric circuit arrangementsEngineeringBoard structure

The invention relates to an integrated flip type LED (Light Emitting Diode) illuminating assembly. The integrated flip type LED illuminating assembly comprises an LED circuit, a glass carrier for bearing the LED circuit as well as a flip type LED chip which is directly welded in a flip way and is packaged on the glass carrier, wherein the LED circuit and the flip type LED chip are integrated on the glass carrier. According to the integrated flip type LED illuminating assembly, the heat radiating performance and the light emitting performance of the LED lamp are greatly improved and a traditional LED circuit board structure is omitted, so that materials and the labor cost are greatly saved. The glass has favorable light transmitting performance, so that the glass can be used as an outer protecting structure of the LED lamp, fox example, the glass is directly used as a lamp tube of the LED lamp. Therefore, the materials, the price and the mounting cost are further saved.

Owner:田茂福

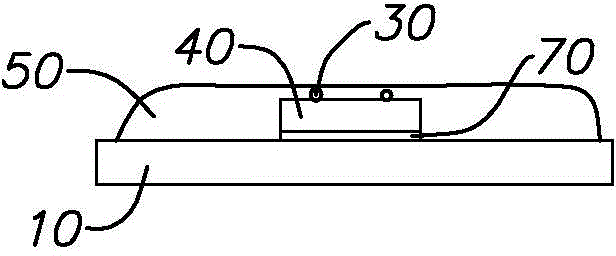

Integrated LED illuminating assembly

InactiveCN102927482ASimple structureReduce process stepsPoint-like light sourceElectric circuit arrangementsEngineeringLED circuit

The invention relates to an integrated LED (Light Emitting Diode) illuminating assembly. The integrated LED illuminating assembly comprises an LED circuit, a glass carrier for bearing the LED circuit as well as an LED chip which is in conductive connection and is packaged on the LED circuit, wherein the LED circuit and the LED chip are integrated on the glass carrier. According to the integrated LED illuminating assembly, the heat radiating performance of the LED lamp is greatly improved and a traditional LED circuit board structure is omitted, so that materials and the labor cost are greatly saved. The glass has favorable light emitting performance, so that the glass can be used as an outer protecting structure of the LED lamp, fox example, the glass is directly used as a lamp tube of the LED lamp. Therefore, the materials, the price and the mounting cost are further saved.

Owner:田茂福

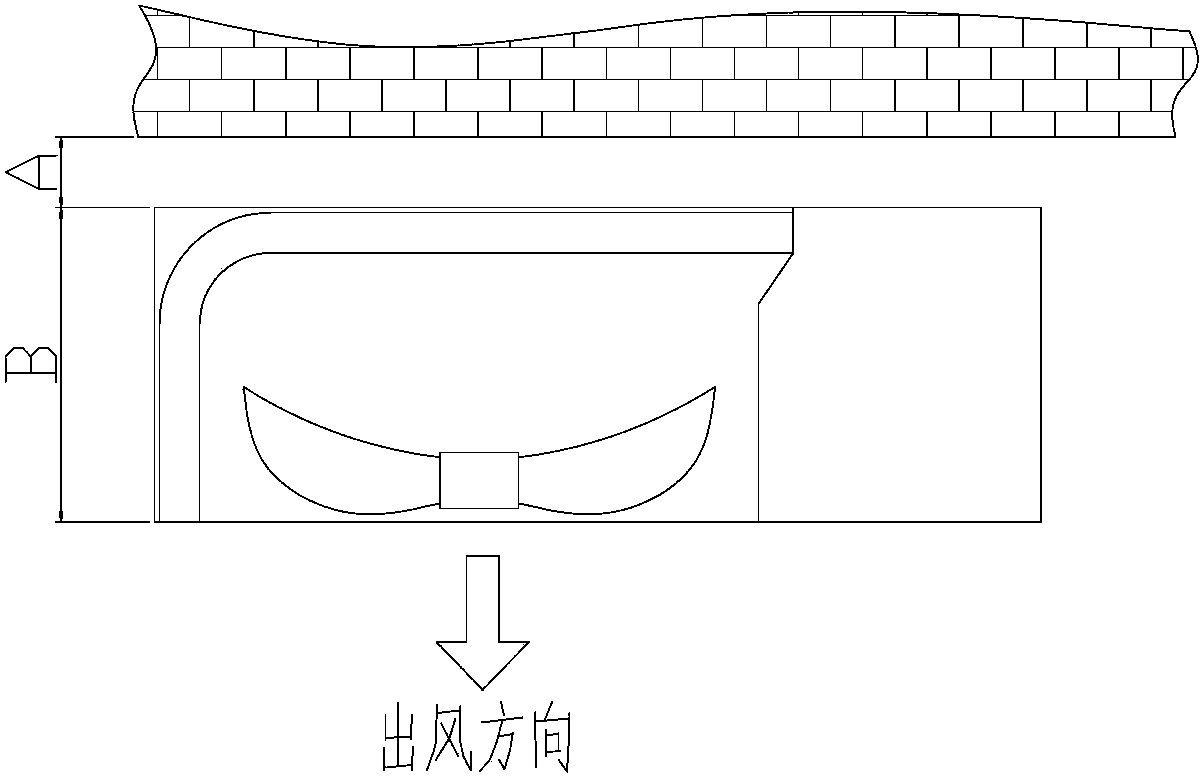

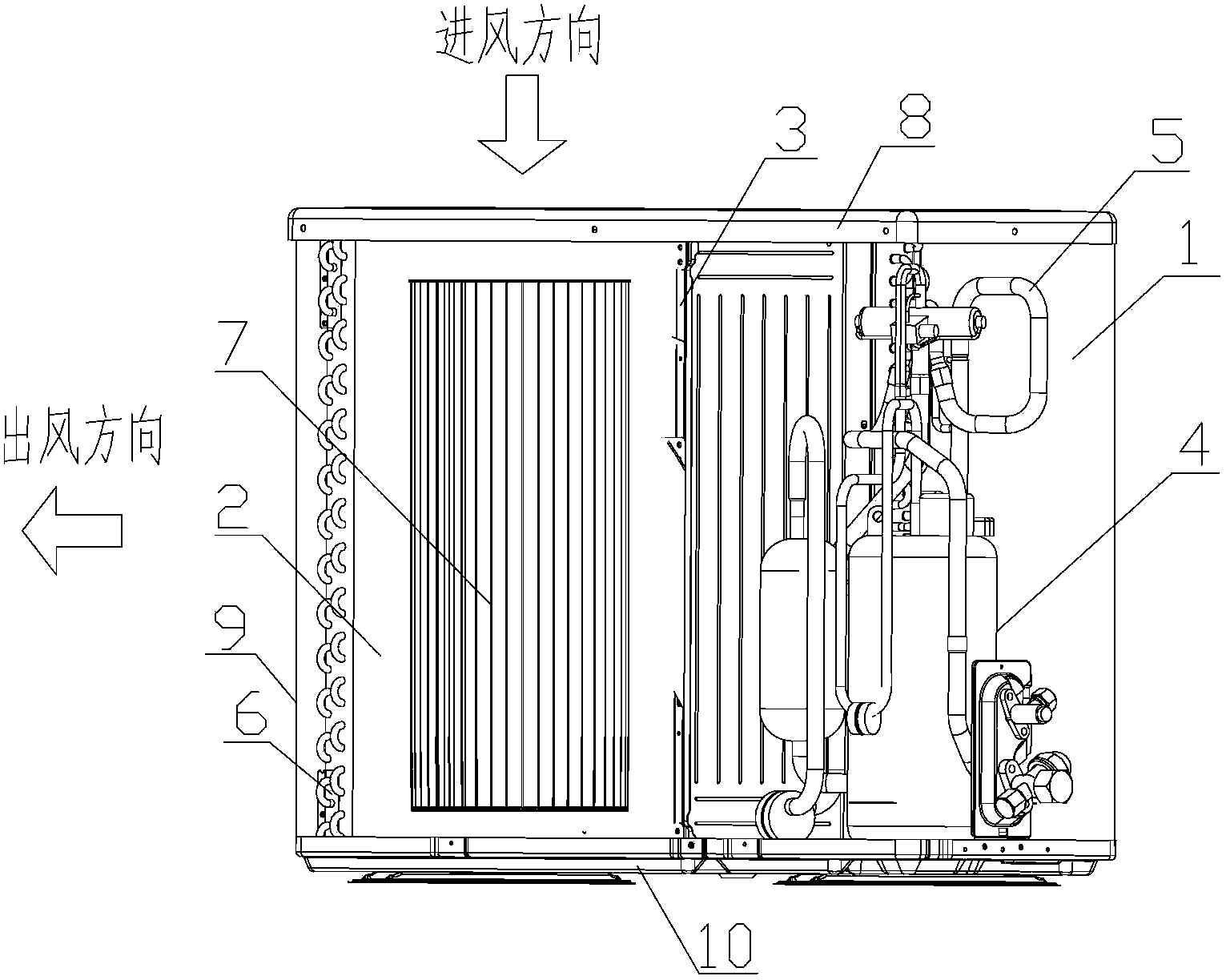

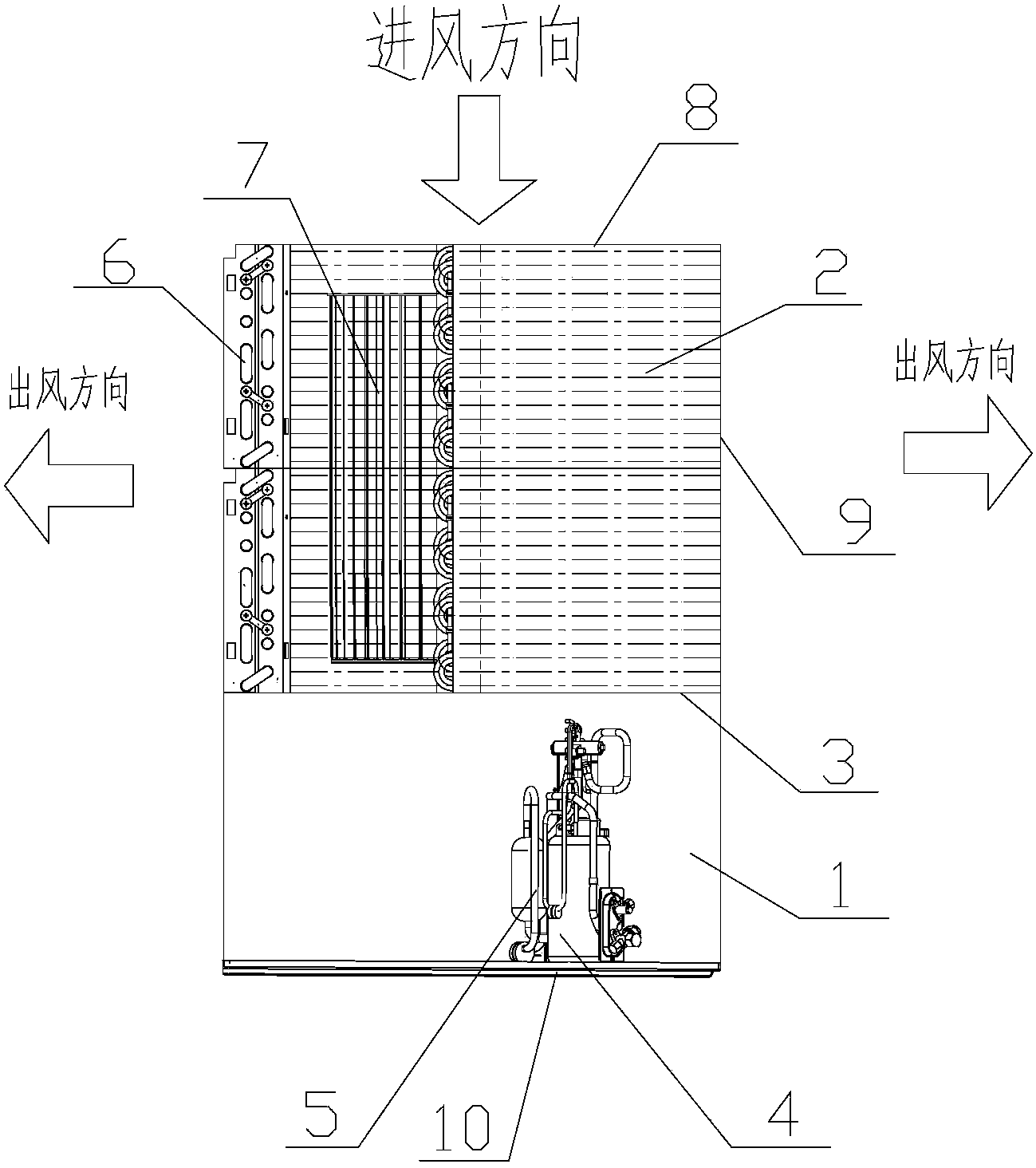

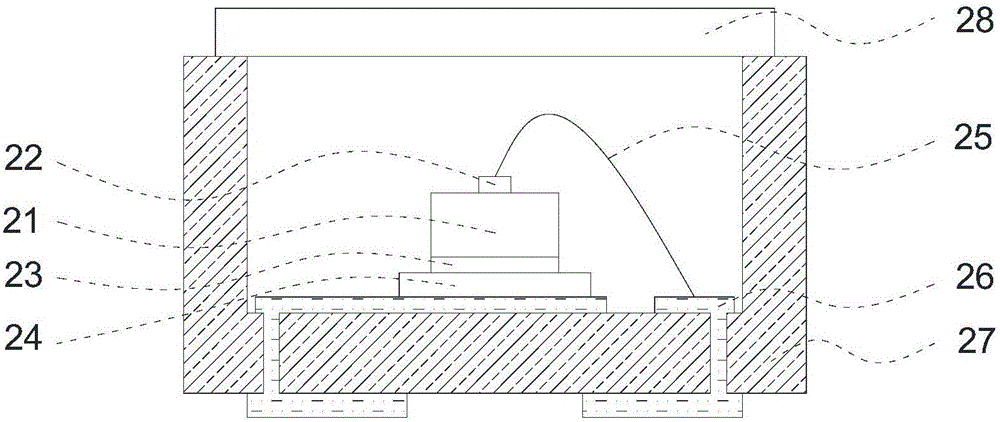

Outdoor unit of air conditioner

InactiveCN104061632AImprove heat transfer effectImprove heat transfer efficiencyLighting and heating apparatusAir conditioning systemsEngineeringCentrifugal force

The invention relates to an outdoor unit of an air conditioner. The outdoor unit comprises a case, wherein the inside of the case is divided into a compressor cavity and a heat exchange cavity by a baffle, a compressor and a pipeline are contained in the compressor cavity, and a heat exchanger and an outdoor fan are contained in the heat exchange cavity; the case consists of a top plate, side plates and a base disc; an air inlet and an air outlet are arranged on the case; the outdoor fan is a centrifugal fan; and the heat exchanger is arranged around the centrifugal fan. With the adoption of the outdoor unit, the accommodating space for the heat exchanger can be enlarged, the even distribution of air flows passing through the heat exchanger can be guaranteed to the maximum extent, and the heat exchange capacity of the outdoor unit and the heat exchange efficiency of the heat exchanger can be improved. In addition, the outdoor unit of the air conditioner adopts the centrifugal fan, can be changed into more forms, can be applied to general mounting conditions and can meet mounting requirements of certain specific places.

Owner:HISENSE HOME APPLIANCES GRP CO LTD +1

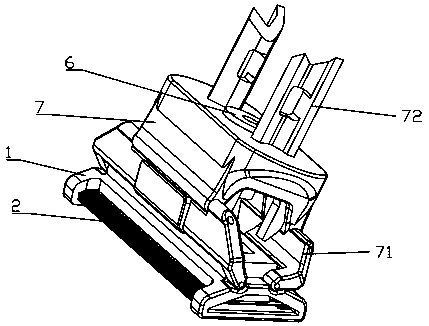

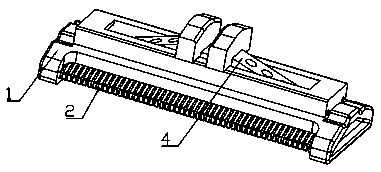

Tool bit structure

The invention provides a tool bit structure. The tool bit structure is characterized in that at least two elastic pieces are arranged on a movable knife, the elastic pieces and the movable knife are of an integrated structure, and the elastic pieces comprise supporting parts and elastic parts on the tops of the supporting parts; and the elastic pieces penetrate through a movable knife rest, and the elastic parts of the elastic pieces abut against a supporting frame and the movable knife rest. The tool bit structure has the beneficial effects that the movable knife and the movable knife rest can be connected and mounted through the elastic pieces, meanwhile, the elastic parts of the elastic pieces can cooperate with the supporting frame, elastic pressure is provided for the movable knife, the movable knife is elastically attached to a fixed knife, compared with an existing conventional tool bit structure, the structures of a set of springs or elastic pieces are omitted, parts are fewer,the cost is lower, and mounting is more convenient.

Owner:WENZHOU RUNWE ELECTRICAL APPLIANCE

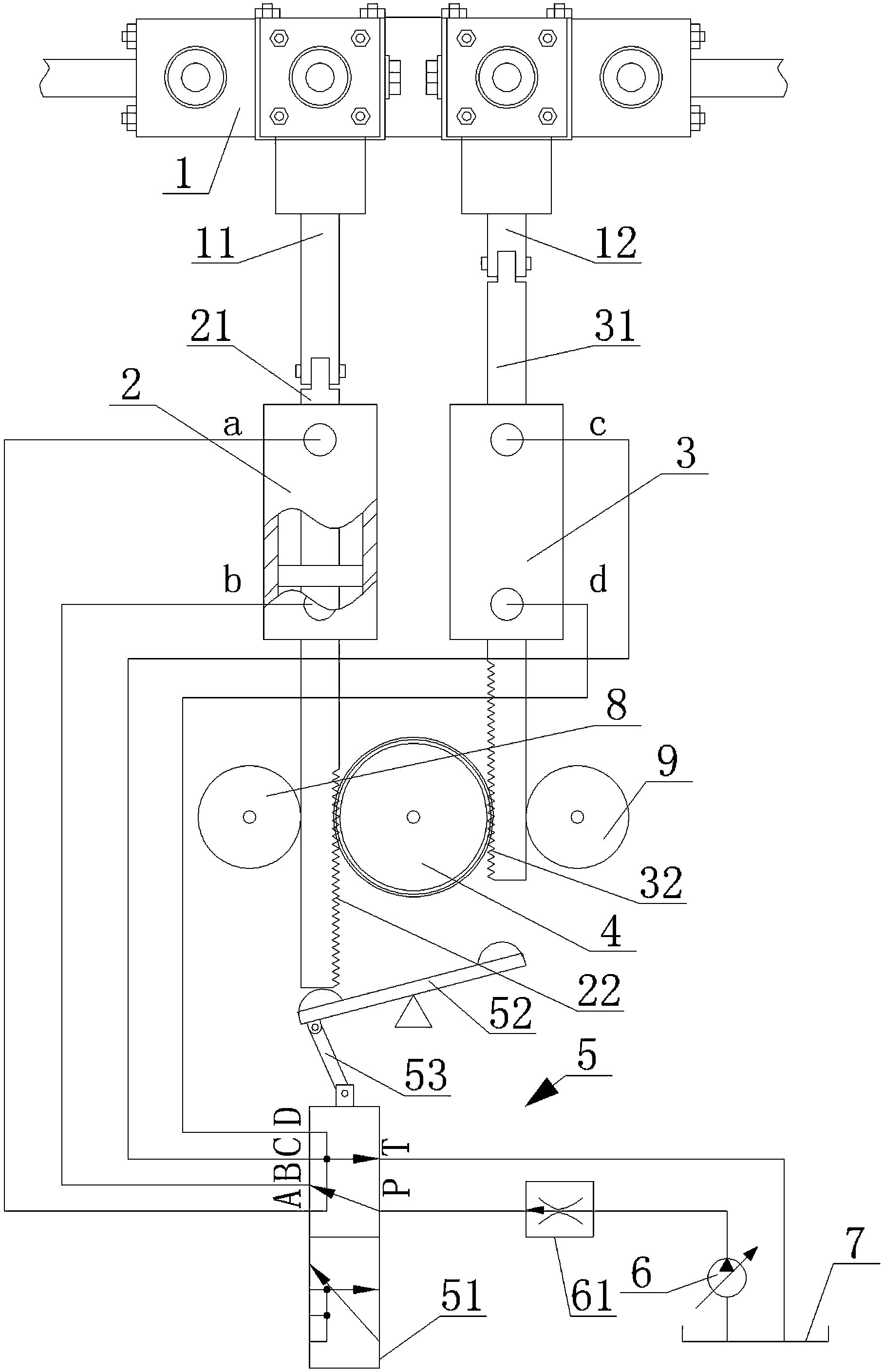

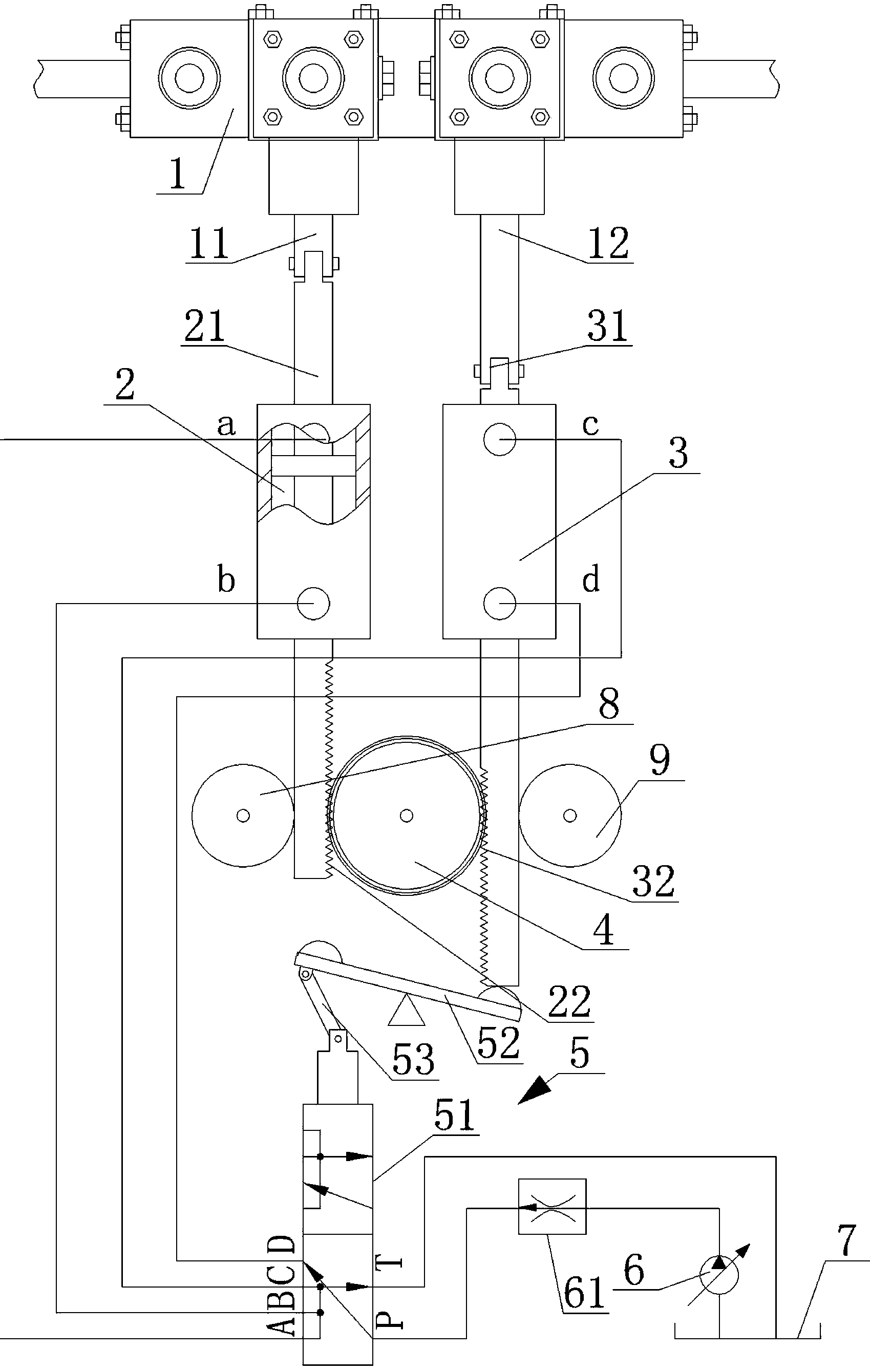

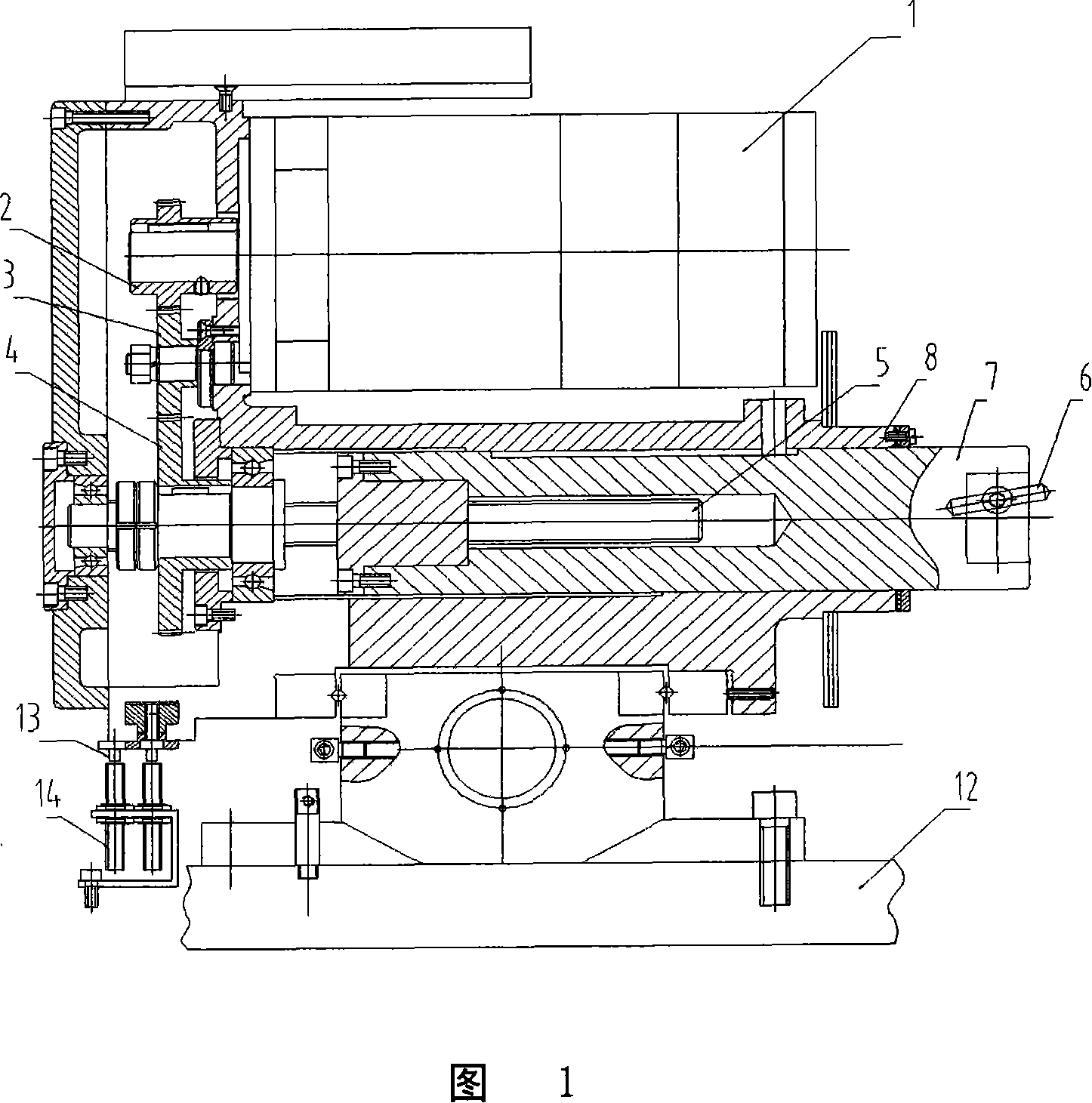

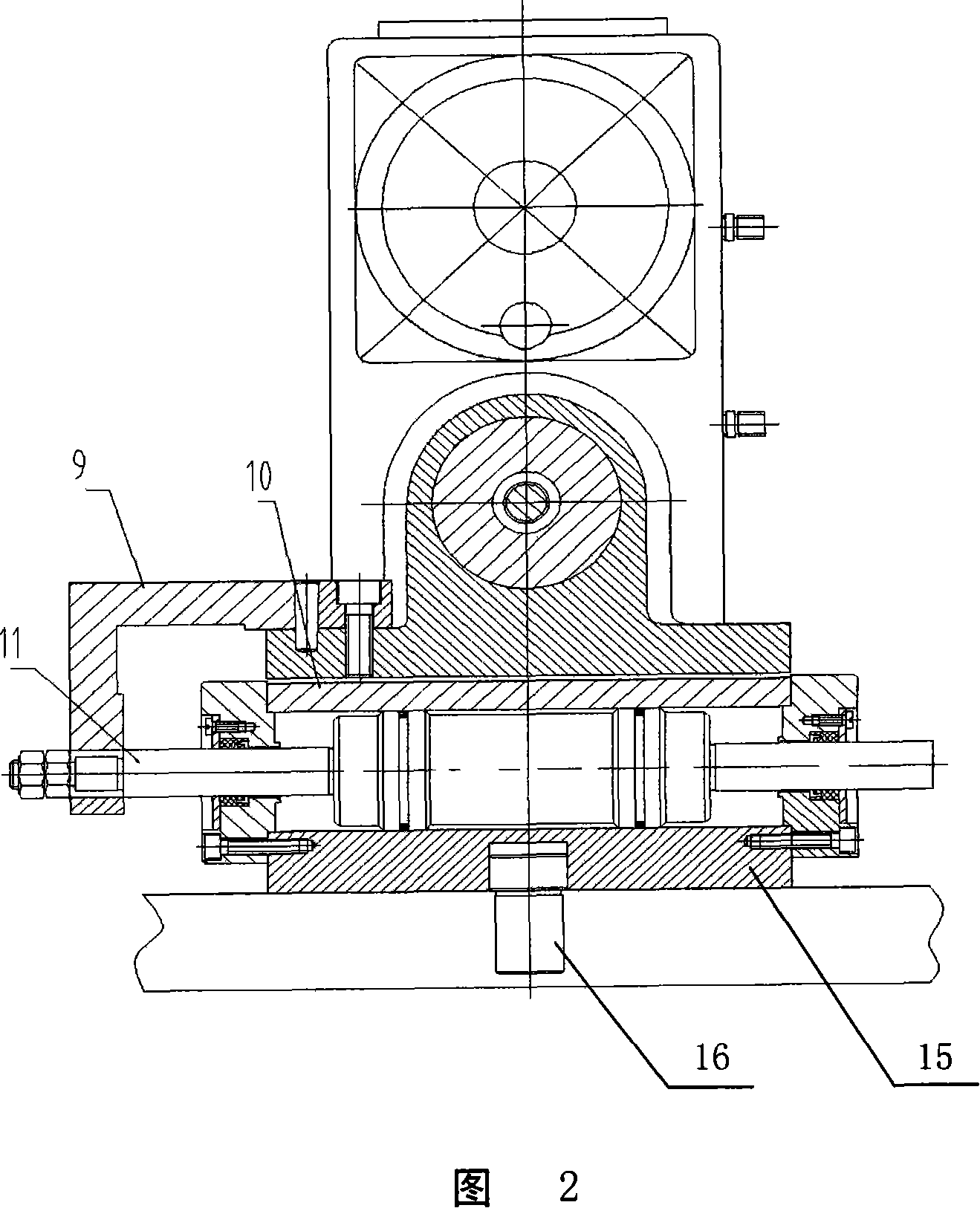

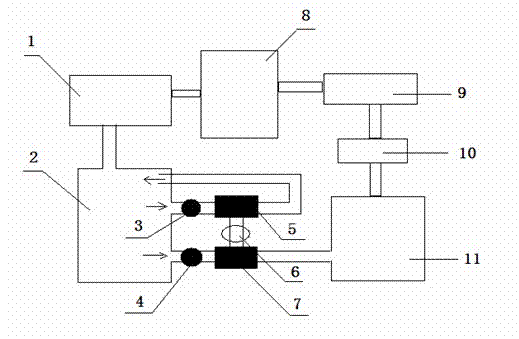

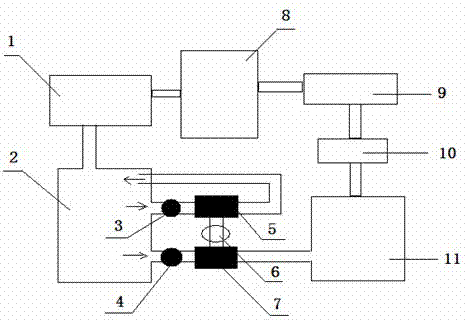

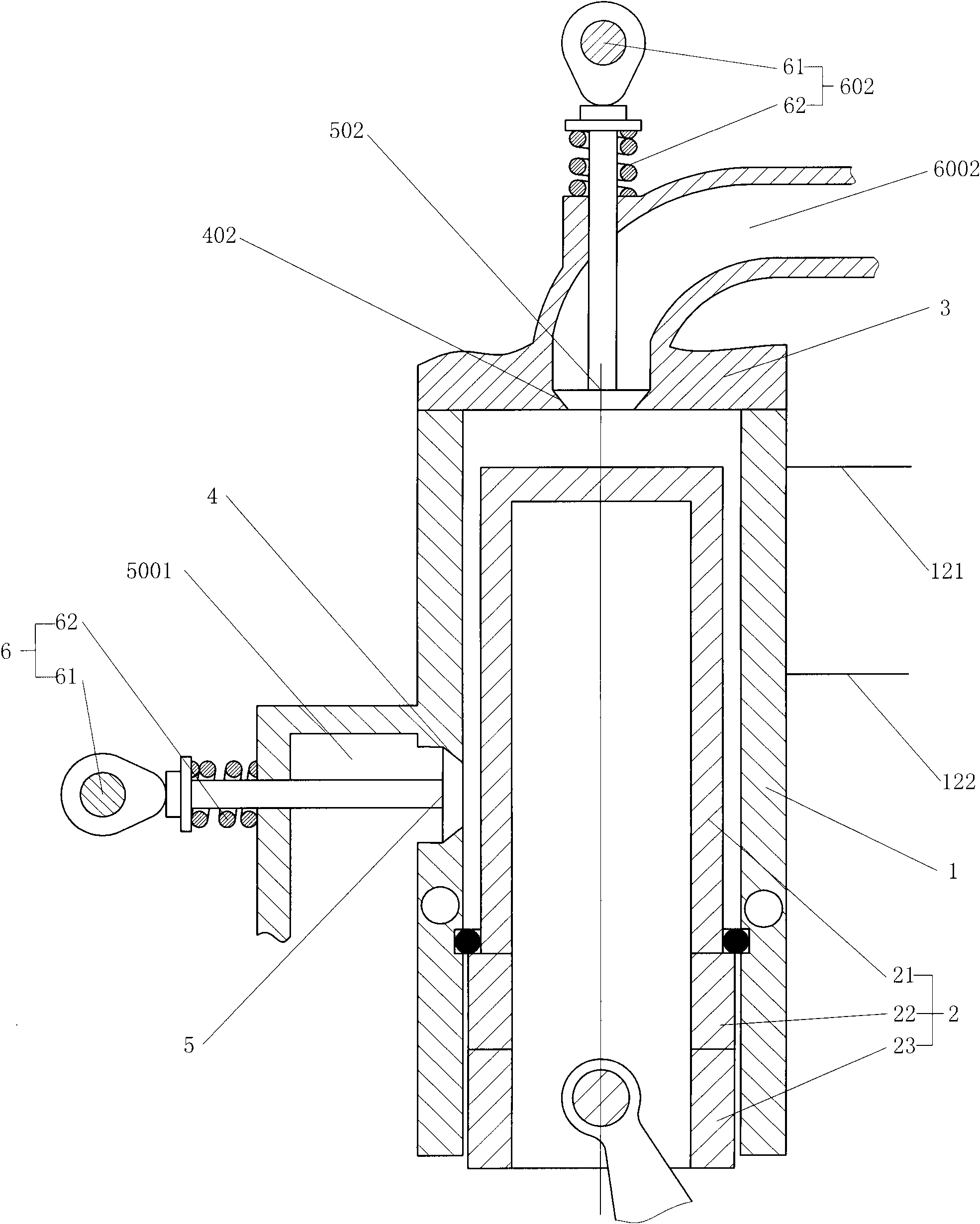

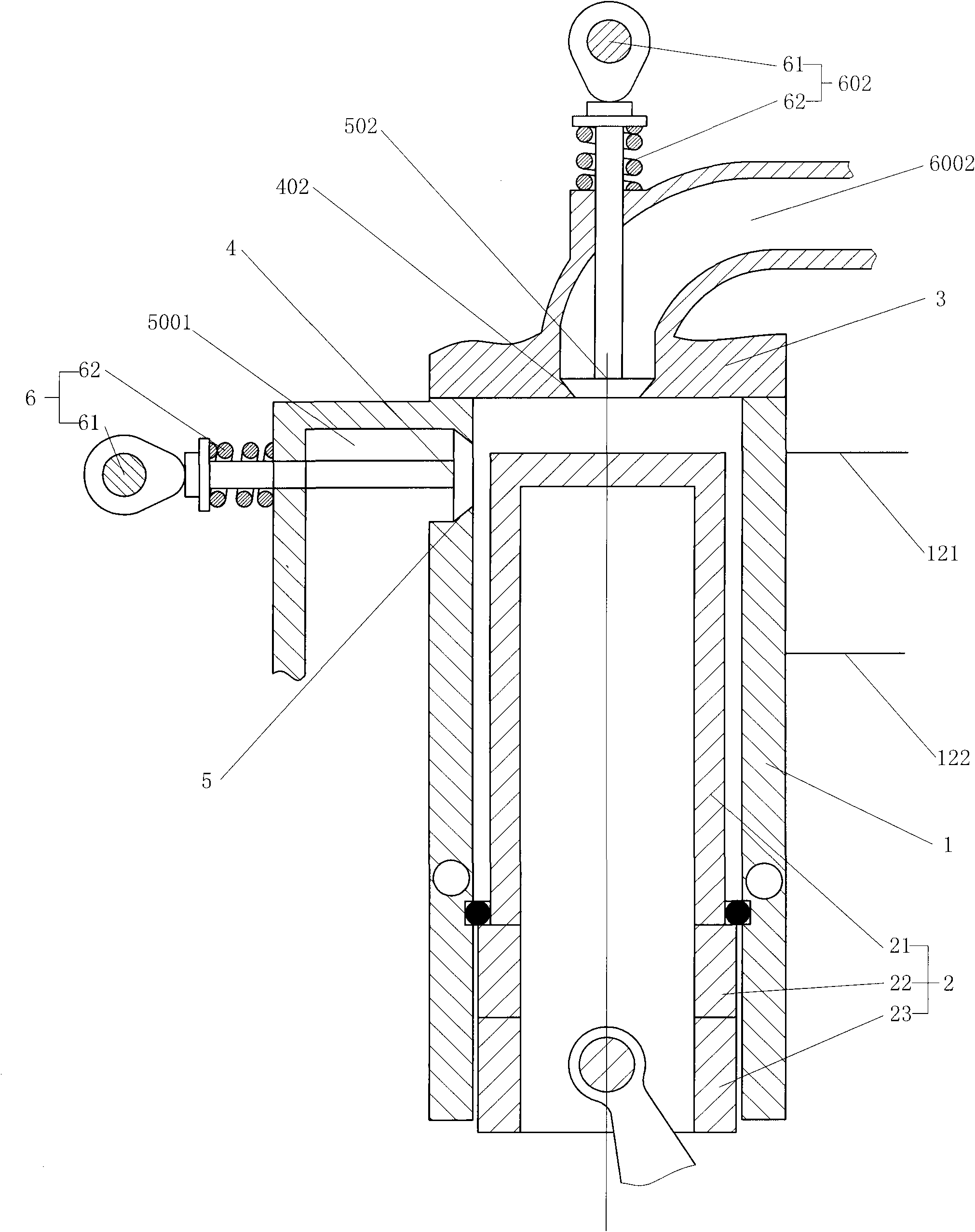

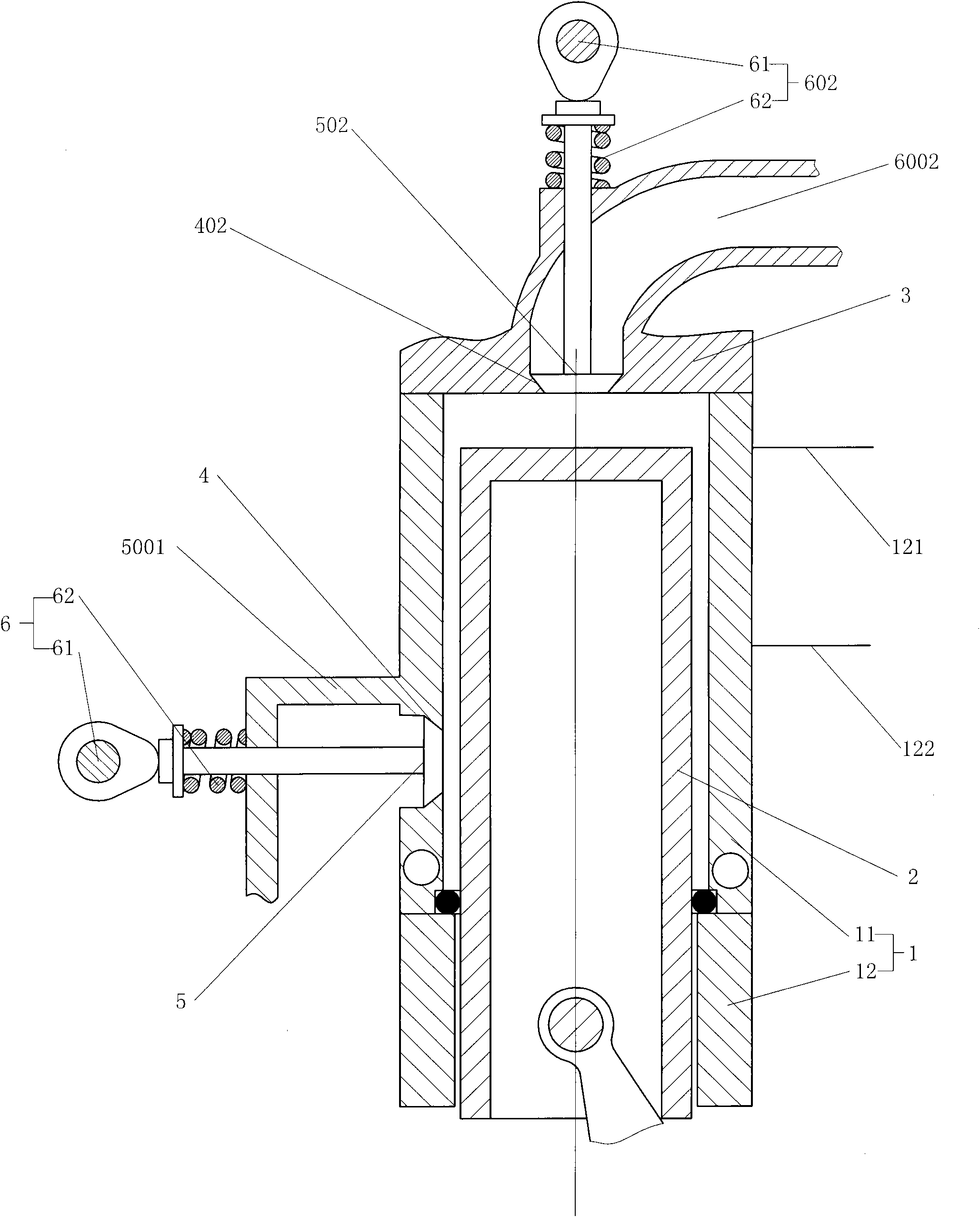

Hydraulic drive reciprocating duplex pump

ActiveCN103821690AEliminate crankshaft and connecting rodOmit structurePiston pumpsPump installationsHydraulic cylinderReciprocating motion

The invention discloses a hydraulic drive reciprocating duplex pump. The hydraulic drive reciprocating duplex pump comprises a duplex pump head installed on a rack. Cylinders of the duplex pump head are driven by a first piston rod and a second piston rod to make suction and discharging motion respectively. The duplex pump further comprises gears, a reversing device, an oil pump, an oil tank, a first single-piston-type double-outlet-rod hydraulic cylinder and a second single-piston-type double-outlet-rod hydraulic cylinder, wherein the first single-piston-type double-outlet-rod hydraulic cylinder and the second single-piston-type double-outlet-rod hydraulic cylinder are arranged on the rack in parallel. The reversing device comprises a two-position six-way reversing valve and a transmission lever, one ends of the piston rods of both the hydraulic cylinders are linearly connected with the corresponding piston rods of the duplex pump head respectively to push the piston rods to make reciprocating motion in the pump cylinders, corresponding tooth patterns are formed in the opposite faces of the other ends of the piston rods of the hydraulic cylinders, and the gears are arranged between the piston rods of the hydraulic cylinders at the end and meshed with the tooth patterns on all the sides to drive the piston rods to move reversely. The hydraulic drive reciprocating duplex pump is small in overall size and convenient to detach and maintain, force does not need to be decomposed or worn down, the overall stroke is performed at a more constant speed, stepless speed regulation can be carried out without shutdown, the synchronous co-movement is strong, and the suction and the discharging are more stable.

Owner:东营盛昶石油机械有限公司

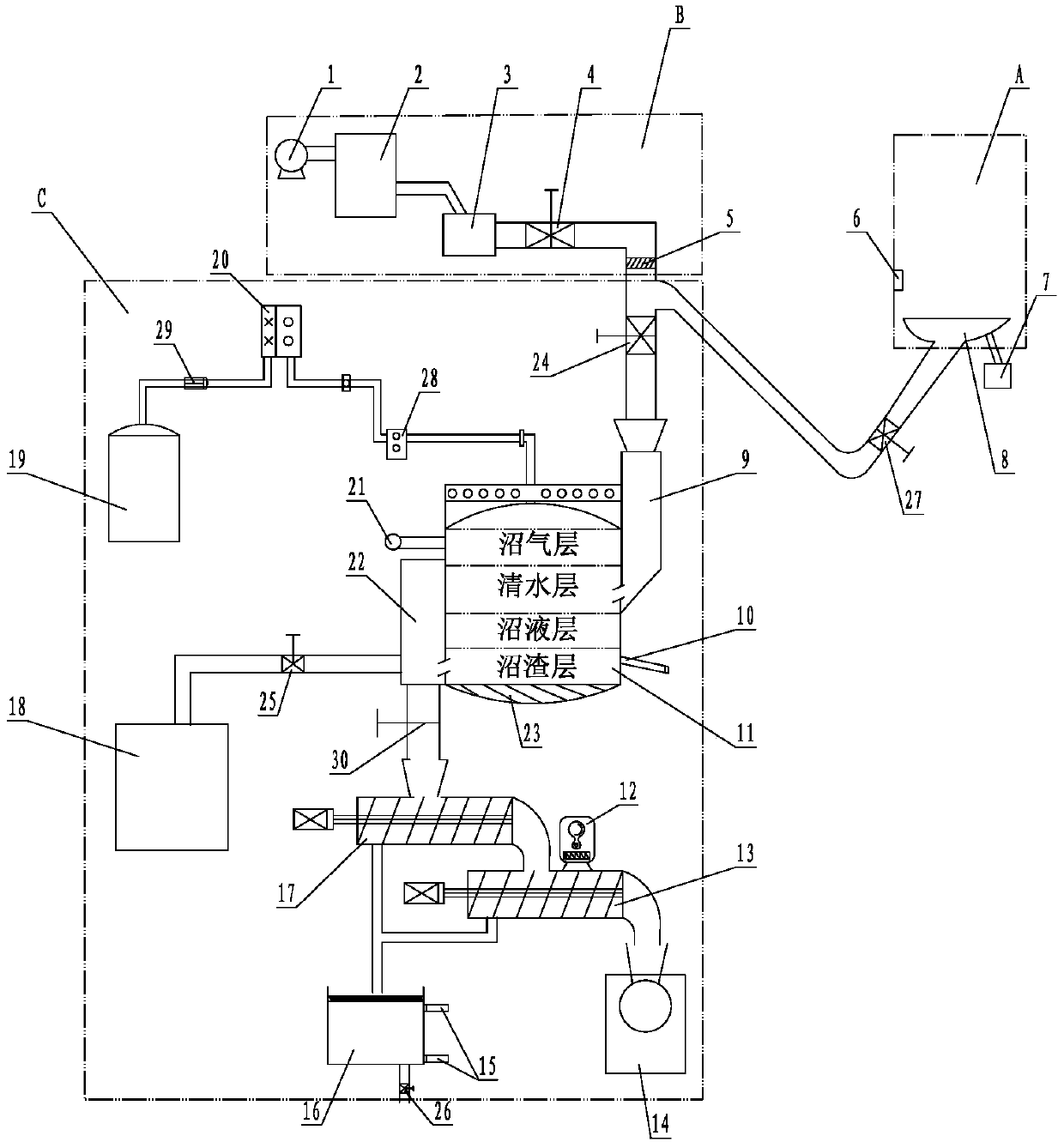

Biogas generator

InactiveCN105505754AOmit structureRealize comprehensive utilizationBioreactor/fermenter combinationsBio-organic fraction processingAir cleaningLiquid storage tank

A biogas generator includes a bathroom, a vacuum system and a fermentation system, the bathroom includes an infrared sensor arranged on a wall, a pedestal pan and an automatic cleaning device, the technical points are as follows: the fermentation system includes a feed tank, a fermentation tank, a discharge tank, a biogas bag, a waste material pond, a first extrusion device, a secondary extrusion device, a packer, a liquid storage tank, and an air cleaning unit arranged on the secondary extrusion device; the bottom of the fermentation tank is provided with a heater and a temperature sensor, the top of the fermentation tank is provided with an air pressure sensor, a mesh-like valve is arranged between the fermentation tank and the feed tank; a drying apparatus and a purifying controller are arranged between the biogas bag and the fermentation tank, a pneumatic valve III is arranged between the waste material pond and the discharge tank, the liquid storage tank is provided with one pair of liquid level sensors, the bottom of the liquid storage tank is provided with a discharge port, and a pneumatic valve IV is arranged on the discharge port. The biogas generator fundamentally solves the problems that in the prior art bathroom stool and urine are not conducive to treatment, a lot of organic matters are not fully used, and the like.

Owner:李应桐

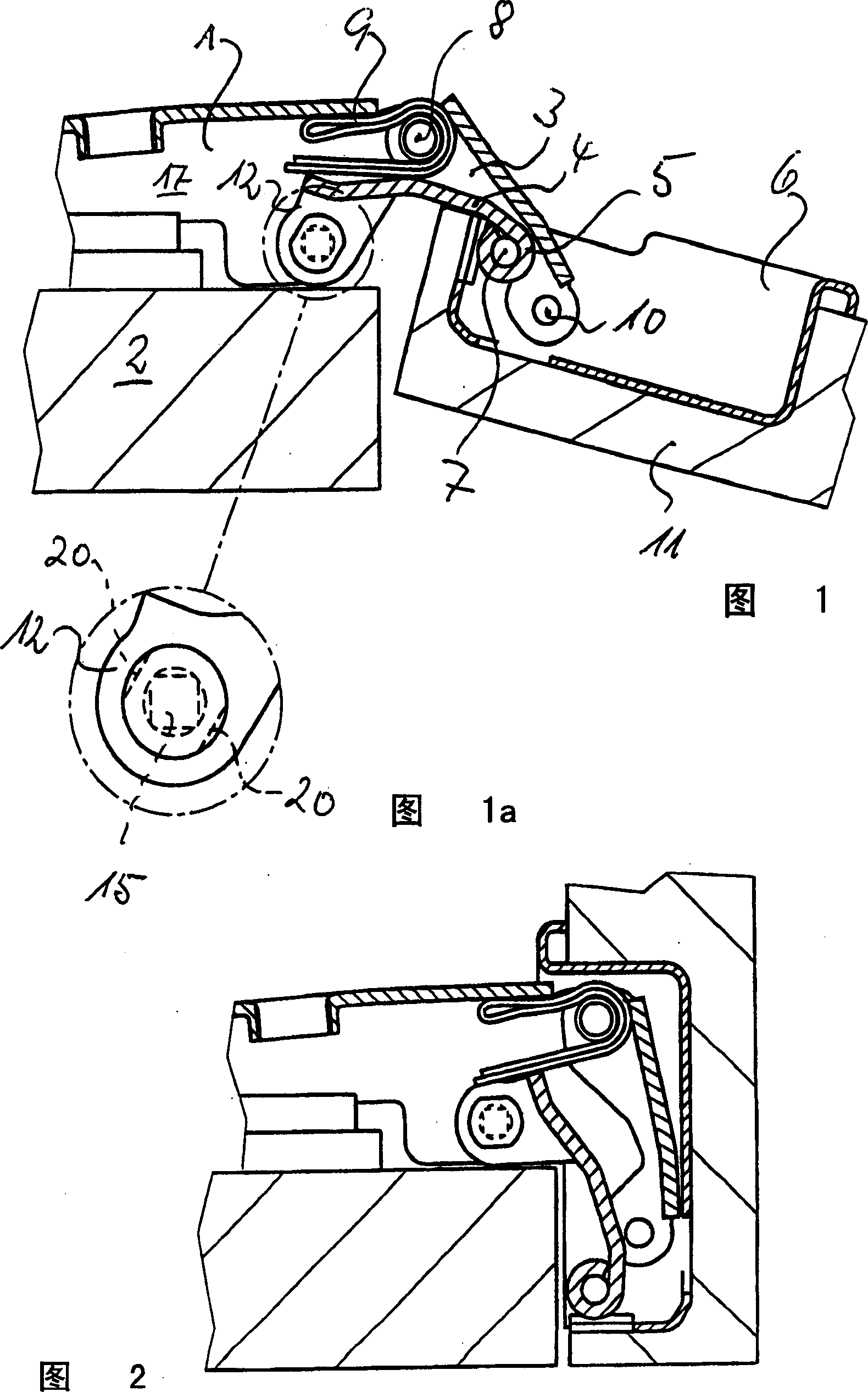

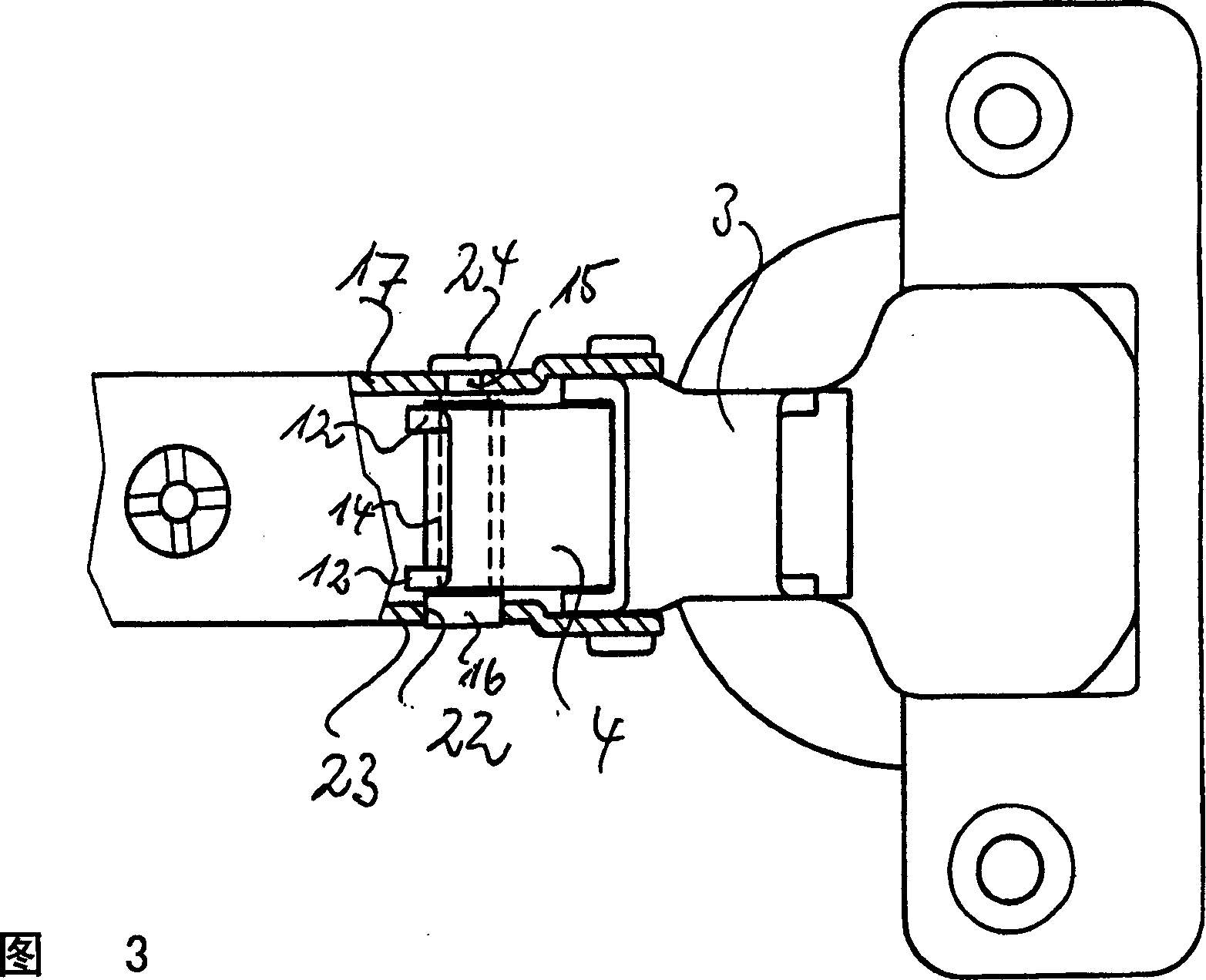

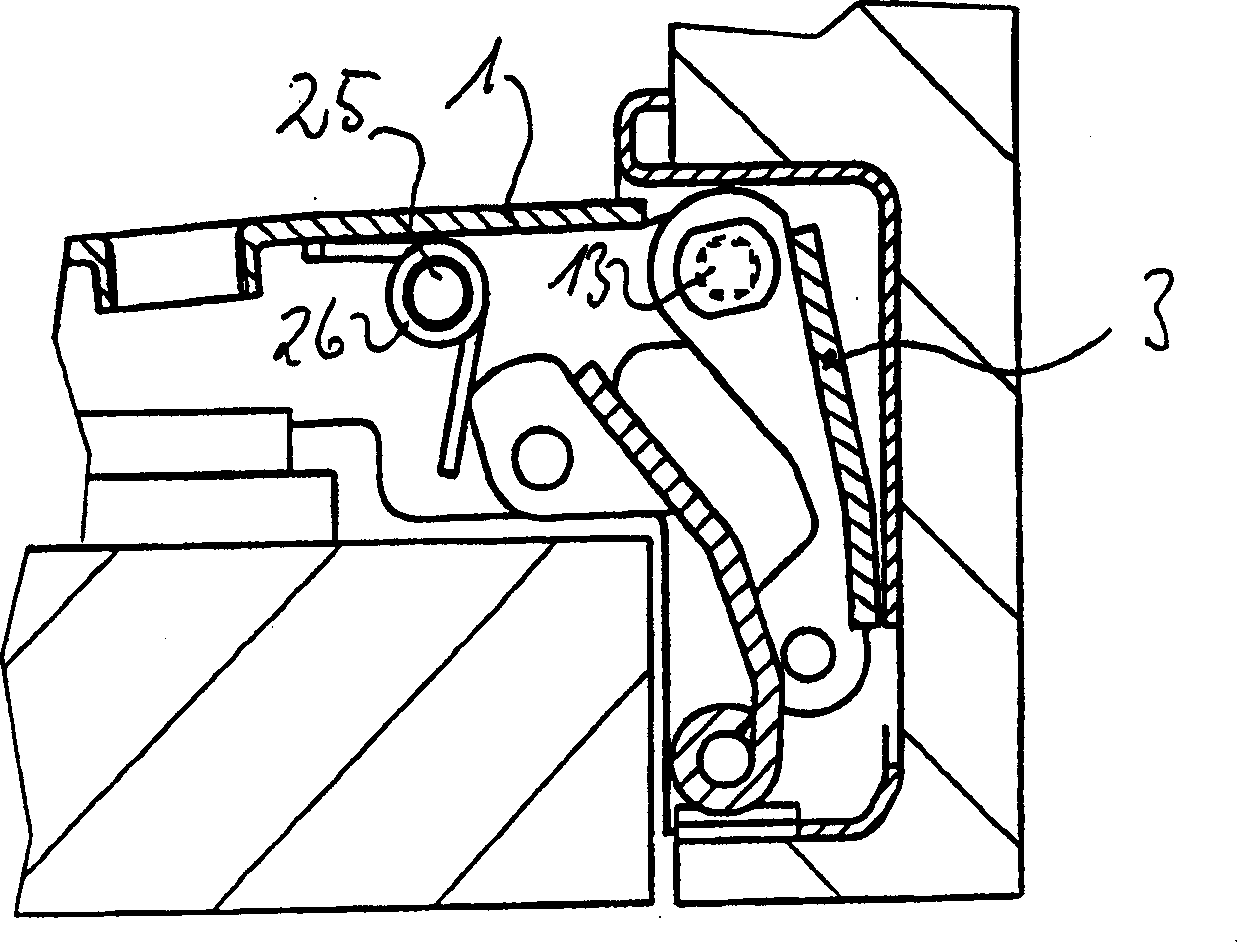

Hinge

InactiveCN1480618AOmit structureIncrease dampingBuilding braking devicesPin hingesControl theoryShock absorber

The movement of a hinge, preferably for furniture, comprising a hinge arm or a fixed-body hinge section and a pivotable hinge section flexibly connected thereto, is damped by a rotation damper at least damped over part of the closure path to the closed position. In order that the hinge can be manufactured at reduced cost, the rotation damper is an axial damper whose axis forms a hinge axis of the hinge and whose cylinder is fixedly connected to the hinge section which is pivotably supported on the axis.

Owner:ARTURO SALICE

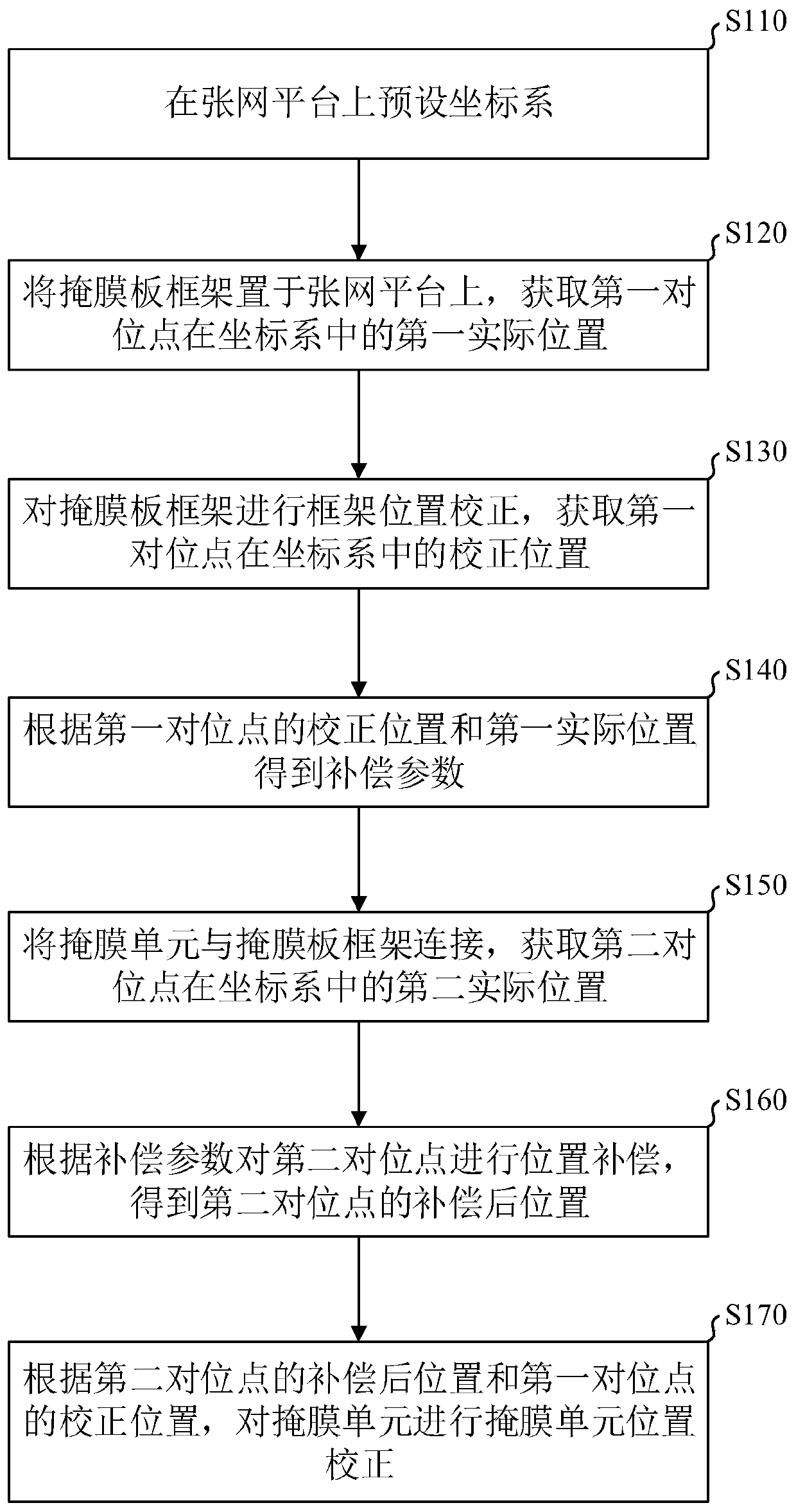

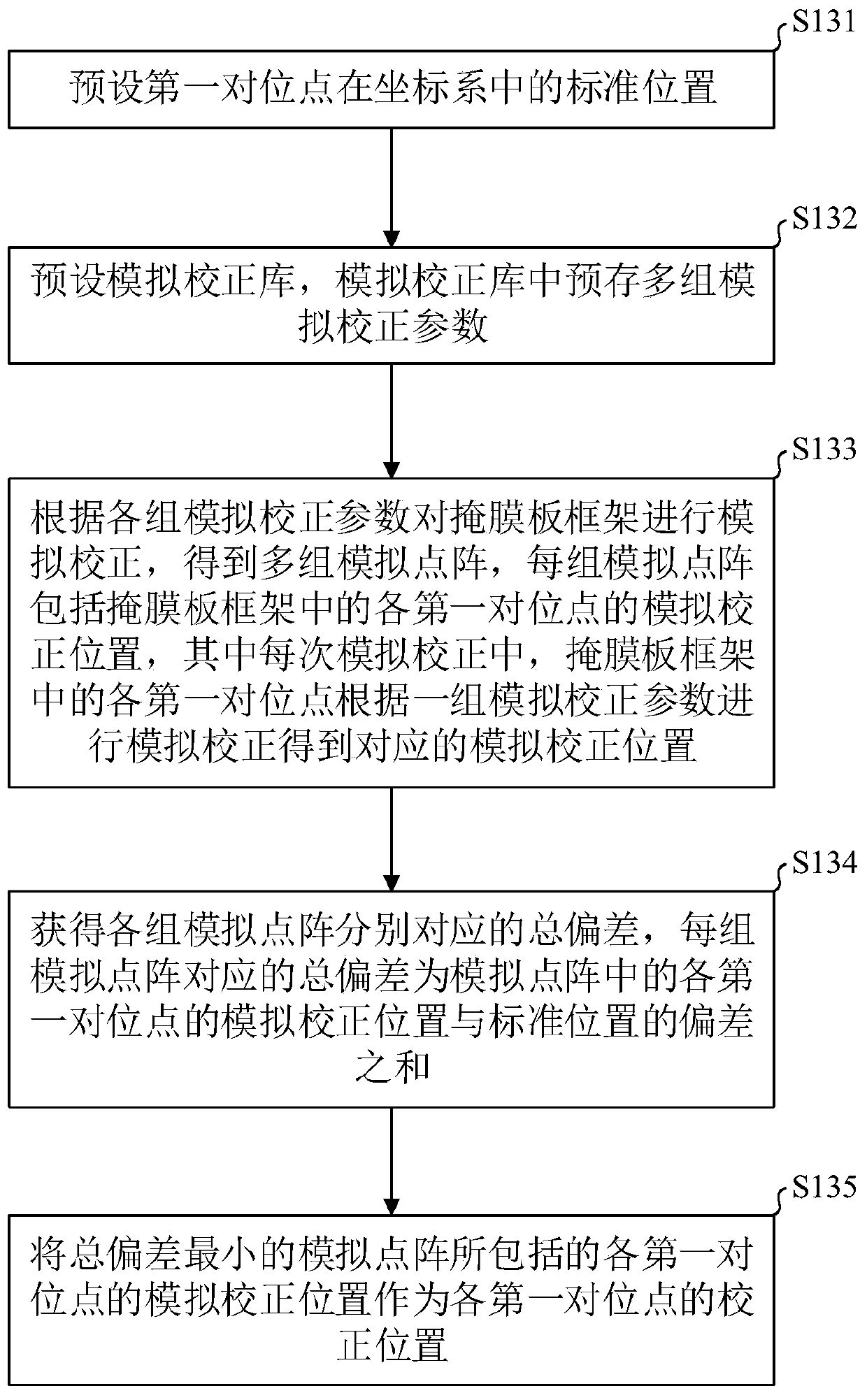

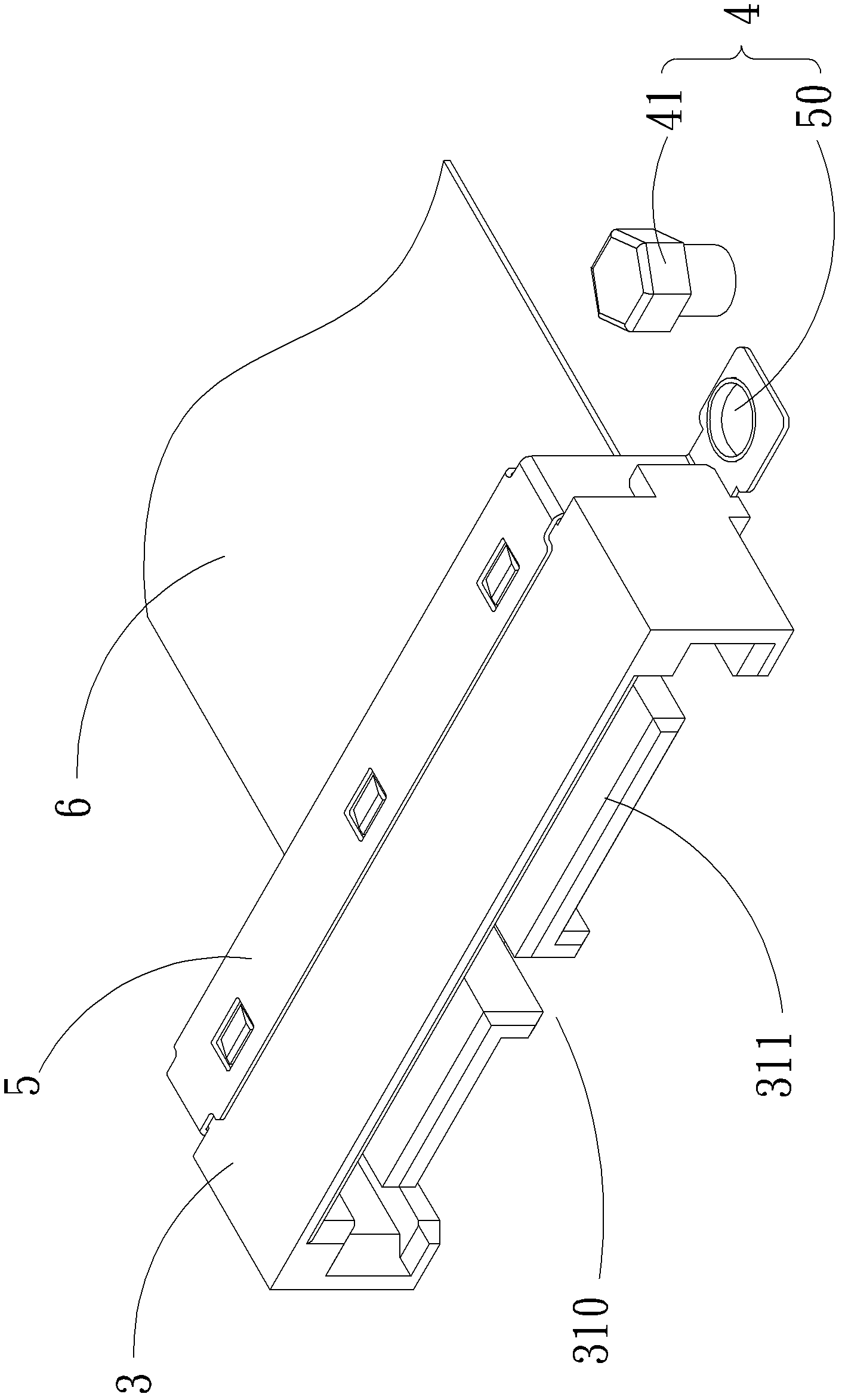

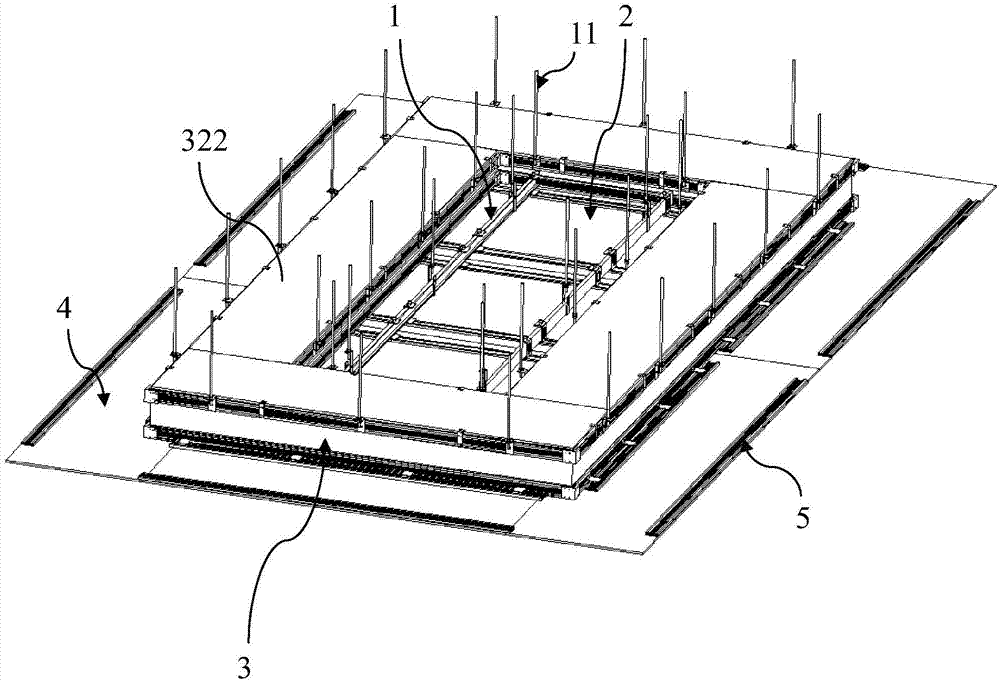

Mask net stretching method and device and mask

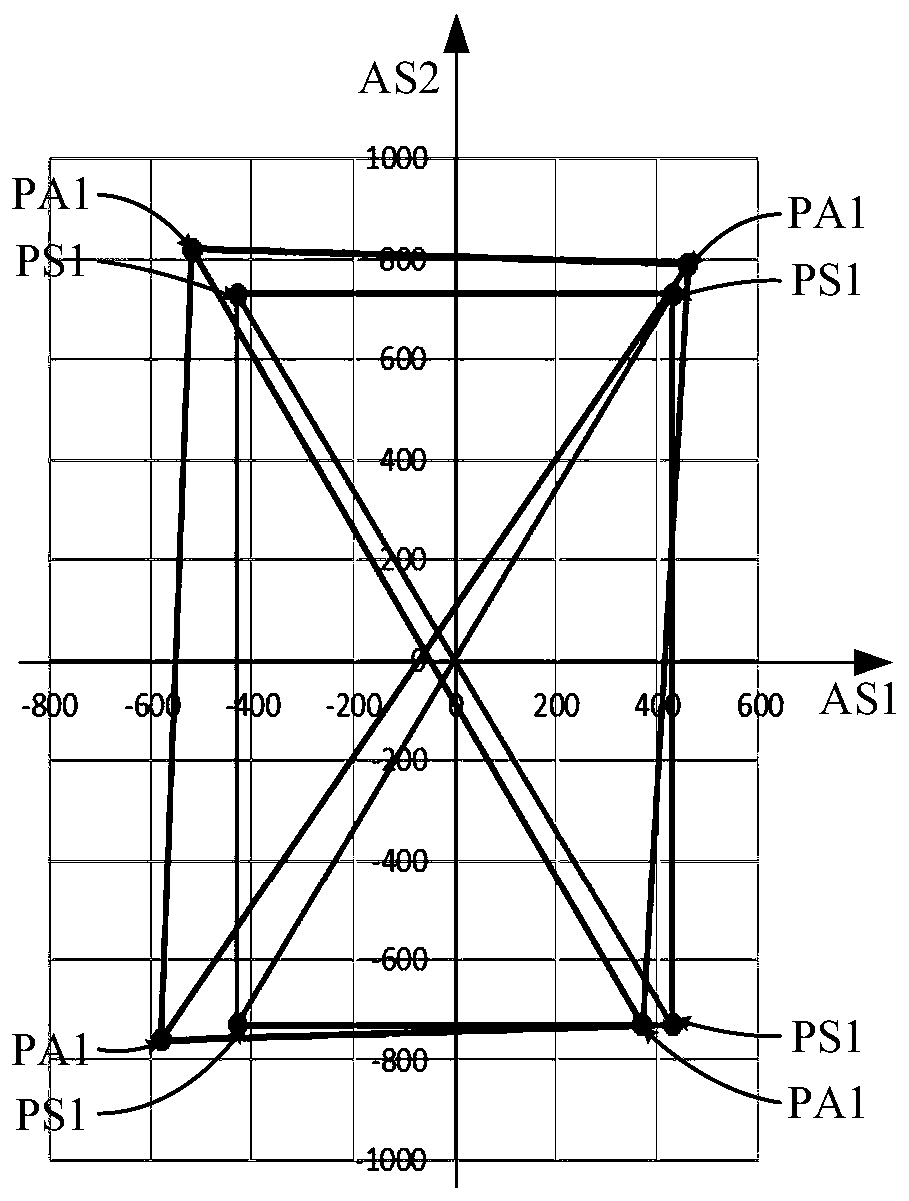

ActiveCN111218645AImprove assembly efficiencyOmit structureVacuum evaporation coatingSputtering coatingEngineeringComputational physics

The invention discloses a mask net stretching method and device and a mask. The mask net stretching method comprises the steps as follows: presetting a coordinate system on a net stretching platform;placing a mask frame on the net stretching platform to obtain first actual positions of first aligning points in the coordinate system; correcting the position of the mask frame to obtain corrected positions of the first aligning points in the coordinate system; obtaining compensation parameters according to the corrected positions and the first actual positions of the first aligning points; connecting mask units with the mask frame to obtain second actual positions of second aligning points in the coordinate system; performing position compensation on the second aligning points according tothe compensation parameters to obtain compensated positions of the second aligning points; and correcting positions of the mask units according to the compensated positions of the second aligning points and the corrected positions of the first aligning points. According to the mask net stretching method of the embodiment, efficiency of the net stretching assembly process is improved.

Owner:YUNGU GUAN TECH CO LTD

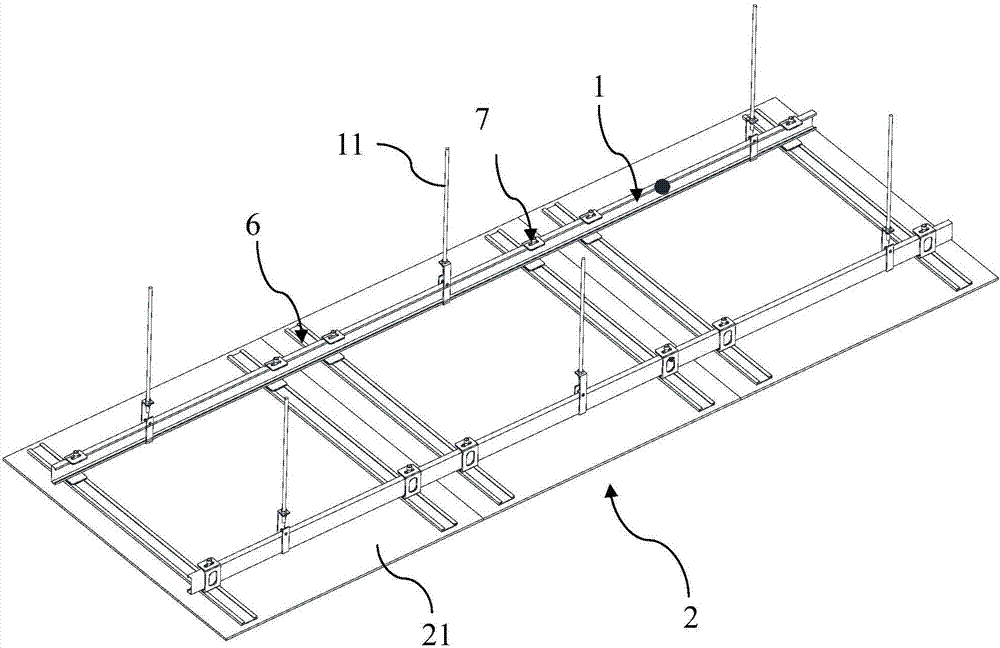

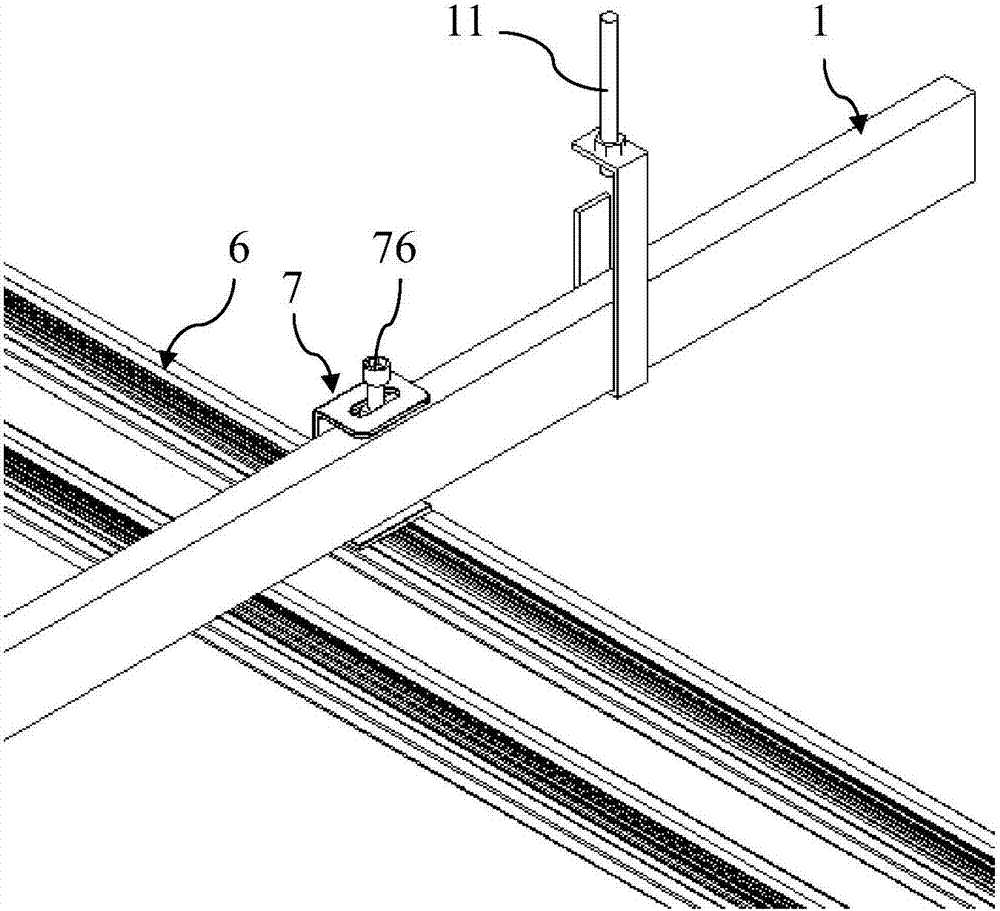

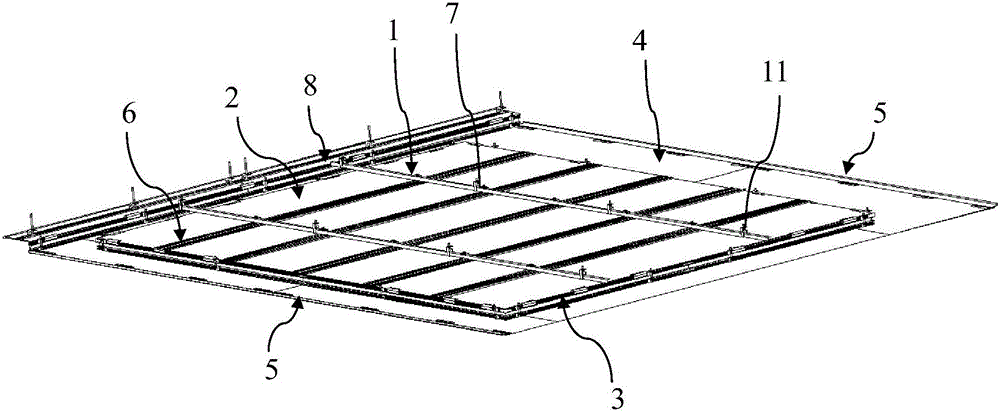

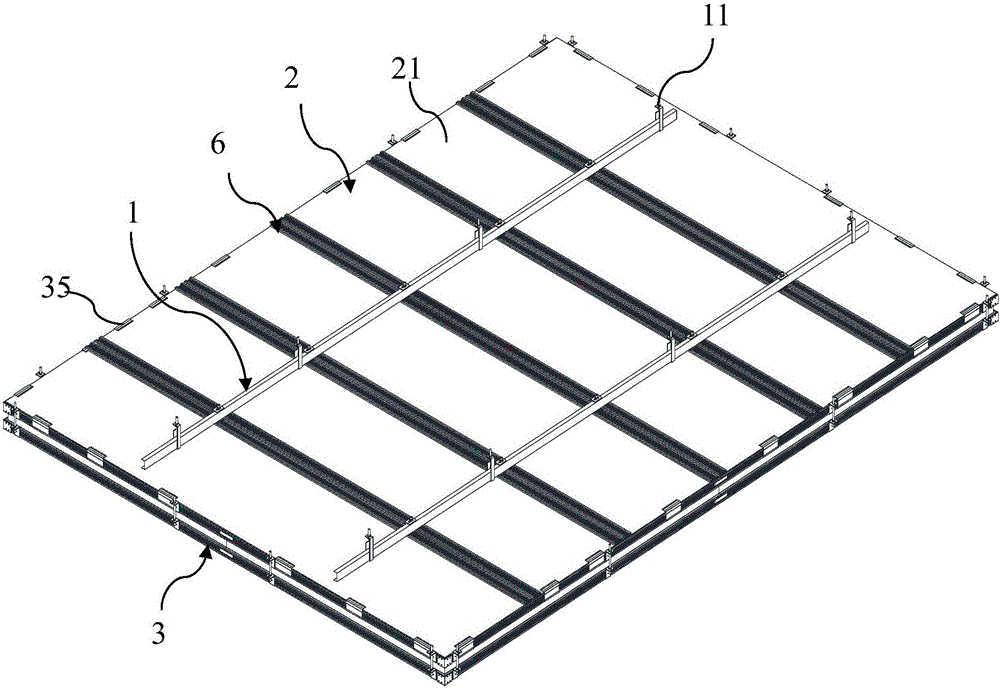

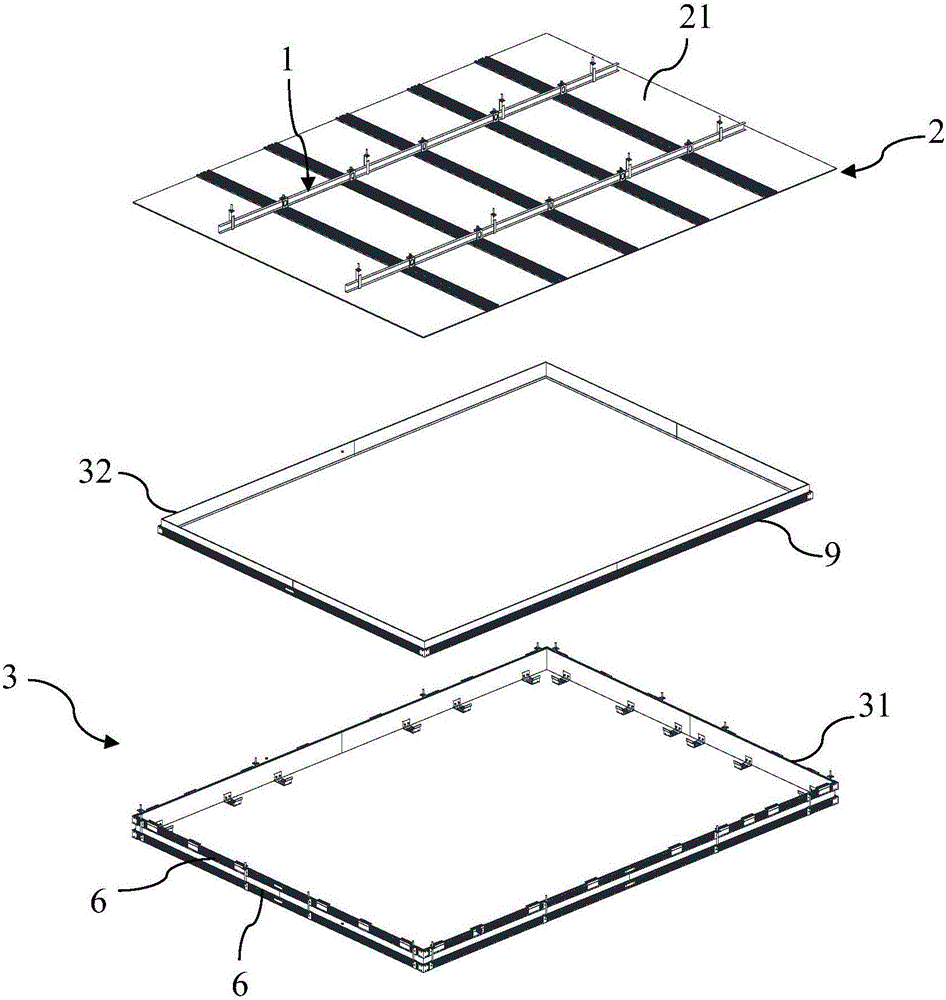

Integrated ceiling and installing method thereof

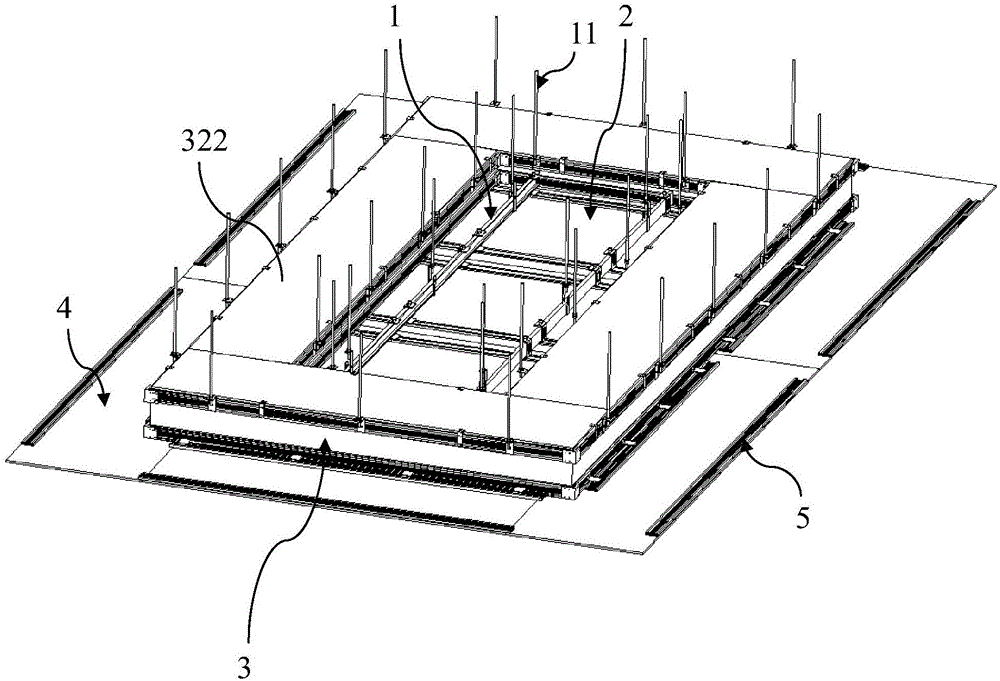

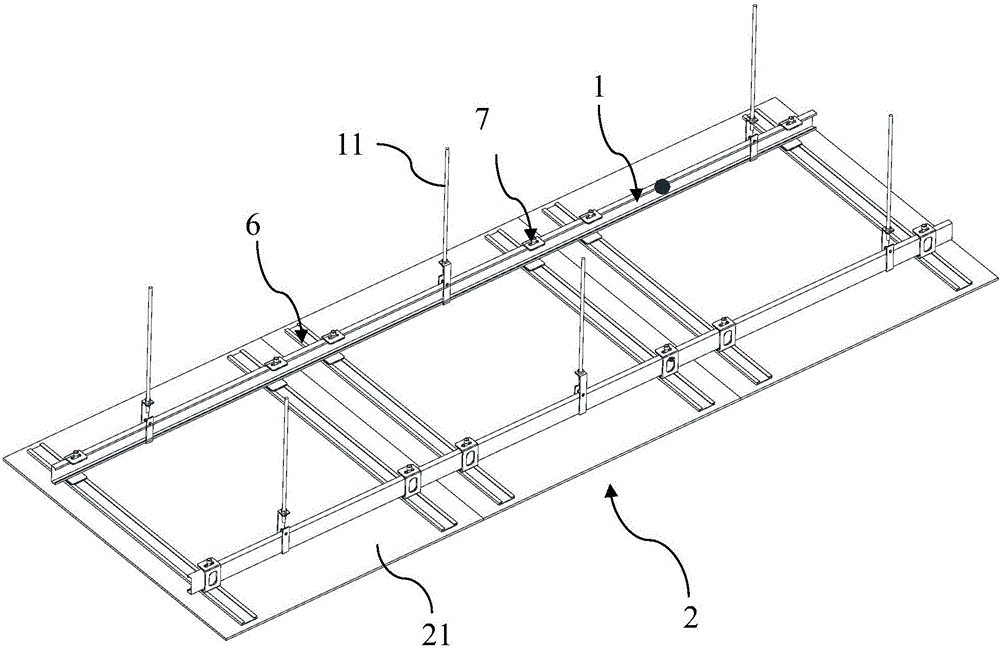

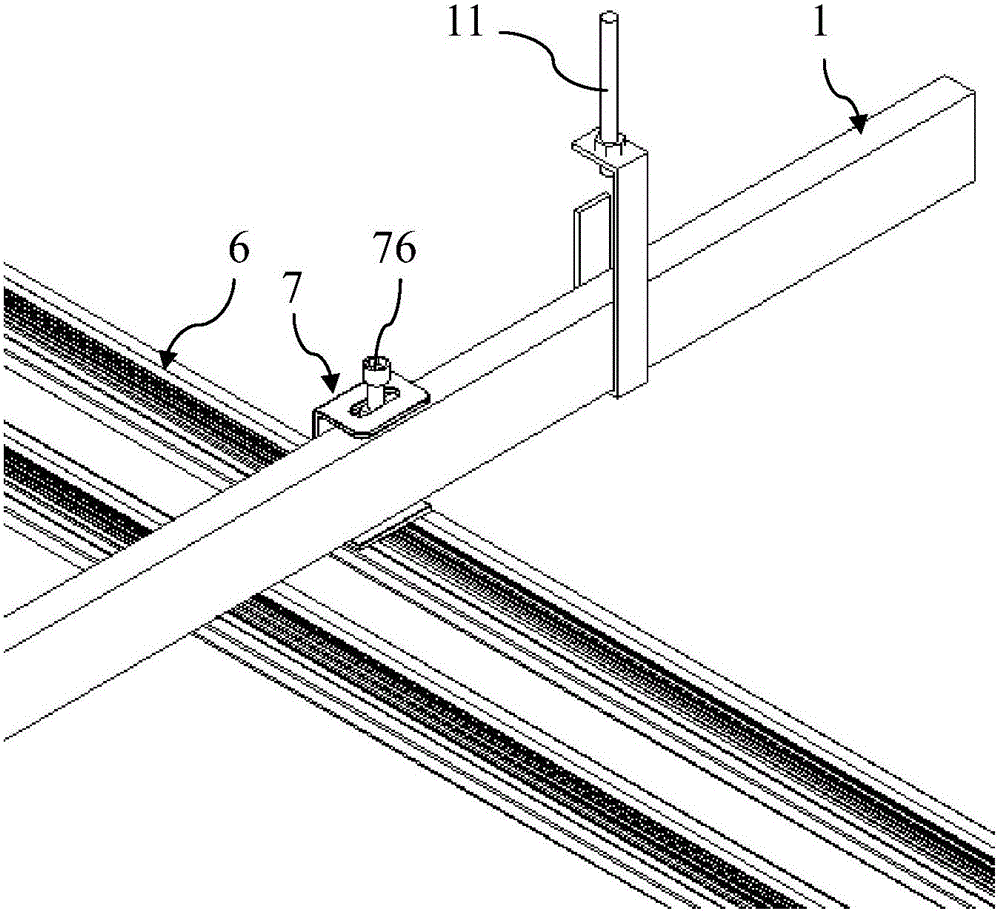

ActiveCN106013581AImprove construction efficiencyShorten the construction periodCeilingsCentral planeEngineering

The invention discloses an integrated ceiling, which comprises at least one main keel, a central plane unit and edge collecting keels, wherein the edge collecting keels are used for being installed on a wall surface; at least one back hanging keel is preinstalled on the central plane unit; the back hanging keel is hung at the lower side of the main keel through a regulating hanging element capable of realizing vertical, leftward and rightward position regulation; the edges of the central plane unit are collected in the edge collecting keels. The invention also discloses an installing method of the integrated ceiling. The integrated ceiling and the installing method of the integrated ceiling have the advantages that the installing procedures are reduced; the fast assembly can be realized; the construction period is shortened; the work intensity is reduced; the environment pollution is reduced; the requirements of different customers are met; the application range is expanded.

Owner:ZHEJIANG YASHA DECORATION

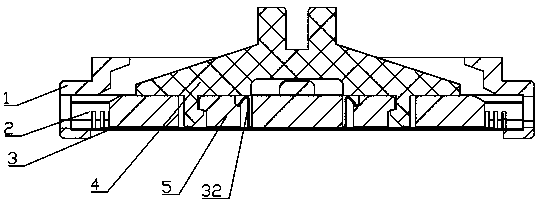

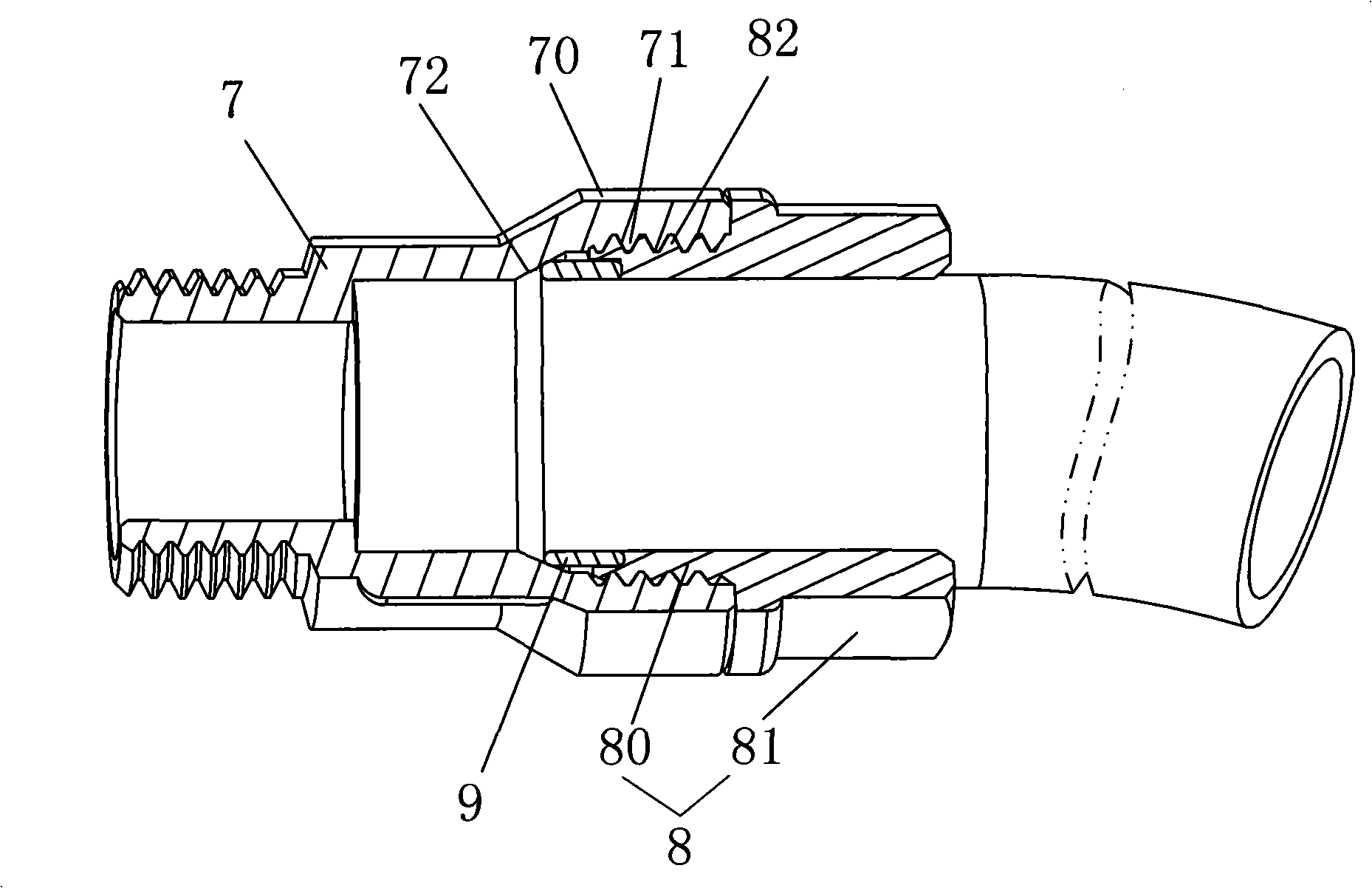

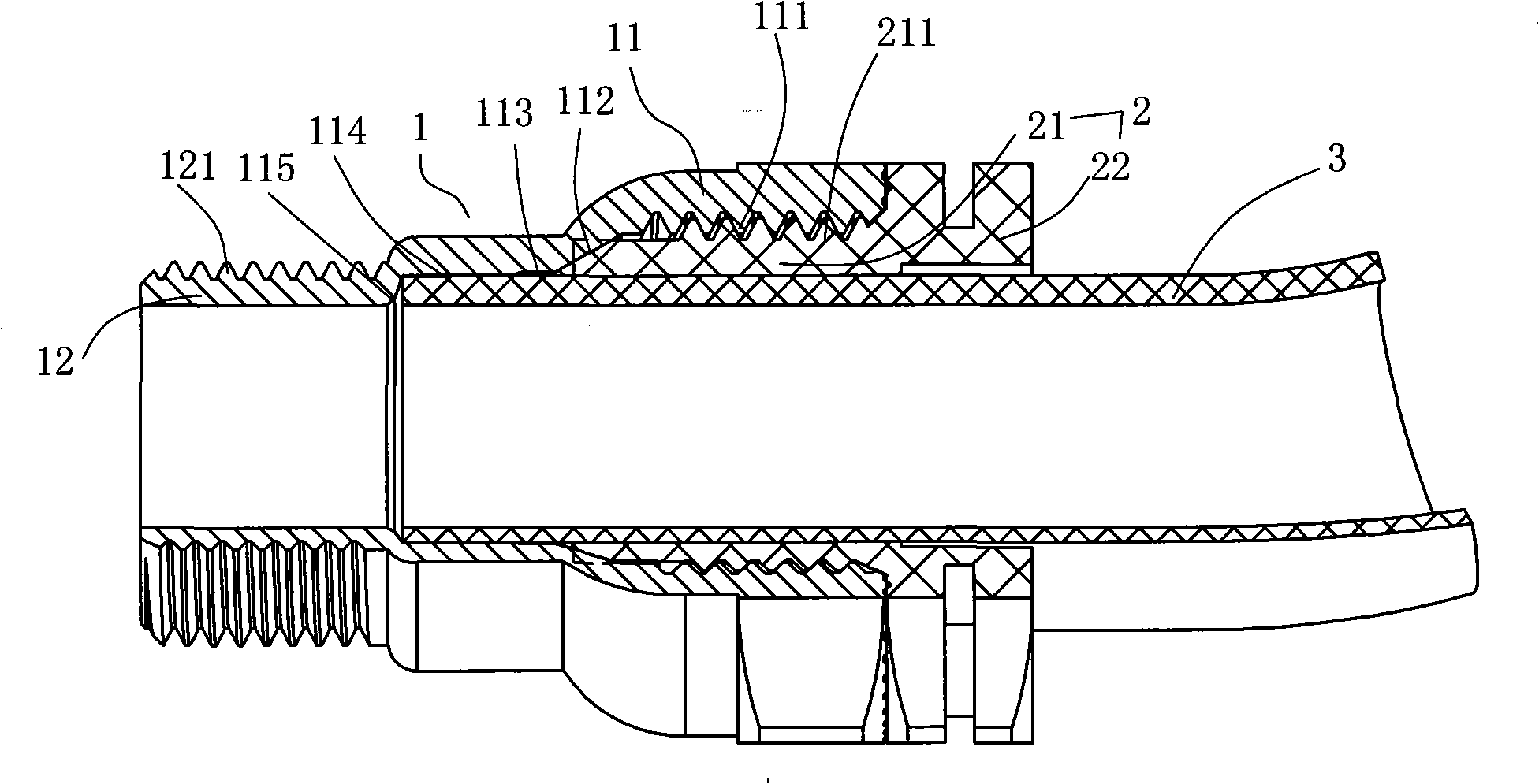

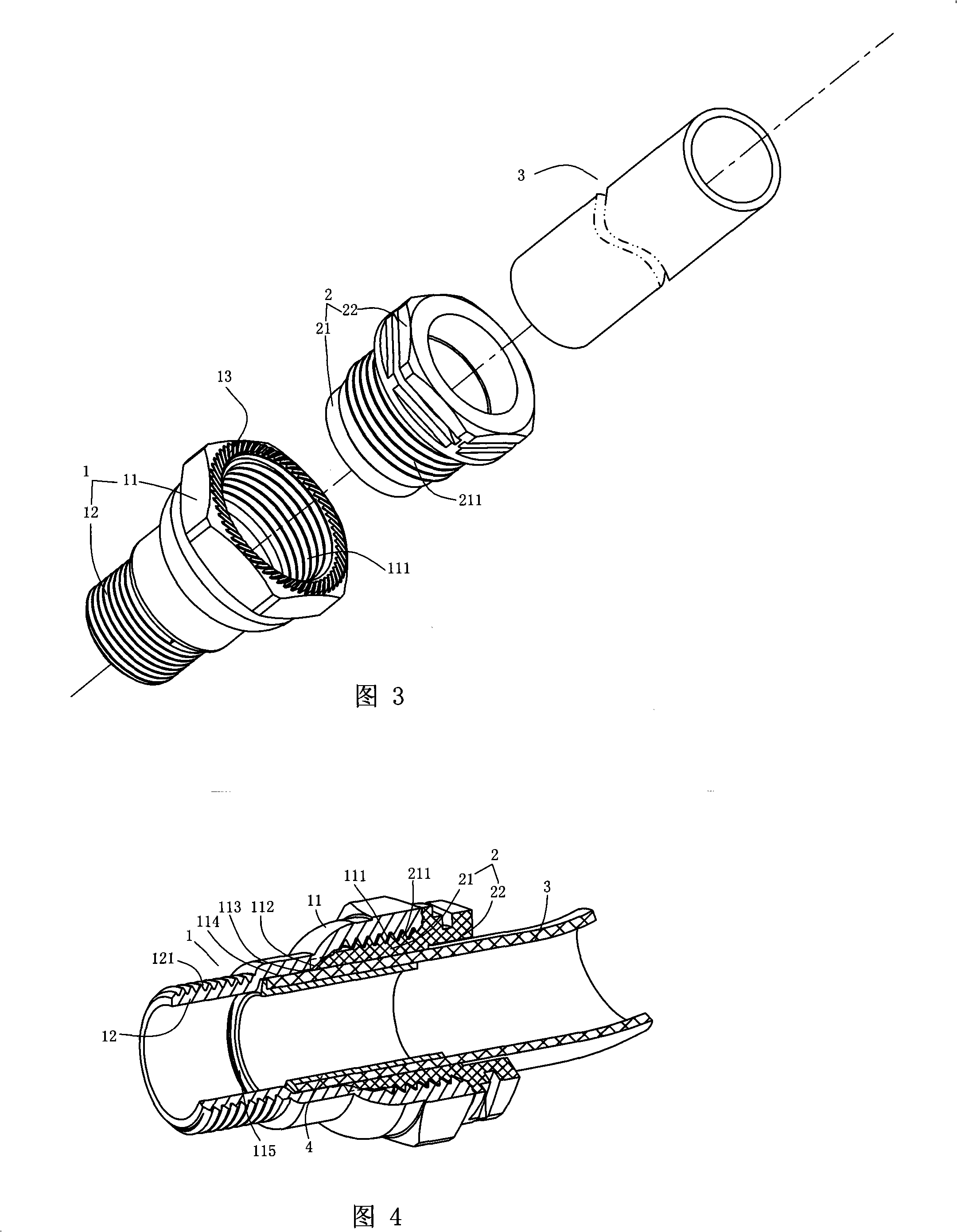

Jointing pipe pieces

InactiveCN101329002ACause sealing hazardOmit structurePipe connection arrangementsPlastic materialsPipe fitting

The invention discloses a connecting pipe fitting, which comprises a pipe fitting connector and an attachment cap matched with the joint of the pipe fitting connector, wherein, the joint of the pipe fitting connector is provided with an internal thread, and the lower end of the internal thread is provided with a fastening port with certain slope, a pipe fitting hole and a stopping ring sequentially. The attachment cap is made of plastic materials, which has a through hole in the middle and comprises a cylinder part and a fastening head part, wherein, part or all of the outer surface of the cylinder is lathed with an external thread matched with the internal thread of the joint of the pipe fitting connector, the length of the cylinder part is greater than that of the inlet of the fastening port of the pipe fitting connector to the end face, the head of the cylinder part pushes against the slope of the fastening port of the pipe fitting connector directly. Compared with the connecting pipe fitting in the prior art, the invention has the advantages of safety, reliability and fast connection, and is particularly applied to the connection between the plastic pipes or between the plastic pipe and the metal pipe fitting.

Owner:浙江世进水控股份有限公司

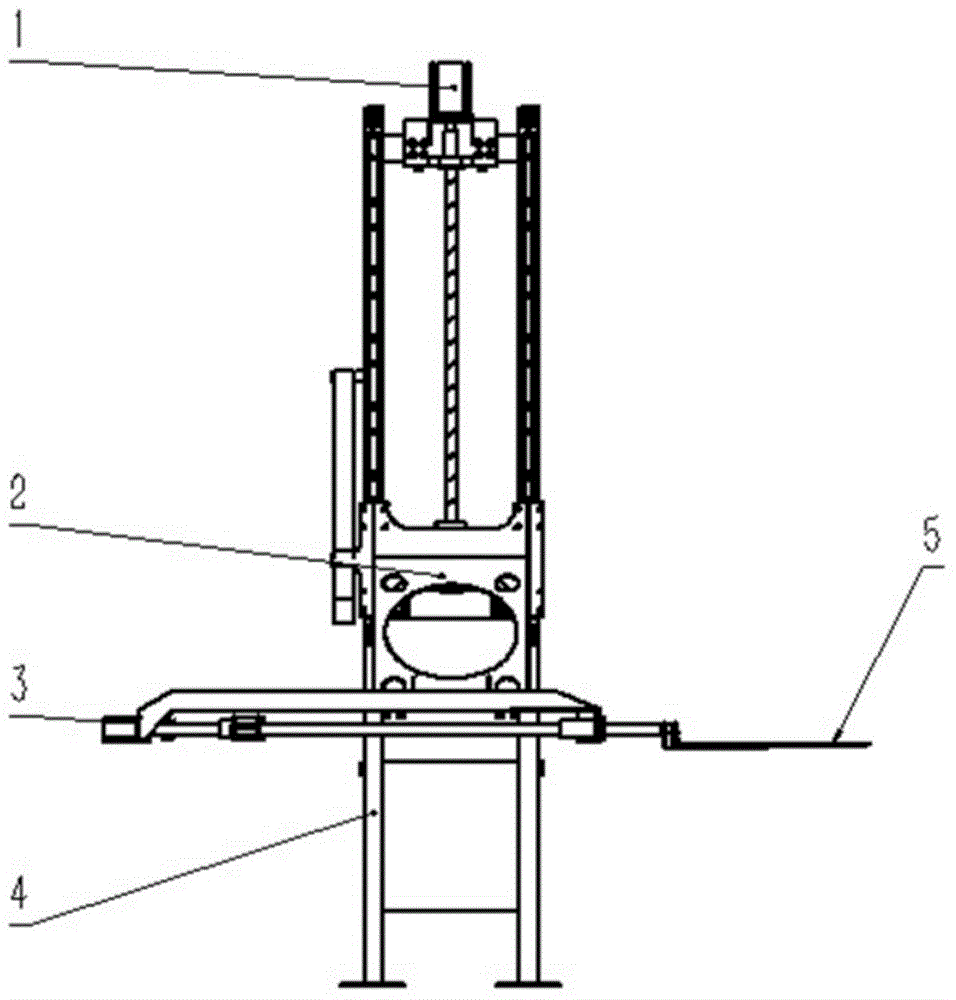

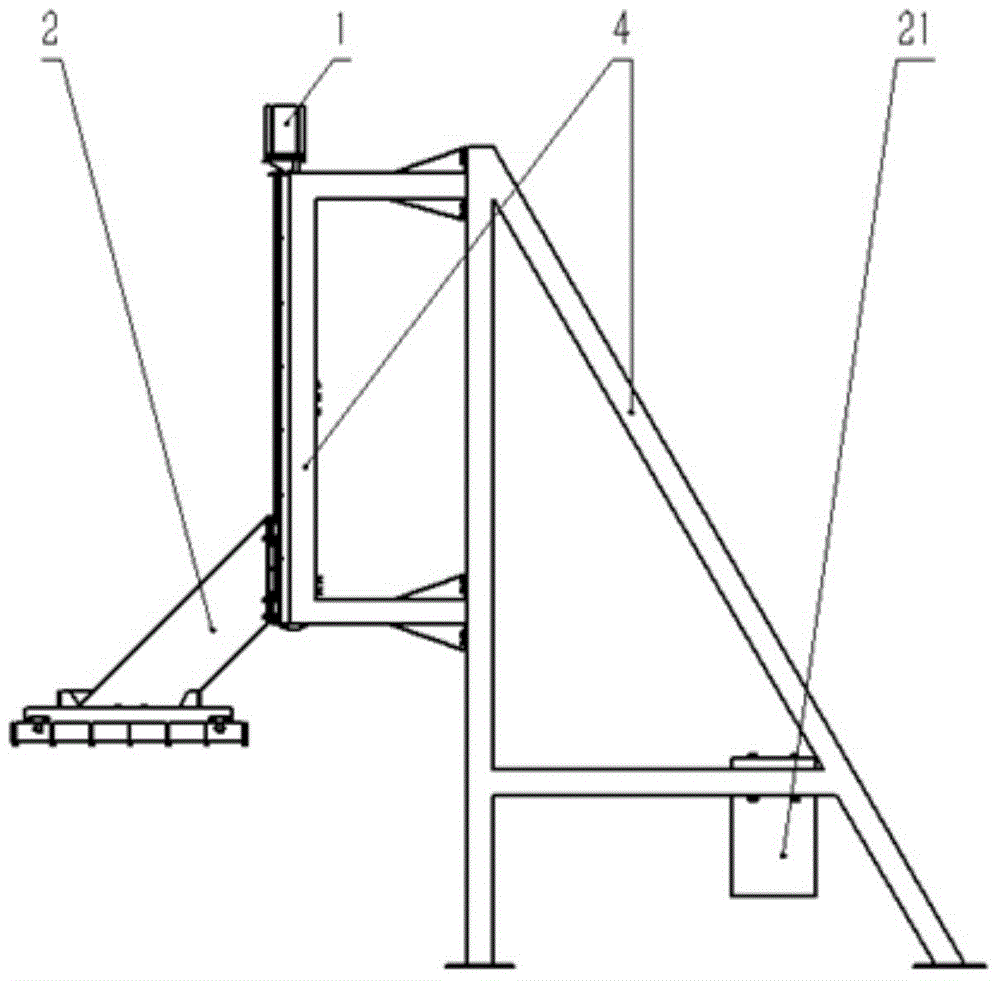

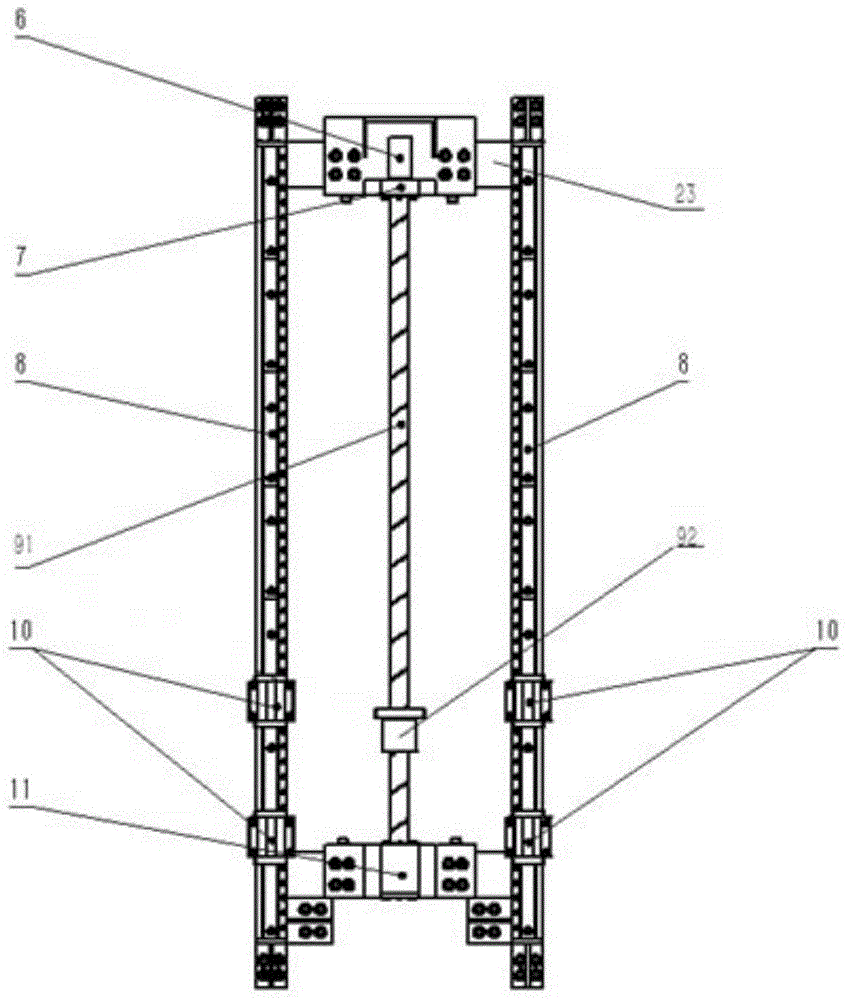

Fast feeding and blanking equipment for multi-layer box type heating furnace

The invention provides fast feeding and blanking equipment for a multi-layer box type heating furnace. The fast feeding and blanking equipment comprises a main supporting frame, a Z-axis up-and-down movement mechanism, a main slider body, an X-axis movement mechanism, a finger changeable manipulator, a Z-axis motor and an X-axis motor, wherein the Z-axis up-and-down movement mechanism is fixed on the main supporting frame, the main slider body is fixed on the Z-axis up-and-down movement mechanism, a ball screw is driven by the Z-axis motor to drive the main slider body to move, the X-axis movement mechanism is fixed on the main slider body, the finger changeable manipulator is fixed on the X-axis movement mechanism, and the ball screw is driven by the X-axis motor to drive the manipulator to move. The equipment provided by the invention is high in feeding and blanking speed, and can perform fast feeding and blanking on any layer of the multi-layer box type furnace in four seconds; the motors are adopted for driving the ball screw to fast make up-and-down movement, the repeated positioning precision is high, the operation vibration is small, and the snatching position is accurate; fast feeding and blanking for the multi-layer box type heating furnace can be carried out on thin plates with the thickness being smaller than 3mm.

Owner:UNIV OF SCI & TECH BEIJING +1

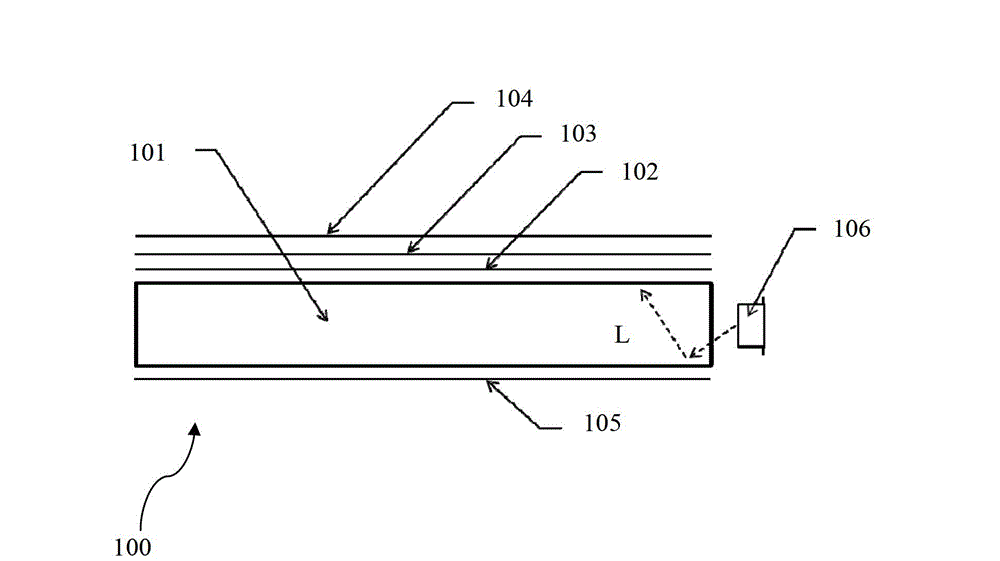

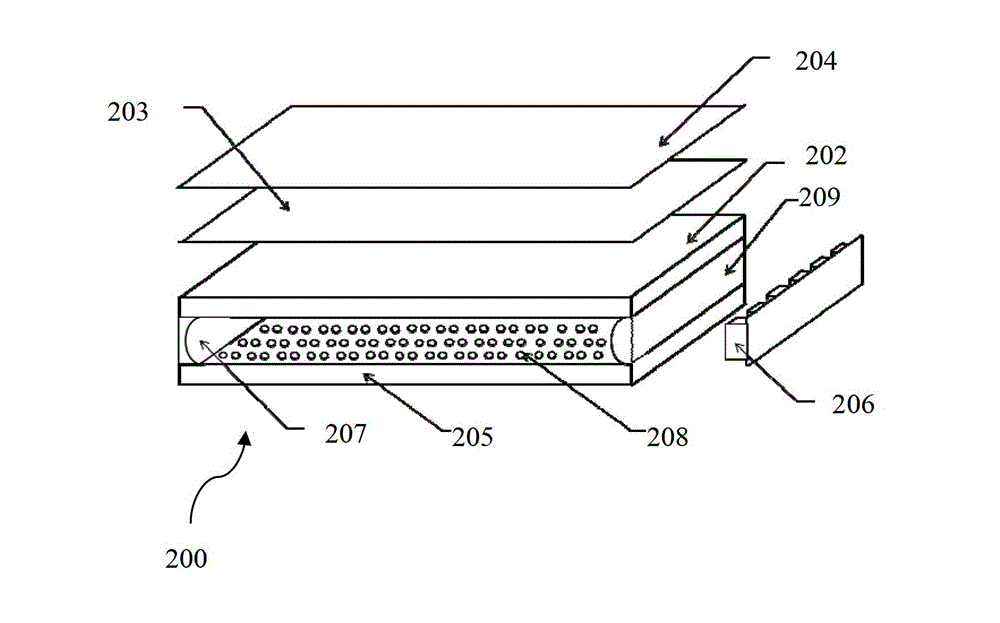

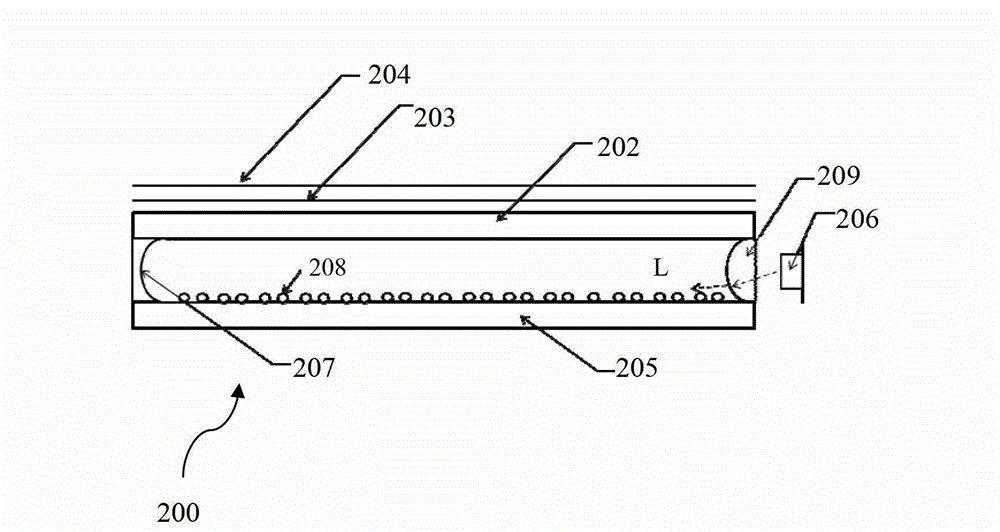

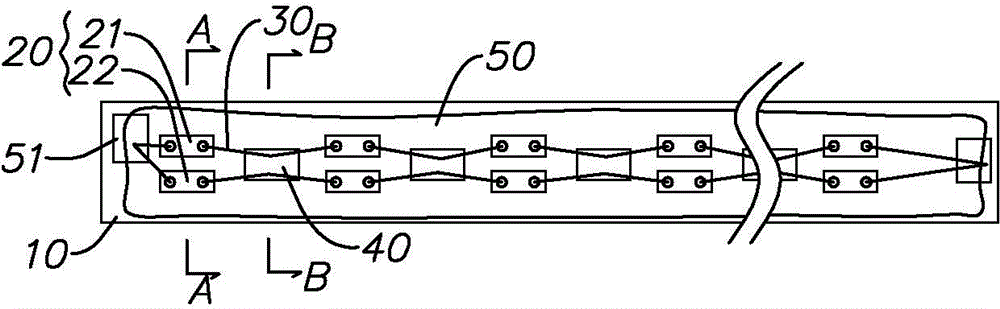

Edge-light backlight and liquid crystal display provided with same

ActiveCN103336387ASimple structureEasy to implementNon-linear opticsOptical cavityLiquid-crystal display

The invention provides an edge-light backlight, and belongs to the technical field of panel display. The edge-light backlight comprises a back board provided with a reflector plate, an optical slice component and a light emitting component, wherein the optical slice component and the back board are arranged at an interval, an optical cavity is formed between the back board and the optical slice component, and the light emitting component is arranged on one side of the back board. A convex lens is arranged between the reflector plate and the optical slice component. Light coming from the light emitting component is led into the optical cavity through the convex lens and then is emitted through the optical slice component. The distance between the convex lens and the light emitting component is greater than the optically-coupling distance. The convex lens can keep the distance between the optical slice component and the reflector plate. Compared with a backlight in the prior art, the edge-light backlight is lighter in weight, thinner in thickness and greatly simplified in manufacturing process.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

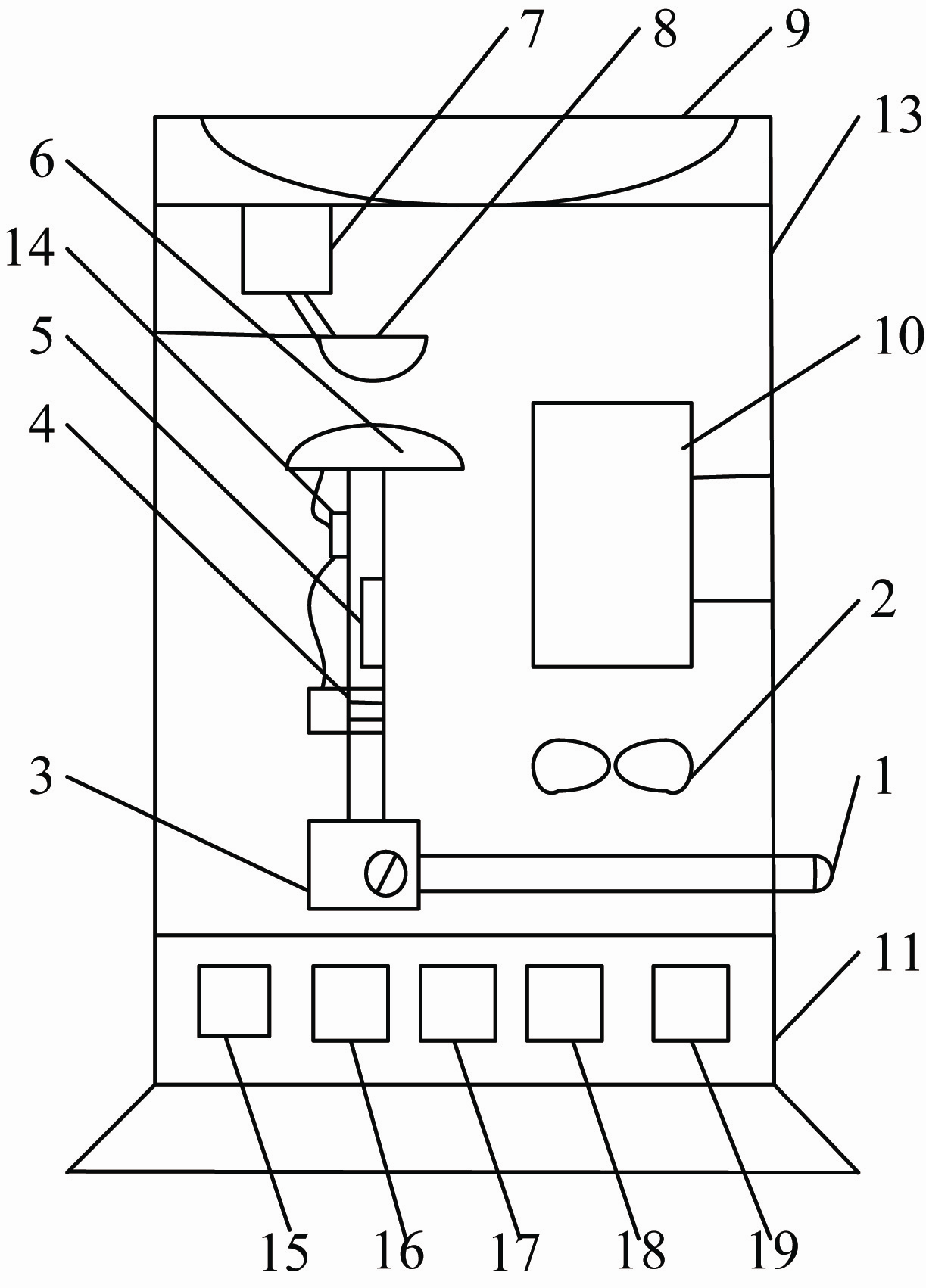

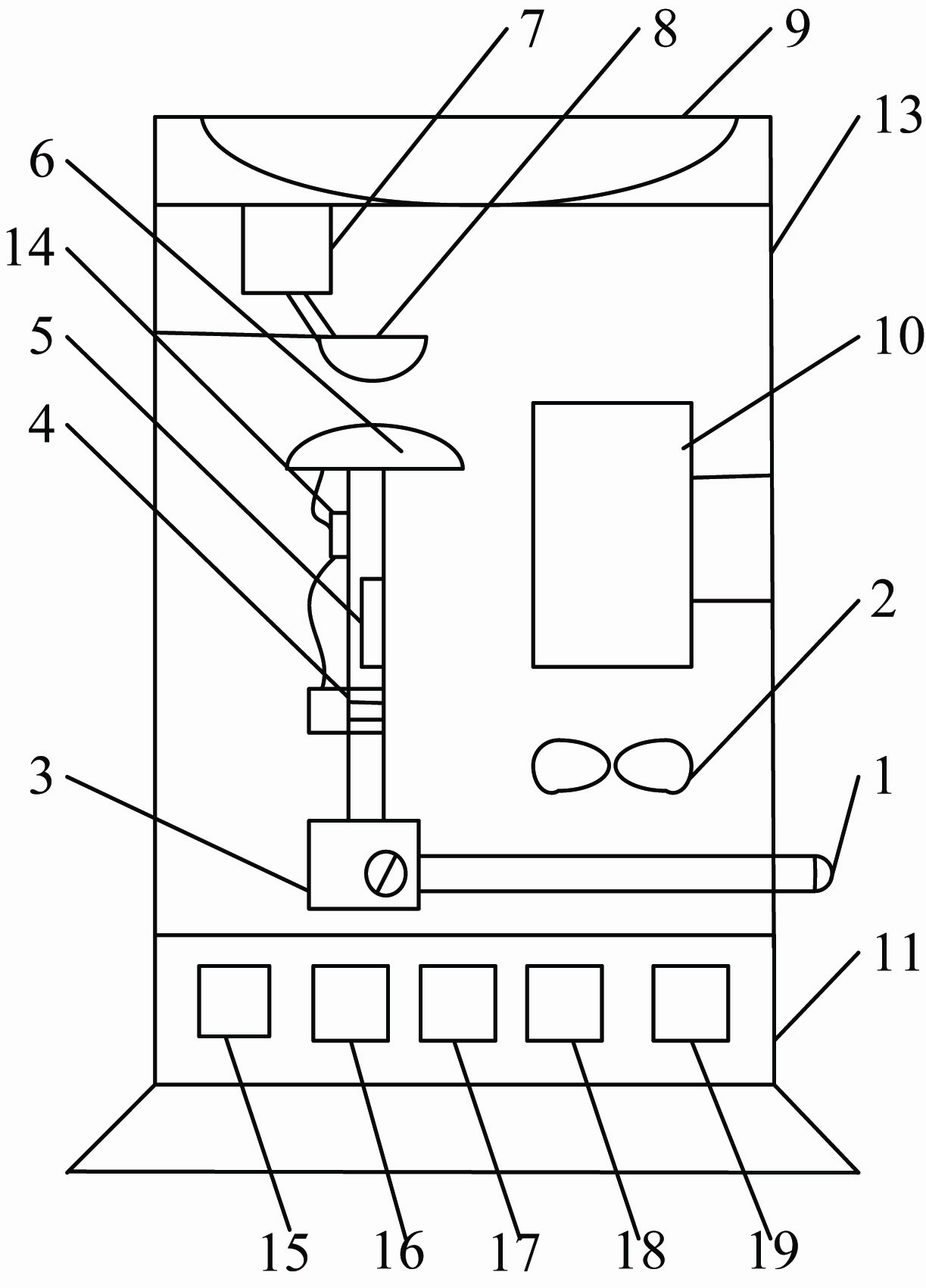

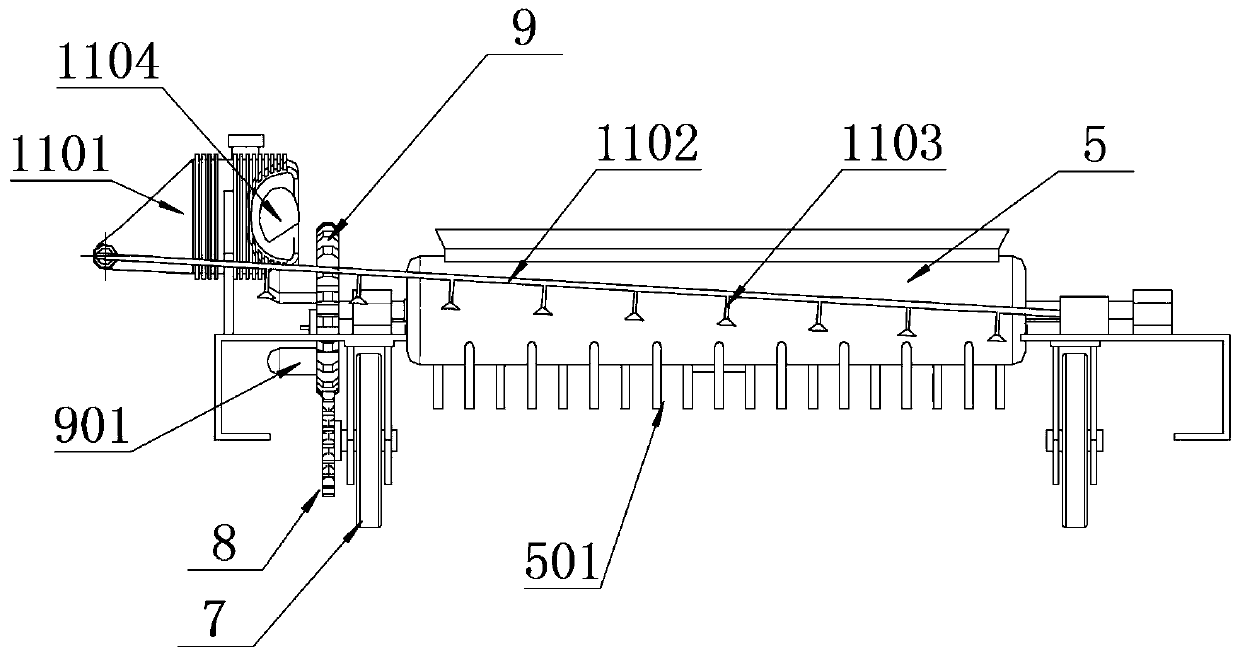

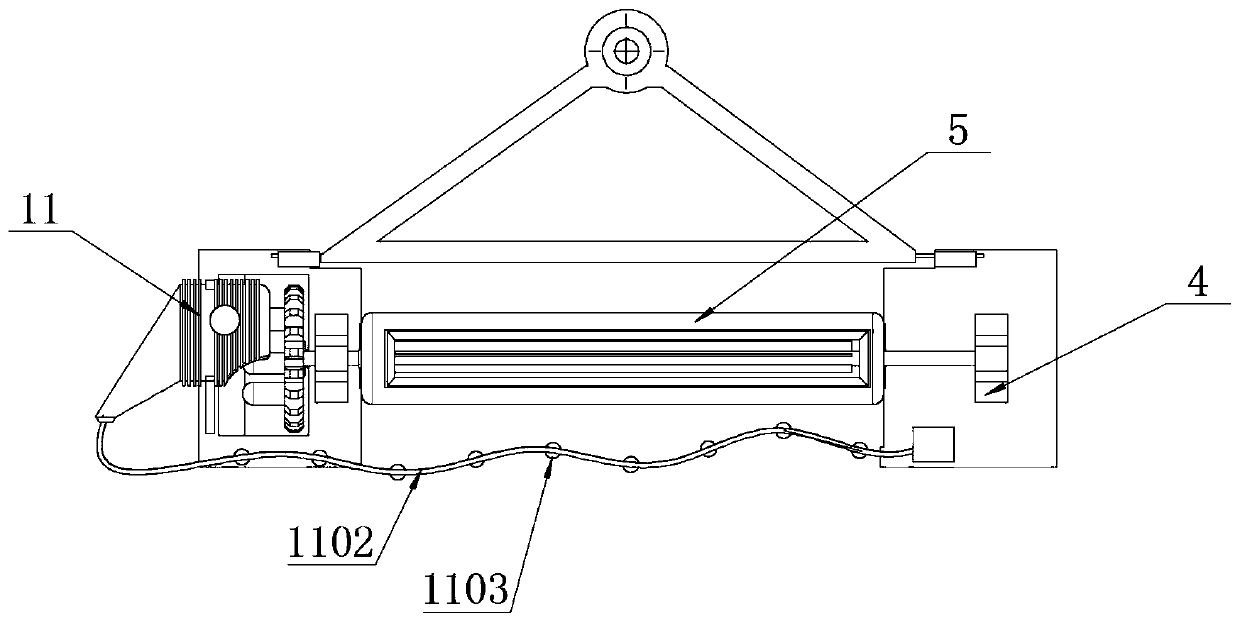

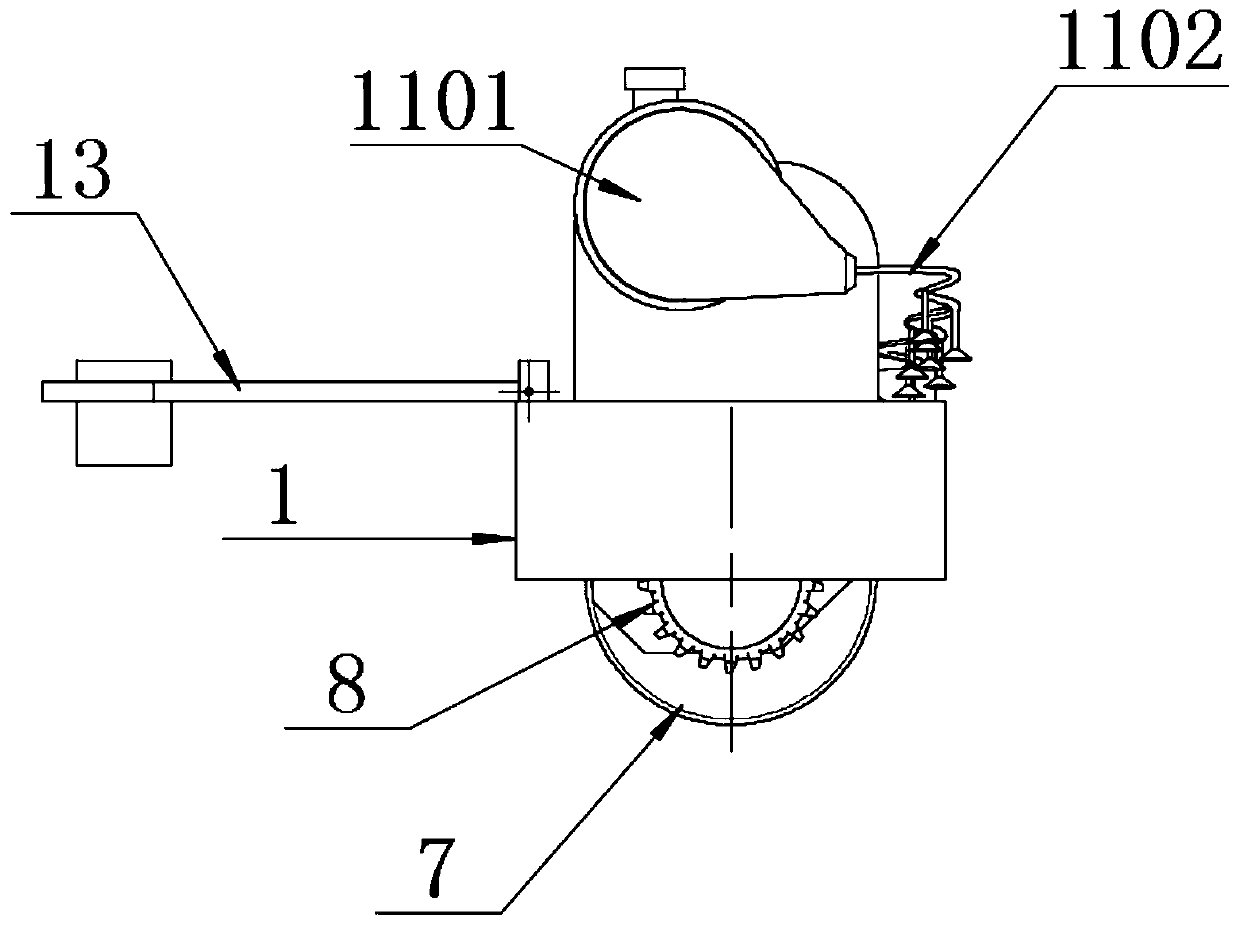

Compact type disease prevention and production increase machine for greenhouse crops

InactiveCN101946656AOmit structureCompact structureClimate change adaptationGreenhouse cultivationOzone generatorAutomatic control

The invention disclose a compact type disease prevention and production increase machine for greenhouse crops, which comprises a shell (13), a gas head (6), a pesticide gasification cup (8), an ozone generator (10) and a control panel (11), wherein the ozone generator (10) is arranged in the inner cavity of the shell (13); and the control panel (11) is arranged at the bottom of the shell (13). The invention omits a fluid director; the ozone generator is arranged in the inner cavity of the production increase machine; the control panel is arranged at the bottom of the shell; the invention has the advantages of compact structure and convenient transportation; and the concentration of carbon dioxide, the concentration of pesticides and the concentration of ozone can be automatically controlled at the same time.

Owner:大连创科君英科技发展有限公司

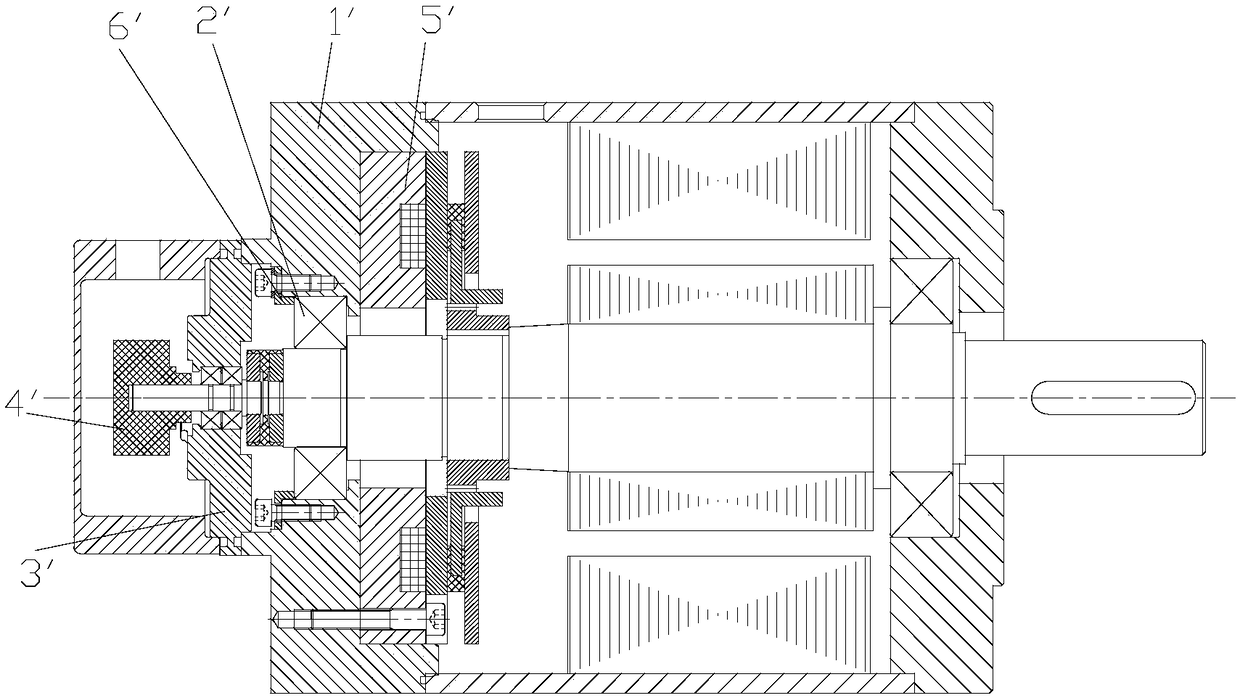

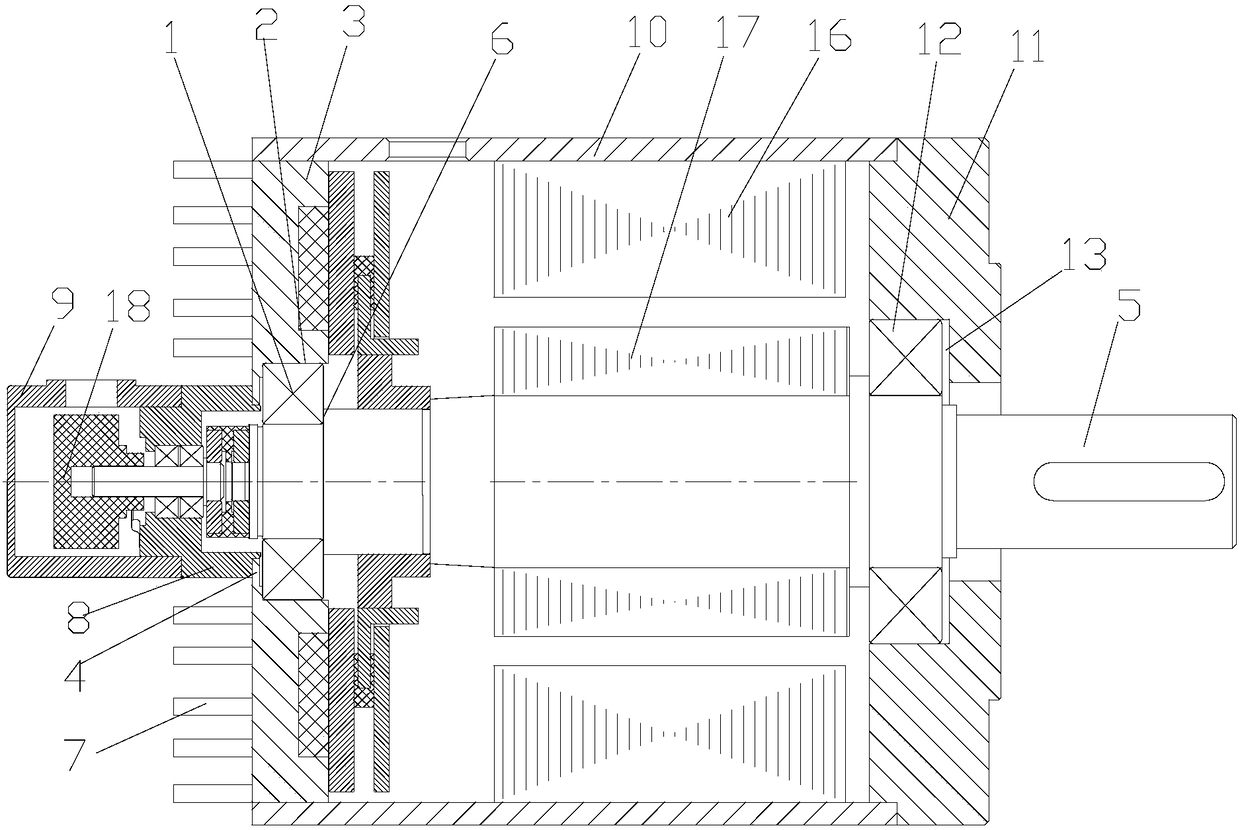

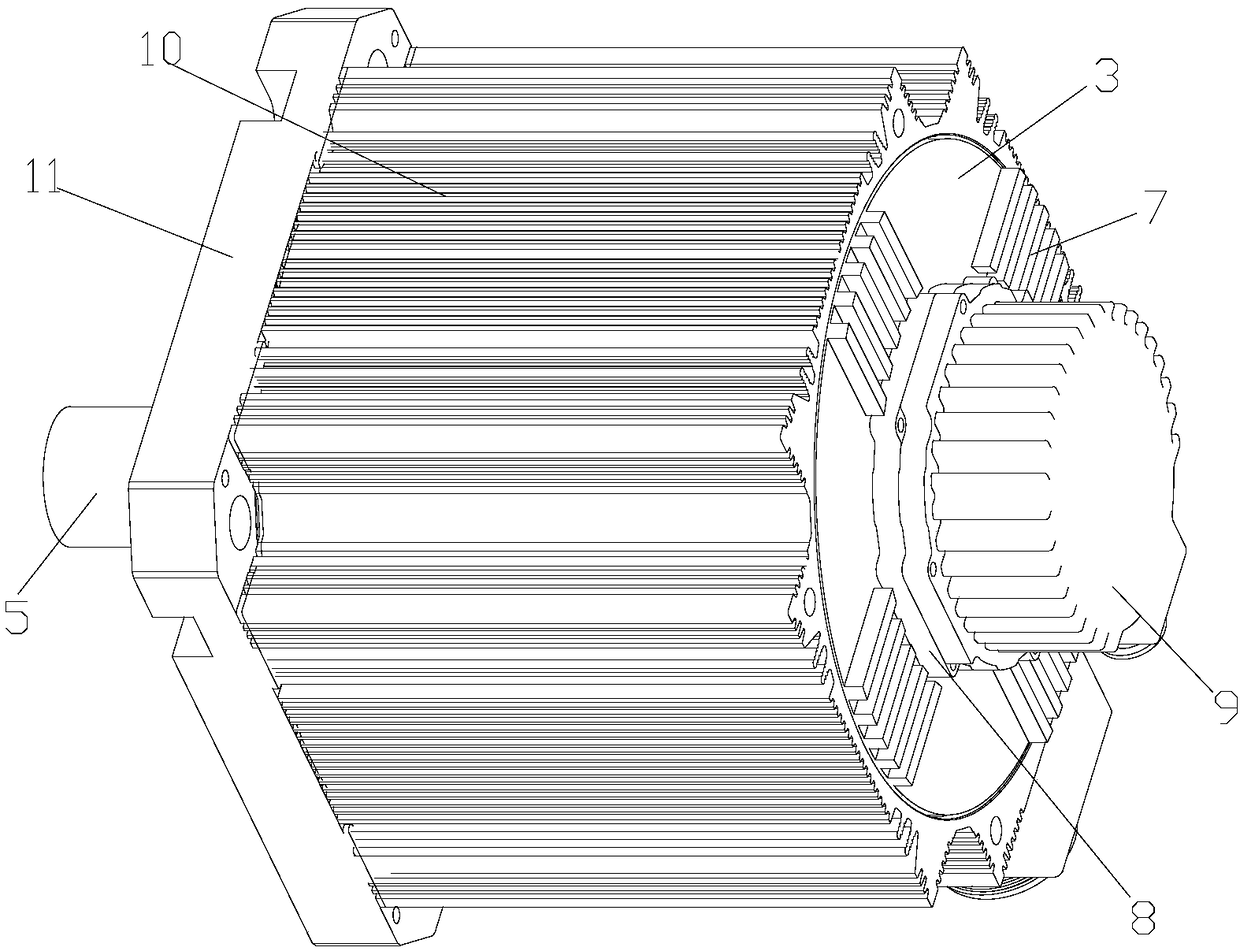

Motor

PendingCN108616195AOmit structureSimple structureMechanical energy handlingSupports/enclosures/casingsElectric machineControl theory

The invention provides a motor. The motor comprises a rear bearing (1) and a brake, wherein a first bearing chamber (2) is arranged on the brake, and the rear bearing (1) is arranged in the first bearing chamber (2) in a limitation way. According to the motor, the cooling efficiency of the motor brake can be improved, and excessively high temperature rise of the motor is prevented.

Owner:GREE ELECTRIC APPLIANCES INC +1

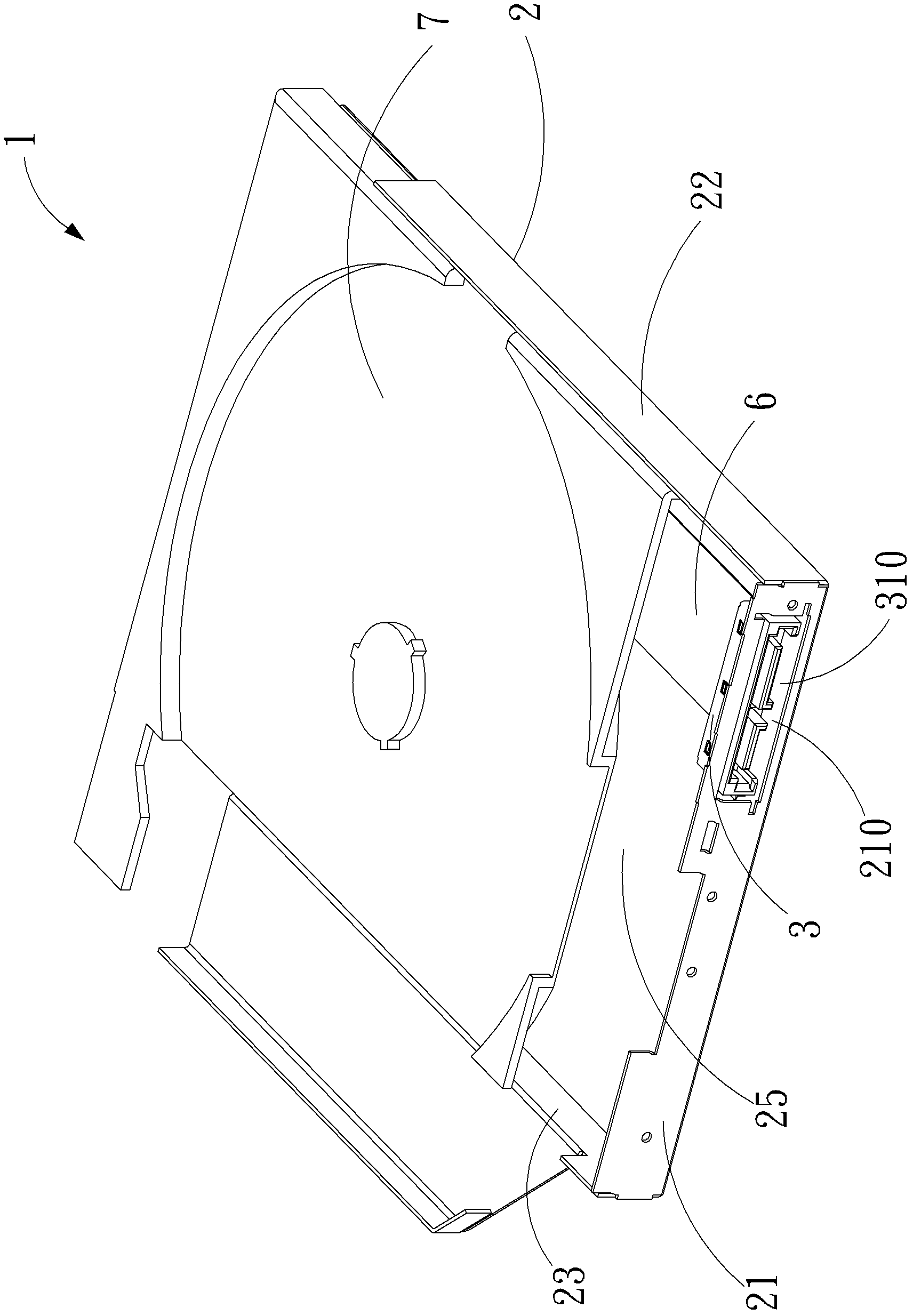

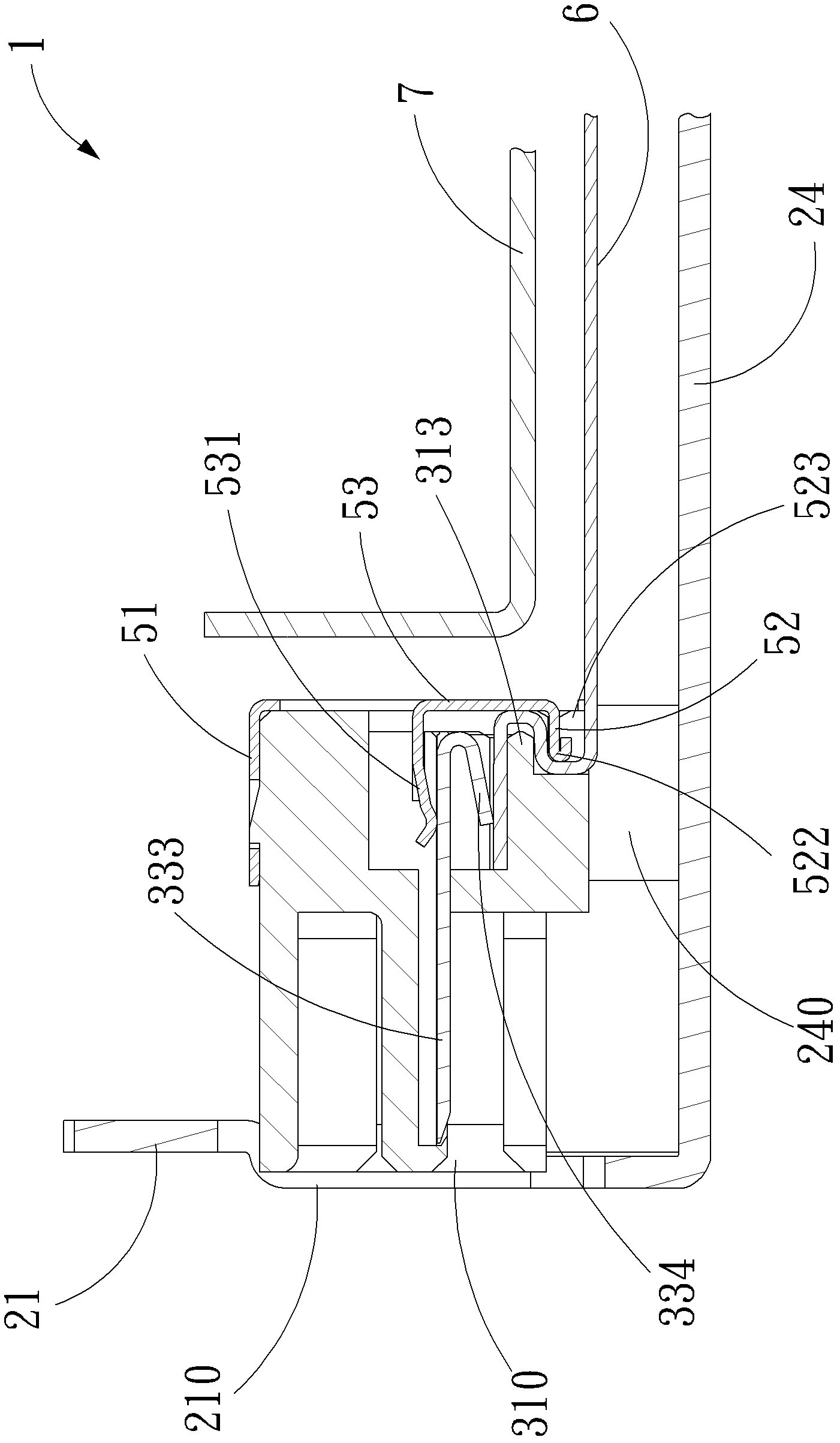

Connector module

ActiveCN103035266AOmit structureReduce space utilizationRecord information storageTwo-part coupling devicesEngineeringMechanical engineering

Owner:DACHANG ELECTRONICS TECH SUZHOU CO LTD +1

Grinder level finisher

InactiveCN101069960AEasy assemblyOmit structureAbrasive surface conditioning devicesPistonScrew joint

The invention discloses a level dresser of grinder. It is composed of a precise feeding device and a hydraulic dressing device. The feeding device contains a motor which connects with a screw. The screw joints a shaft lever which is fixed with diamond tools. The dressing device has a piston equipped in the cylinder. A signal block linking a triggering signal switch is fixed on the shell P. The two ends of the connection block are fixed on piston and shell separately to adjust the whole wheel dresser. The core shaft for dressing angle is equipped on the cylinder. The invention has simple structure, good rigidity and stable dressing. It can adjust the every-time dressing amount and the interval dressing times randomly based on different grinding wheels and grinding materials, which reduces the production cost and improves the production efficiency greatly.

Owner:长沙金岭数控磨床有限公司

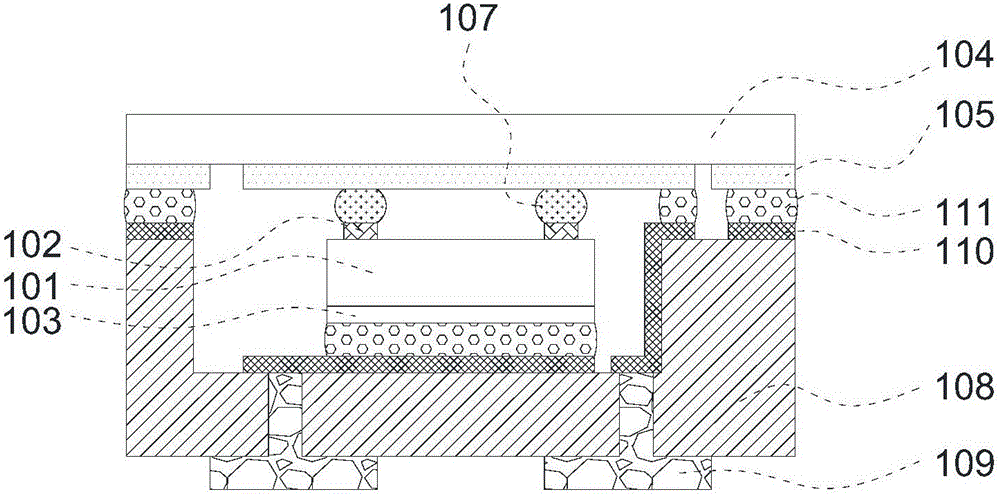

Configuration and manufacturing process of LED module

InactiveCN104659028AHigh light efficiencyFixing process is simpleSolid-state devicesSemiconductor devicesPhosphorEngineering

The invention discloses a configuration and a manufacturing process of an LED module. The manufacturing process is characterized by comprising the following steps: LED chips are fixed on the upper surface of a substrate by an insulating adhesive layer; two LED chips form a group and form an LED pair, electrode surfaces are upward; electrodes of the substrate are fixed on the upper surface of the substrate by the insulating adhesive layer; bonding wires are bonded to the electrodes of the substrate and the electrodes of the LED chip; a parallel connection part is arranged between every two adjacent LED pairs, and the bonding wire is led out from the electrodes of each LED chip in the LED pair and then is connected to the parallel connection part, so that the LED pairs become parallel connection units electrically connected in parallel; all parallel connection units are connected in series by the parallel connection part to form an LED string; finally, a phosphor layer is coated to cover the LED chips, the bonding wires and the insulating adhesive layer. According to the invention, all insulating layers and welding points of the substrate body are omitted; the thermal resistance is low; the uneven heat conduction caused by the welding process / configuration is further avoided; the LED chips are simple in fixing process and structure, and high in processing speed.

Owner:莆田康布斯光电科技有限公司

Special heat pump for power plant

InactiveCN102261768AOmit the structure of external heat exchangeOmit structureHeat pumpsHeat recovery systemsCooling towerEngineering

The invention provides a special heat pump for a power plant. The condensed water in the condenser is divided into two parts, and a part is used as the heat source of the heat pump to extract heat. and cooling to maintain a lower saturated vapor pressure, and then form condensed water again, and the other part is used as the heated liquid of the heat pump, and the recovered heat is sent from the condensed water pump to the low-pressure heater, thereby performing heat recovery. The device of the present invention The beneficial effect is: the condensed water is divided into two parts as the heat source of the heat pump and the heated liquid, which can omit the external heat exchange structure of the current condenser, save water for cooling towers, reduce heat discharge and reduce heat exchange energy loss, At the same time, it can directly recover the heat of exhausted steam to improve the power generation efficiency, that is, compared with the current power generation level of 340 g / kW*, it can save 20-60 g / kW* of coal, and can also recover some low-grade heat .

Owner:杨贻方

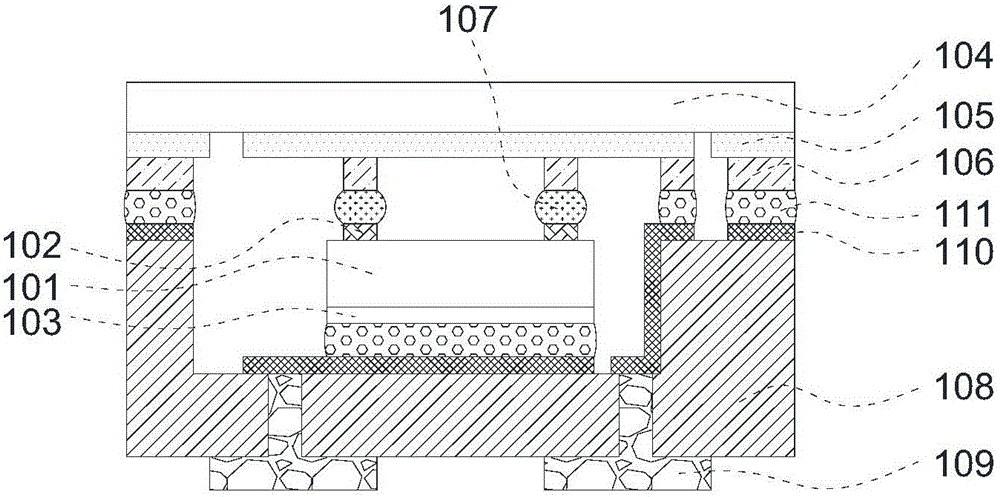

LED luminescent device and LED light source

ActiveCN105845813AReduce light lossFit tightlySolid-state devicesSemiconductor devicesEngineeringInorganic materials

The present invention discloses a LED luminescent device and a LED light source. The LED luminescent device comprises a LED chip with a vertical structure, an upper substrate and a lower substrate, wherein the upper substrate and the lower substrate are buckled to form a LED holding cavity to enclose the LED chip; the P electrode of the LED chip is led out by the P electrode lead-out circuit arranged at the lower substrate; the N electrode of the LED chip is electrically connected with the N electrode connection layer distributed on the substrate, and the N electrode connection layer is connected with the lower substrate through the leading wire arranged on the LED holding cavity side wall for leading out; and the packaging connection positions of the upper substrate and the lower substrate employ inorganic materials for connection, and the upper substrate is a transparent substrate. The LED luminescent device and the LED light source are longer in service life and smaller in the LED light extraction loss.

Owner:苏州汇杰紫芯光电有限公司

An integrated ceiling and its installation method

Owner:ZHEJIANG YASHA DECORATION

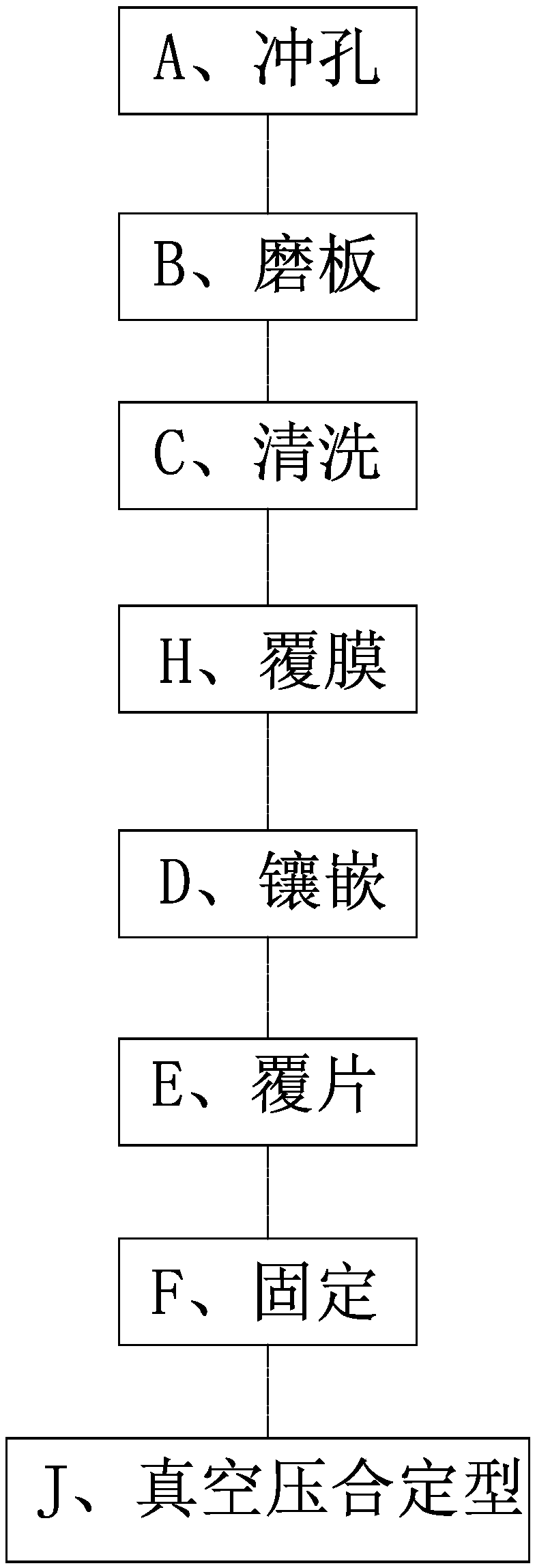

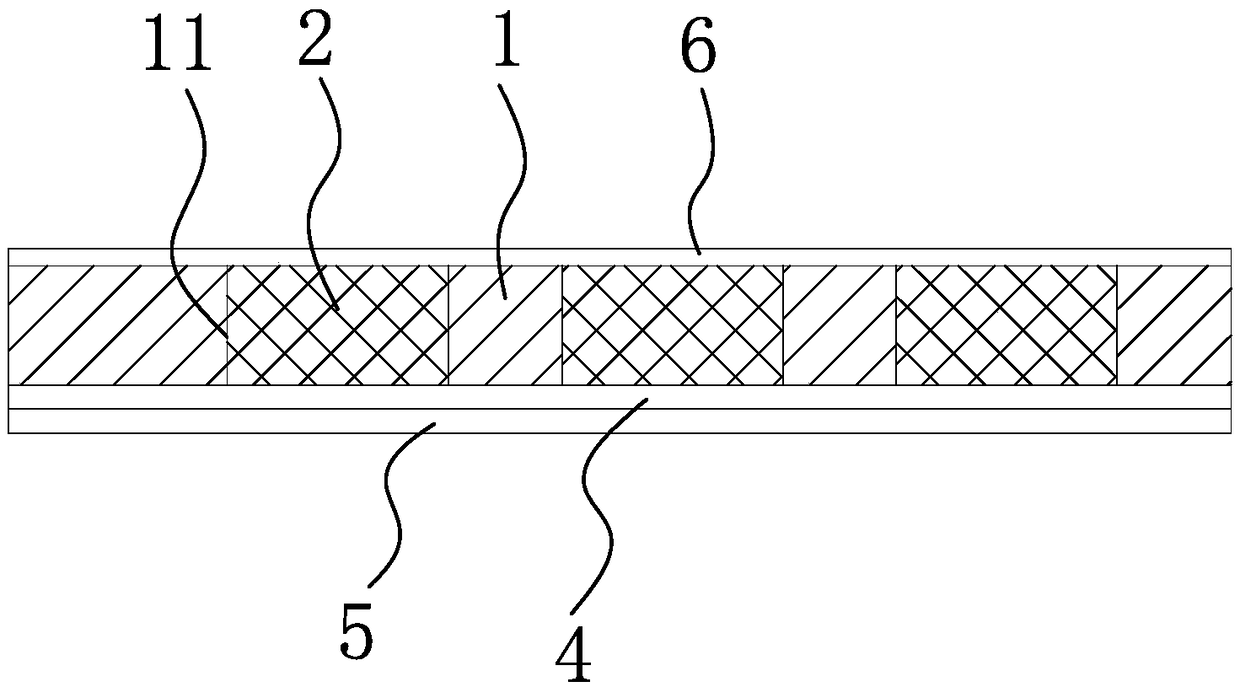

Composite aluminum substrate, production technology thereof, and LED circuit board

ActiveCN108848619AIncrease productivityReduce manufacturing costInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentPunchingOptoelectronics

The invention belongs to the technical field of circuit boards, and particularly relates to a production technology of a composite aluminum substrate, and an LED circuit board. The problems of unreasonable design and the like in the prior art are solved. The production technology of the composite aluminum substrate comprises the following production steps of A, punching, B, plate grinding, C, cleaning, D, inlaying, E, sheet cladding, and F fixing. The production technology of the composite aluminum substrate has the advantages that the bonding strength can be improved, the cost can be reduced,and the production efficiency is improved.

Owner:俊萱新材料(杭州)有限公司

Split-type disease and insect pest pesticide liquid spraying device based on corn planting

ActiveCN110521708ASave electricOmit structureFertiliser distributersInsect catchers and killersTypes diseasesDrive wheel

The invention provides a split-type disease and insect pest pesticide liquid spraying device based on corn planting. The split-type disease and insect pest pesticide liquid spraying device comprises aleft bearing, a right bearing, a driving wheel and a pull frame; a left frame and a right frame are both L-shaped plate bending pieces, and the inner end faces of the left frame and the right frame are jointly connected with a function bin; the left bearing and the right bearing are symmetrically installed on the top faces of the left frame and the right frame left and right, and mobile wheels are further installed on the bottom faces of the left frame and the right frame through welded wheel frames; a welding plate is vertically welded to the left side of the top face of the left frame, a semi-circular arc opening is formed in the top of the welding plate, and a lateral leather bag is in screw fixation with the semi-circular arc opening. Other complicated mechanisms actuated by a fertilizer application mechanism are omitted, and a helpful structure with two kinds of functional linkage actuation is achieved. In this way, the split-type disease and insect pest pesticide liquid sprayingdevice is simple in structure and can complete fertilizer application and downward pesticide liquid spraying simultaneously after being hung on an agricultural vehicle, and therefore, agricultural bacteria which are turned out when soil is turned in the last working procedure are quickly killed in the next working procedure of fertilizer application.

Owner:MAIZE RES INST HEILONGJIANG ACAD OFAGRI SCI

Right-angled distribution engine with suspension piston

ActiveCN101793192AAvoid scratchesAvoid enteringValve arrangementsInternal combustion piston enginesCombustion chamberEngineering

The invention discloses a right-angled distribution engine with a suspension piston, which comprises a cylinder 1 and a piston 2. The sidewall forming part of the cylinder 1 for suspension or quasi-suspension of the piston 2 is provided with one or a plurality of lower sidewall distribution channel(s) 5001, the sidewall of the cylinder 1 in each lower sidewall distribution channel 5001 is provided with one or a plurality of lower sidewall distribution base opening(s) 4, and a lower sidewall distribution valve 5 is arranged at each lower sidewall distribution base opening 4 and is controlled by a lower sidewall distribution valve timing control mechanism 6 to open or close the lower sidewall distribution base opening 4 according to a timing relationship. Since the valve seat opening on the side face of the cylinder is arranged above the seal section of the piston, the invention can avoid the engine oil from being scraped into the channel, thereby preventing the engine oil scraped into the channel from flowing into the combustion chamber or being directly discharged into the atmosphere, reducing the environmental pollution and prolonging the service life of the engine.

Owner:张家港市乐余科创园投资发展有限公司

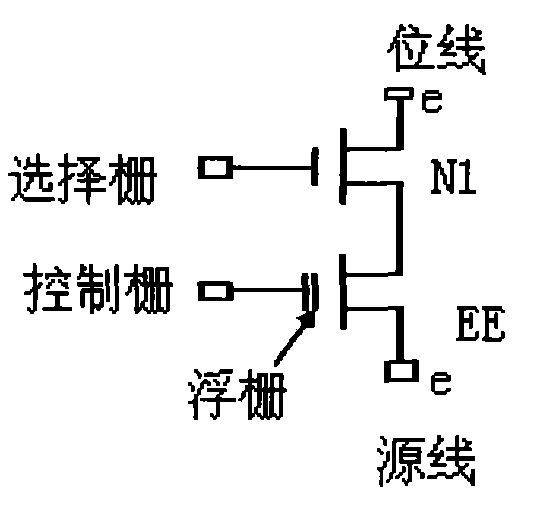

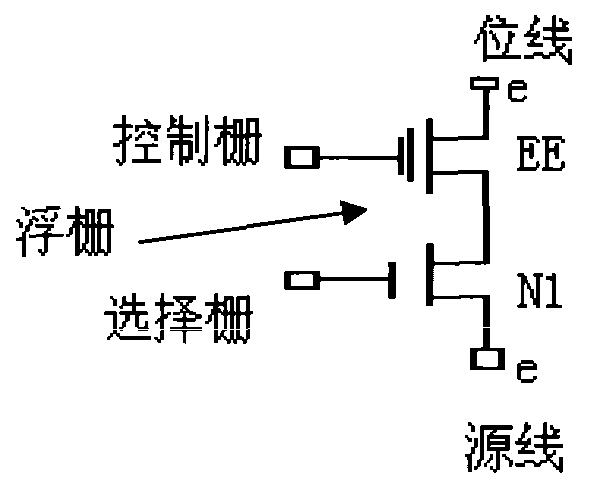

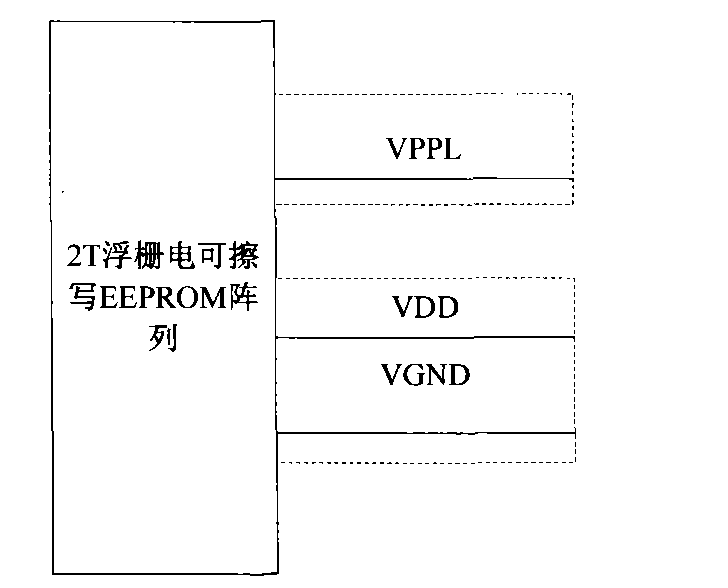

2T embedded FLOTOX EEPROM

InactiveCN101751999AOmit structureReduce areaRead-only memoriesProgrammable read-only memoryHemt circuits

The invention discloses a 2T (2-transistor) embedded FLOTOX (floating gate tunnel oxide) EEPROM (electrically erasable programmable read only memory) characterized in that a selectron is located in the source area of a memotron in a memory cell. By arranging the selectron in the source area of the memotron, a memory array can achieve the operations of erasing and writing-in by only one high voltage. Therefore, the invention dispenses with the voltage peak-peak H (VPPH) and a circuit structure for generating the VPPH, and further reduces a high-voltage resistant component for generating and transferring the VPPH in the circuit, thereby dispensing with at least two layers of photomasks and various technological steps and saving the chip area.

Owner:SHANGHAI HUA HONG NEC ELECTRONICS

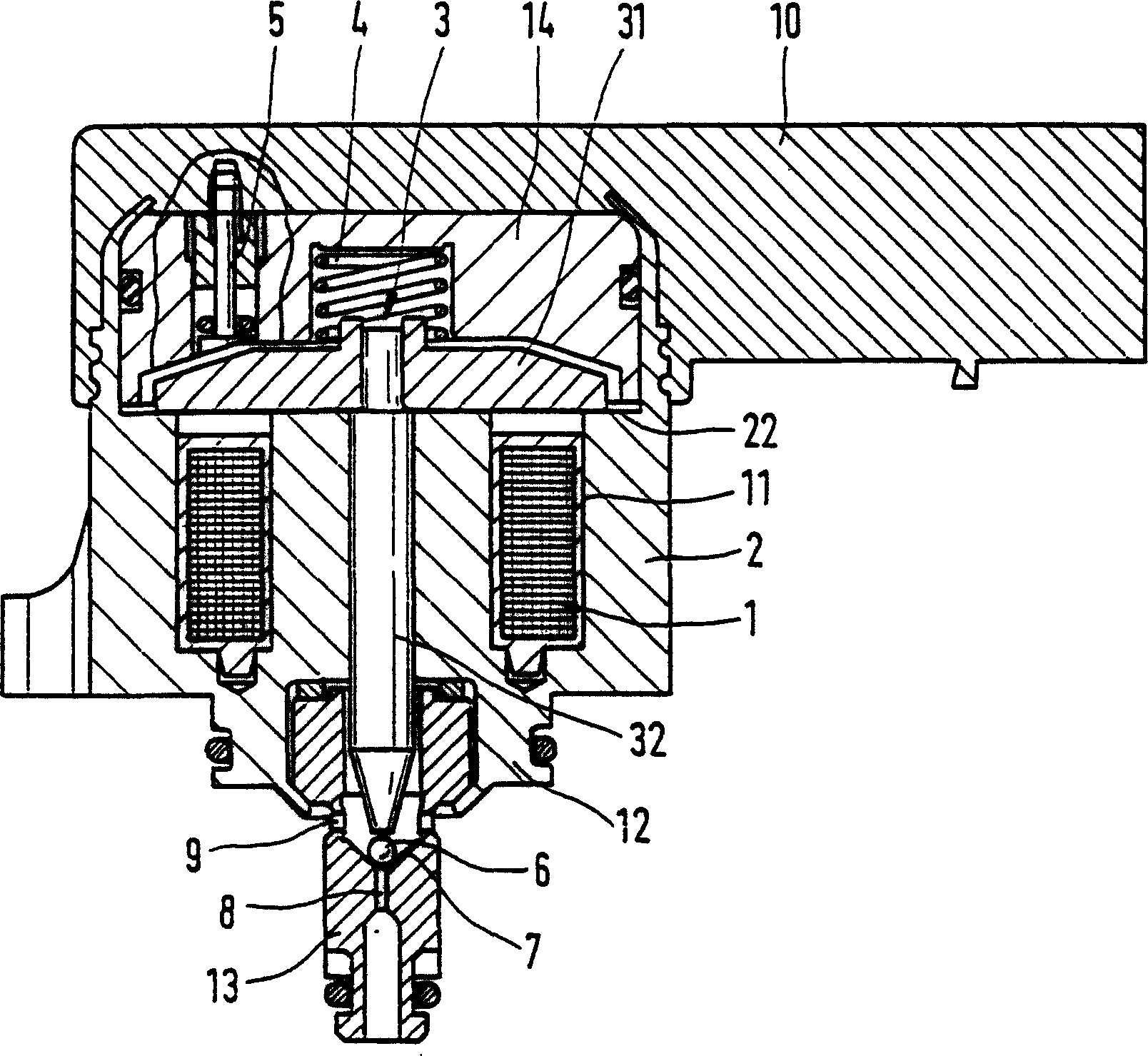

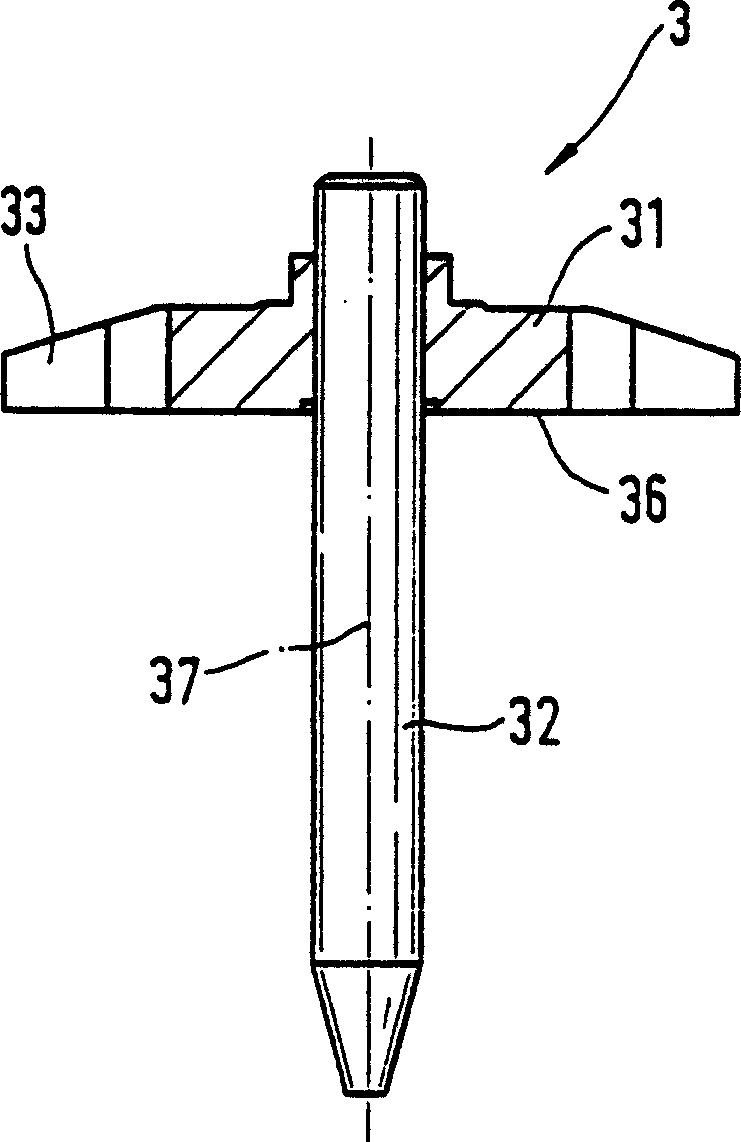

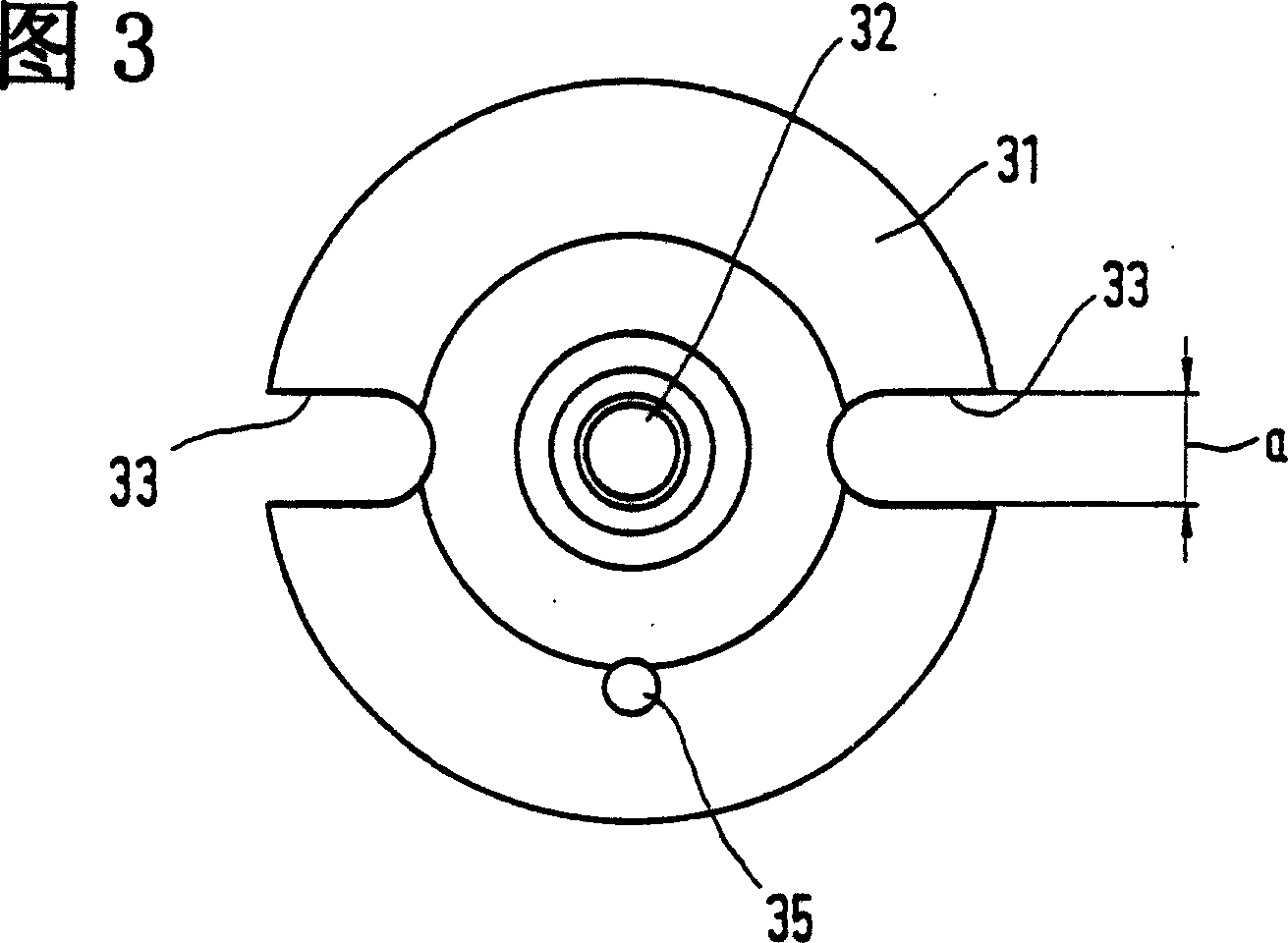

Electromagnetic with a magnet armature

InactiveCN1270329CAvoid the disadvantages associated with usingOmit structureFuel injection apparatusMachines/enginesMagnetic valveElectric current flow

The invention relates to an electromagnet with a magnet armature, especially for use in an electromagnetic valve, which has a magnet coil (1), a magnet core (2) which passes through the magnet coil (1) and which has at least one pole face (22); a magnet armature (3) which is arranged in such a way as to be vertically displaceable in relation to the at least one pole face (22) of the magnet core (2) and which has an armature plate (31) that faces towards the pole face (22); and an armature pin (32) which projects from the armature plate (31) and is mounted in such a way that it can slide and rotate; and alignment means, which are configured on the electromagnet and / or the magnet armature and which effect the alignment of the armature plate (31) to a predetermined rotation position. The invention provides that the alignment means take the form of at least one first recess (33) which is radially offset from the armature pin (32) and which is configured in the armature plate (31), and at least one second recess (27) which is situated in the at least one pole face (22) of the magnet core (2) and which is associated with the first recess (33). When the magnet coil (1) is subjected to a current, said second recess magnetically interacts with the first recess (33) in such a way that the armature plate (31) is aligned to the predetermined rotation position.

Owner:ROBERT BOSCH GMBH

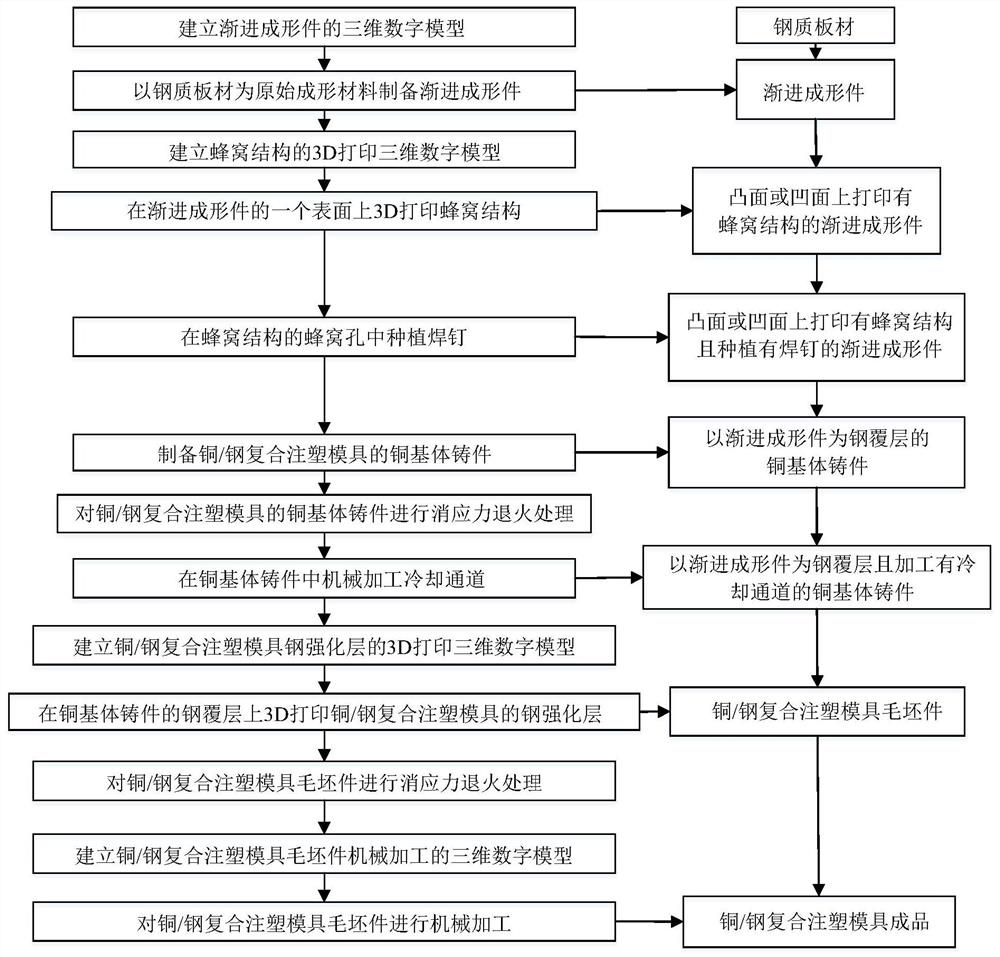

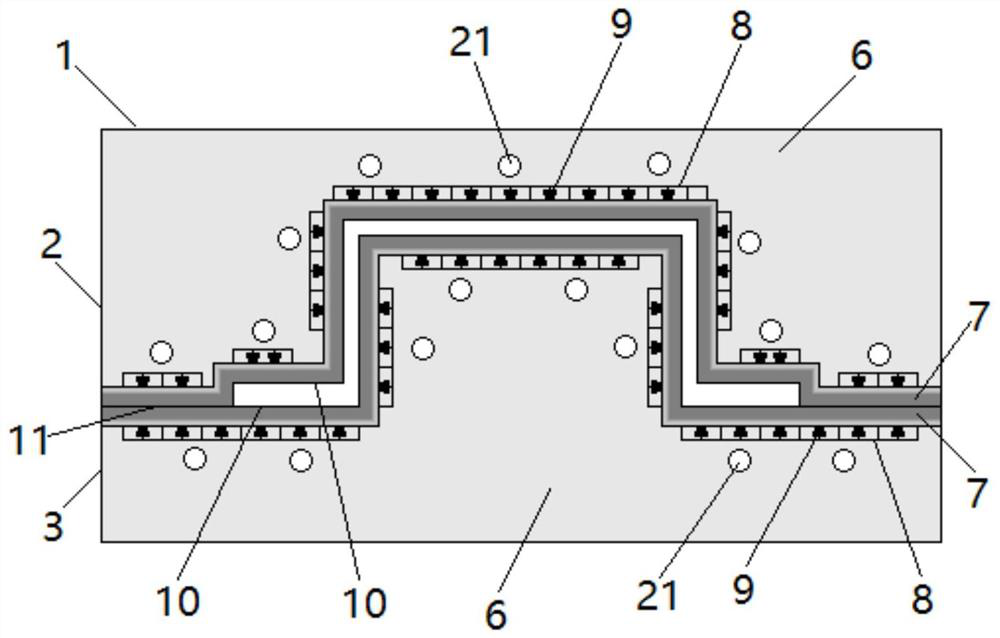

Manufacturing method of copper/steel combination injection mold with honeycomb and planted nail interface structure

ActiveCN111716084AIncrease binding areaReduce the impactAdditive manufacturing apparatusPlasma welding apparatusBond interfaceHoneycomb structure

The invention discloses a manufacturing method of a copper / steel combination injection mold with a honeycomb and planted nail interface structure. The manufacturing method comprises the following steps that a steel plate serves as a raw forming material, and a steel plate incremental forming part is manufactured according to an incremental forming method; then a honeycomb structure is arranged onone surface of the incremental forming part in a 3D printing mode; welding nails are planted in honeycomb holes; a copper substrate casting of the copper / steel combination injection mold is cast in amold-free mode; cooling channels are machined; and steel reinforcing layers of the copper / steel combination injection mold are formed on the surface of a steel coating of the copper substrate castingin a 3D printing mode. According to the manufacturing method, the interface bonding of a copper substrate and the steel reinforcing layers of the copper / steel combination injection mold is achieved through the honeycomb and planted nail structure in the manufacturing process, the outline of a bonding interface is similar to the curved surface of a mold cavity of the copper / steel combination injection mold, the whole manufacturing process is free of molds, and high-quality and low-cost rapid manufacturing of the copper / steel combination injection mold is achieved.

Owner:NANJING ENIGMA IND AUTOMATION TECH CO LTD

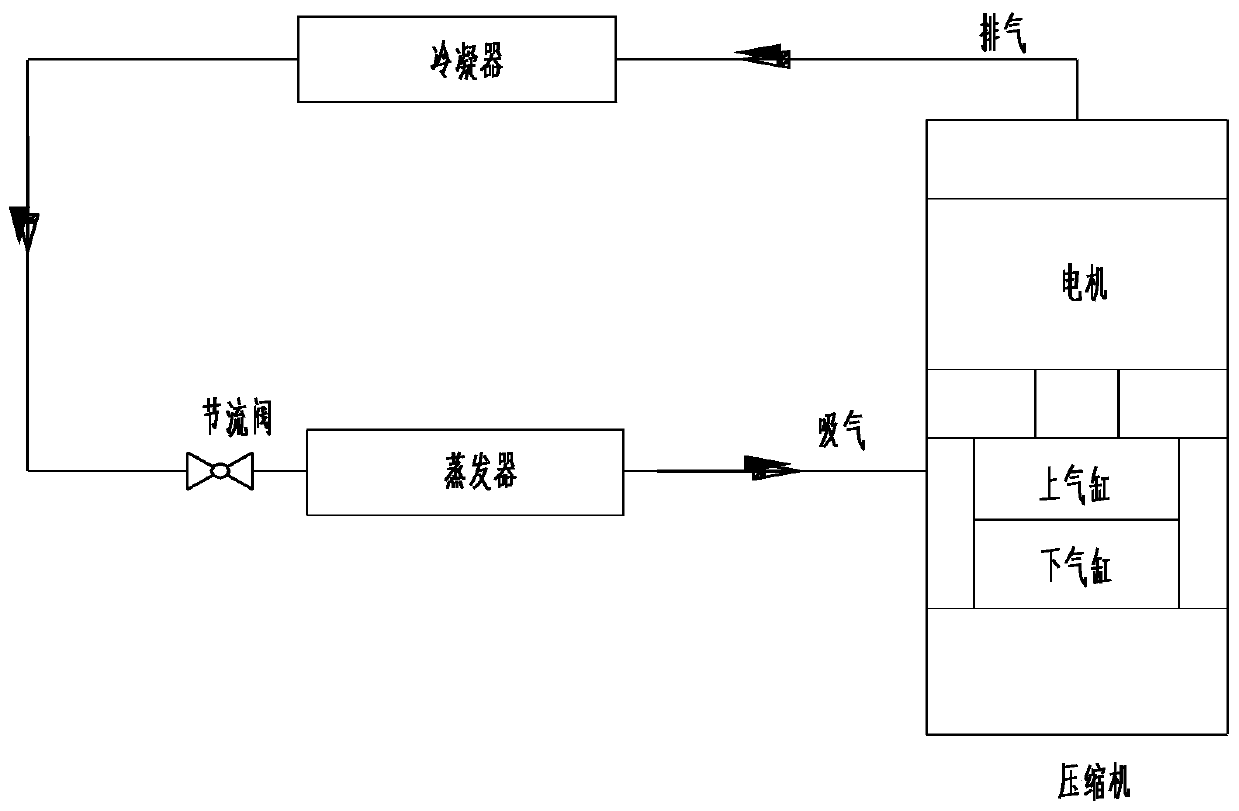

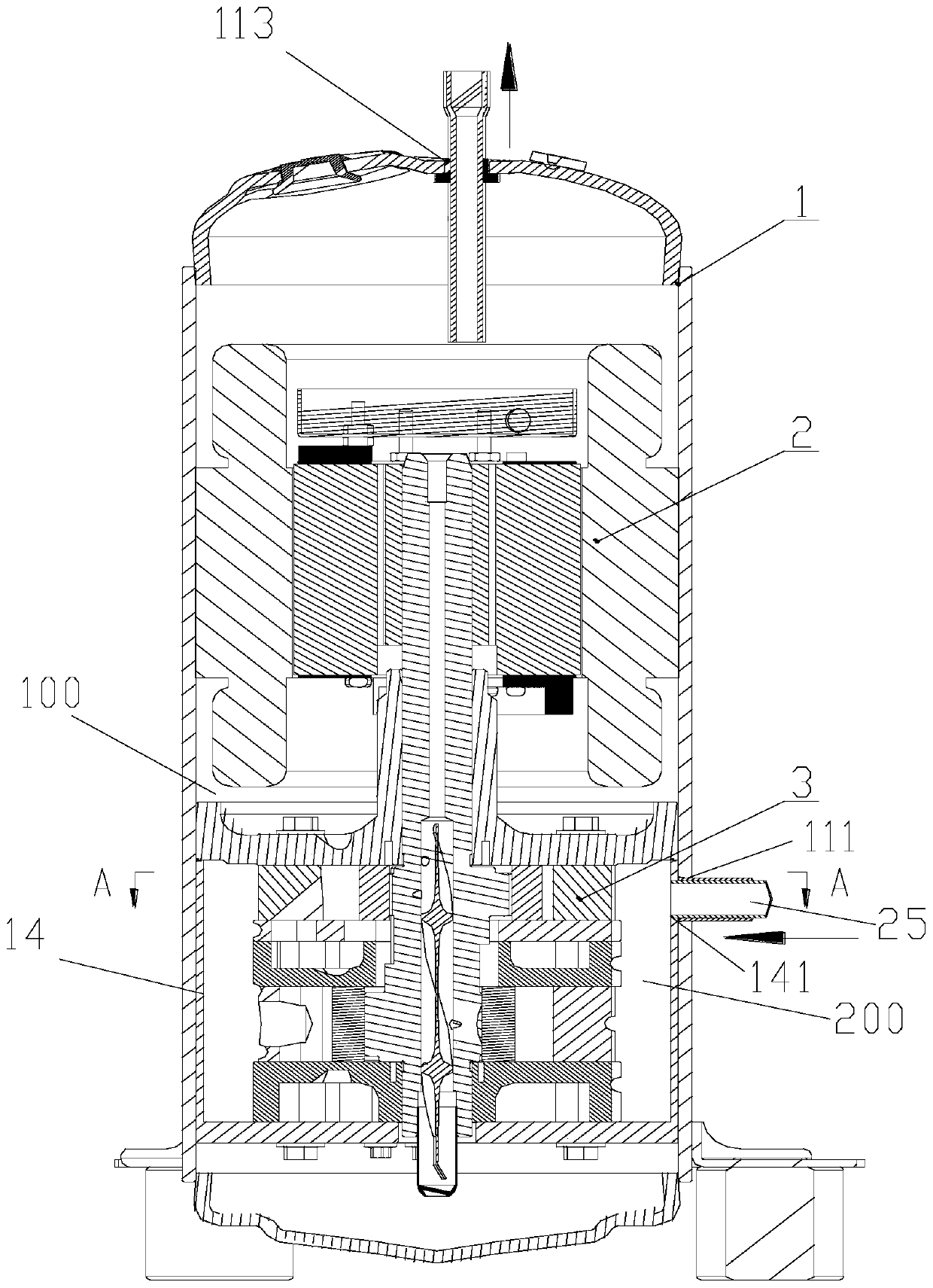

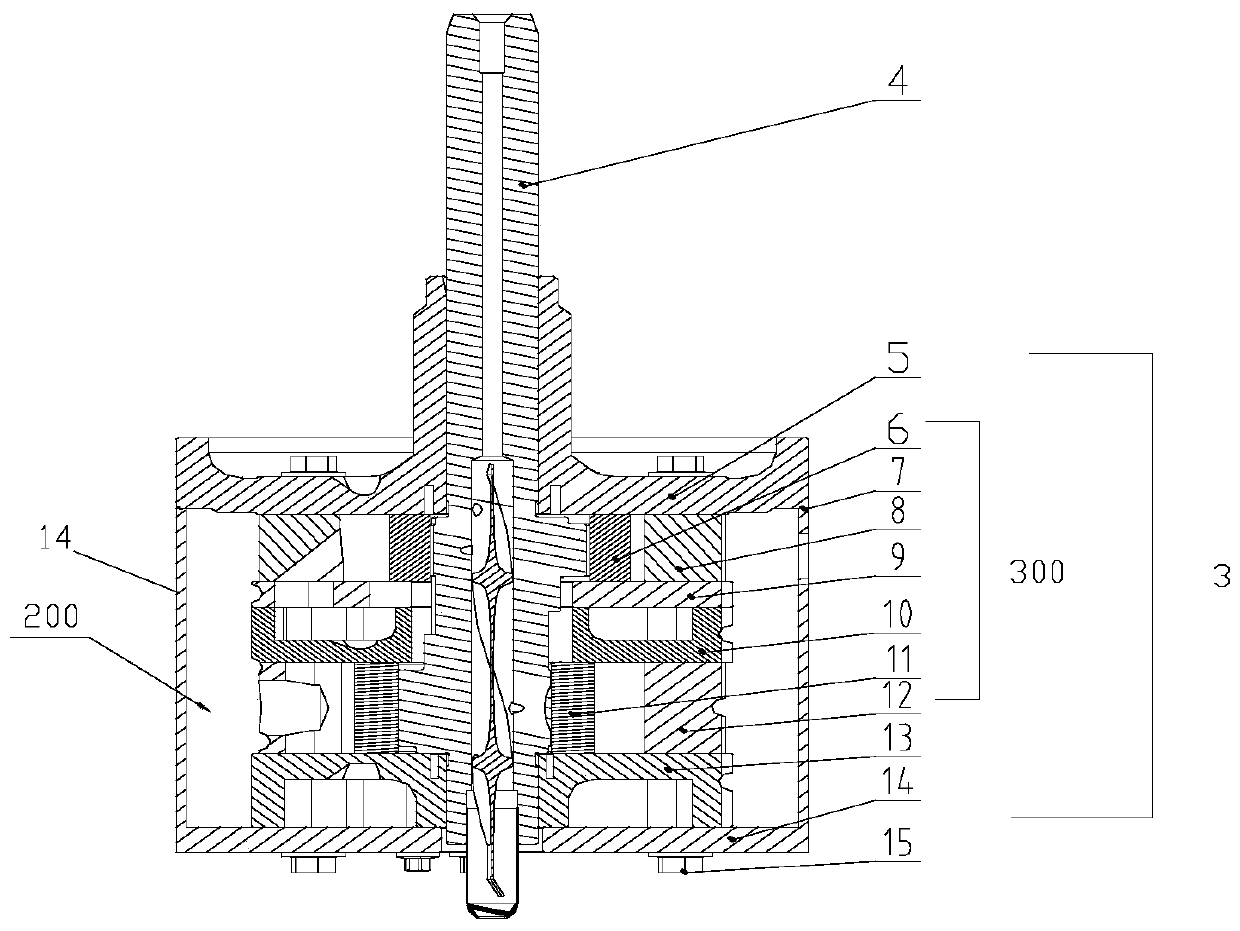

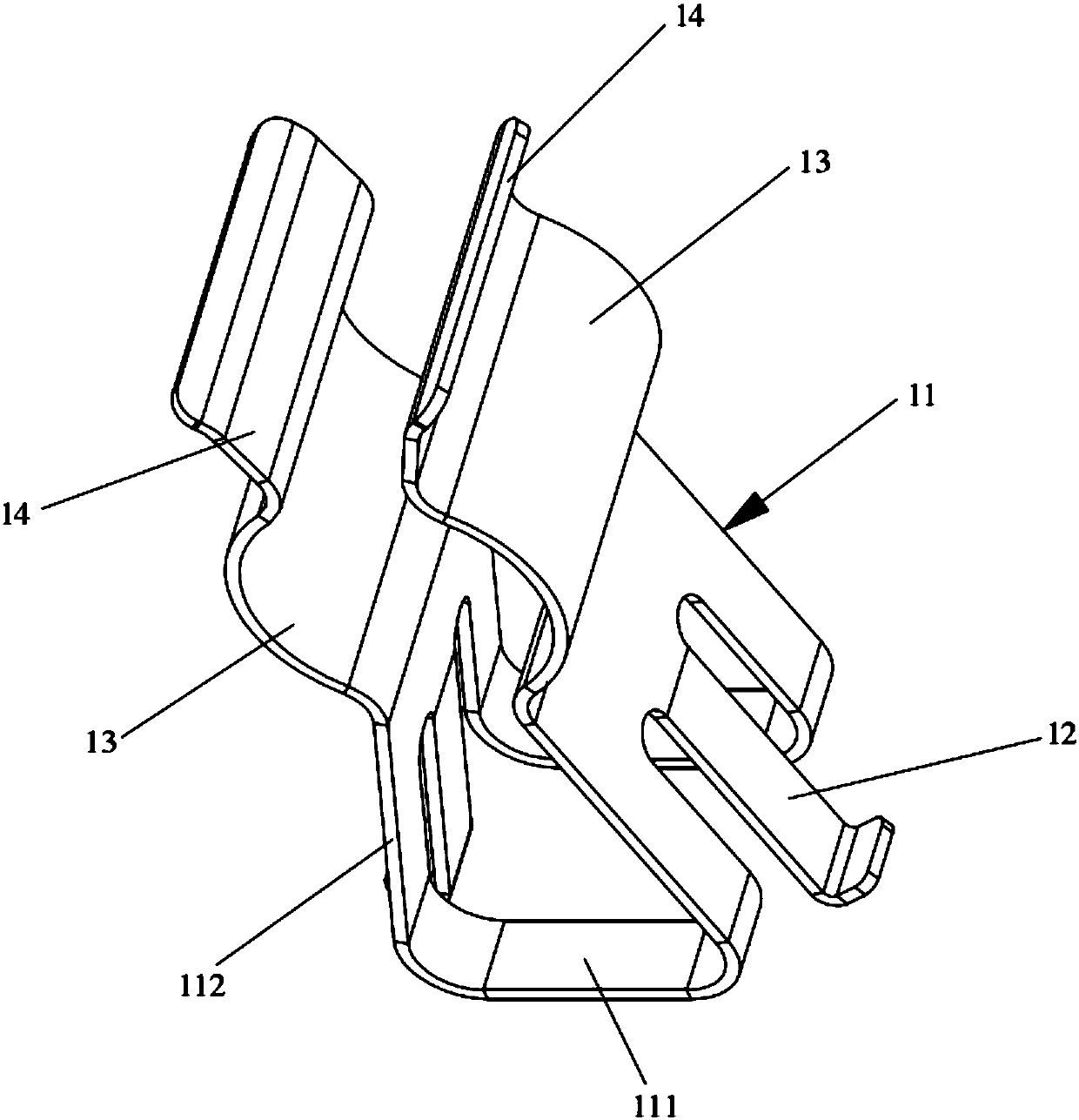

Compressor and air conditioner

PendingCN110985385ALight in massReduce volumeCompressorRotary/oscillating piston combinations for elastic fluidsVapor–liquid separatorOil separation

The invention provides a compressor and an air conditioner. The compressor comprises a shell body assembly (1), a pump body assembly (3) is arranged in the shell body assembly (1), a shell body cavity(100) is formed in the shell body assembly (1), a pump body cavity (200) sealed with the shell body cavity (100) is formed in the pump body assembly (3), and thus fluid entering the pump body cavity(200) can be subjected to gas-liquid separation or oil-gas separation. According to the compressor and the air conditioner, the gas-liquid separation can be completed, meanwhile a structure of a gas-liquid separator is further effectively omitted, the oil-gas separation is completed, meanwhile a structure of an oil-gas separator is further effectively omitted, the structure volume can also be greatly decreased, the mass is decreased, it can be guaranteed that the gas-liquid separation and oil-gas separation can be conducted, and meanwhile the volume and mass of the compressor can be effectively decreased.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

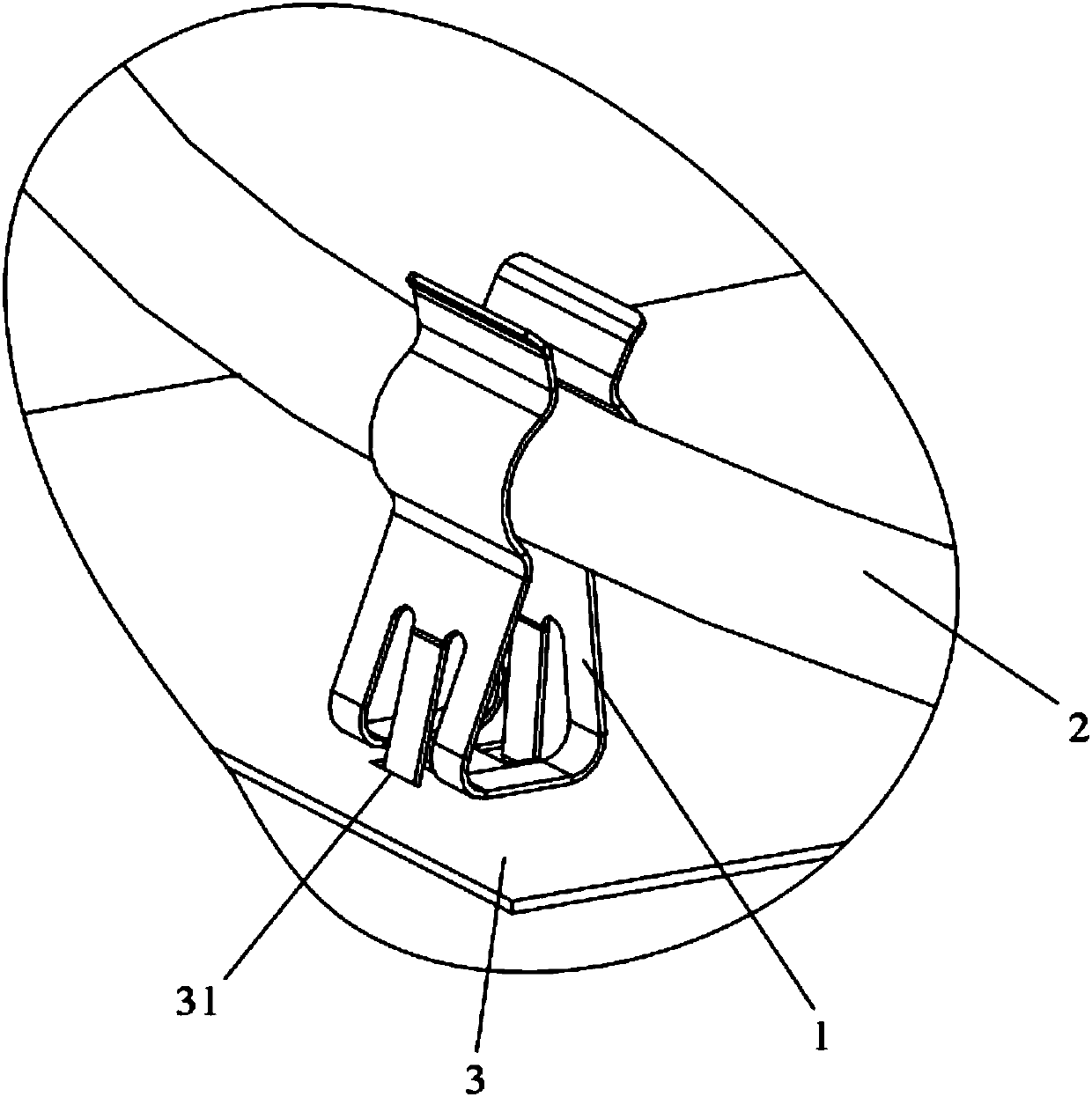

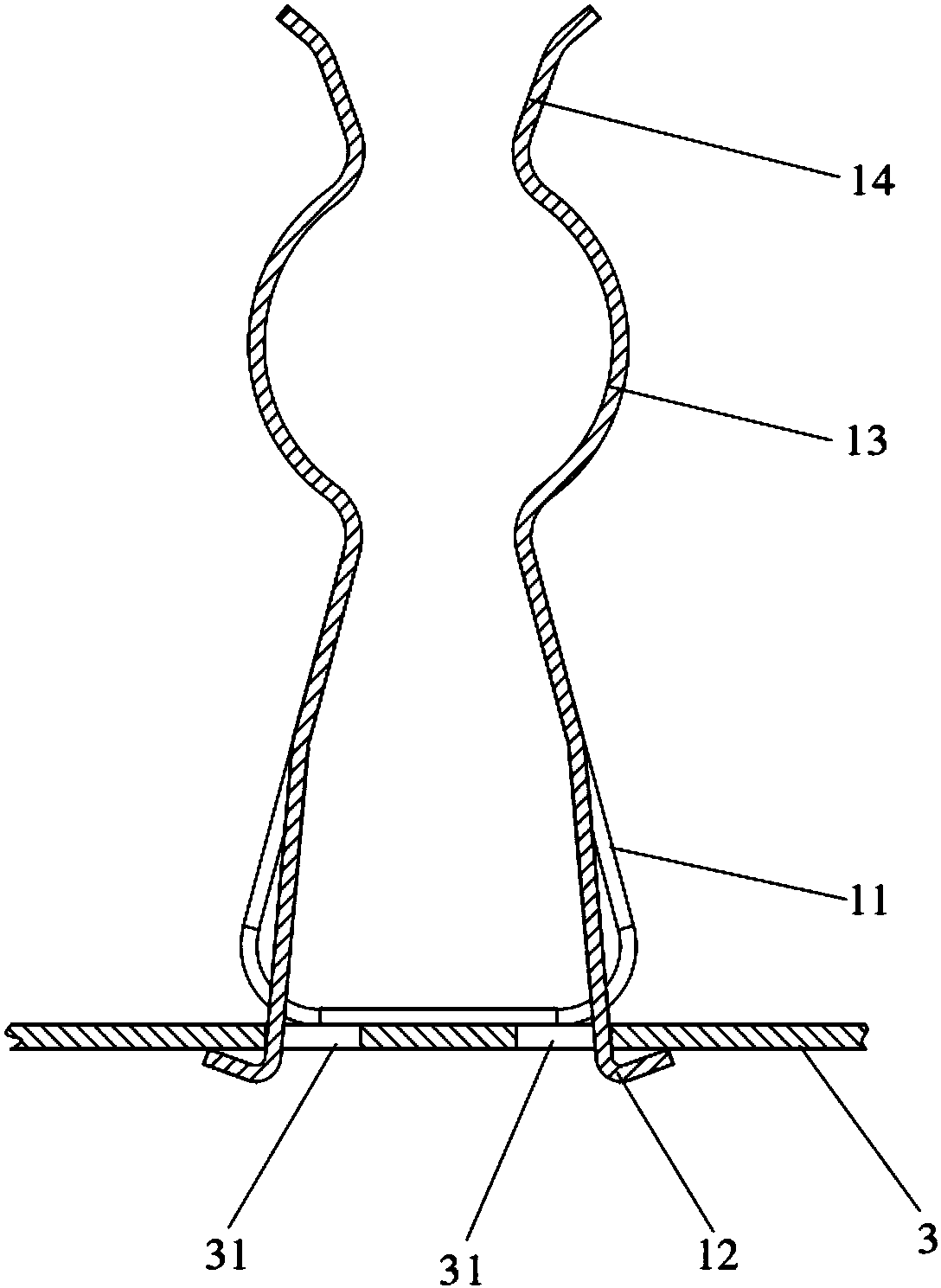

Fixing pipe clamp and disinfecting cabinet using same

ActiveCN109780013AFirmly connectedOmit structureLavatory sanitoryFriction grip releasable fasteningsPipe fittingEngineering

The invention relates to the technical field of disinfecting cabinets, and discloses a fixing pipe clamp and a disinfecting cabinet using same. The fixing pipe clamp is used for fixing a pipe fittingand a fixing wall. The fixing pipe clamp comprises a bottom support part, wherein elastic clamping hooks are correspondingly arranged at two sides of the bottom support part and are clamped to fixingholes in the fixing wall; a clamping ring part which fits the pipe fitting by structure is connected to the upper part of the bottom support part, and the clamping ring part is used for clamping the pipe fitting; and an opening part through which the pipe fitting can be clamped into the clamping ring part is formed in the upper part of the clamping ring part. According to the fixing pipe clamp, the elastic clamping hooks are arranged at two sides of the fixing pipe clamp and can be clamped into the fixing holes in the fixing wall so as to realize firm connection of the fixing pipe clamp and the fixing wall, and a screw, a nut plate and other structures can be saved; the material cost is saved; the mounting process is simplified; the production efficiency is improved; and the damage of thescrew structure to the fixing wall and the pipe fitting can be avoided.

Owner:QINGDAO HAIER WISDOM KITCHEN APPLIANCE CO LTD

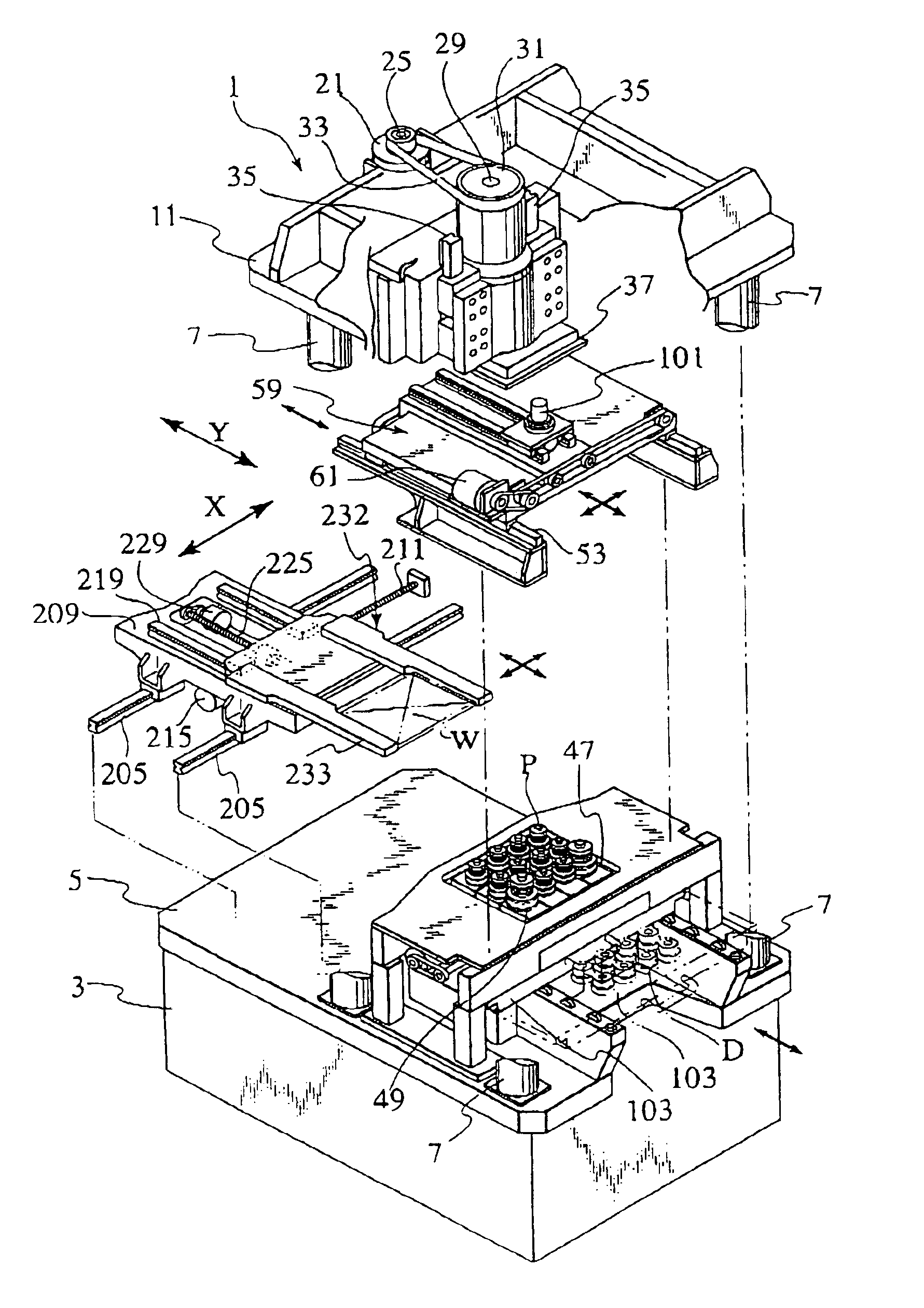

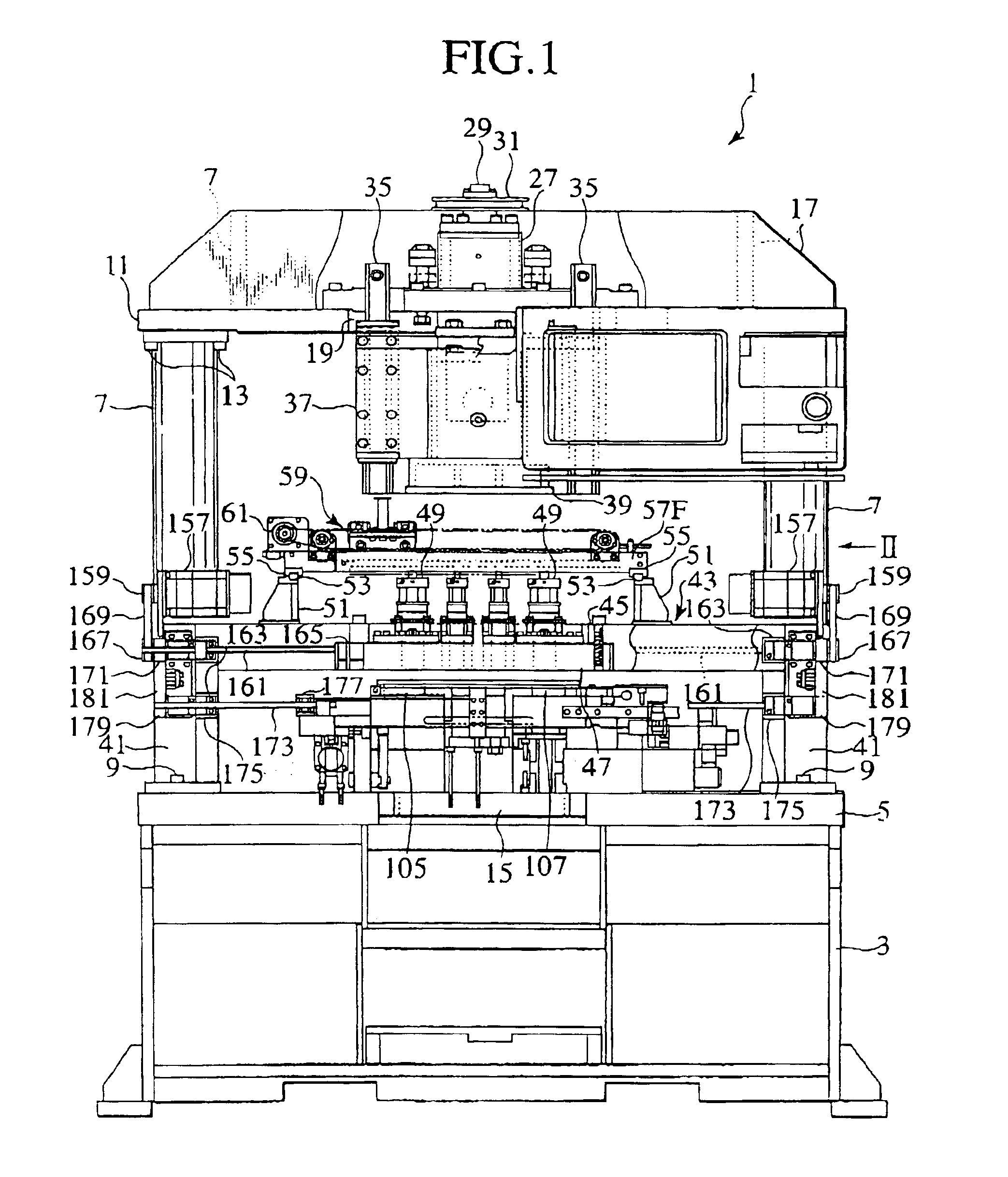

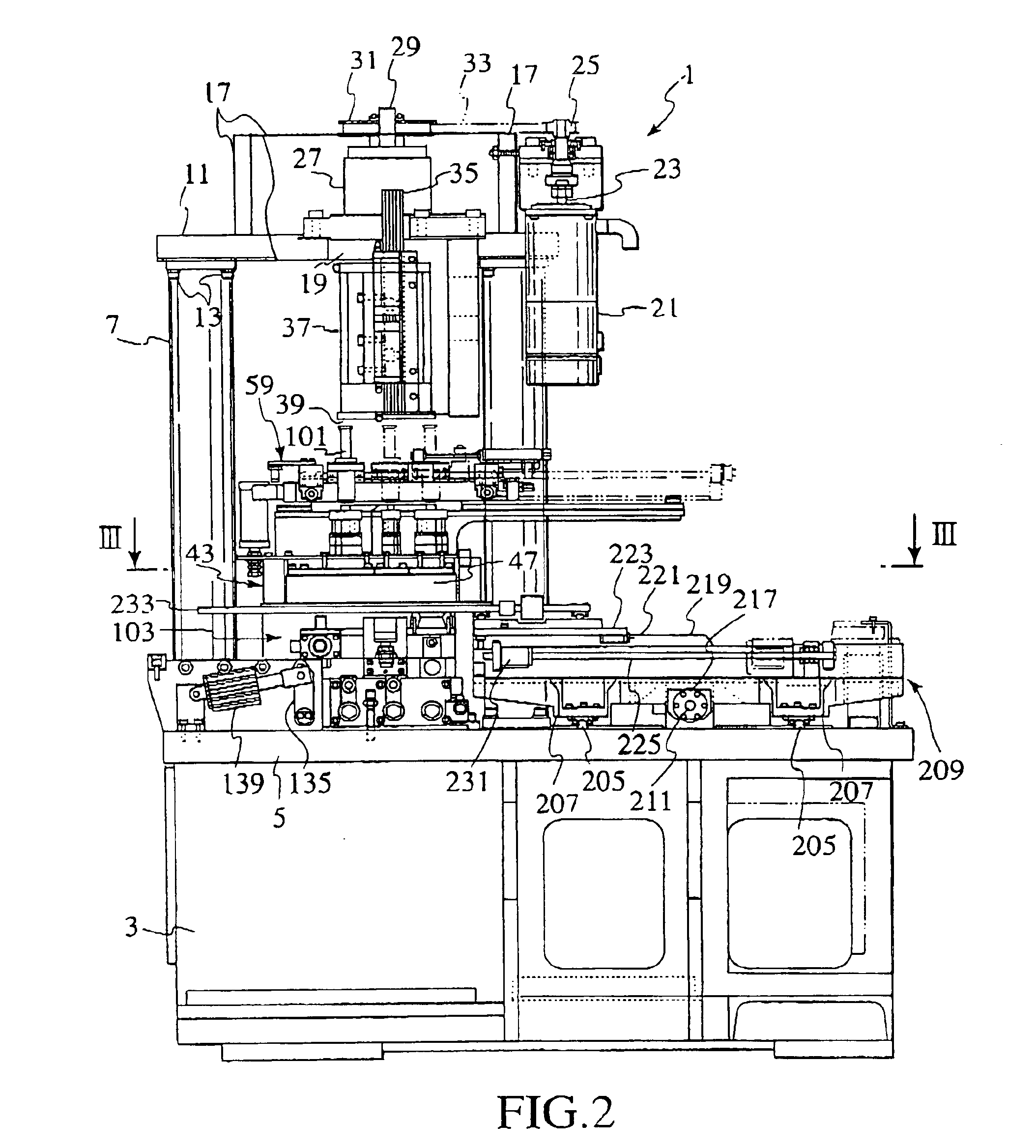

Punch press

InactiveUS6931909B2High precisionSuppress vertical stroke amountShaping toolsMetal-working feeding devicesPunch pressEngineering

In a cube space having high rigidity, the following members are provided: a die holder (103) which can be pulled out forward, a punch holder (47) fixed to a separate bridge structure, a striker which can be positioned in an XY plane for selecting a desired punch P, a striker supporting frame (59) which can be positioned in the XY plane for selecting a desired punch P and which can slide in a horizontal direction, and a clamp device (232) having clamp arms (233) which are provided with a vertically movable ram (37) and which can enter between the punch holder (47) and the die holder (103) and which hold the opposed ends of the workpiece W. Therefore, it is possible to constitute a punch press (1) which is suitable for precise machining of a thin plate and in which tools can easily be exchanged.

Owner:AMADA CO LTD +1

Integrated ceiling component and mounting method thereof

The invention discloses an integrated ceiling component which comprises at least one main keel, a ring-shaped lamp groove frame unit, a frame top plane unit, a connecting unit and an edge storage keel, wherein the ring-shaped lamp groove frame unit is used for mounting a lamp; the edge storage keel is used for being mounted on the wall; main suspension pieces for being connected with the plane of a roof are arranged on the main keels; lamp groove frame suspension pieces for being connected with the plane of the roof are arranged on the ring-shaped lamp groove frame unit; the frame top plane unit covers a top opening of the ring-shaped lamp groove frame unit, and the frame top plane unit is suspended below the main keels by regulating suspension pieces of which positions can be regulated up and down and left and right; the inside edge of the connecting unit is connected with the ring-shaped lamp groove frame unit, and the outside edge of the connecting unit is stored in the edge storage keel. The invention further discloses a mounting method of the integrated ceiling component. According to the integrated ceiling component and the mounting method thereof, which are provided by the invention, the mounting procedure is reduced, the integrated ceiling component can be rapidly assembled, the construction period can be shortened, the labor strength can be reduced, and the environment pollution is reduced.

Owner:ZHEJIANG YASHA DECORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com