Motor

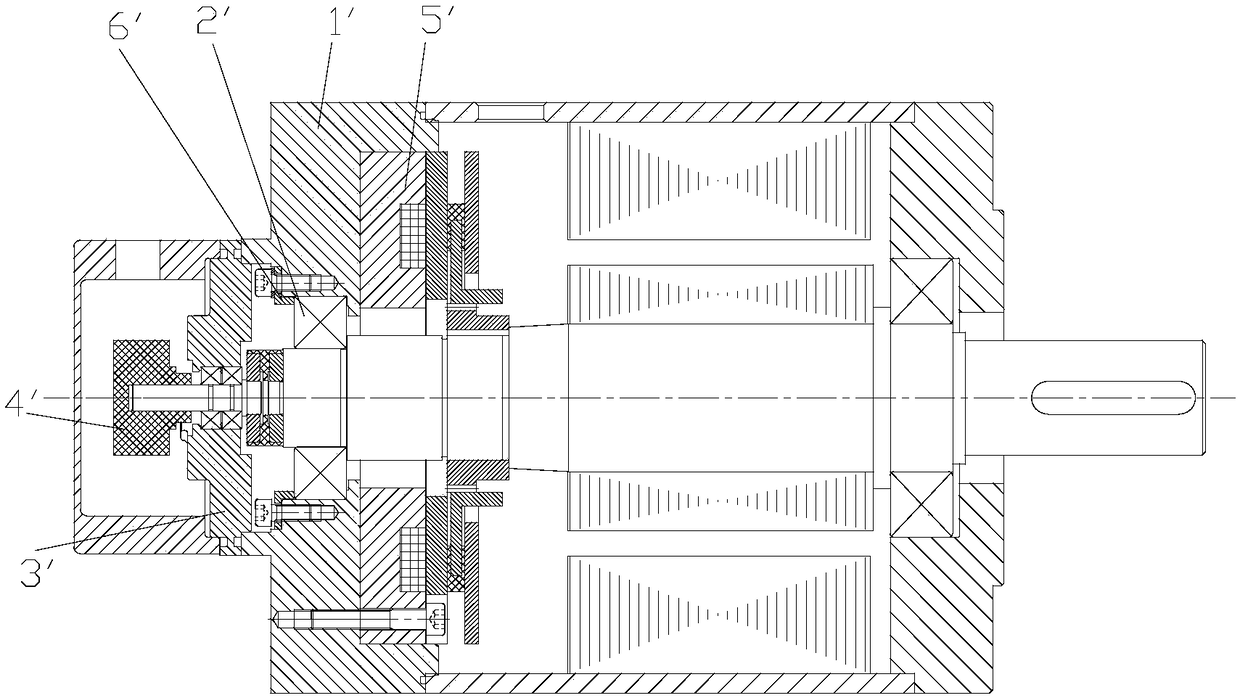

A casing and brake technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of reducing the heat dissipation efficiency of the brake 5', reducing the heat dissipation area of the brake 5', and the encoder 4' being easily damaged, etc. The effect of shortening the length of the motor, simple structure, and avoiding excessive temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

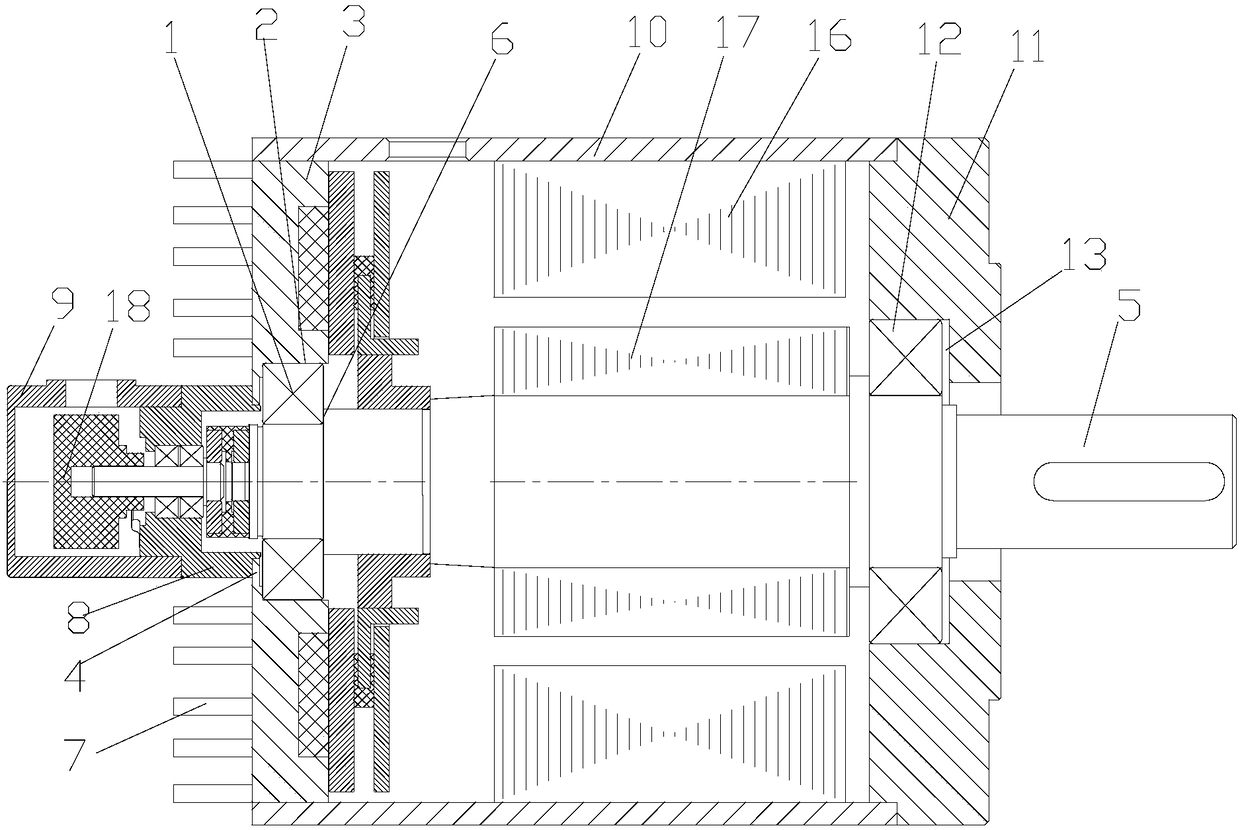

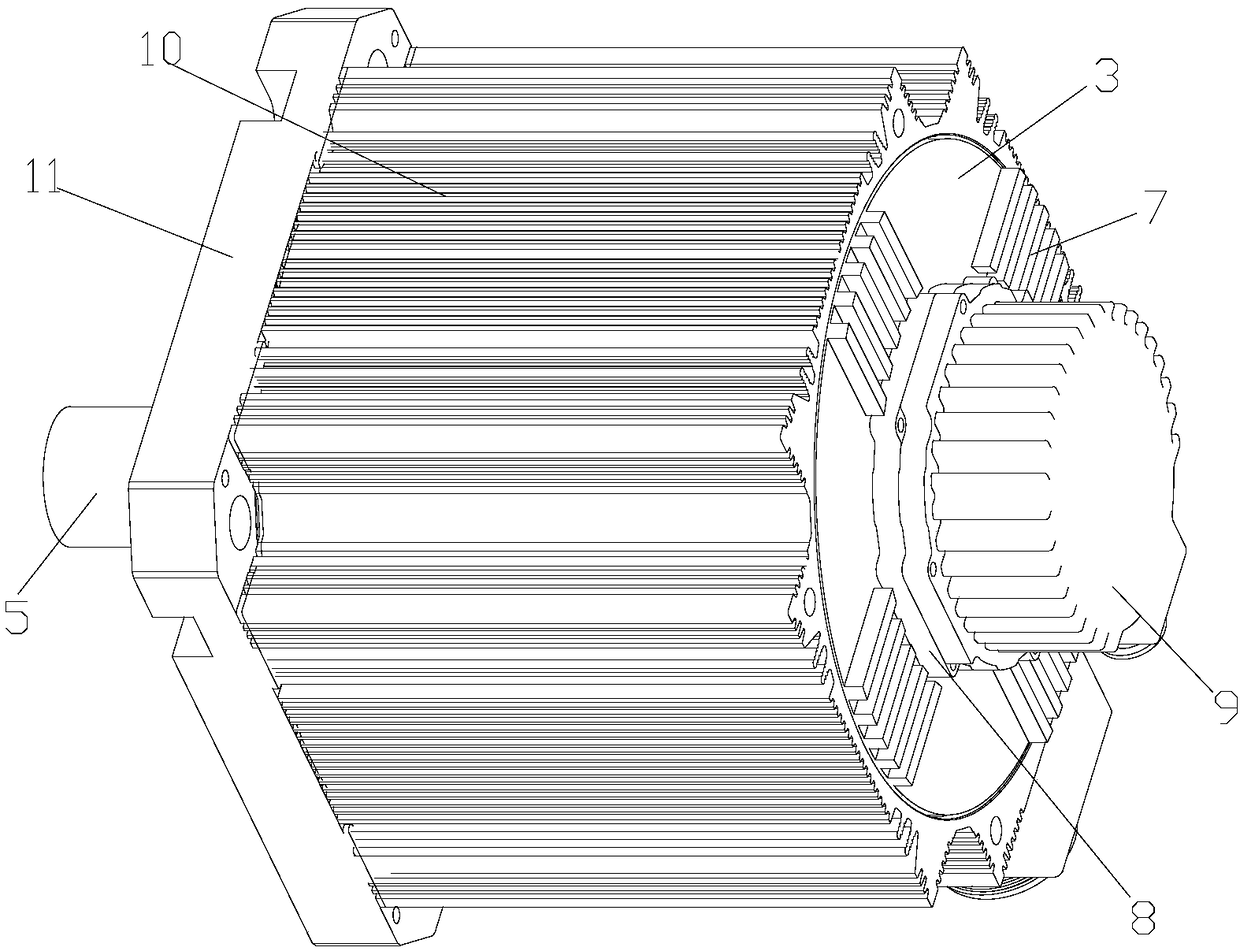

[0029] see in conjunction Figure 2 to Figure 9 As shown, according to the embodiment of the present invention, the motor includes a rear bearing 1 and a brake. The brake is provided with a first bearing chamber 2 , and the rear bearing 1 is limitedly installed in the first bearing chamber 2 .

[0030] The motor is provided with a first bearing chamber 2 on the brake, and then the rear bearing 1 is installed in the first bearing chamber 2, so there is no need to set a separate rear end cover for installing the rear bearing 1, the rear end cover structure can be omitted, and the Reduce the cost, shorten the length of the motor, facilitate the miniaturization of the motor, make the structure of the motor simpler, and improve the power density of the motor; since the first bearing chamber 2 is directly arranged on the brake, the rear end cover structure is omitted, so the brake can be used Direct heat exchange with the outside air reduces the heat transfer resistance of the brake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com