Compressor and air conditioner

A technology in compressors and spaces, applied in the field of compressors, can solve problems such as the inability to guarantee the volume and quality of the compressor, the large volume and high quality of the compressor, and achieve the effect of reducing the structural volume, reducing the quality, and reducing the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

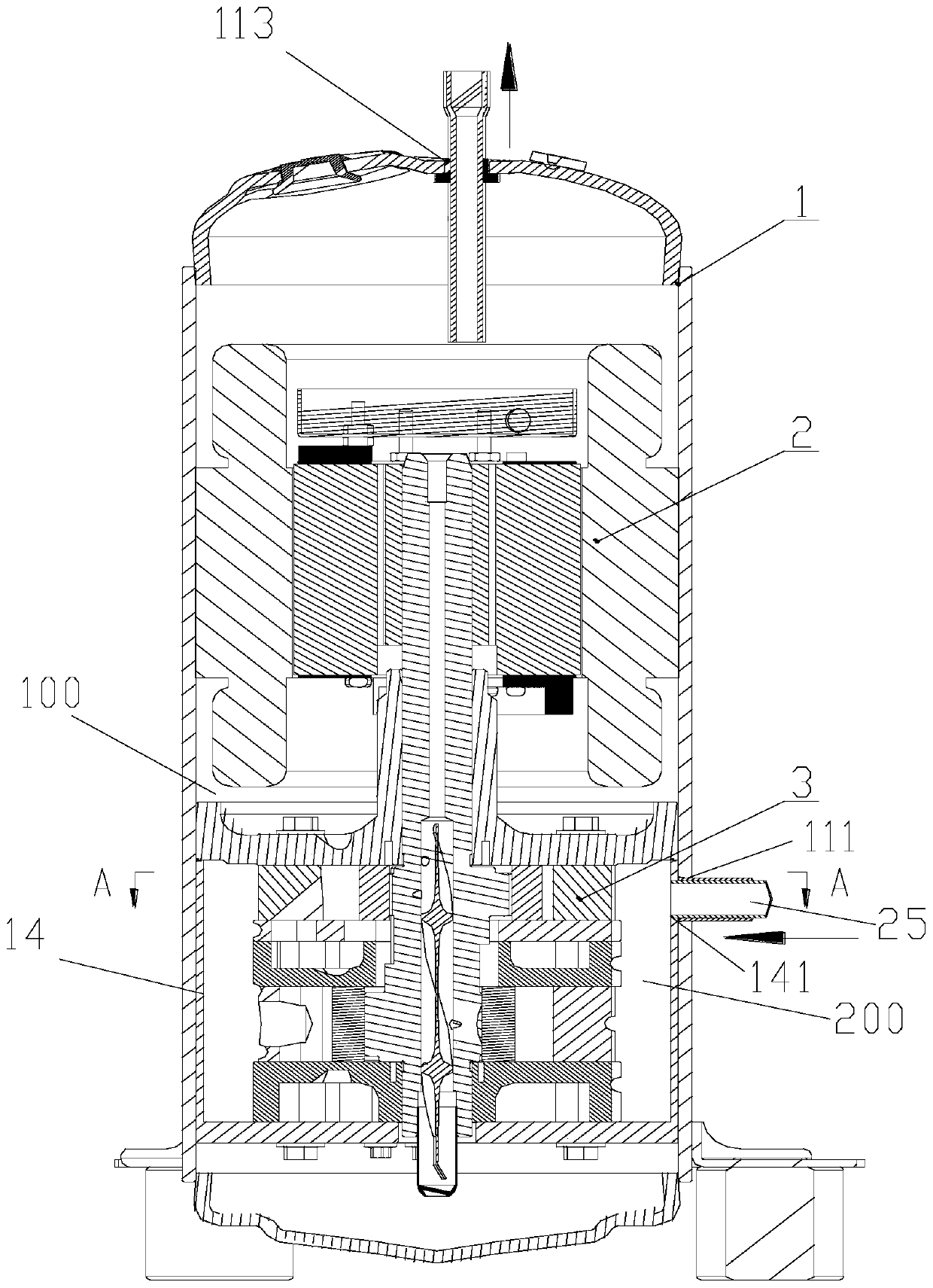

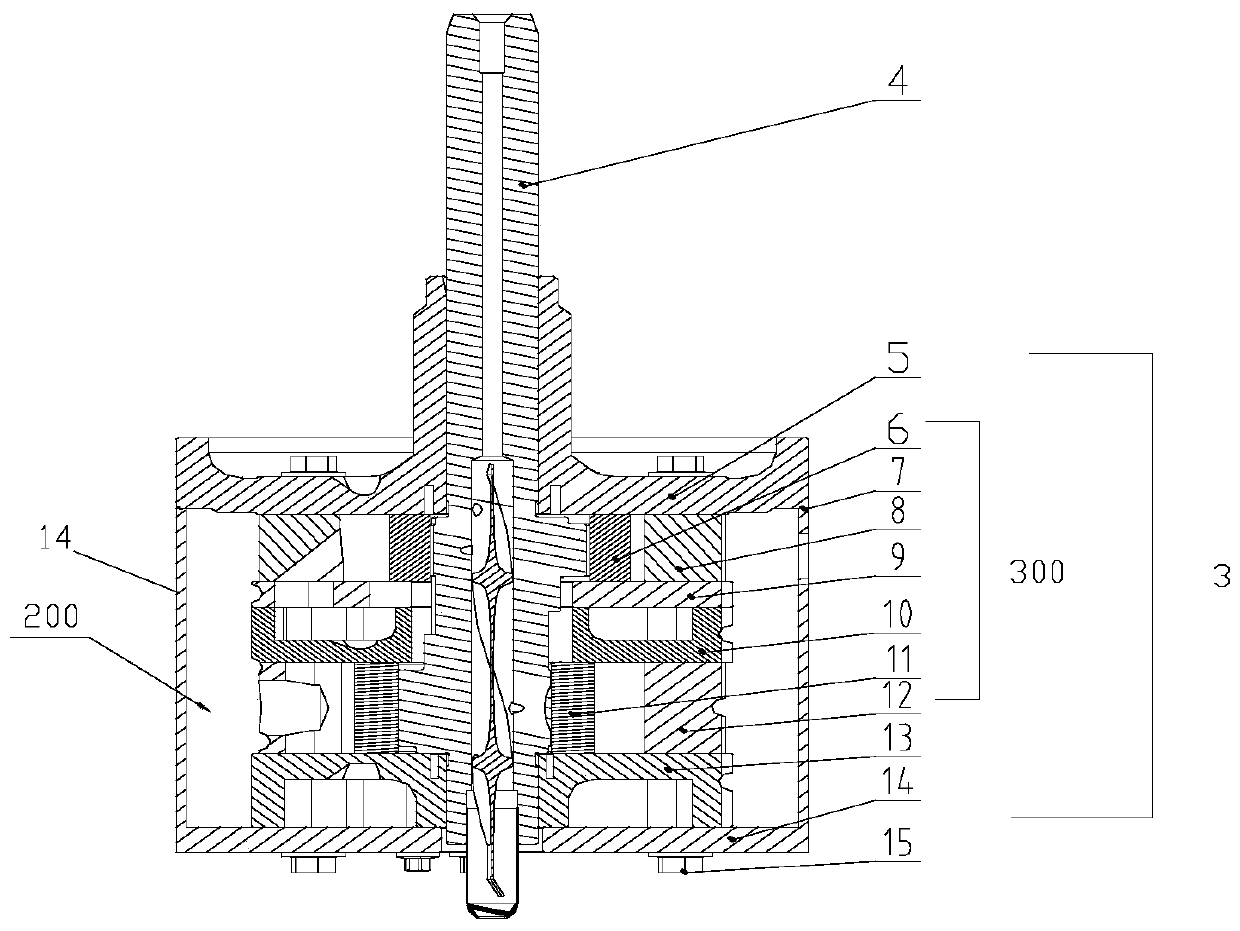

[0057] Example as Figure 1-7b As shown, the present invention provides a compressor, which includes:

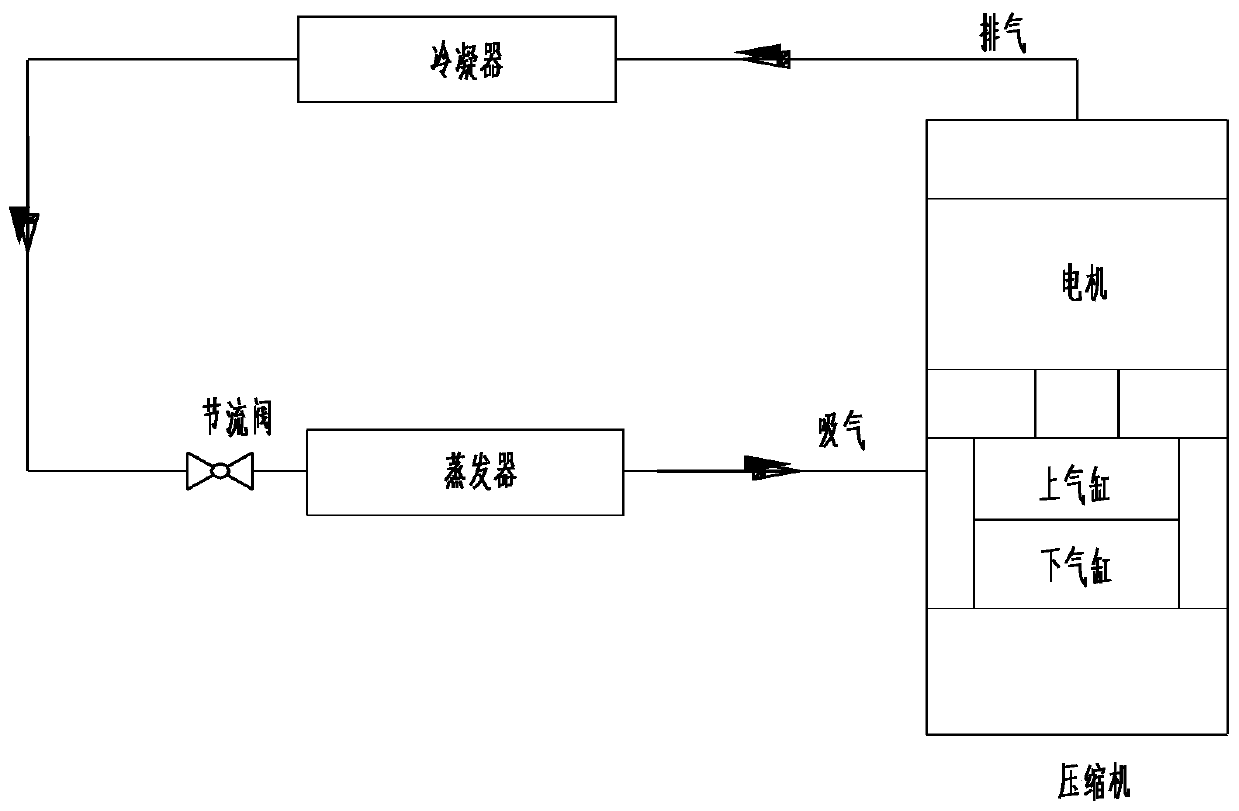

[0058] The present invention has embodiments as follows: the air-conditioning system of high back pressure two-stage compressor application, such as figure 1 As shown, the mixed refrigerant that flows into the compressor through the evaporator enters the cavity outside the pump body and undergoes gas-liquid separation, and then is sucked by the lower cylinder to compress the refrigerant once and discharge it into the cavity of the lower flange and the lower partition. Then it enters the upper cylinder through the flow hole of the pump body; the upper cylinder compresses the refrigerant twice to form a high-temperature and high-pressure gaseous state and discharges it into the compressor shell, where it becomes a low-temperature and high-pressure gas-liquid mixed refrigerant through the condenser, and then passes through the throttle valve After throttling and reducing press...

Embodiment 2

[0083] Embodiment two, such as Figure 8-10b As shown, preferably,

[0084] The pump body 300 also includes a crankshaft 4, and at least one helical partition 20 is disposed in the pump body cavity 200, and the spiral partition 20 is rotated in the opposite direction to the crankshaft 4. Such as Figure 8 As shown, the main difference between Embodiment 2 and Embodiment 1 is: as Figure 8 Shown, upper cylinder 8, upper dividing plate 9, lower dividing plate 10, lower cylinder 12, lower flange 13 cancels the helical groove 18 that is set around crankshaft 4. Such as Figure 9 As shown in Figure 10, the lower flange cover 14 is provided with a spiral partition 20 opposite to the rotation direction of the crankshaft 4, which enhances the spiral rotation guiding effect of the inner cavity of the lower flange cover 14 on the refrigerant.

[0085] Preferably,

[0086] When the flange includes a lower flange 13 and a lower flange cover 14, and the lower flange cover 14 is a cyli...

Embodiment 3

[0090] Such as Figure 11 As shown, the upper cylinder 8, the upper partition 9, the lower partition 10, the lower cylinder 12, and the lower flange 13 are provided with a spiral groove 18 around the crankshaft 4, and the lower flange cover 14 is provided with a spiral groove opposite to the rotation direction of the crankshaft 4. The separator 20 further effectively improves the spiral rotation guiding effect of the inner cavity of the lower flange cover 14 on the refrigerant, that is, it has a spiral groove and a spiral separator at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com