Hydraulic drive reciprocating duplex pump

A double-cylinder pump and reciprocating technology, which is applied in the direction of liquid displacement machinery, pumps, piston pumps, etc., can solve the problems of complex oil circuit connection, large overall volume, and unusability, so as to ensure synchronous linkage and overall volume Smaller and easier to disassemble and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

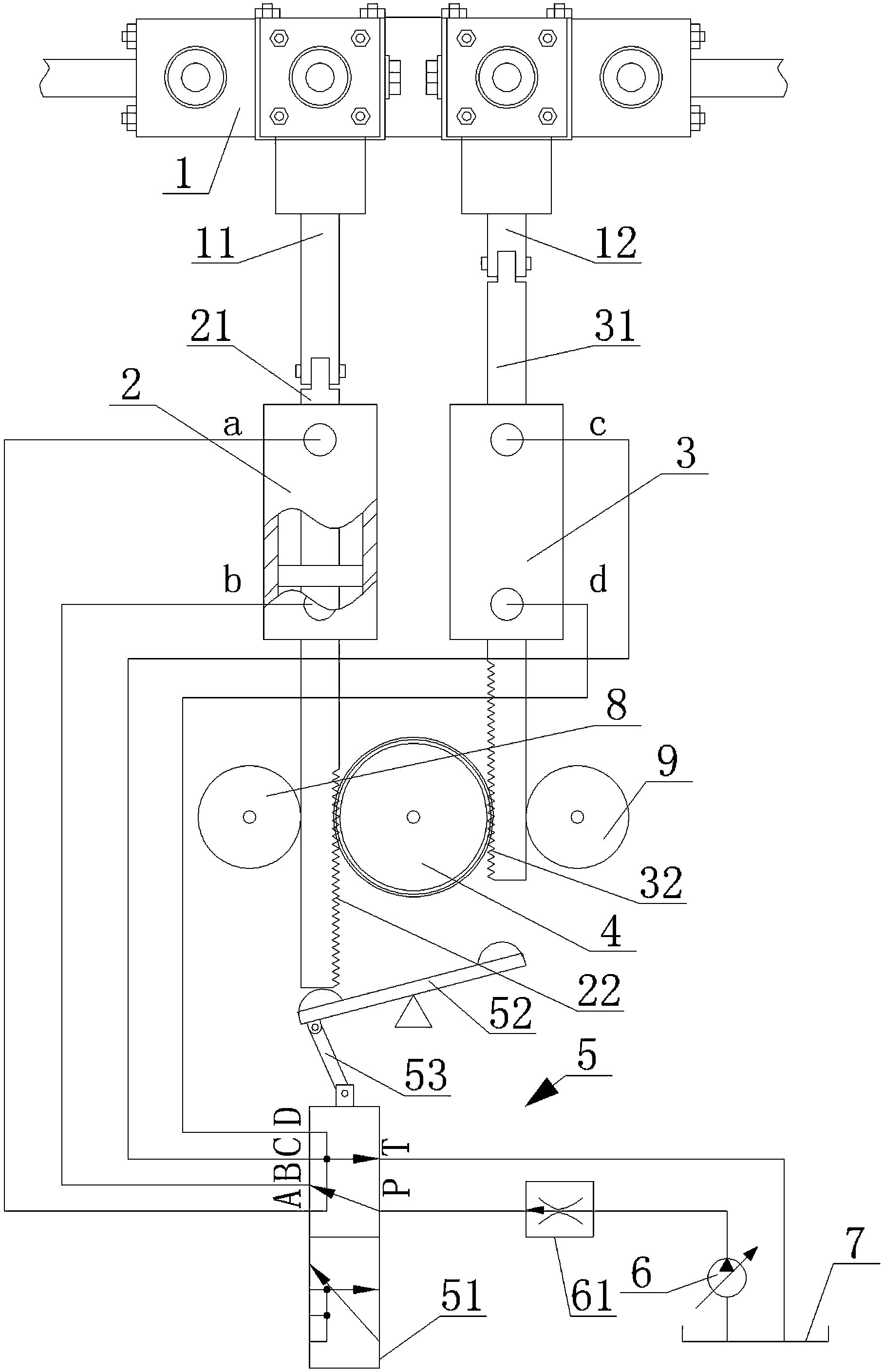

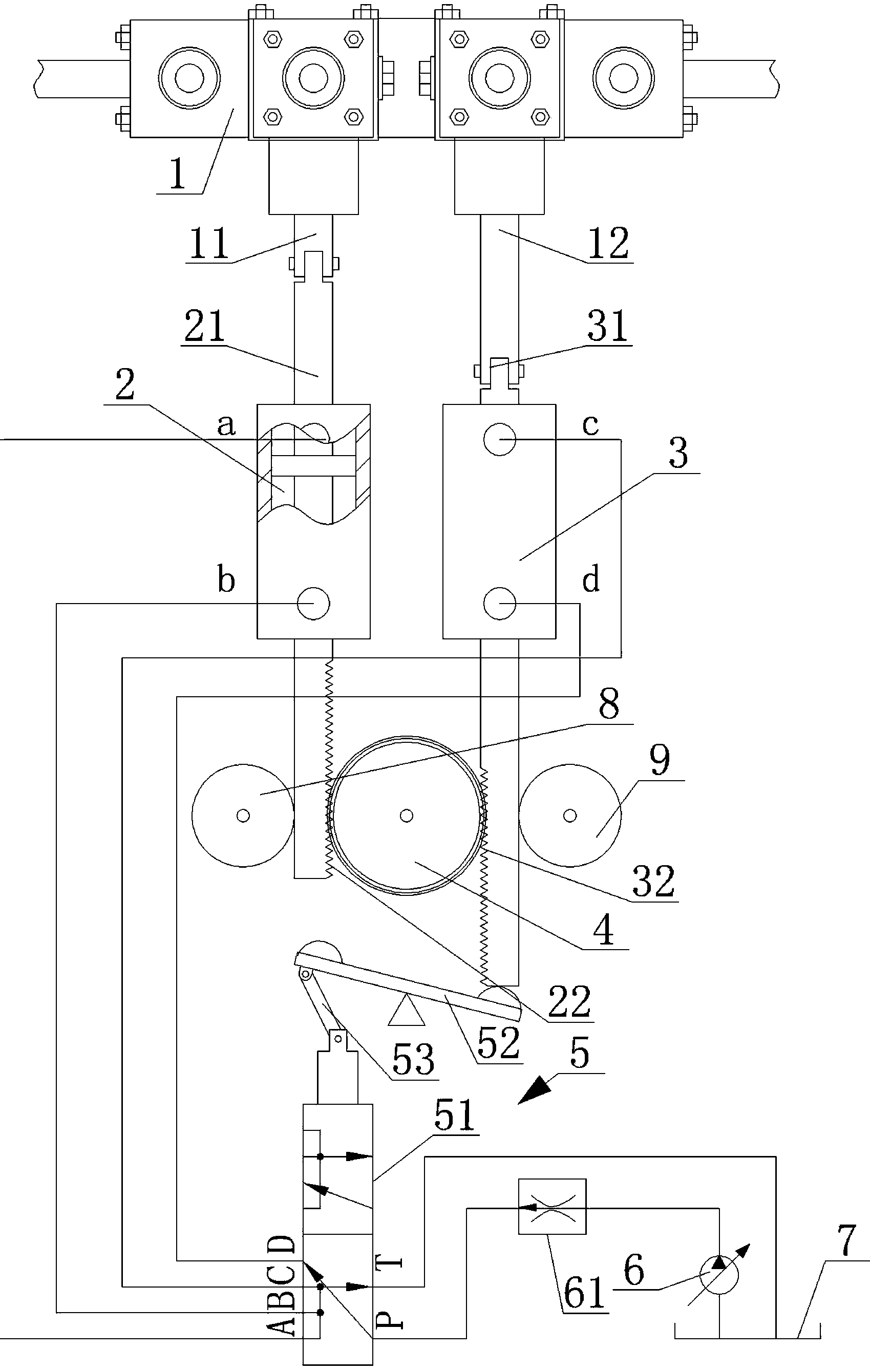

[0015] From figure 1 and figure 2 It can be seen that the hydraulically driven reciprocating double-cylinder pump of the present invention includes a double-cylinder pump head 1 installed on the frame, a single-piston double-rod hydraulic cylinder one 2, a single-piston double-rod hydraulic cylinder two 3 , gear 4, reversing device 5, oil pump 6 and oil tank 7, double-cylinder pump head 1 includes piston rod one 11 and piston rod two 12 respectively connected with each cylinder to drive suction and discharge movement, reversing device 5 includes two-position six-way switch Directional valve 51, transmission lever 52 and connecting rod 53, single-piston double-rod hydraulic cylinder one 2 and single-piston double-rod hydraulic cylinder two 3 are arranged in parallel on the frame, single-piston double-rod hydraulic cylinder one 2 One end of the piston rod three 21 is linearly connected with the piston rod one 11 to push it to reciprocate in the pump cylinder, and one end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com