Connector module

A technology of connectors and modules, which is applied in the direction of connection, connection part installation, two-part connection device, etc., and can solve the problem that the product cannot be thinned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further illustrate the technical means adopted by the invention and its effects, the following describes in detail in conjunction with the preferred embodiments of the invention and the accompanying drawings.

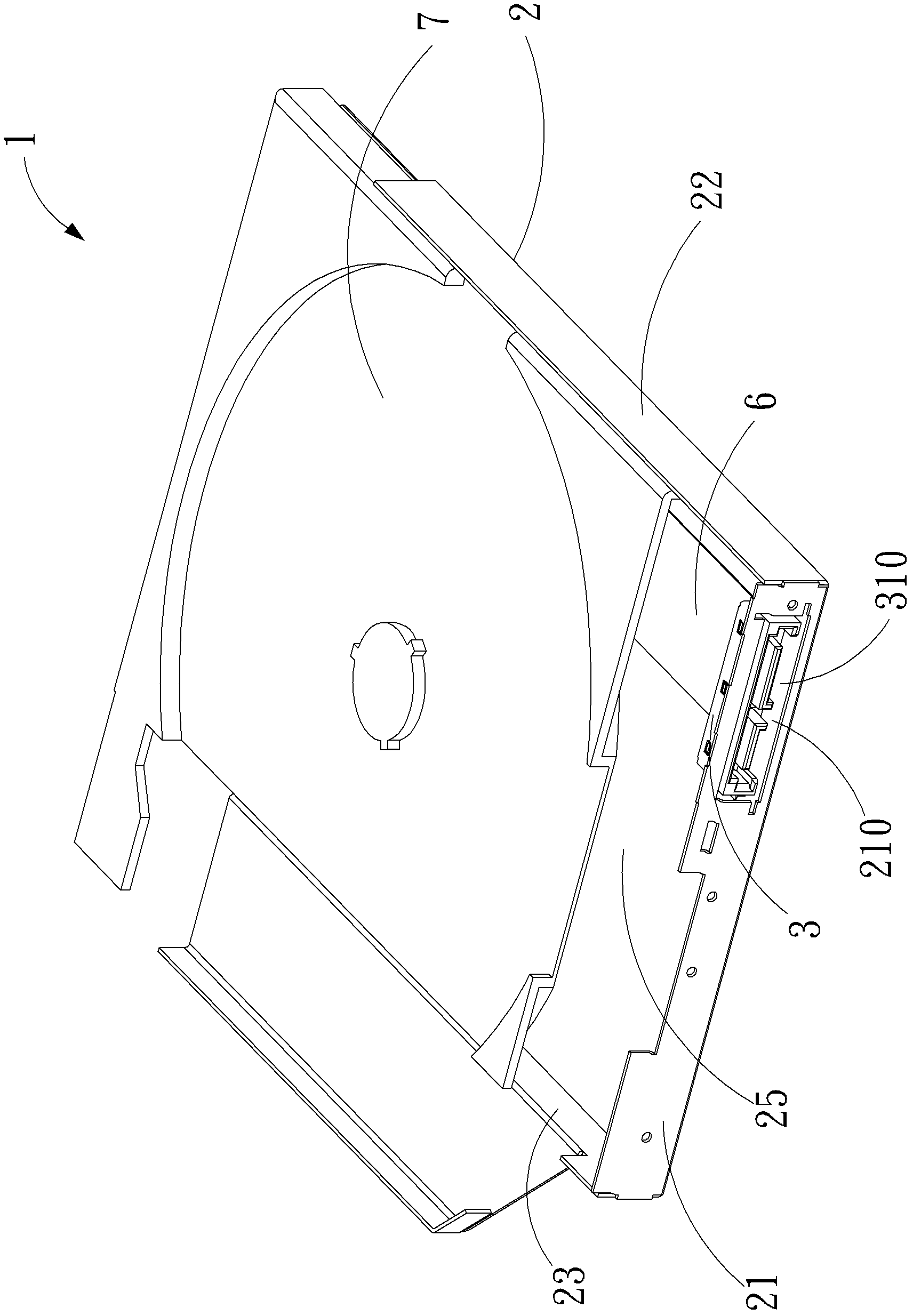

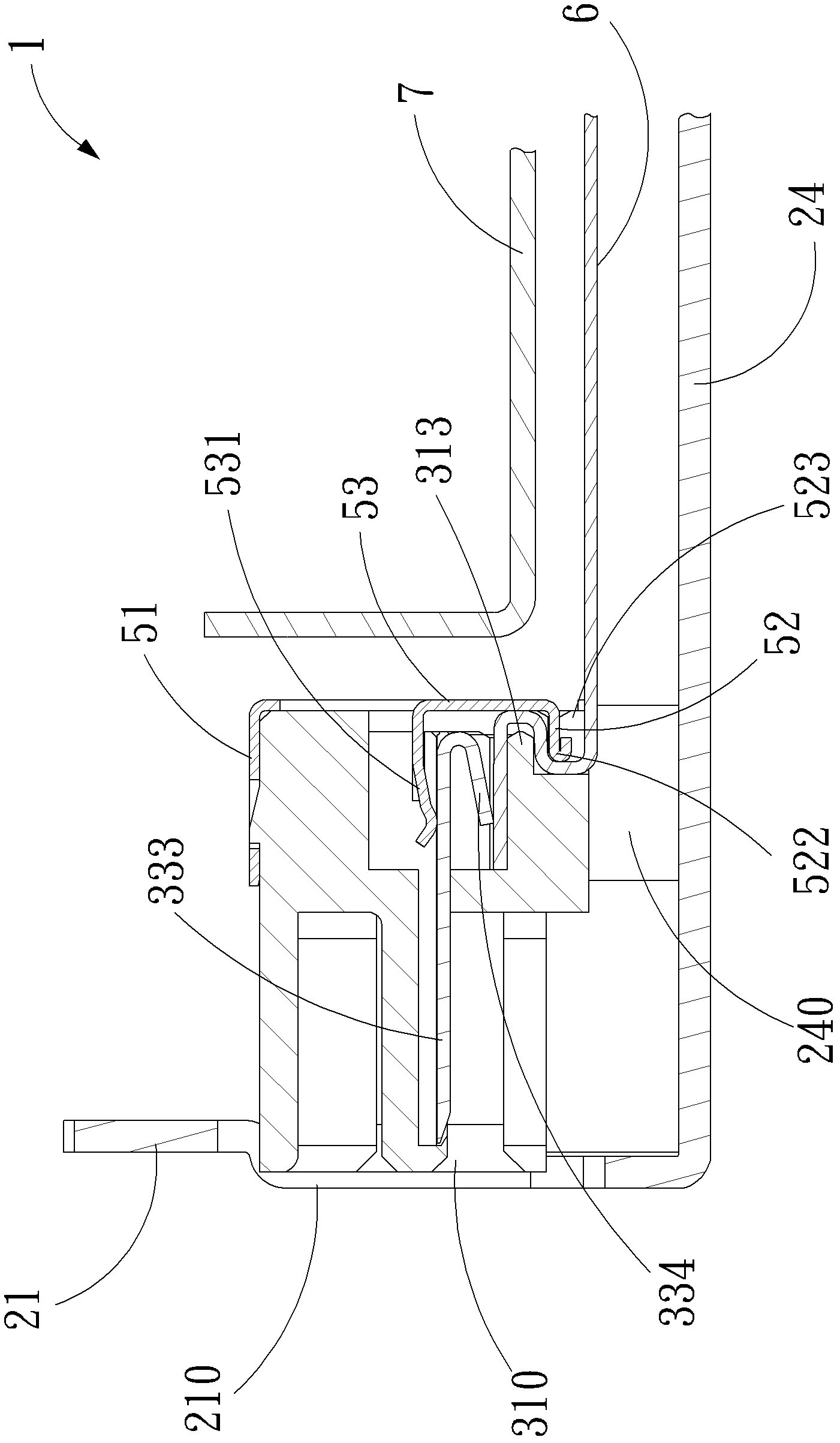

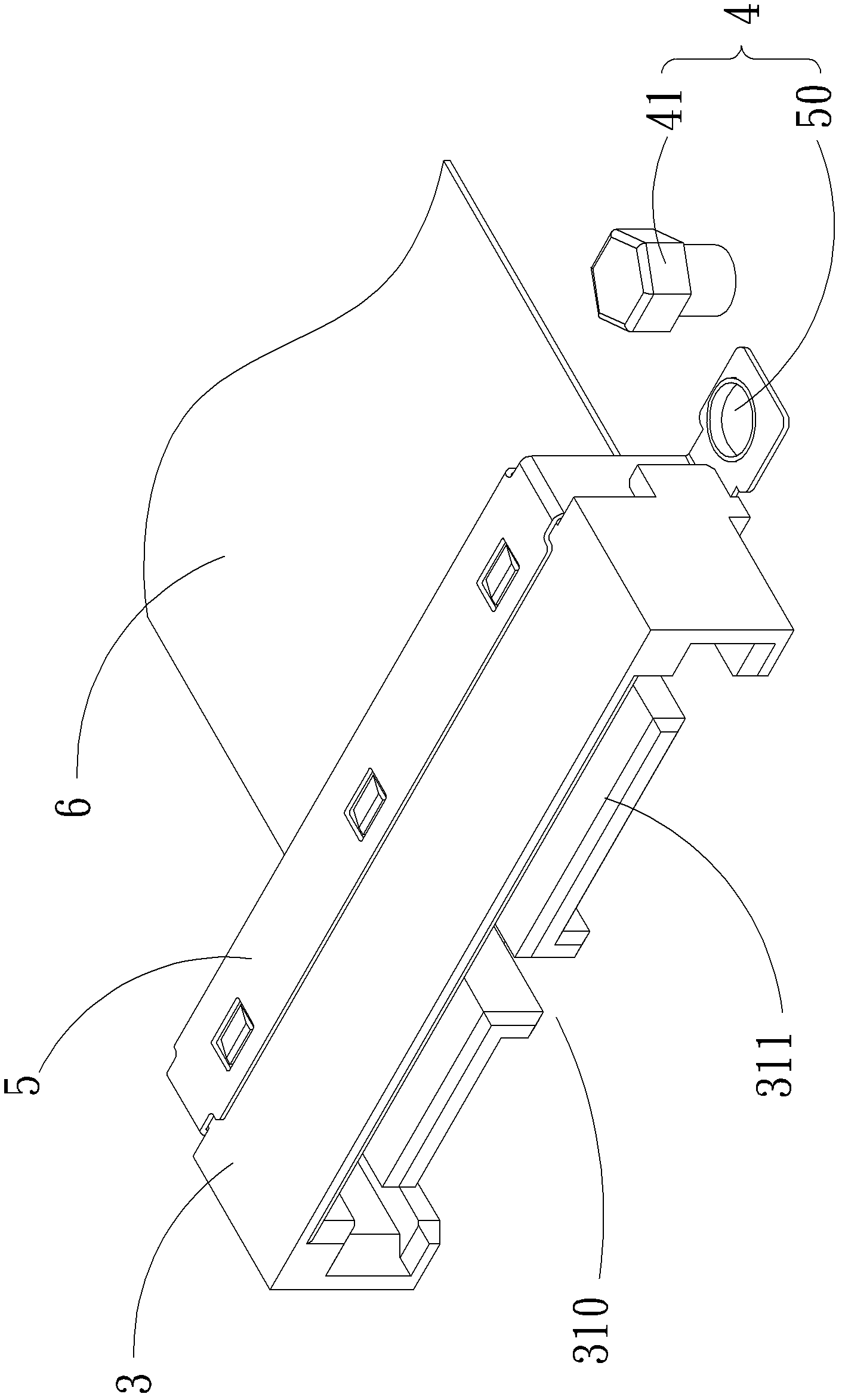

[0032] Please refer to Figure 1 to Figure 6 As shown in the preferred embodiment, the present invention provides a connector module 1 , which includes an organic case 2 , a connector 3 , a fixing mechanism 4 , a metal case 5 and a flexible transmission unit 6 .

[0033] The casing 2 is used to assemble an optical disc 7, wherein the casing 2 is provided with a first side wall 21, a second side wall 22, a third side wall 23 and a bottom wall 24, the first side wall 21, the second side wall 22 and the third side wall 23 are arranged on the bottom wall 24 to form an accommodating space 25 approximately in the shape of "ㄇ", which can be used to accommodate the connector 3, the fixing mechanism 4, the metal shell 5, the flexible The transmission unit 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com