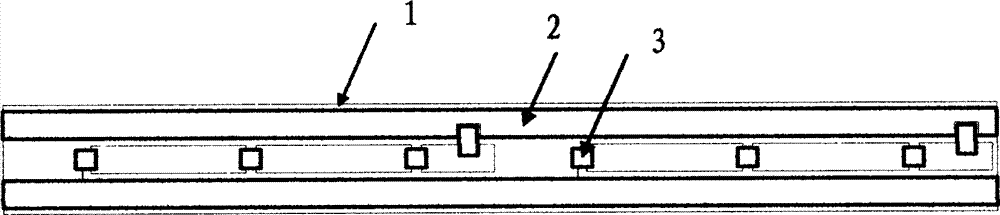

Integrated LED illuminating assembly

A technology of LED lighting and LED circuits, which is applied to the components of lighting devices, lighting devices, semiconductor devices, etc., and can solve problems such as reducing the service life, durability and reliability of LEDs, being difficult to adapt to welding LEDs, and being difficult to install and carry. , to achieve the effect of saving process cost, good light transmission performance and improving heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in more detail below.

[0035] Glass is a transparent, airtight, and hard material. Glass is chemically inert in everyday environments and does not interact with living things. Glass is generally insoluble in acid (exception: hydrofluoric acid reacts with glass to form SiF 4 , leading to corrosion of the glass); but soluble in strong bases such as cesium hydroxide.

[0036] Glass in a narrow sense is defined as: an inorganic substance that does not crystallize during the cooling of the melt. According to this definition, amorphous substances produced by methods other than melting, such as vacuum evaporation, radiation exposure, gel heating, etc., cannot be called glass. There are also amorphous metals and amorphous polymer materials that are different from inorganic substances in composition and cannot be called glass. However, the broad definition of glass scientifically classifies glass according to the state and properties ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com