Top cover assembly, assembling method of top cover assembly and battery

An assembly method and top cover technology are applied to battery pack components, secondary battery manufacturing, circuits, etc., which can solve problems such as ineffective use of space, unfavorable energy density of batteries, and vertical space occupied by modules. The effect of ample space, improved assembly efficiency, and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

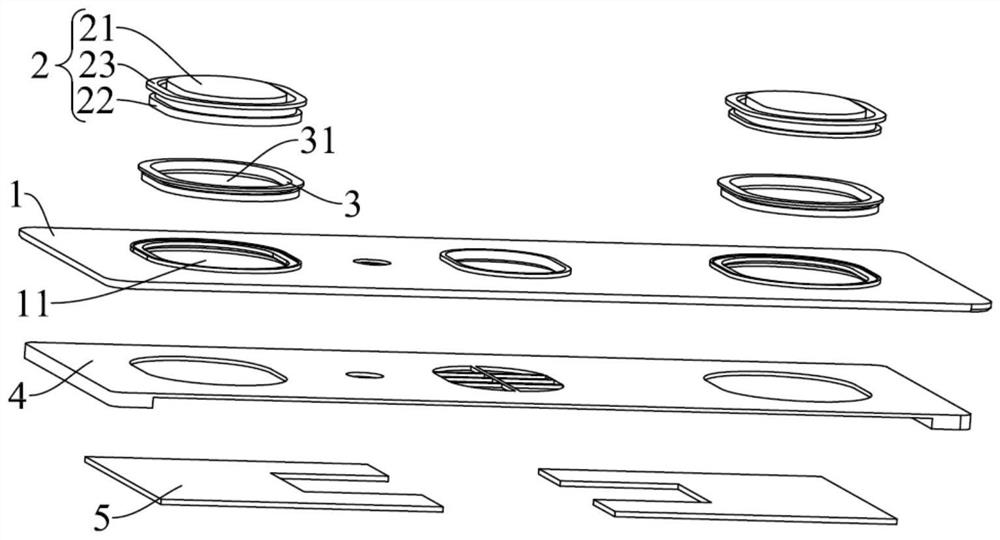

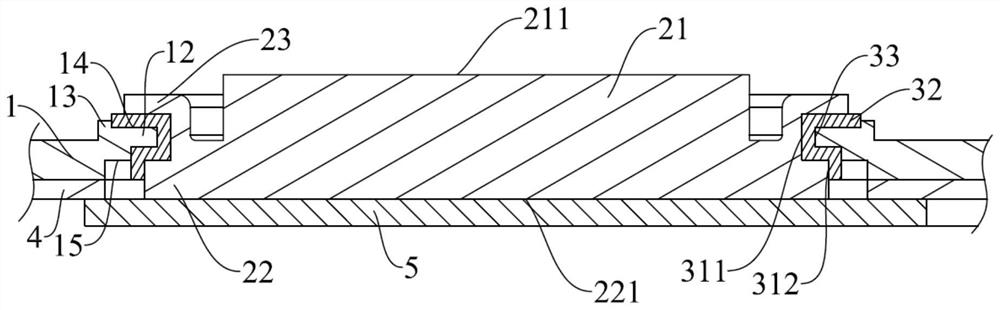

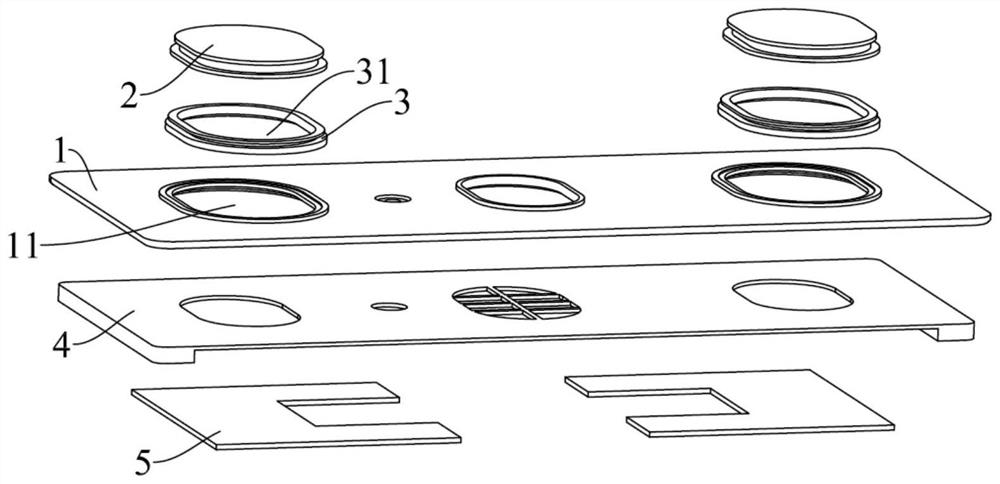

[0057] Refer below Figure 1-Figure 7 The specific structure of the roof assembly of a specific embodiment of the present invention is described.

[0058] Such as figure 1 As shown, the top cover assembly includes a top cover sheet 1, a terminal pole 2, a seal 3, a lower plastic part 4, and an electrical connector 5. The top cover sheet 1 is provided with a pole fitting hole 11, and the pole fitting hole 11 Annular projections 12 are arranged at intervals along the circumferential direction on the inner side wall, matching projections 13 are provided on the upper surface of the top cover sheet 1 , and receiving grooves 14 are provided on the matching projections 13 . The lower surface of the top cover sheet 1 is provided with an escape groove 15 arranged around the pole matching hole 11 . The terminal pole 2 is penetrated in the pole matching hole 11, and has a first connection surface 221 and a second connection surface 211 oppositely arranged. The terminal pole 2 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com