Patents

Literature

31results about How to "Guaranteed insulation properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

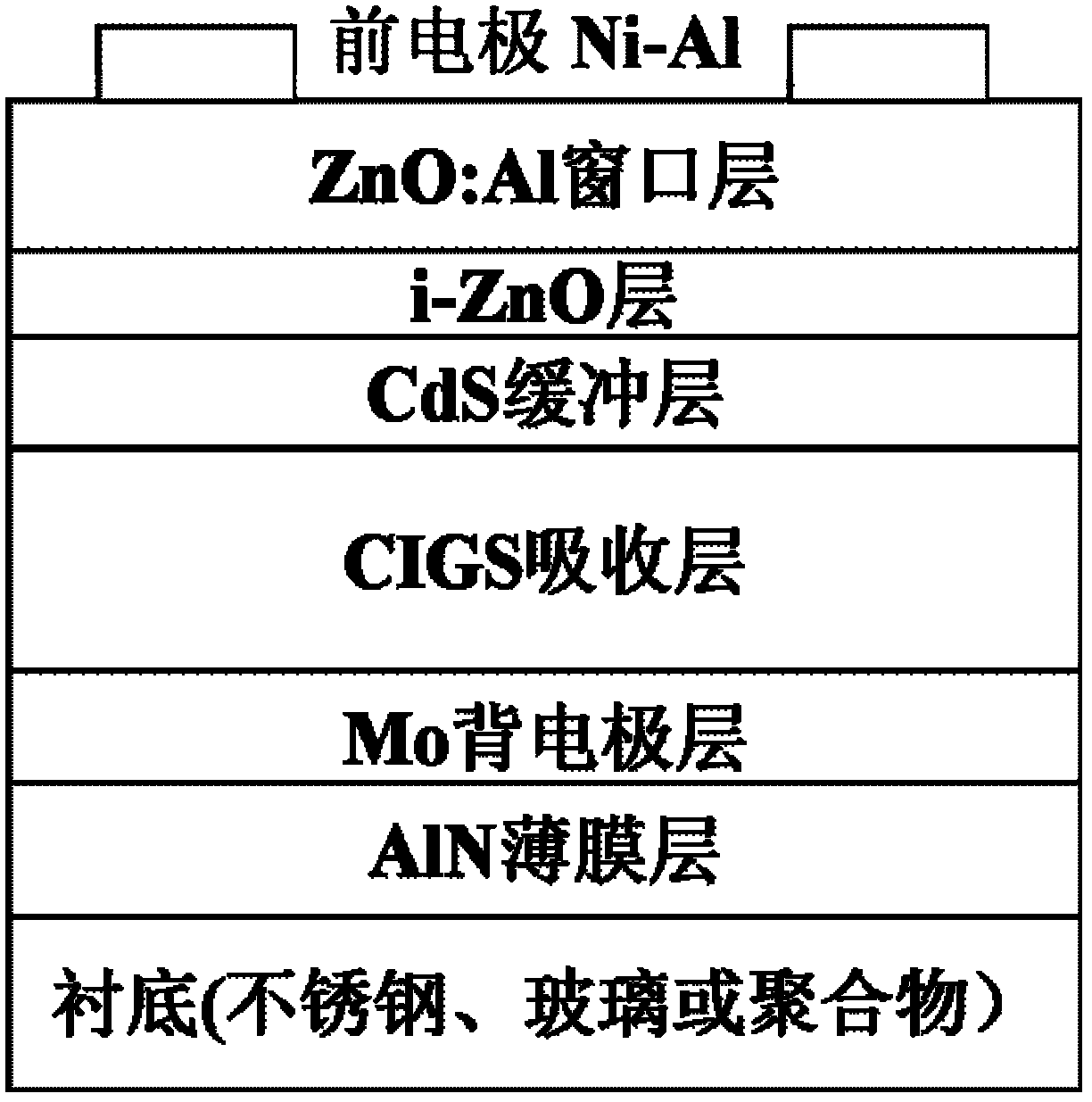

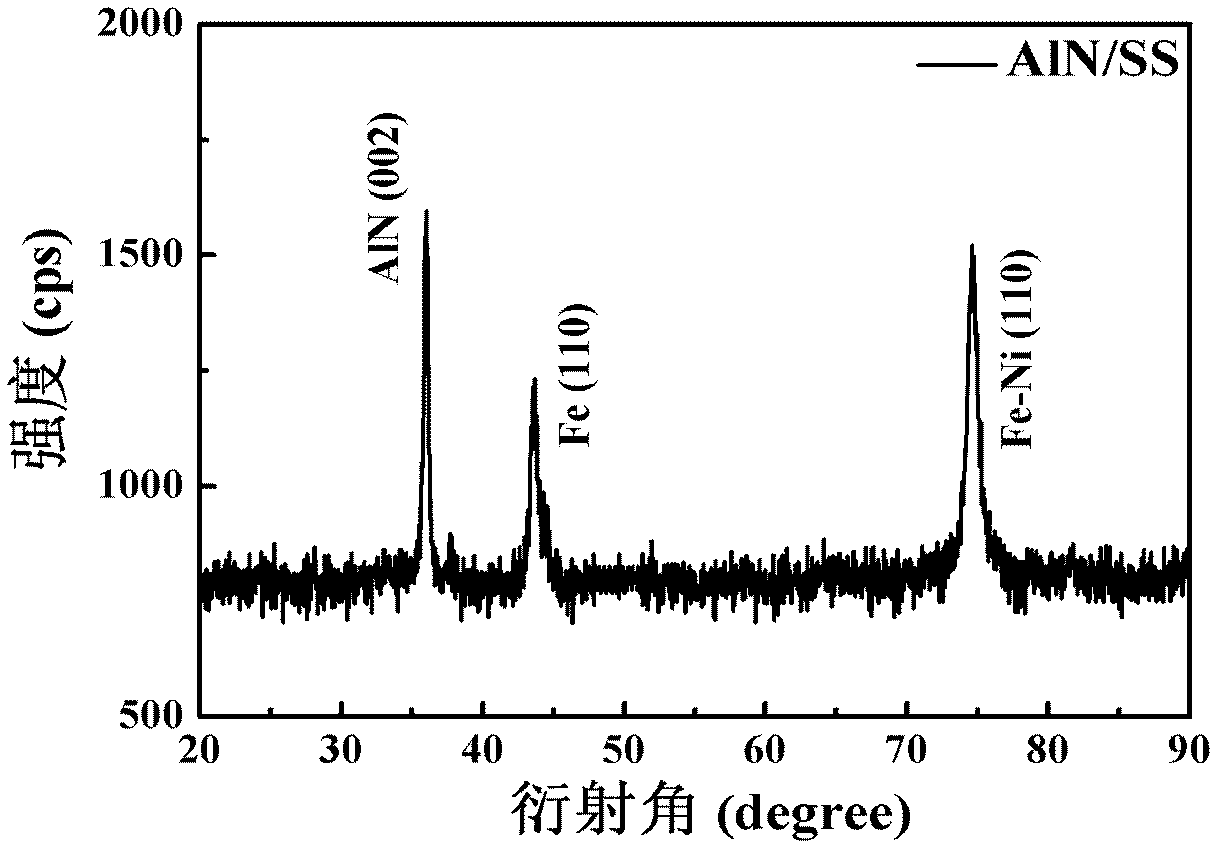

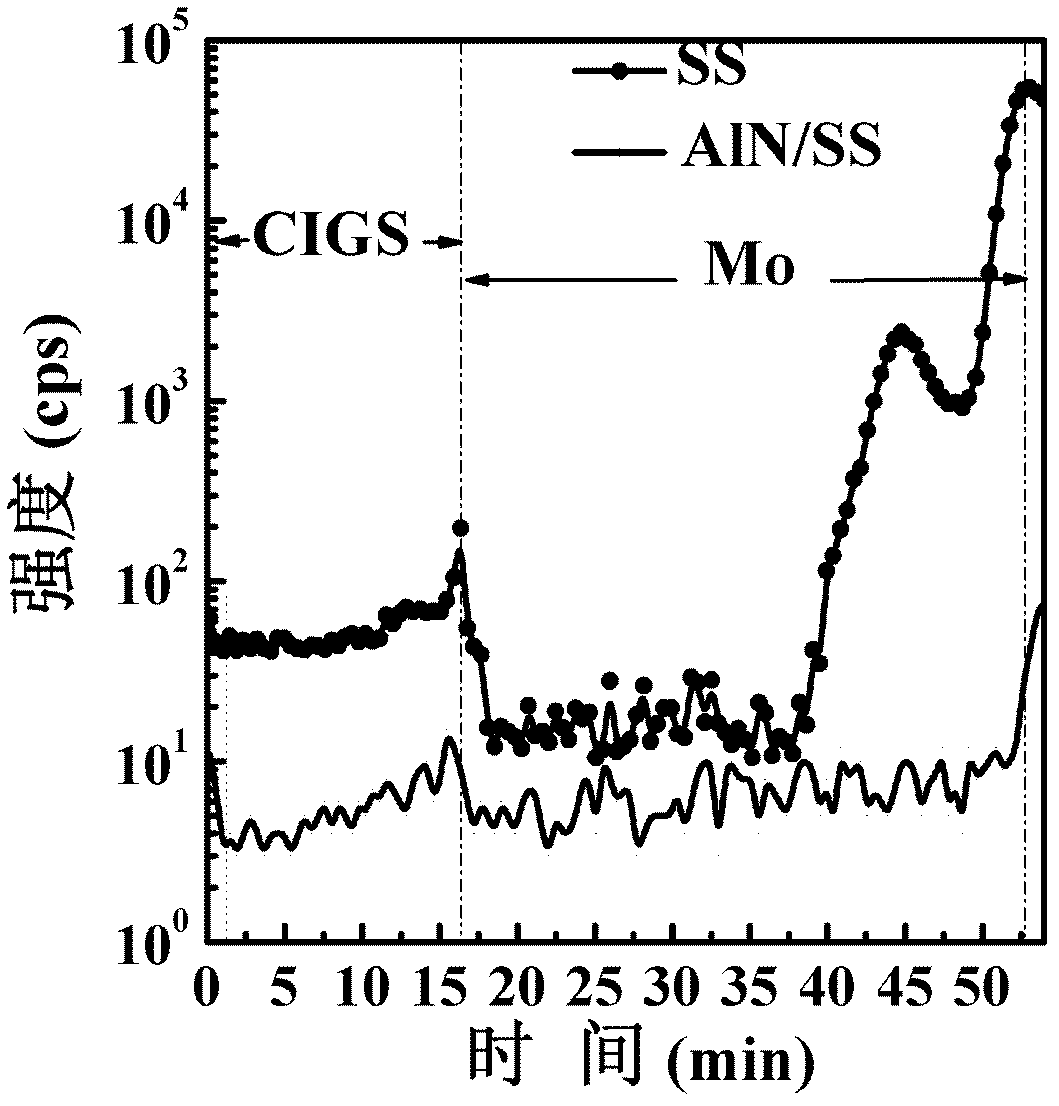

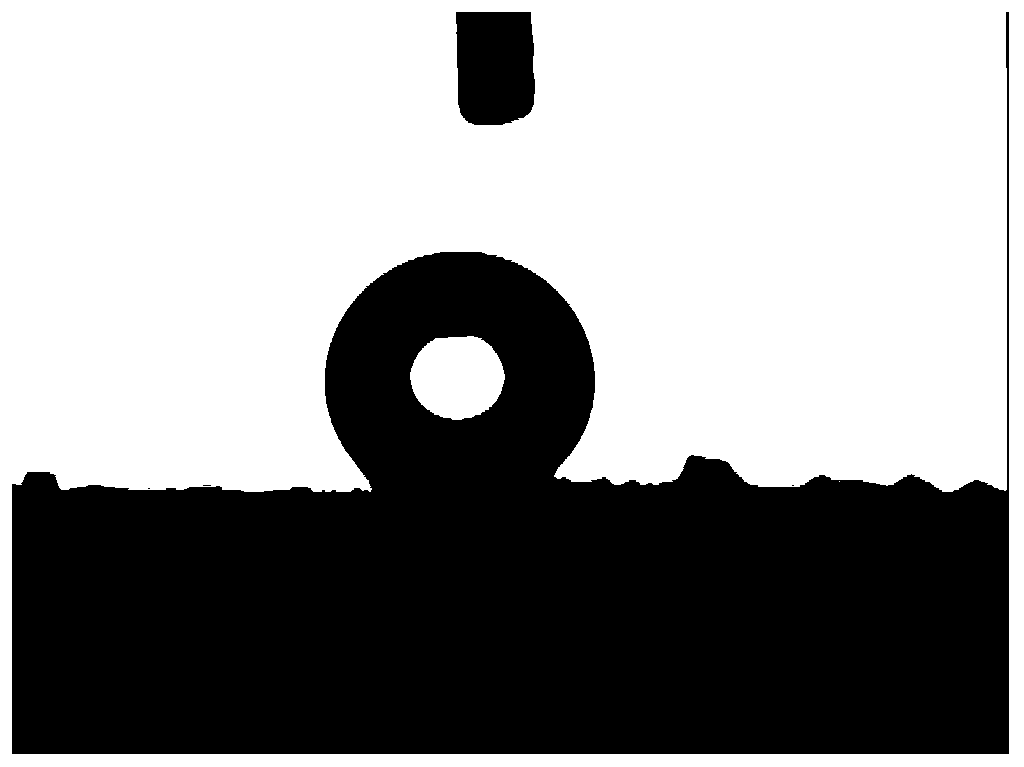

Copper indium gallium selenium thin film solar cell provided with aluminum nitride (AIN) thin film layer

InactiveCN102544138AInhibited DiffusionBarrier diffusion dopingPhotovoltaic energy generationSemiconductor devicesIndiumImpurity

A copper indium gallium selenium (CIGS) thin film solar cell provided with an aluminum nitride (AIN) thin film layer comprises a substrate, a molybdenum (Mo) back electrode layer, a CIGS absorbed layer, a cadmium dating sulphide (CdS) buffer layer, an intrinsic zinc oxide (i-ZnO) layer, a mixing zinc oxide (ZnO:AI) window layer and front electrode nickel aluminum. The AIN thin film layer is arranged between the substrate and the Mo back electrode layer and serves as an electric insulation impurity barrier layer when the substrate is made of metal, the AIN thin film layer serves as an impurity barrier and stress intermediate layer when the substrate is made of glass, and the AIN thin film layer serves as a heat buffer layer when the substrate is made of polymer. The thin film solar cell has the advantages of adopting simple and cheap magnetic control sputtering technology to prepare an AIN thin film to serve as the impurity barrier layer or the electrical insulating layer of the substrate, being capable of having good resisting effects and keeping insulation characteristics of metal atoms even through the solar cell is prepared at high substrate temperature, and providing prerequisite conditions for manufacturing inline type tinsel substrate thin film solar cells.

Owner:NANKAI UNIV

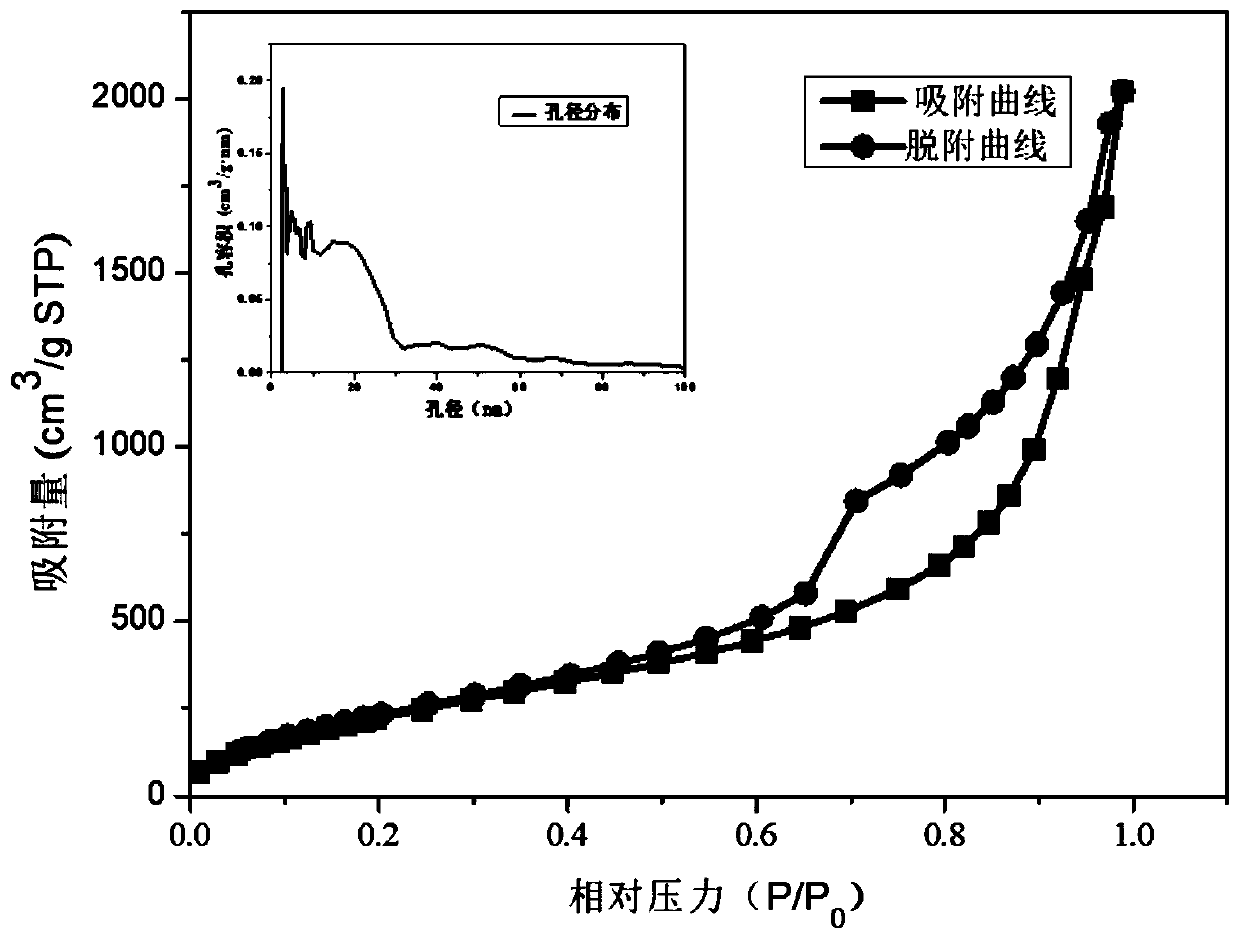

Normal-pressure preparation method of high specific surface area intensive-hydrophobicity graphene oxide/silica composite aerogel

InactiveCN110422850AImprove bindingShorten the formation timeCarbon compoundsSilicon compoundsSolventChemical bond

The invention discloses a normal-pressure preparation method of a high specific surface area intensive-hydrophobicity graphene oxide / silica composite aerogel. The method comprises the following steps:by taking tetraethoxysilane as a precursor, adding a graphene oxide turbid liquid under an acidic condition, adding an ethanol liquid of aminopropyl triethoxy silane and graphene oxide hydrosol, continuously dropping the ethanol liquid of aminopropyl triethoxy silane, forming a graphene oxide / silica composite alcogel under an ultrasonic condition, and performing aging, maturing, solvent replacement, surface modification, and normal-pressure drying, so as to obtain the composite aerogel. By adopting the method, a silane coupling agent, namely the aminopropyl triethoxy silane, is adopted to replace a conventional alkali catalyst, and the aminopropyl triethoxy silane is used as a silicon source and is easy in chemical bond combination with an acidic group carboxyl in the graphene oxide because of an alkali group amino in the aminopropyl triethoxy silane, so that the combination force can be improved, in addition, the formation time of the gel is greatly shortened, and the graphene oxide / silica composite aerogel which is high in specific surface area, intensive in hydrophobicity and low in heat conduction coefficient can be prepared.

Owner:SOUTH CHINA UNIV OF TECH

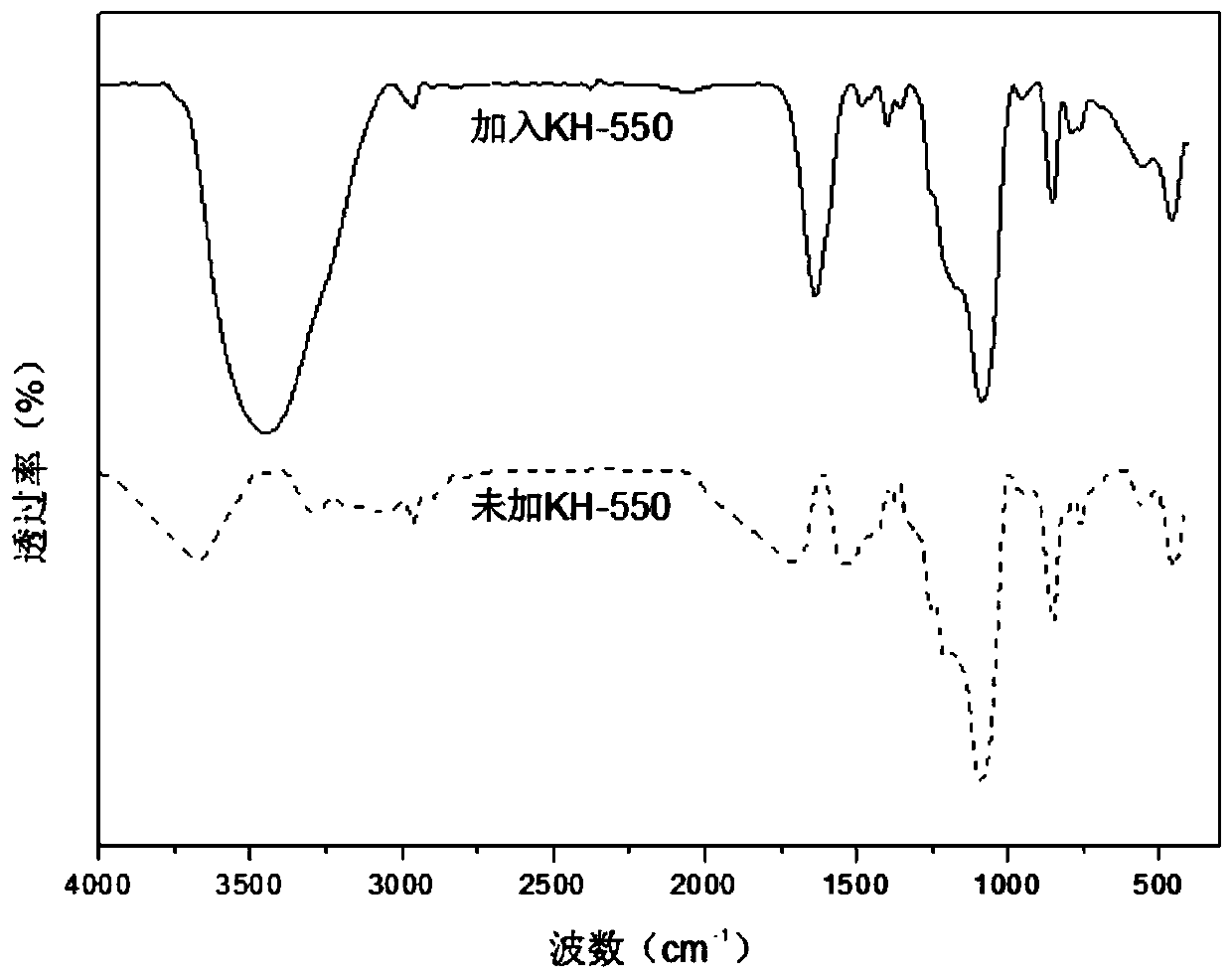

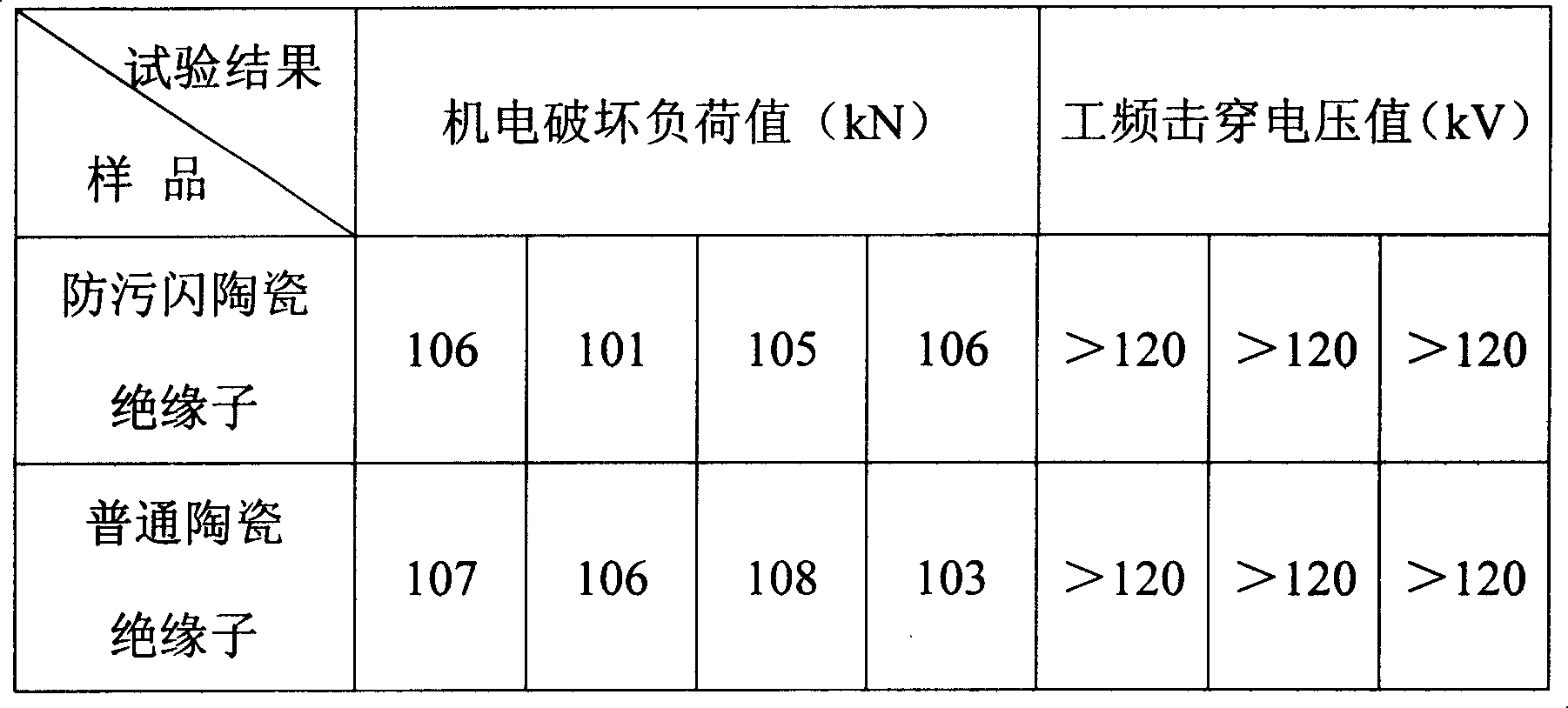

Method for manufacturing anti pollution flashover high tension ceramic and glass insulators

ActiveCN1686951AAnti-agingBest integrated anti-fouling flash functionQuartz/glass/vitreous enamelsHigh pressureSurfactant free

The present invention discloses a high voltage ceramic and glass insulator with the function of resisting pollution flashover and its preparation method. Said method includes the following processes: firstly, preparing titanium dioxide base sol, adding surfactant into the sol, then applying the titanium dioxide sol containing the above-mentioned surfactant or containing no surfactant on the surface of high-voltage ceramic and glass insulator, low-temperature heat treatment to make the titanium dioxide sol be solidified on the insulator surface so as to form a layer of nano inorganic film capable of raising pollution flashover resisting function of genral ceramic insulator.

Owner:FUZHOU UNIV +2

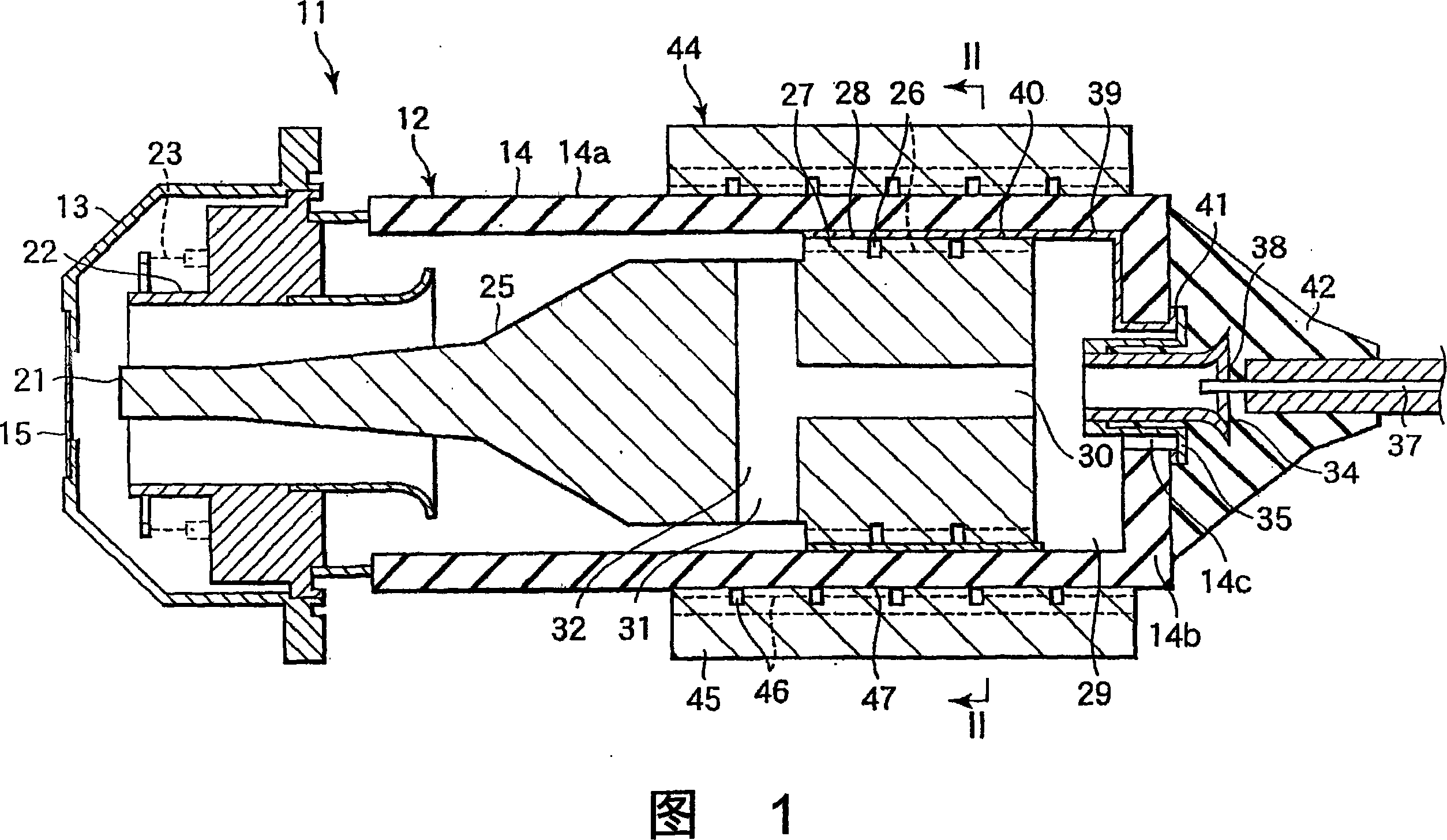

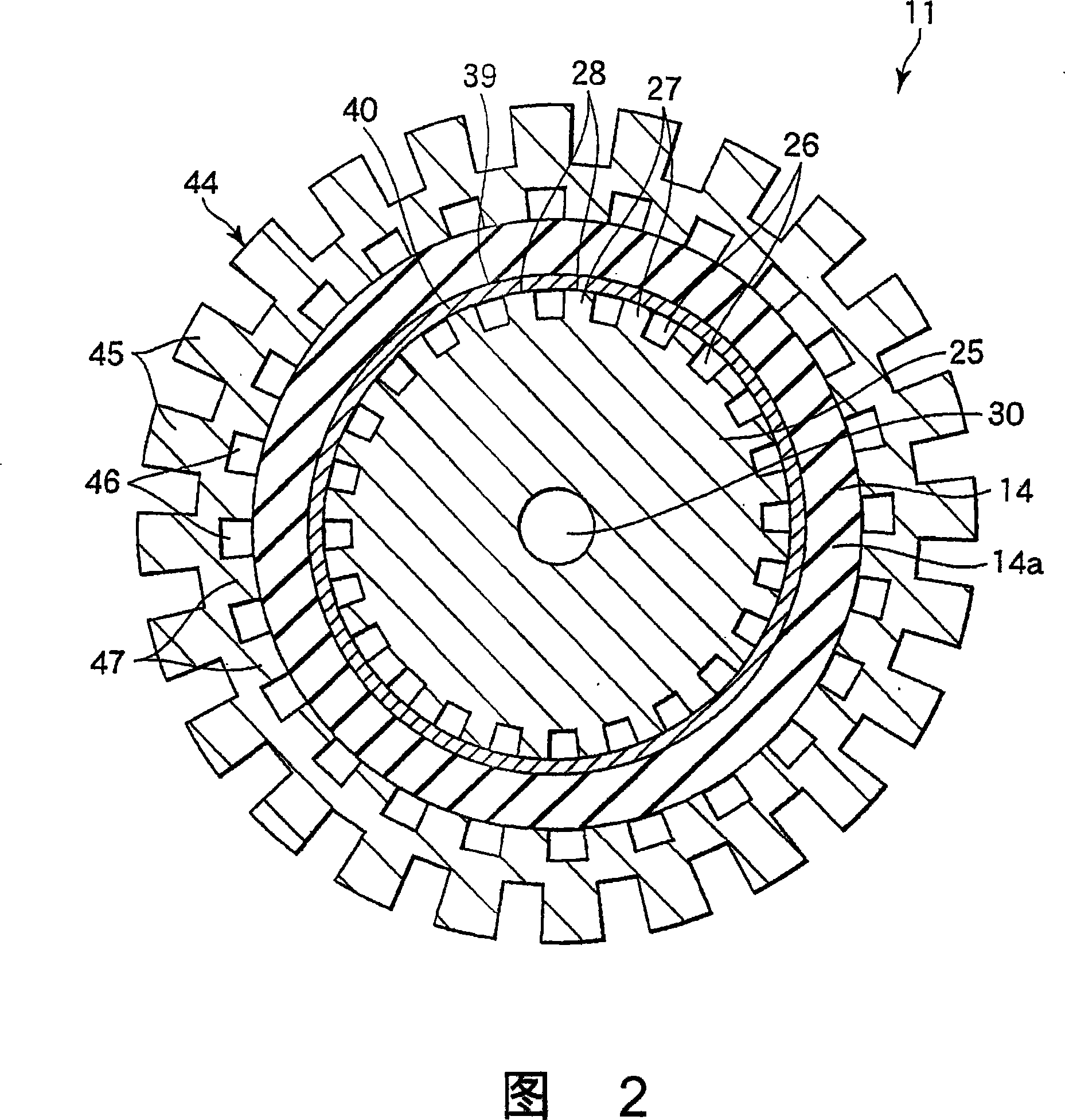

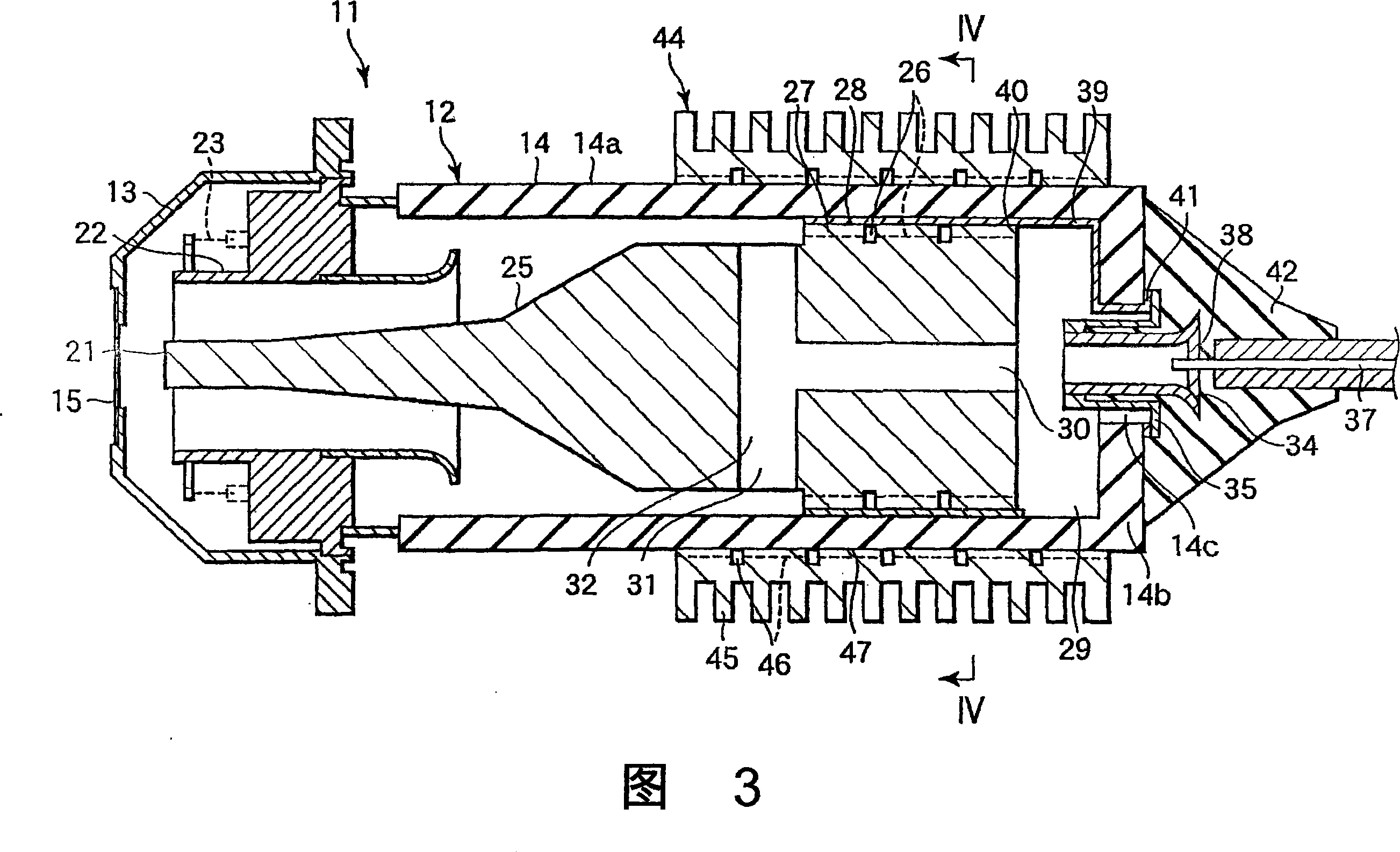

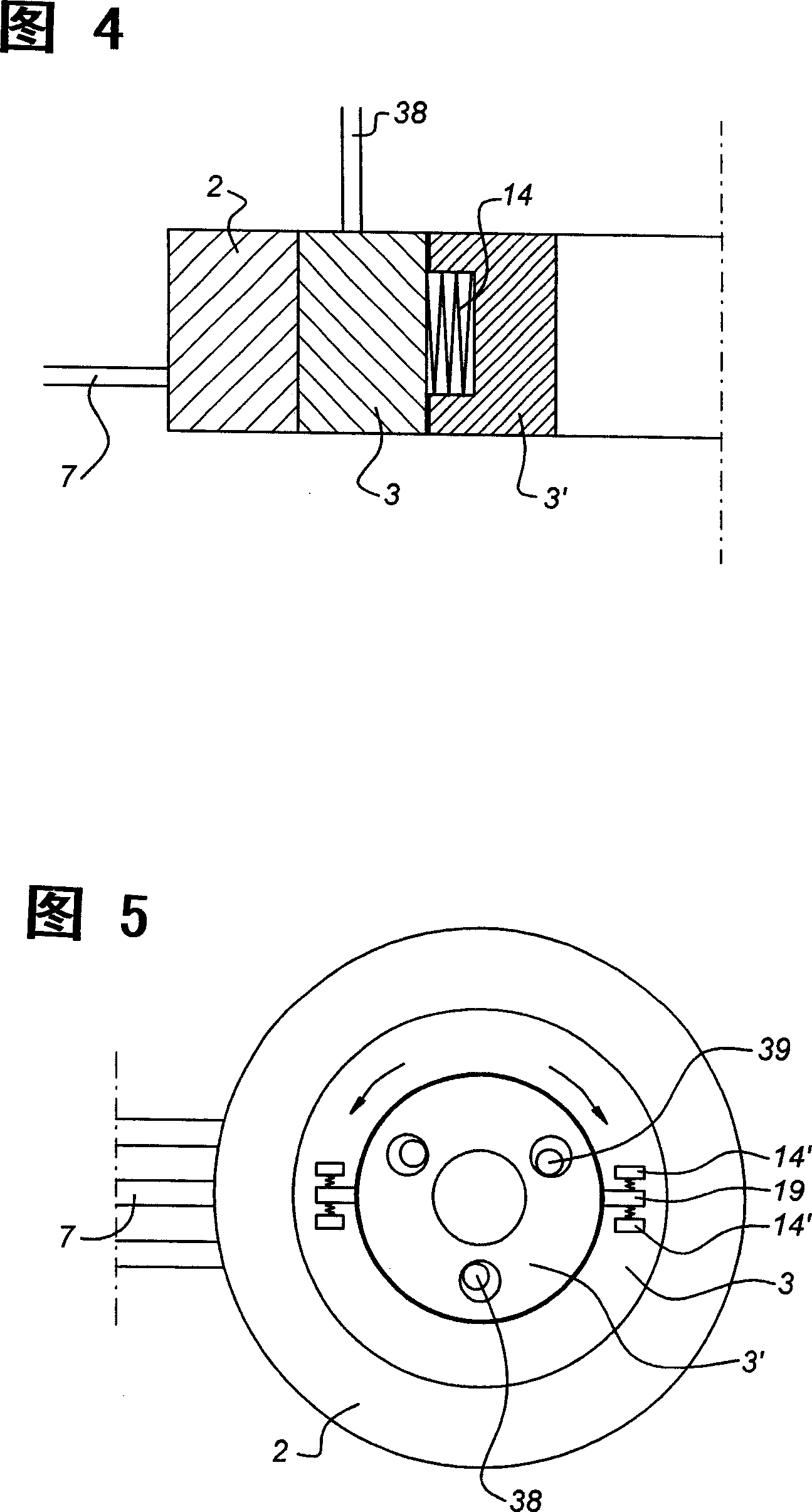

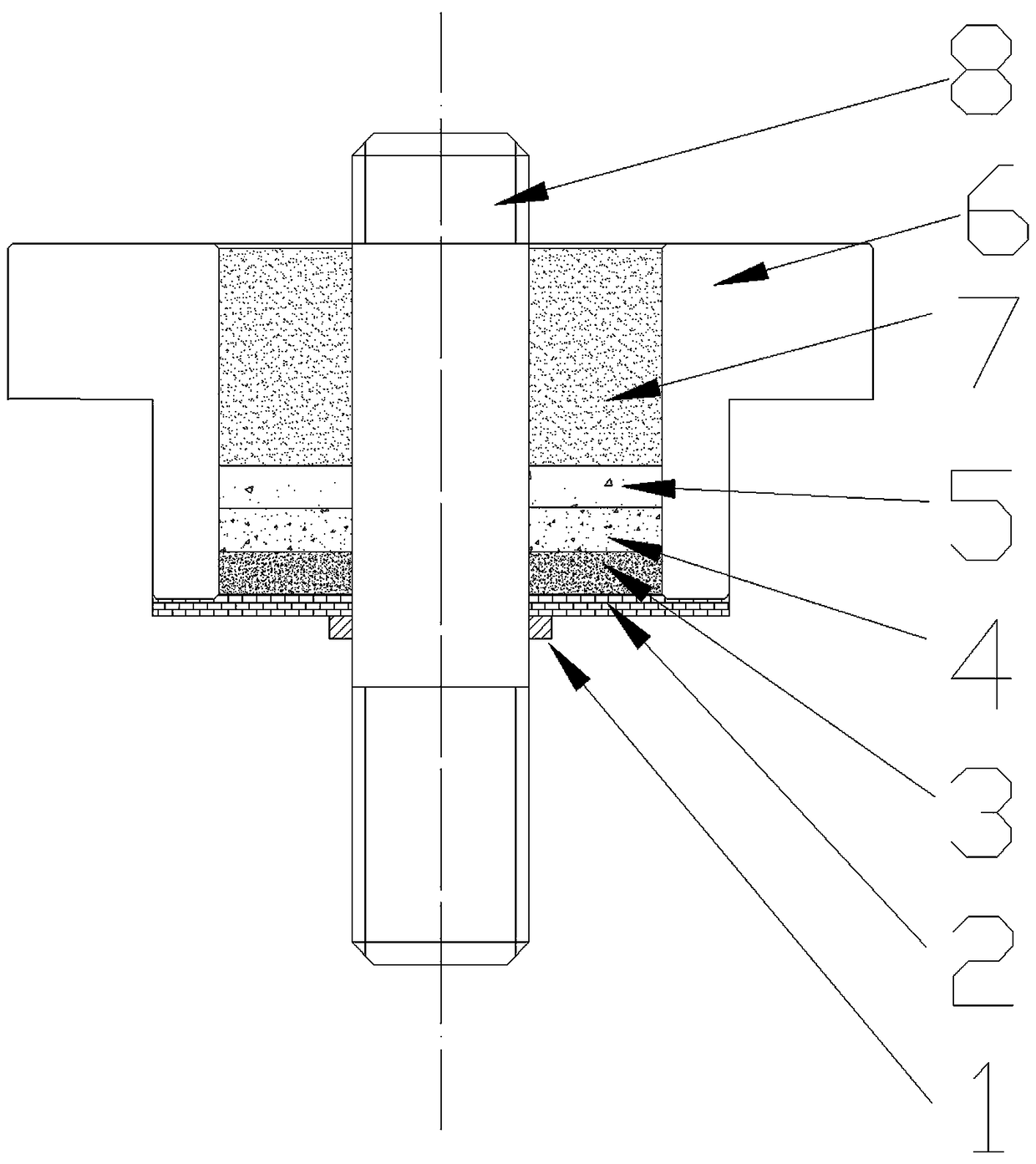

X-ray tube

InactiveCN101091232AGood heat dissipationEnsuring insulating propertiesX-ray tube electrodesX-ray tube vessels/containerEngineeringVoltage

Disclosed is an x-ray tube (11) wherein heat dissipation characteristics are improved and insulation characteristics are secured for a long time. In the x-ray tube (11), a supporting body (25) supports an anode target (21) at one end and is provided with a joint portion (28) on the outer surface of the other end portion. The joint portion (28) is joined with the inner surface of a cylinder portion (14a) of a second envelope (14) for improving heat transfer from the supporting body (25) to the second envelope (14) through the joint portion (28). A terminal (38) for supplying a voltage to the anode target (21) is provided on the end face (14b) of the other end portion of the second envelope (14). By arranging the terminal (38) away from the joint portion (28), the temperature of an insulating material (42) for insulation of the terminal (38) is kept low, thereby securing the insulation characteristics for a long time.

Owner:KK TOSHIBA +1

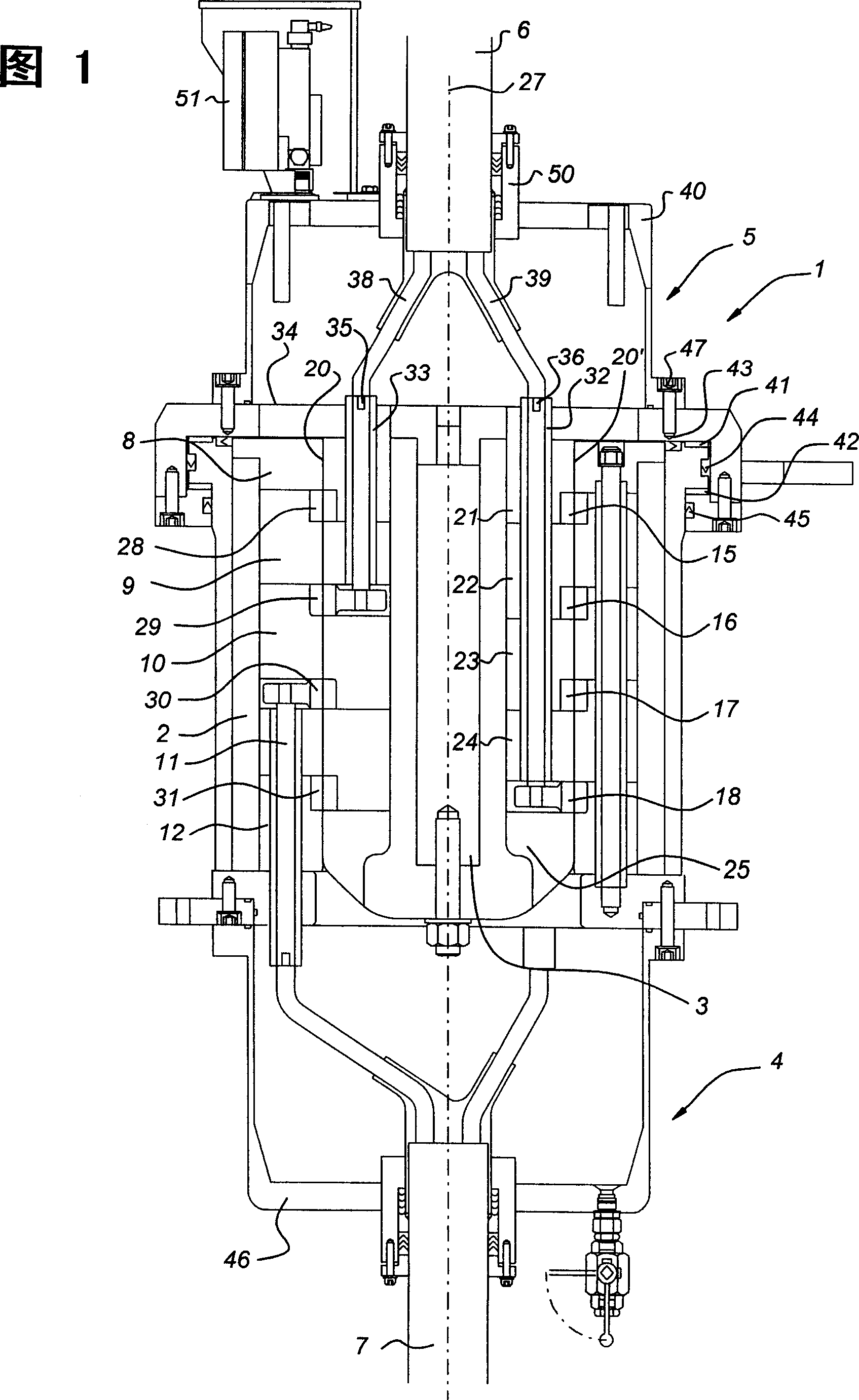

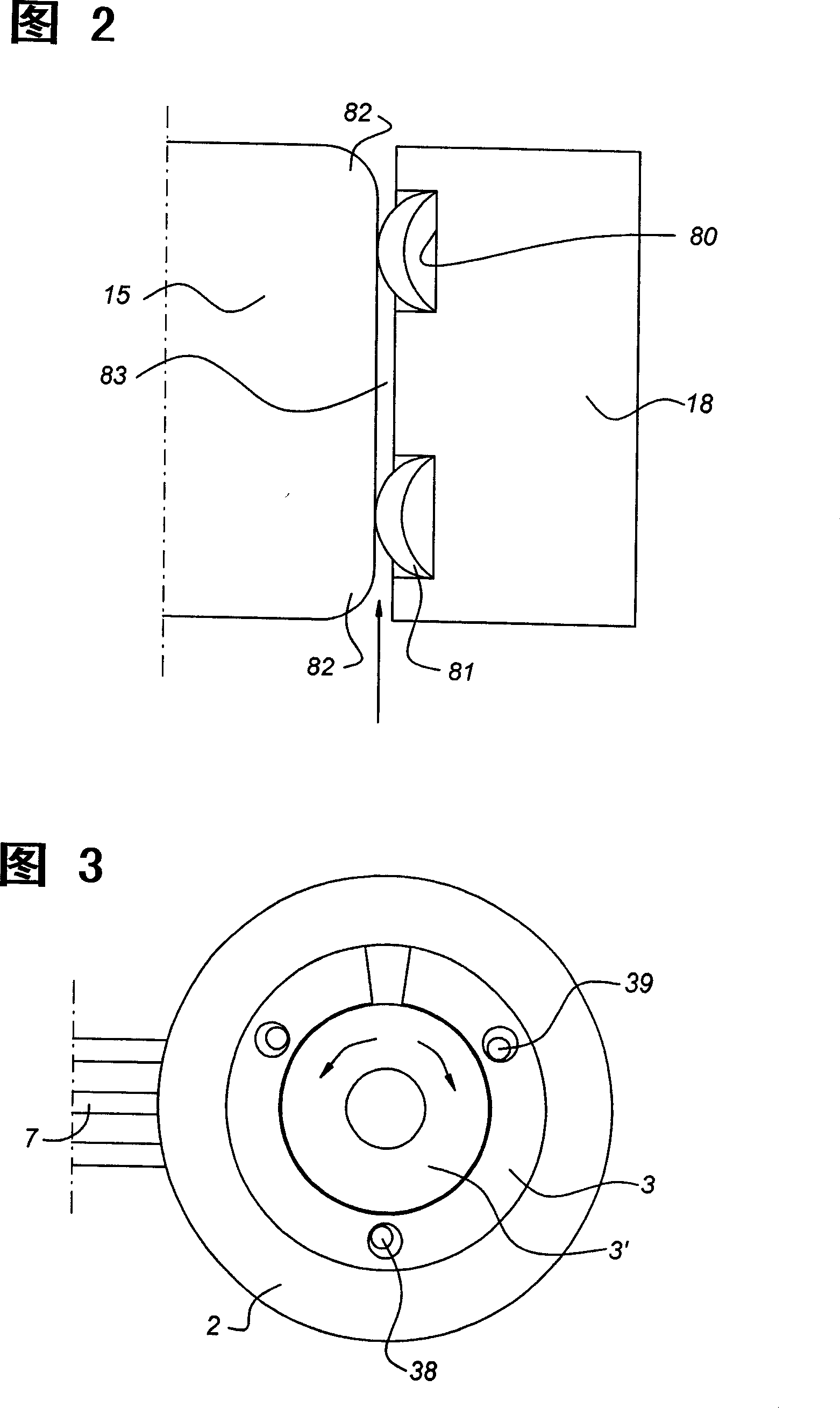

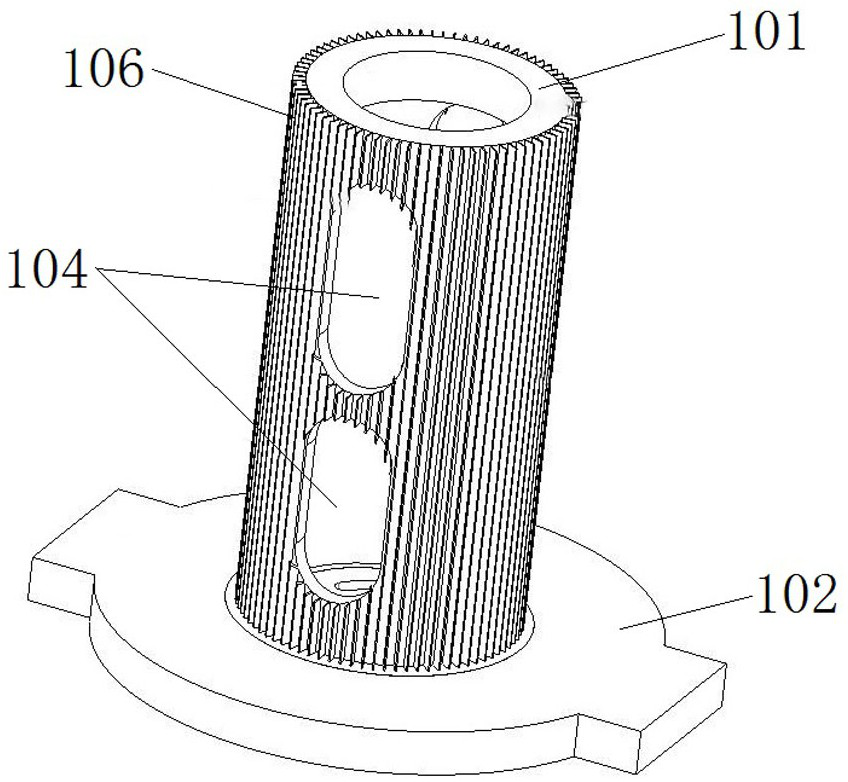

High pressure or middle pressure rotating connector

InactiveCN101009416AReduce pollutionSmall sizeRotary current collectorElectrical conductorHigh pressure

The invention relates to high pressure swivel joint that comprises ring outward element and inner cylindrical element. The inner element and outward element include at least two axially-spaced electric conductors which can rotate with the corresponding inner element and outward element, the conductors are at least two pairs, they are set to contact surfaces which are contacted with each other. One of the pair of conductor is set on the inner element, the other is at the outward element, and every conductor is connected with the relative voltage line which is extended to the input end and output end, the conductor is surrounded by insulating materials. The electric conductor of the outward element is set in the rabbet of the ring solid outer insulation ring, the electric conductor of the inner element is set in the rabbet of the ring solid inner insulation ring, the inner insulation ring and the outer insulation ring are coaxial, and they separately limit the boundary surface which extends along the axial, the boundary surfaces of ring are closely adjacent, the contact surface of the electric conductor is at or near the boundary surface.

Owner:SINGLE BUOY MOORINGS INC

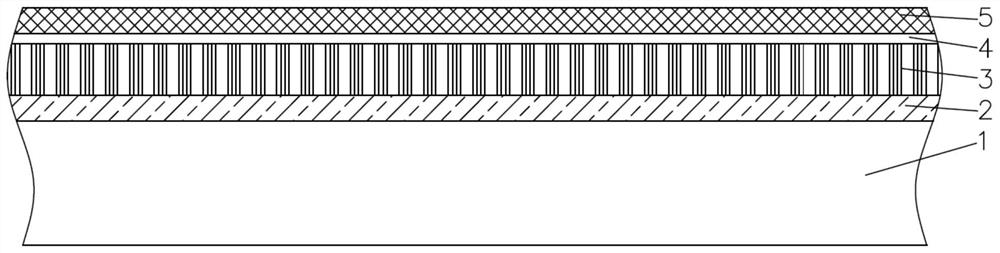

High-temperature-resistant composite ceramic insulating coating and preparation method thereof

ActiveCN112725720AImprove antioxidant capacityImprove long-term reliabilityMolten spray coatingEfficient propulsion technologiesOxide ceramicInter layer

The invention provides a high-temperature-resistant composite ceramic insulating coating. A transition layer (2) made of a metal compound material, a middle layer (3) made of pure ceramic, a metal layer (4) made of a metal compound material and a surface layer (5) with holes sealed by metal oxide ceramic are sequentially arranged on the surface of an alloy matrix (1) outwards. The composite ceramic insulating coating is obtained by sequentially pretreating a base body, sequentially preparing the transition layer (2), the middle layer (3), the metal layer (4) and the surface layer (5) by adopting plasma spraying and finally performing laser cladding on the surface layer (5). The high-temperature-resistant composite ceramic insulating coating is good in high-temperature oxidation resistance, high in insulativity, excellent in environmental adaptability and high in working reliability.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

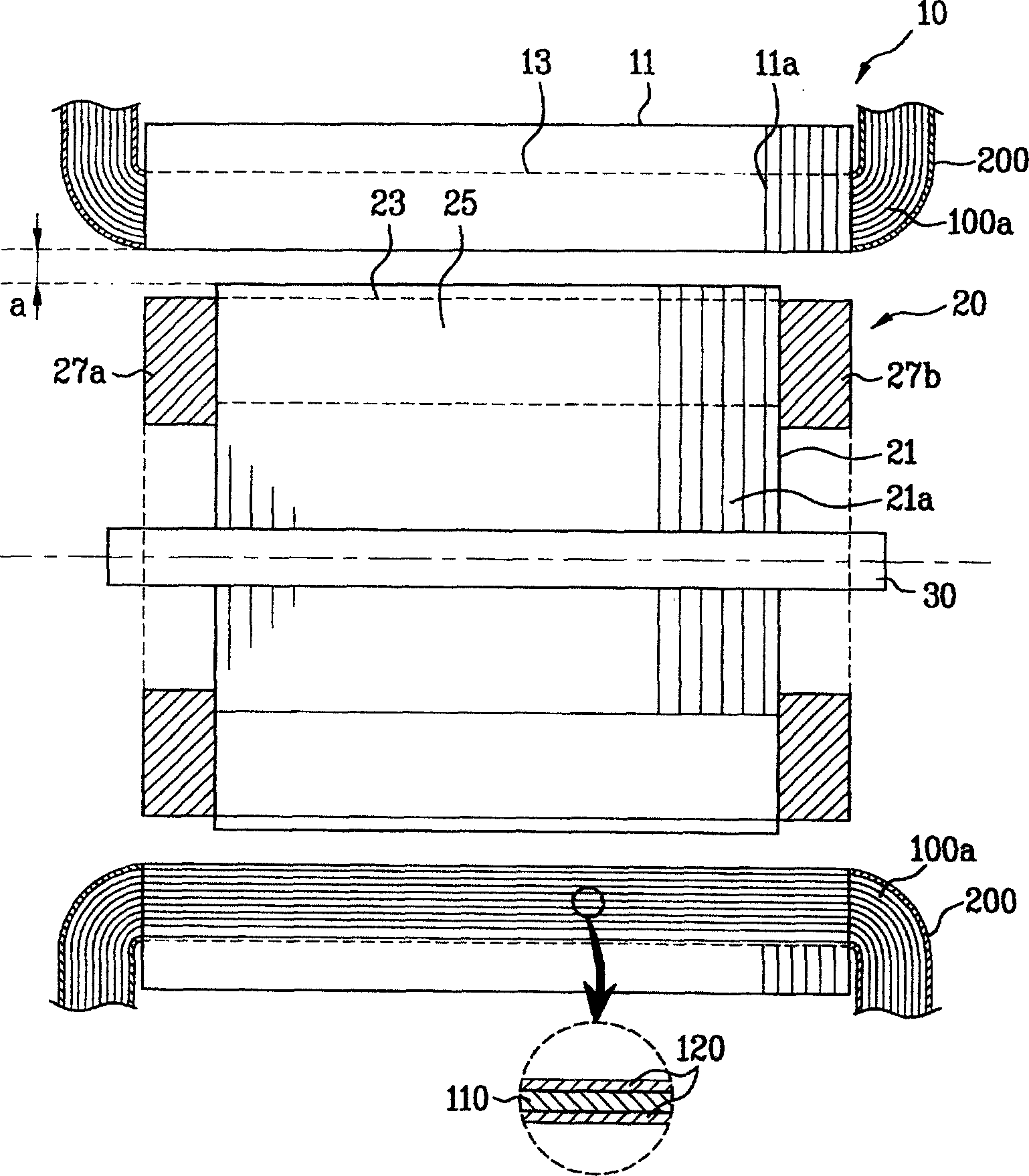

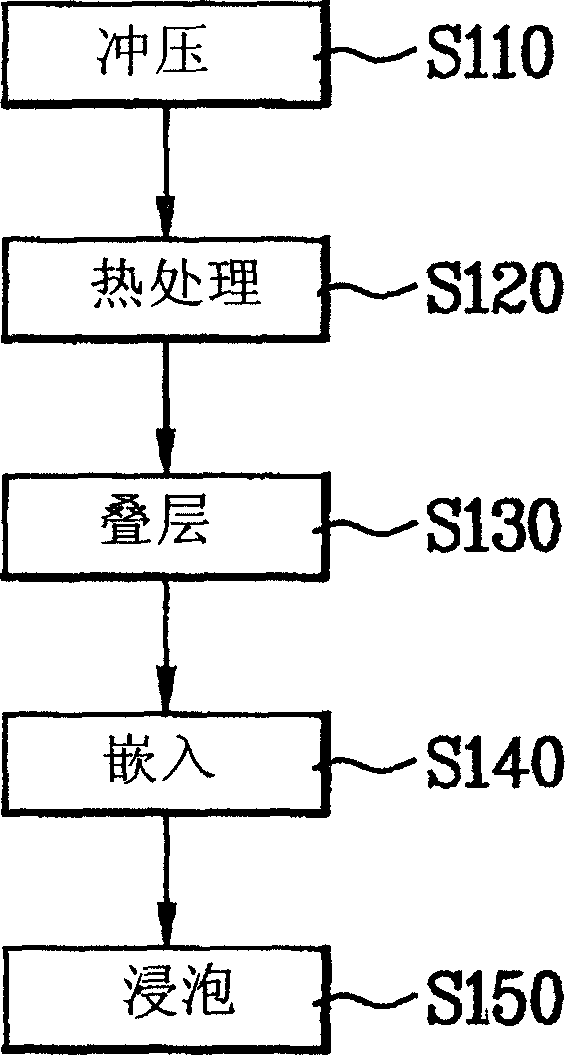

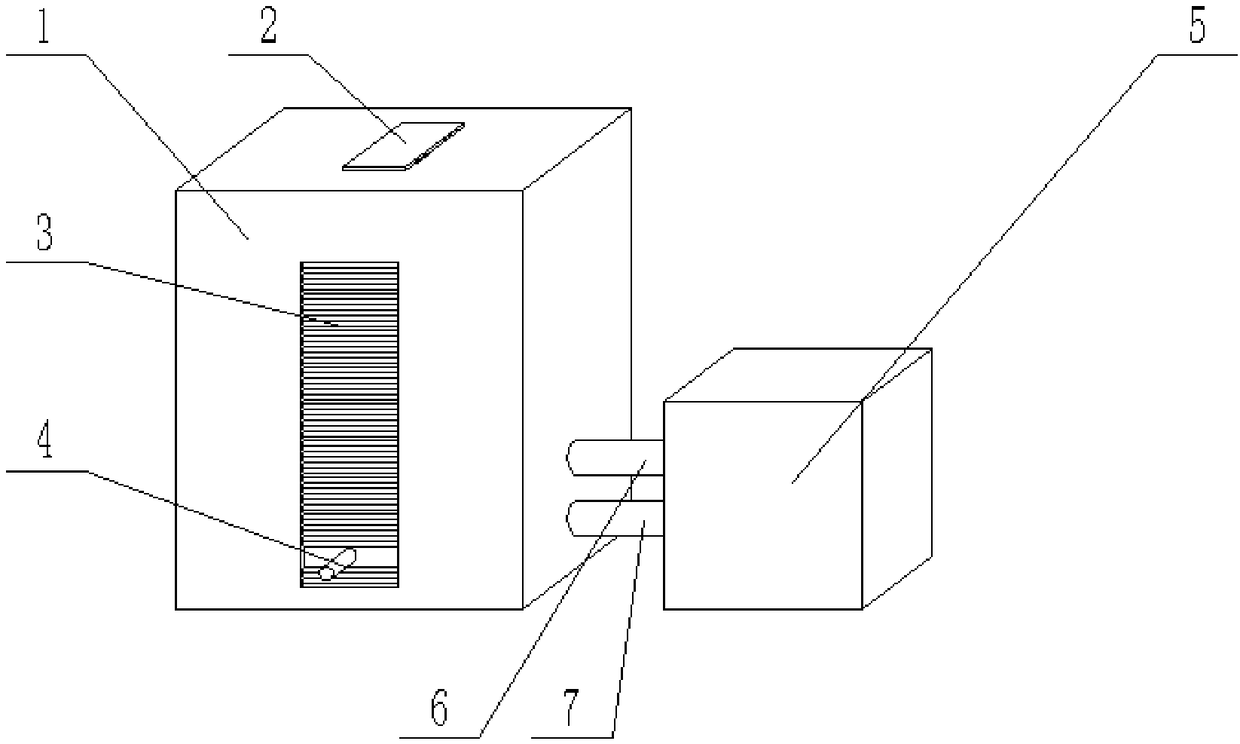

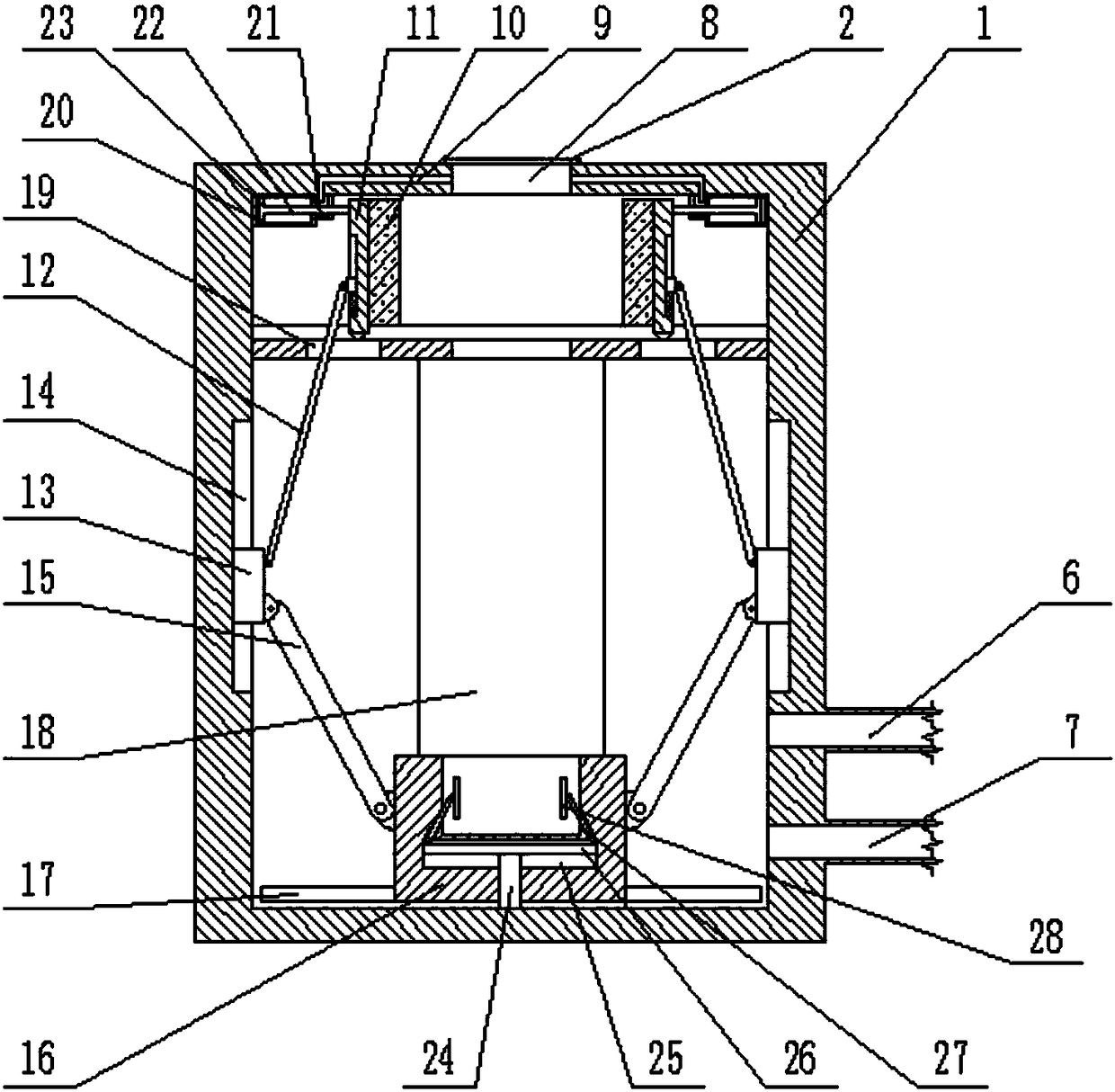

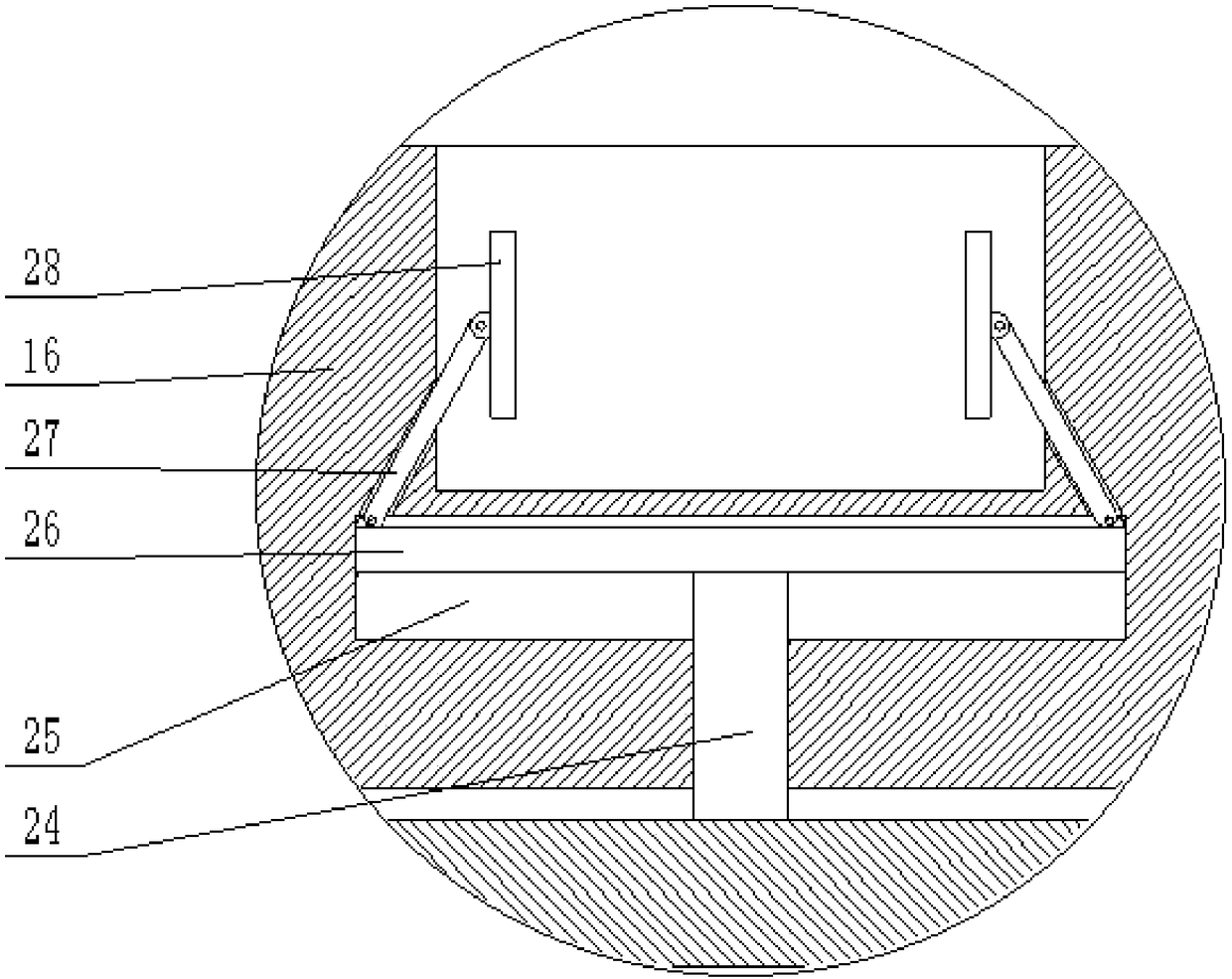

Coil, induction motor for motor and its stator manufacturing method

InactiveCN1767322AImprove efficiencySimple and efficient operationWindings insulation materialMagnetic circuit rotating partsEngineeringHeat treated

The invention relates to a motor used coil which comprises: a chip wire with conducting function and a ceramic insulating film formed on the surface of the chip wire; the stator core of the sensing motor of the motor used coil is formed by a plurality of round laminated silicon-steel sheets; the inner around side of the stator evenly forms a plurality of stator coil grooves on shaft direction; the stator coil grooves form radial radioactive type structure; the coil end turn of the stator coil is fixed on the stator core by the insulating film; the method for making the stator of the sensing motor comprises: punching stage, heat processing stage, laminating stage, embedding stage and drenching stage.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

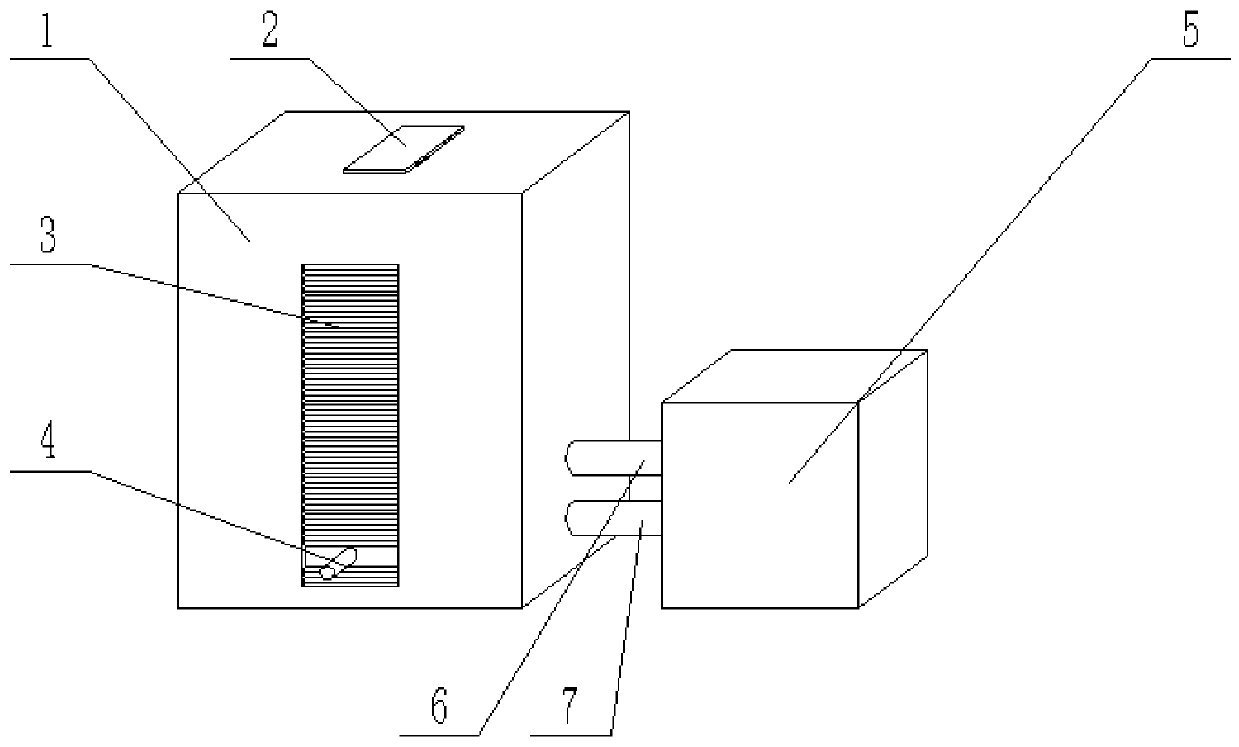

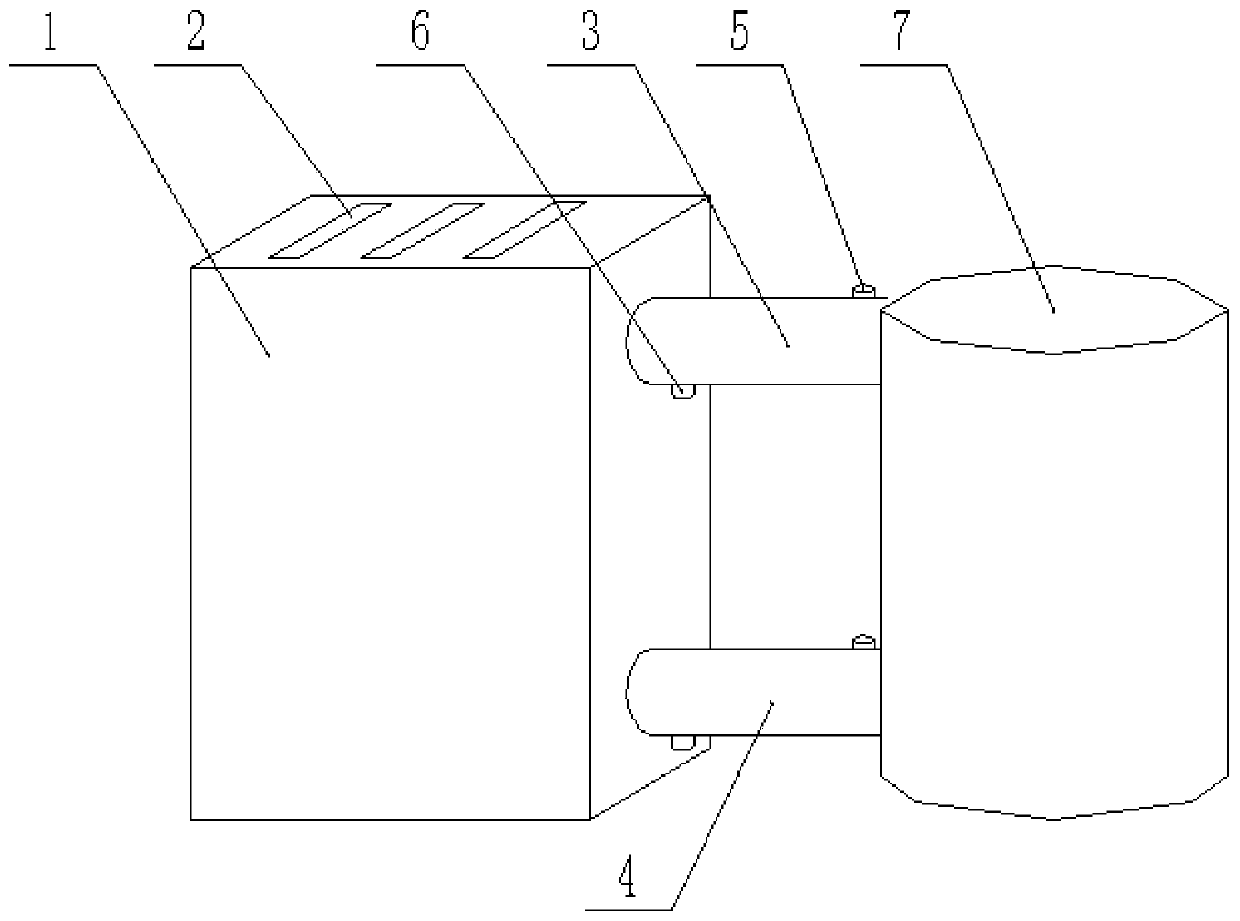

Method for cooling server through oil

ActiveCN108174583ASpeed up heat dissipationAffect normal operationHeat-exchange elementsCooling/ventilation/heating modificationsCarbon numberSide chain

The invention belongs to the technical field of special methods for cooling electric equipment, and specifically discloses a method for cooling a server through oil. The method comprises the followingsteps: (1) a cabinet and an oil circulation device are prepared, and oil raw materials, including insulating mineral oil and 2,6-di-tert-butyl-p-cresol, are prepared, wherein the carbon atoms on thealkyl side chain in the insulating ore oil account for 42-50% of the total molecular carbon number; (2) the oil raw materials prepared in step (1) are mixed to form oil; (3) a server is put in the cabinet, and the oil is put in the oil circulation device; and (4) the oil circulation device is started to make the oil enter the cabinet and go over the server, the oil absorbing heat is sucked by theoil circulation device and cooled and then enter the cabinet again, and the temperature of the cooled oil is between -10 DEG C and 20 DEG C. The invention aims to solve the problems in the prior art:the air flow carries and blows impurities into the server to cause dust accumulation during heat dissipation based on cold and hot air exchange, and the low thermal conductivity of air results in lowheat dissipation efficiency of the server.

Owner:中南信息科技(深圳)有限公司

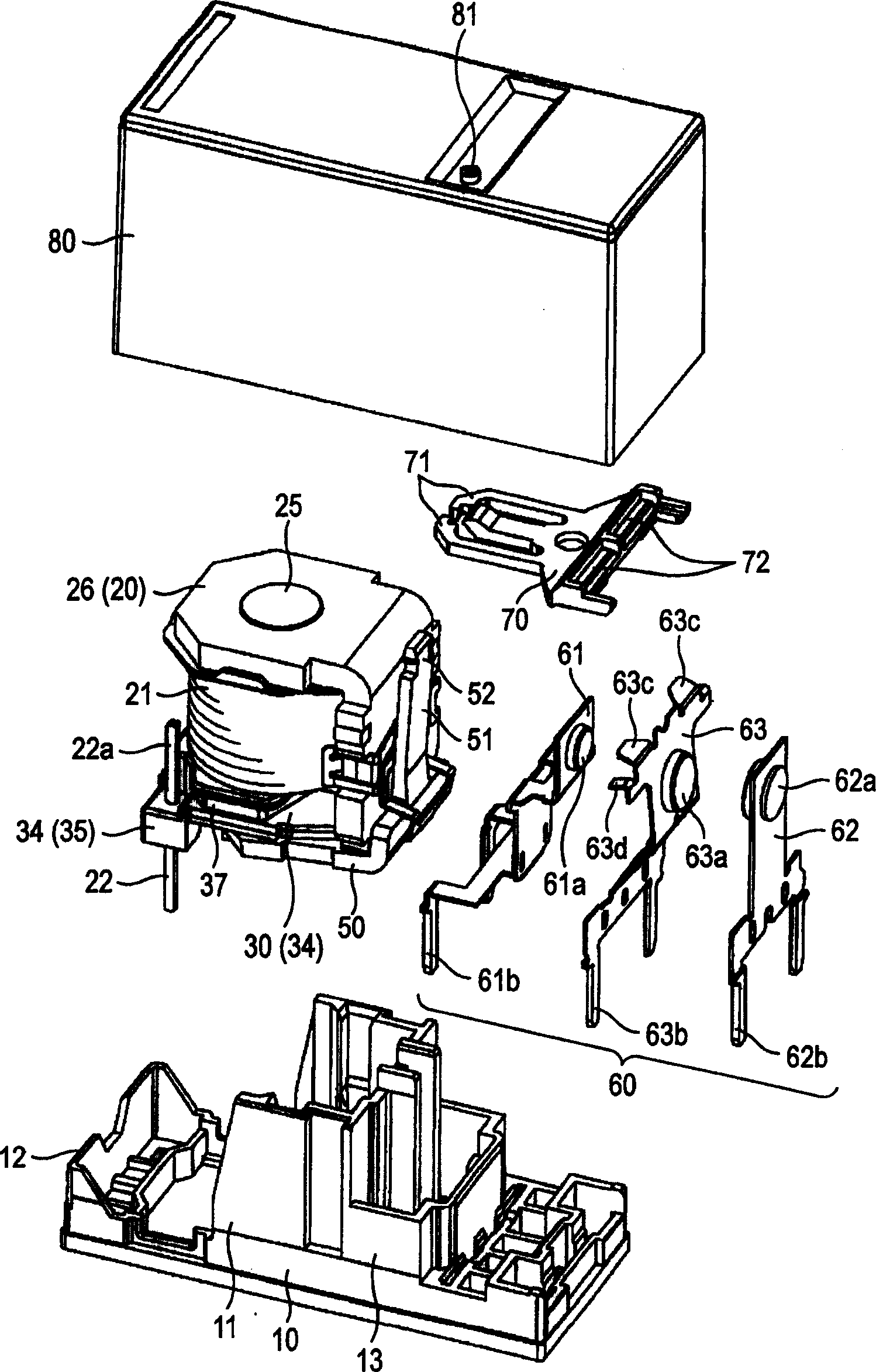

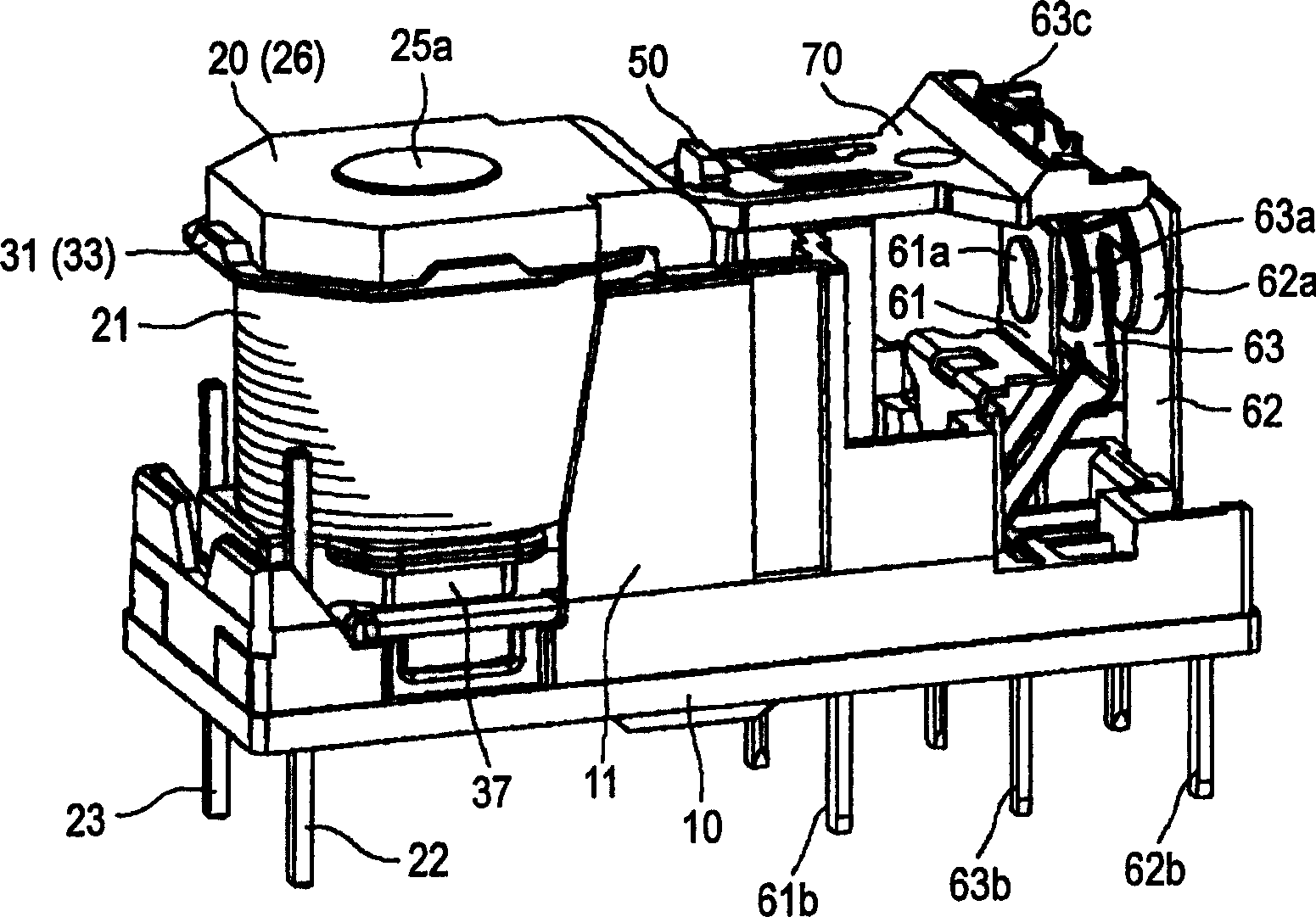

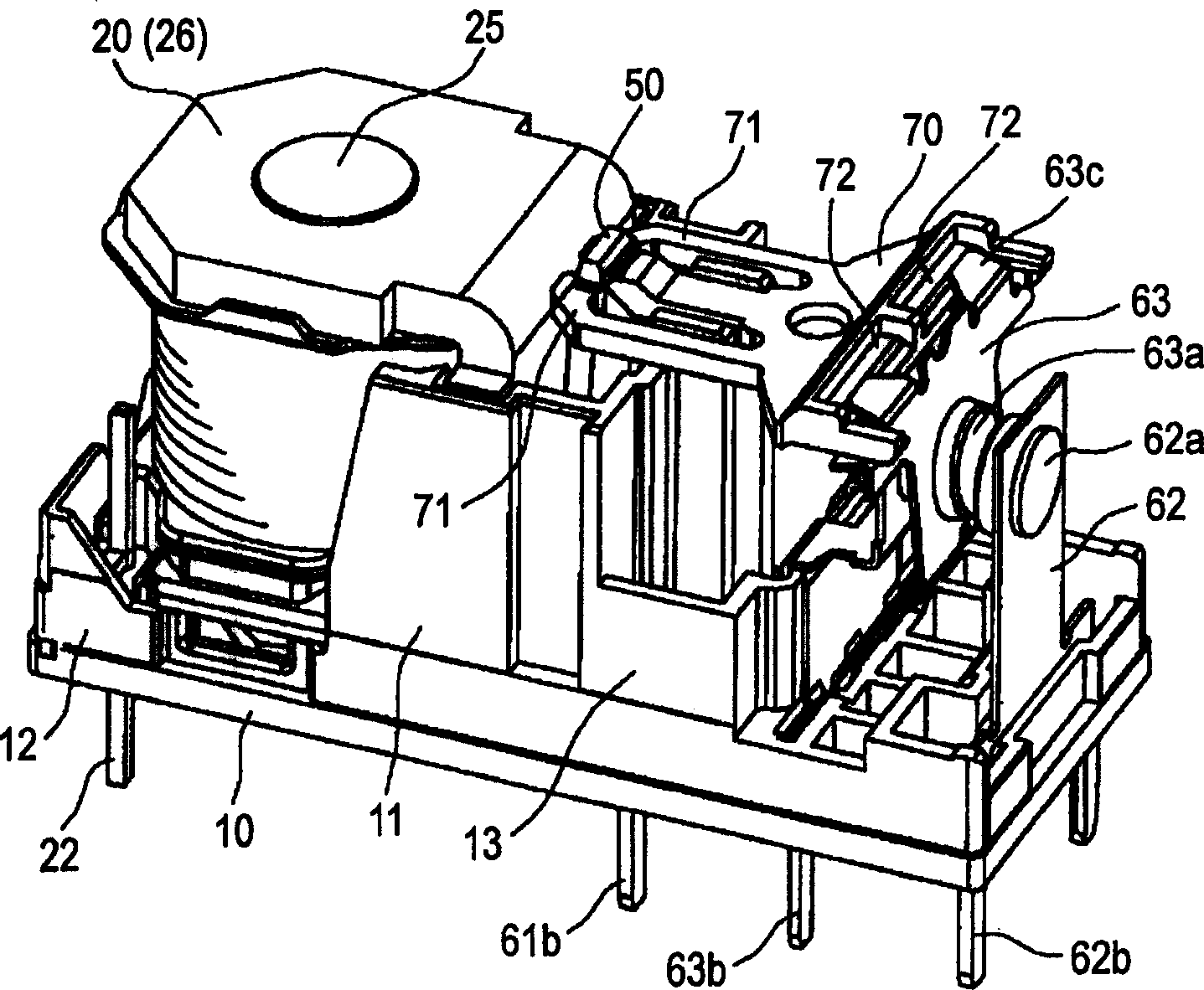

Electromagnetic relay

ActiveCN1551274ALimit Height DimensionsSmall heightElectromagnetic relay detailsTelephone set constructionsProduction rateMagnetic poles

Owner:ORMON CORP

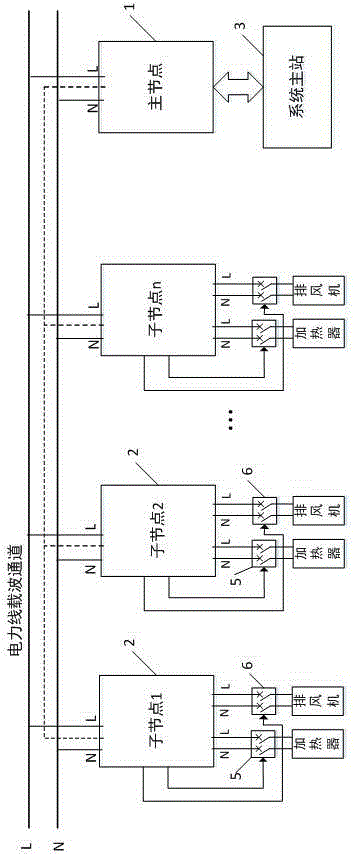

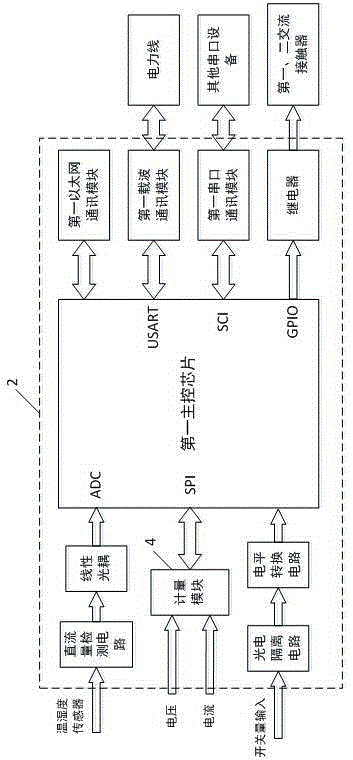

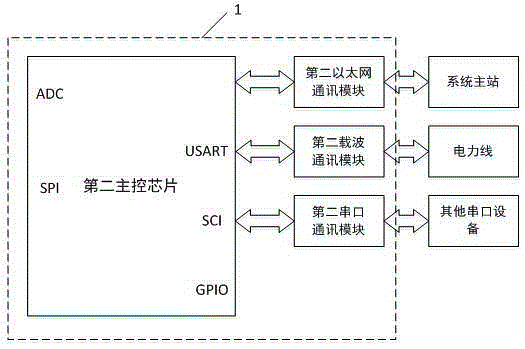

Intelligent temperature controller and intelligent temperature controller system applied to power distribution cabinet temperature monitoring

InactiveCN105259951AOvercome rangeOvercoming adjustmentTemperatue controlCarrier signalAlternating current

The invention relates to an intelligent temperature controller applied to power distribution cabinet temperature monitoring. The intelligent temperature controller comprises a first master control chip which performs bidirectional communication with a first carrier wave communication module and a metering module used for metering consumption of a heater and an exhaust fan. An output end of the first master control chip is connected with an input end of a relay, and an output end of the relay is connected with control ends of first and second alternating current contactors. One end of the first alternating current contactor is connected with the metering module, and the other end of the first alternating current contactor is connected with the heater. One end of the second alternating current contactor is connected with the metering module, and the other end of the second alternating current contactor is connected with the exhaust fan. The invention can overcome defects that the temperature control range of a temperature controller is required to be manually set and cannot be remotely controlled and adjusted; the metering function is achieved, that whether the threshold of temperature control is reasonable or not can be determined, and remote control is achieved; in addition, the intelligent temperature controller and an intelligent temperature controller system adopt power line carrier communication based on a high speed narrowband protocol, thereby being stable and fast in communication and convenient in networking.

Owner:KEDA INTELLIGENT ELECTRICAL TECH +1

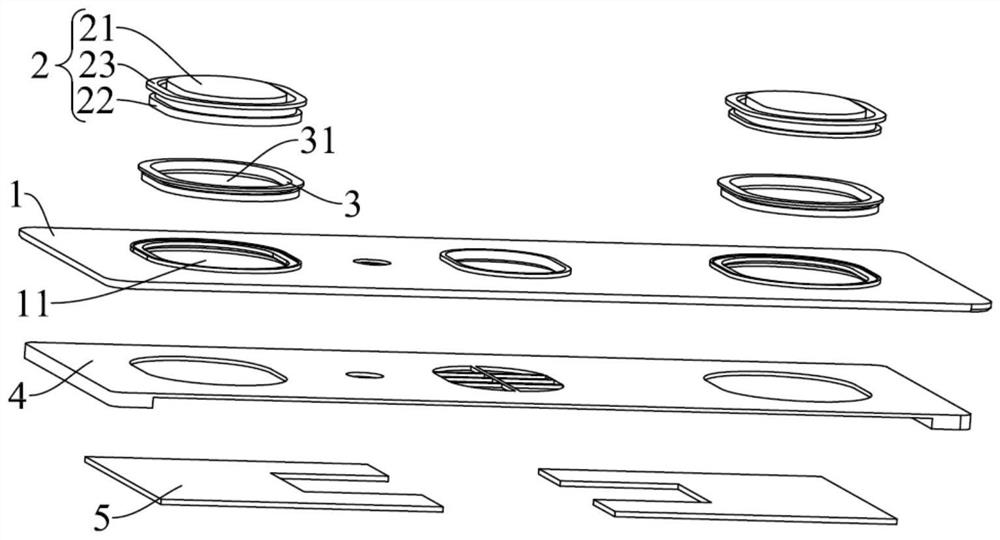

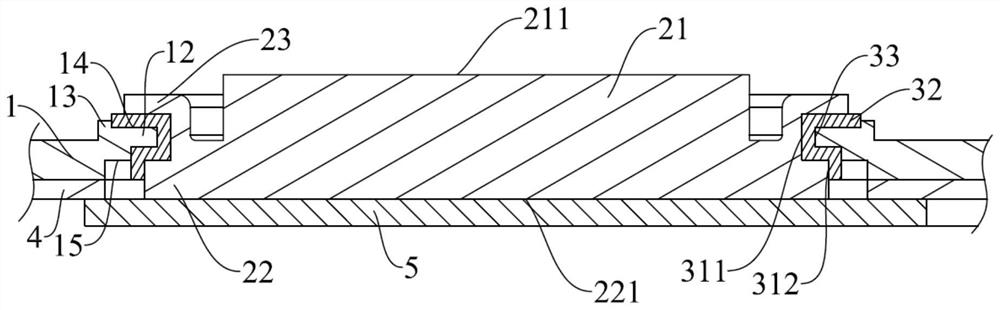

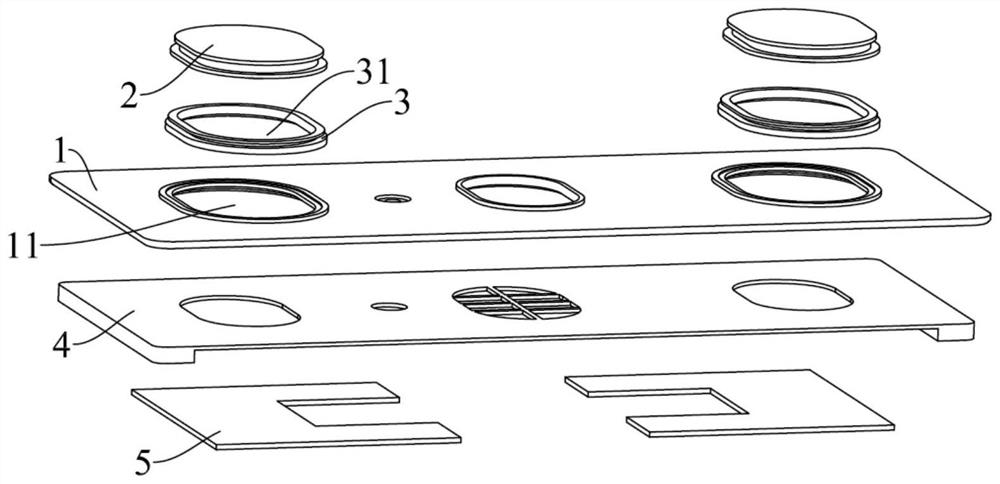

Top cover assembly, assembling method of top cover assembly and battery

PendingCN114361667ALower the altitudeSimple structureFinal product manufactureSecondary cells manufactureElectrical batteryElectrical connection

The invention discloses a top cover assembly, an assembling method of the top cover assembly and a battery, the top cover assembly comprises a top cover piece, a terminal post, a sealing piece, a lower plastic piece and an electric connecting piece, the top cover piece is provided with a post matching hole, the terminal post is arranged in the post matching hole in a penetrating manner and is provided with a first connecting surface and a second connecting surface which are oppositely arranged, and the sealing piece is arranged on the first connecting surface; the sealing piece is arranged on the terminal pole in a sleeving mode and clamped among the terminal pole, the inner circumferential wall of the pole matching hole and the upper surface of the top cover piece, the lower plastic piece is attached to the lower surface of the top cover piece, and the electric connecting piece is attached to the lower plastic piece and connected with the terminal pole. According to the top cover assembly, the overlapping height of the terminal post and the top cover plate is increased on the premise of ensuring insulation of the terminal post and the top cover plate, so that the energy density of a battery cell is improved.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

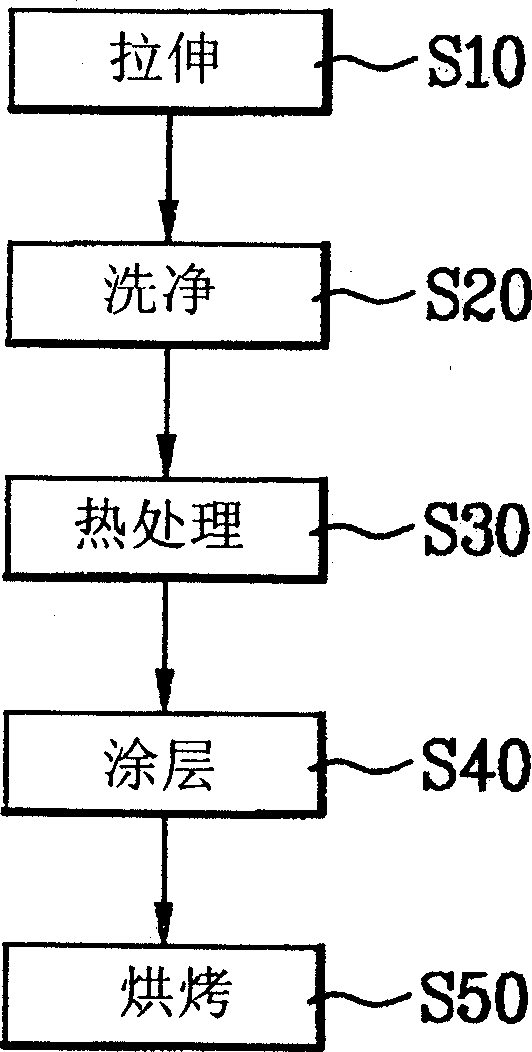

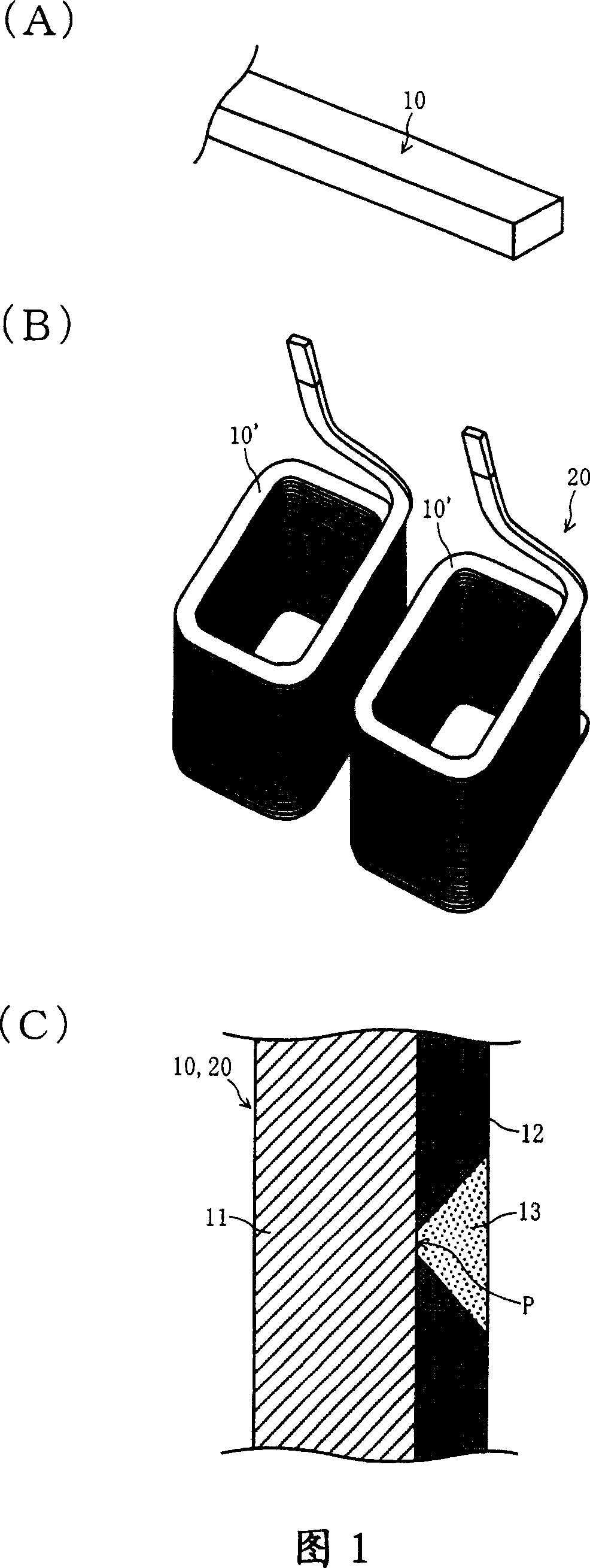

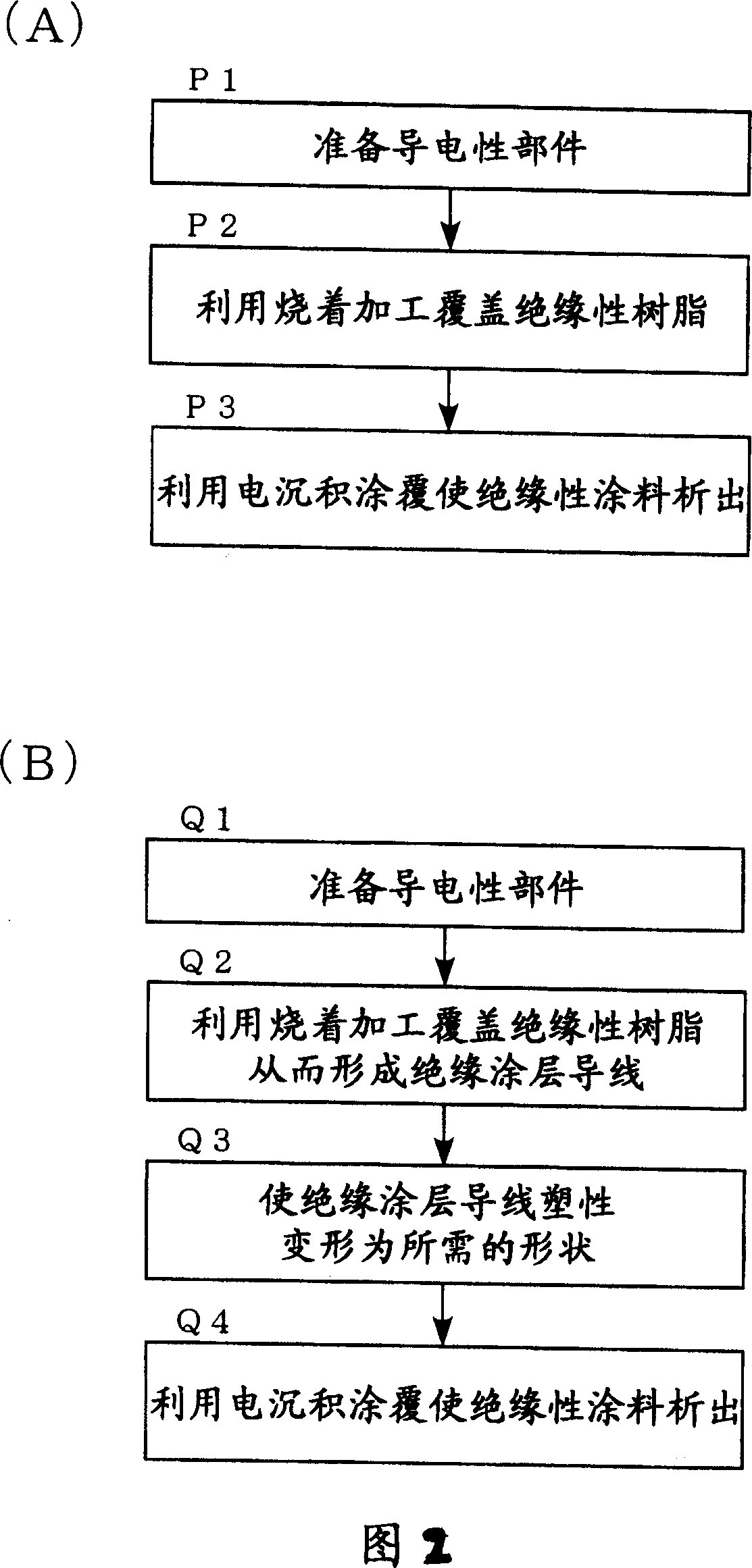

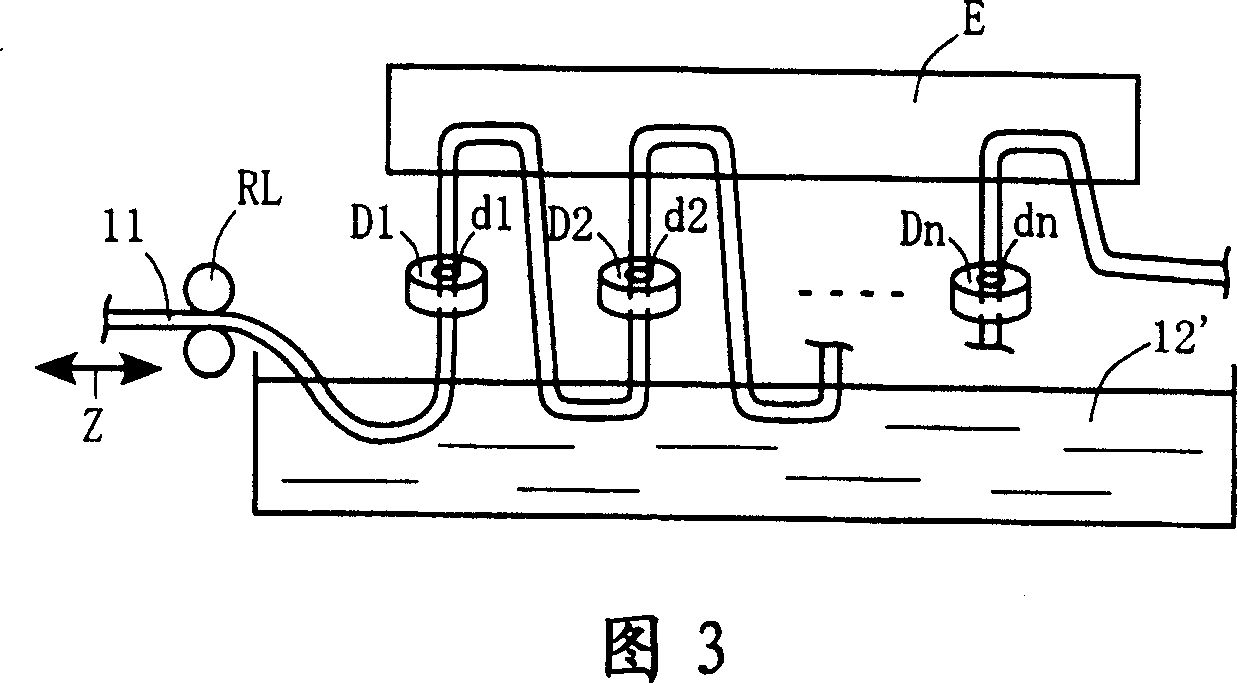

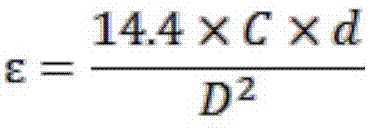

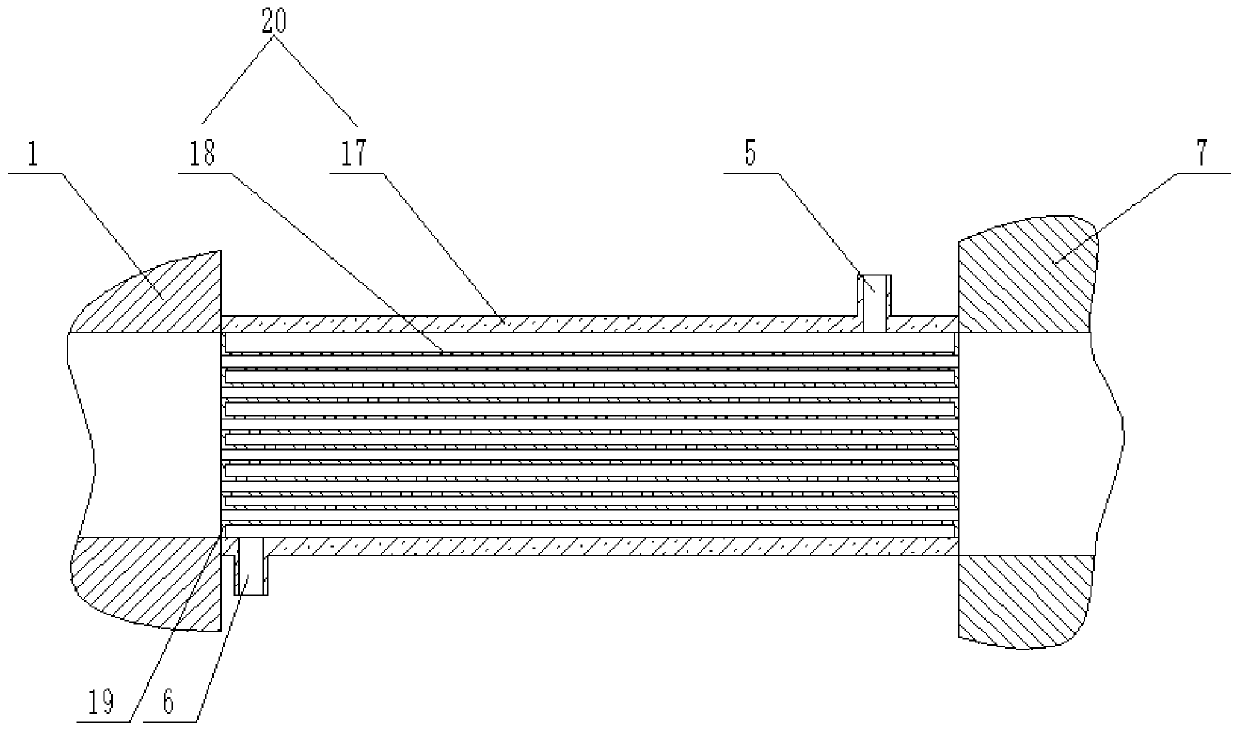

Insulating coated wire and its producing method, insulating coated wire product and its producing method

ActiveCN1933034ALow costPrevent peelingTransformers/inductances coils/windings/connectionsInsulated cablesMaterials scienceCoating

To provide an insulation coated conductor, where cost increase of small-lot production is avoided and the deterioration of an insulating property due to occurrence of pinholes can be prevented effectively, and provide an insulation coated conductor mold product and its manufacturing method. The insulation coated conductor provided a conductive member 11, insulating resin 12 coated with the conductive member 11 by a burning process, and an insulating coating material 13 which is electrodeposited on a peeled part P of the insulating resin 12, and its manufacturing method, in which the conductive member 11 is coated with the insulating resin 12 by a burning process, a peeled part P where the conductive member 11 is exposed is coated by the insulating coating material 13 in electrodeposition coating, are provided.

Owner:SANCALL CORP

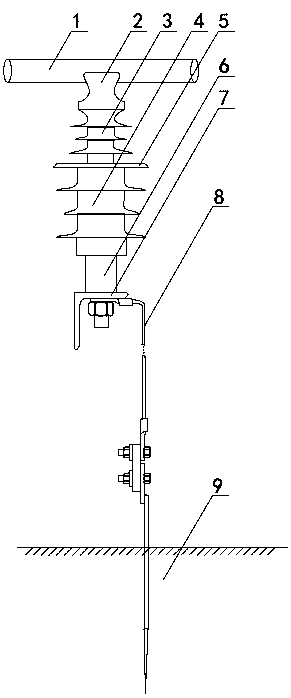

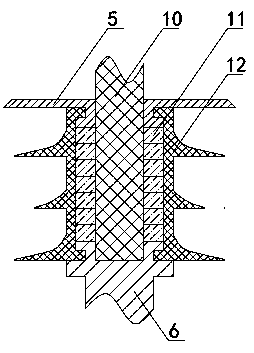

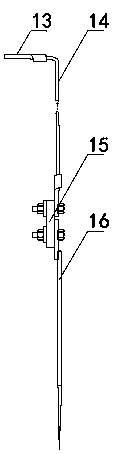

Insulator type voltage limiter with grounding function

InactiveCN107834356AExtended service lifeImprove lightning performanceOverhead installationOvervoltage arrestors using spark gapsLightning strikeNormal state

The invention, which belongs to the technical field of lightning protection of the distribution line, provides an insulator type voltage limiter with the grounding function. The insulator type voltagelimiter is characterized in that a bleeder part includes an insulating core rod (10); an upper armour clamp (2) and a lower armour clamp (6) are fixed at the upper end and the lower end of the insulating core rod (10) respectively; the upper armour clamp (2) supports an overhead distribution line (1); an annular electrode (5) is arranged between an insulating support section (3) and a bleeder section (4); and a plurality of valve blocks (11) are arranged between the annular electrode (5) and the lower armour clamp (6) in a contact manner. Besides, a grounding part (8) is also arranged; the lower armour clamp (6) is connected to the upper end of the grounding part (8); and the lower end of the grounding part (8) is connected to the ground (9). According to the insulator type voltage limiter, because the bleeder section with the valve blocks is arranged at the lower armour clamp, the valve blocks are insulated with the overhead distribution line in a normal state, so that the valve blocks are in a low potential state and are not in conduction until being hit by lightning strikes. Therefore, the service life of each valve block is prolonged substantially.

Owner:YANTAI POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +2

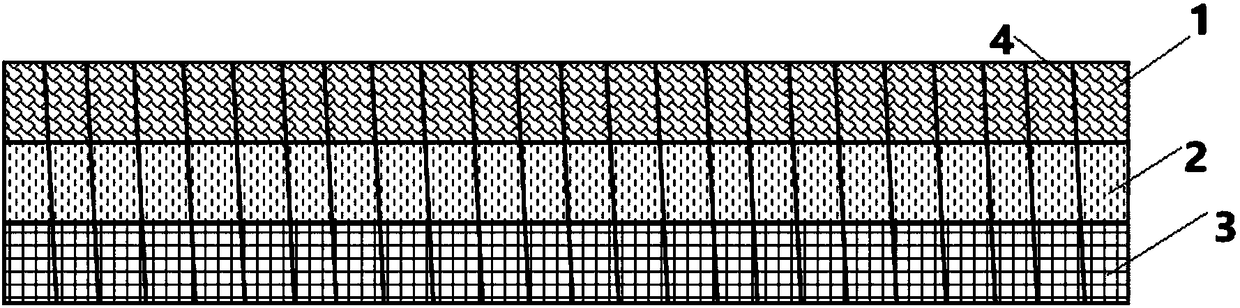

Assorted fiber felt body

The invention discloses an assorted fiber felt body. The felt body comprises a high-strength carbon fiber assorted layer located on the surface layer and a high-strength ceramic fiber layer located under the high-strength carbon fiber assorted layer, a high-modulus carbon fiber layer is arranged between the high-strength carbon fiber assorted layer and the high-strength ceramic fiber layer, and the high-strength ceramic fiber layer, the high-strength carbon fiber assorted layer and the high-modulus carbon fiber layer are formed through stitching structures. The felt body is a felt-shaped textile with a combined structure taking carbon fiber as the primary material assorted with other fibers. Comprehensive characteristics of different fibers can be achieved by an assorted fiber multi-layerstructure to improve the integrated strength and tearing resistance degree of the felt-shaped textile; a stitching structure multi-layer textile has higher heat-insulation and heat-preserving characteristics and mechanical processing characteristics. By means of the multi-layer felt-shaped structure, the overall tearing resistance degree and the overall heat-insulation and heat-preserving characteristics can be ensured, and the assorted fiber felt body can be extensively applied to heat-preserving parts of high-temperature heating furnaces.

Owner:吉林市圣赢碳纤维制品科技有限公司

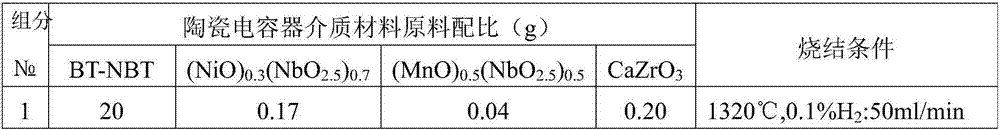

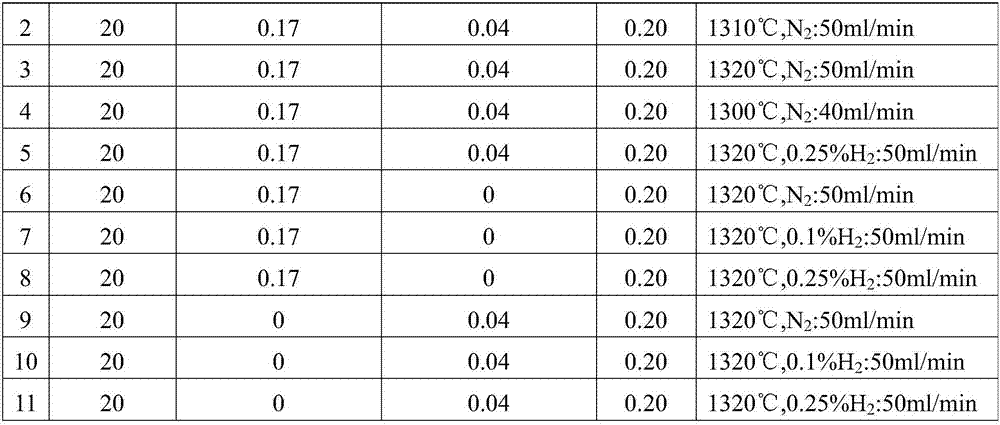

MLCC (multilayer ceramic capacitor) dielectric material with excellent insulation characteristic

InactiveCN107399970AGuaranteed insulation propertiesLarge working temperature zoneFixed capacitor dielectricCapacitanceHydrogen

The invention discloses an MLCC (multilayer ceramic capacitor) dielectric material with an excellent insulation characteristic. BaTiO3 powder serves as a base material, components including, in percentage by mass, 0.3%-0.8% of Na0.5Bi0.5TiO3, 0-1.5% of (NiO)(1-x)(NbO2.5)x, 0-0.5% of (MnO)(1-y)(NbO2.5)y and 1.0%-3.0% of CaZrO3 are added, wherein x ranges from 0.6 to 0.8, and y ranges from 0.4 to 0.6. BaTiO3 powder serves as the base material, Na0.5Bi0.5TiO3 is added, and a BT-NBT mixture is prepared after calcination; (NiO)(1-x)(NbO2.5)x, (MnO)(1-y)(NbO2.5)y and CaZrO3 are added to the BT-NBT mixture, the mixture is subjected to ball milling, dried, sieved, granulated and pressed into a green body, the green body is calcined in the nitrogen and hydrogen mixed atmosphere at the temperature of 1,300-1,320 DEG C, and the MLCC dielectric material is prepared. The MLCC dielectric material has the capacitance change rate smaller than or equal to plus or minus 15%, high dielectric constant (41729), lower dielectric loss (0.026) and the resistivity higher than 1011 omega.cm within the temperature zone of subzero 55-150 DEG C.

Owner:TIANJIN UNIV

Boron nitride composite thermal interface material

InactiveCN113265227AHigh thermal conductivityGuaranteed insulation propertiesHeat-exchange elementsThermal conductivityHeat flow

The invention discloses a boron nitride composite thermal interface material which comprises a high polymer material matrix, a boron nitride heat conduction filler and a phase change heat conduction filler; the boron nitride heat conduction filler and the phase change heat conduction filler fill into the high polymer material matrix in a blending manner. According to the invention, the boron nitride heat conduction filler can significantly improve the overall heat conductivity of the thermal interface material and ensure the insulation characteristic of the thermal interface material; the phase change heat conduction filler provides the capability of solving instantaneous high heat flow or periodic high heat flow for the thermal interface material by utilizing phase-change latent heat of the phase-change heat conduction filler; the high polymer material matrix ensures the flexibility and compressibility of the thermal interface material, can fully fill the gap between the electronic component and the heat dissipation module, and also serves as a carrier of the phase change heat conduction filler, so that the problem of overflow of the traditional phase change material is avoided.

Owner:苏州浩科通电子科技有限公司

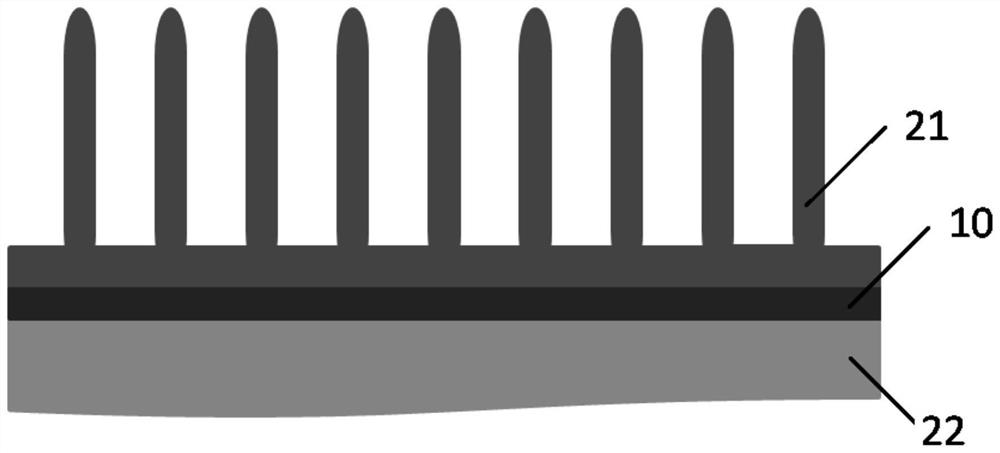

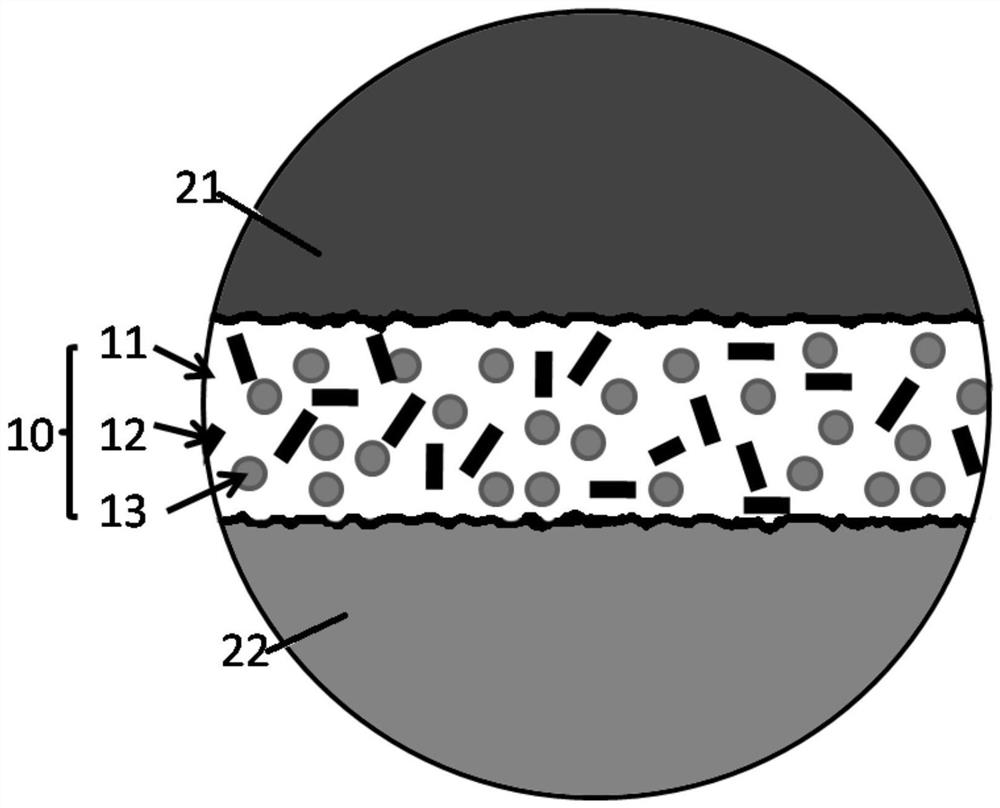

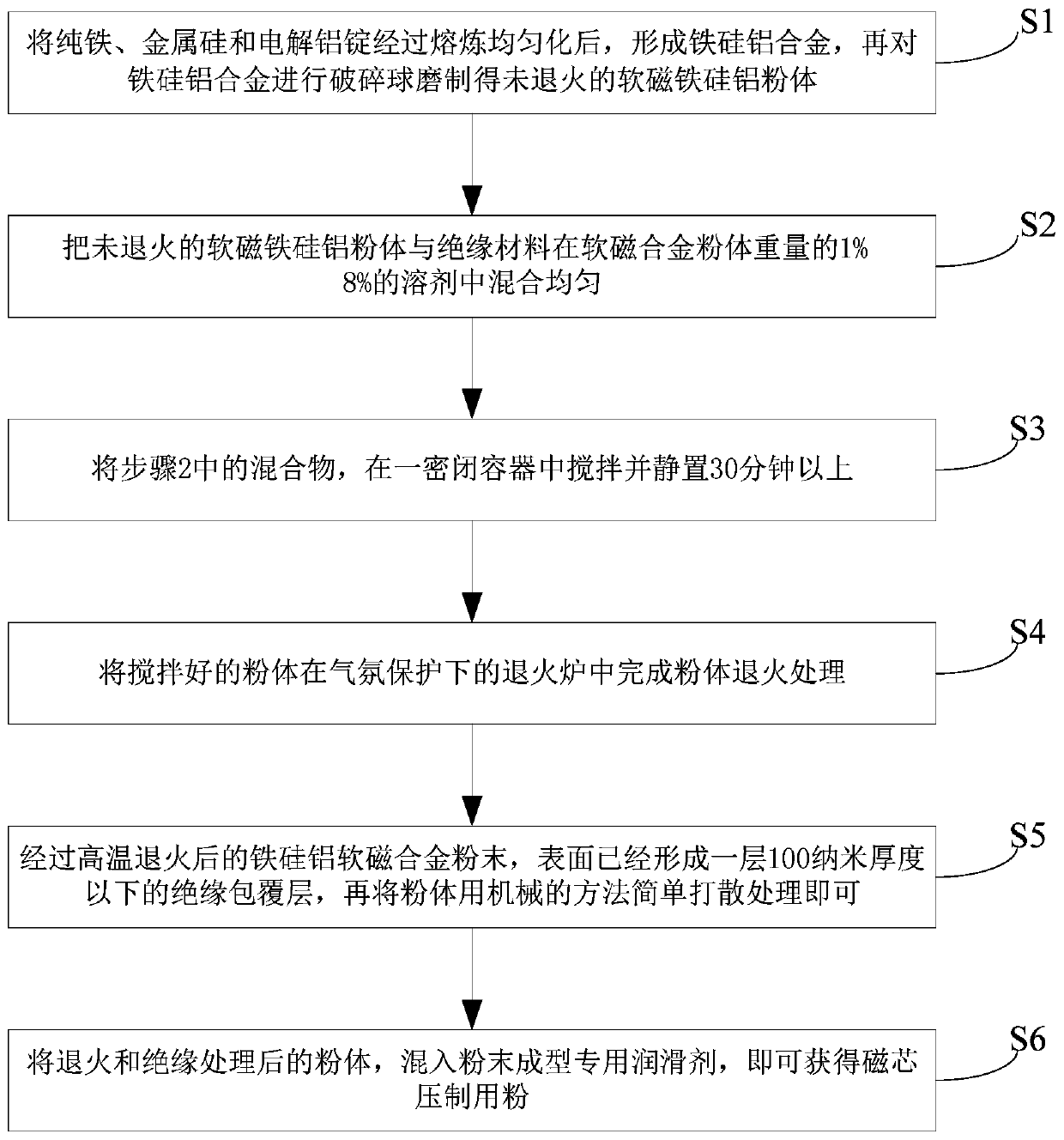

A method for insulating and wrapping FeSiAl soft magnetic alloy powder

ActiveCN108269670BHigh densityHigh saturation magnetic inductionTransportation and packagingMetal-working apparatusAl powderSoft magnet

The invention discloses an insulating and wrapping treatment method of Fe-Si-Al soft magnetic alloy powder, which comprises the following steps: S1, after melting and homogenizing pure iron, metal silicon and electrolytic aluminum ingots, forming Fe-Si-Al alloy, and manufacturing Obtain non-annealed soft magnetic silicon-alumina powder; S2, mix the non-annealed soft magnetic silicon-alumina powder and insulating material in a solvent of 1%-8% of the weight of the soft magnetic alloy powder; S3, mix the mixture in Stir in a closed container and let it stand for more than 30 minutes; S4, complete the powder annealing treatment in the annealing furnace under the protection of the atmosphere; S5, the sendust soft magnetic alloy powder after high temperature annealing, the surface An insulating coating layer with a thickness of less than 100 nanometers has been formed; step 6, mixing the annealed and insulating powder with a special lubricant for powder molding. The high-temperature annealing and insulating coating integrated method adopted in the present invention reduces a powder drying process, avoids the insulating coating drying process, and improves production efficiency.

Owner:广东美瑞克微金属磁电科技有限公司

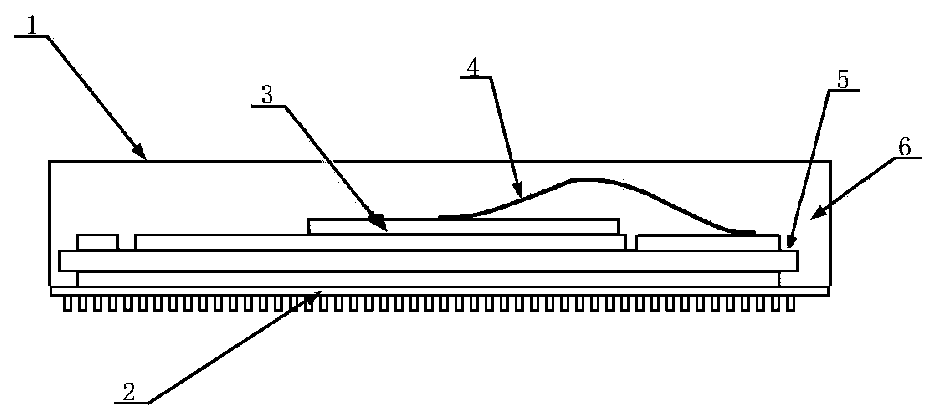

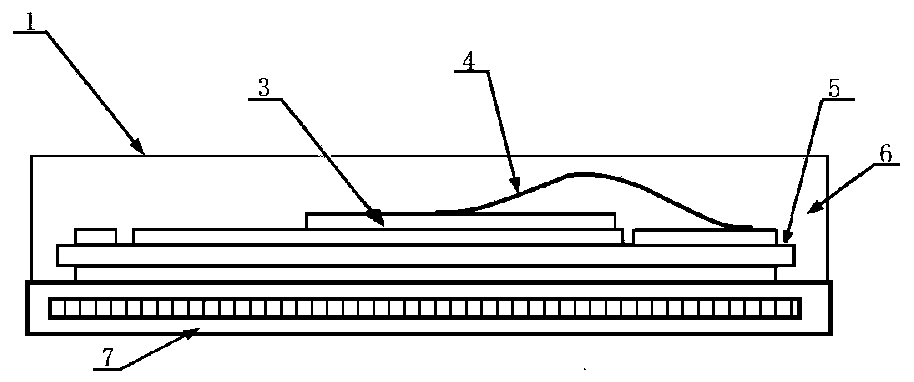

A power semiconductor module packaging structure and packaging method

ActiveCN108493166BReduce thermal resistanceReduce distortionSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingHeat conducting

The invention relates to a power semiconductor module packaging structure and a packaging method thereof. A resin or other curable material is injected into a gap of a specially processed metal circuit layer and then solidification is carried out; the metal circuit layer and a heat-conducting insulating resin film are pressed on a metal bottom plate; and bubbles in the gap of the metal circuit layer and in the heat-conducting insulating resin film are removed and solidified by using the solidified material, so that the insulation property is ensured. Or bubbles in the heat-conducting insulating resin film are removed and solidified by using the solidification process of the plastic-packaging resin in the plastic-packaging process, so that the insulation property is ensured. Therefore, themetal circuit layer with the small gap and the large thickness can be formed on the heat-conducting insulating resin film even when a Pinfin metal bottom plate, a metal bottom plate with one side being a non-plane surface, or a metal bottom plate with a water-cooled flow path inside. The module based on the structure has advantages of low thermal resistance, small deformation and high reliability.

Owner:WUXI LEAPERS SEMICON CO LTD

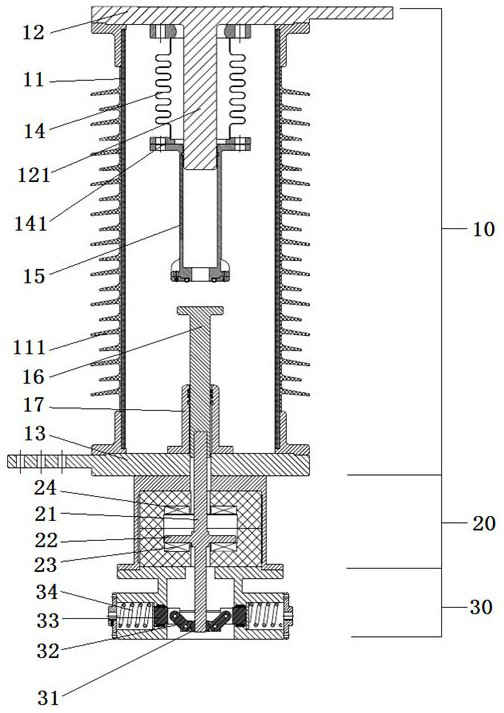

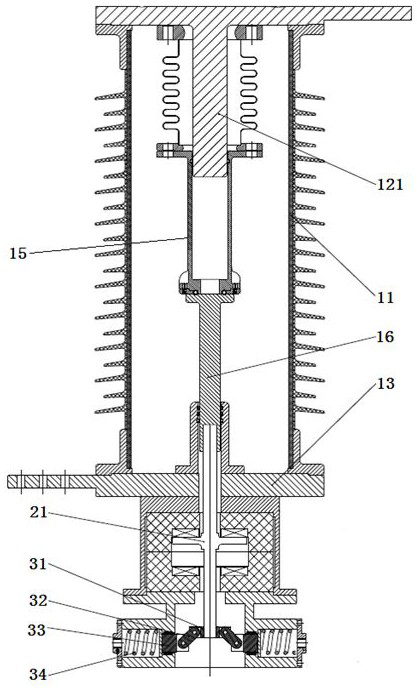

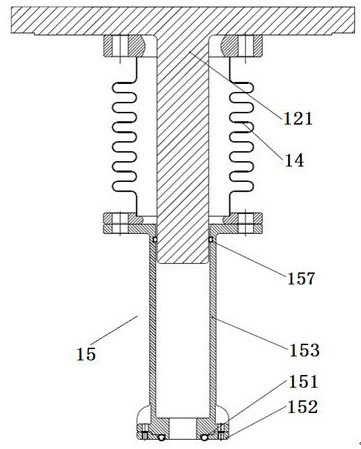

Vacuum circuit breaker and supporting conductor structure thereof

PendingCN113745043AImprove heat transfer effectReduce the temperatureHigh-tension/heavy-dress switchesAir-break switchesElectrical conductorEngineering

The invention belongs to the technical field of vacuum switches, and relates to a vacuum circuit breaker and a supporting conductor structure thereof. The supporting conductor structure comprises a conductive supporting cylinder and a lower conductive seat arranged at the bottom of the conductive supporting cylinder, wherein the conductive supporting cylinder is used for being conductively connected with a moving end conductive rod; cooling fins are arranged on the outer portion of the conductive supporting cylinder so that heat on the conductive supporting cylinder can be conducted out. After the cooling fins are added, the heat dissipation area can be increased, the natural heat exchange capacity and the radiation heat exchange capacity between the conductive supporting cylinder and the outside are improved, and heat on the conductive supporting cylinder can be rapidly conducted out, and the conductive supporting cylinder is connected with moving and static contacts, so that the temperature of the moving and static contacts can be reduced after heat on the conductive supporting cylinder is conducted out, plastic deformation of the moving and static contacts in the opening and closing process is avoided, and the mechanical characteristic and the insulation characteristic of a vacuum arc-extinguishing chamber are ensured.

Owner:PINGGAO GRP +1

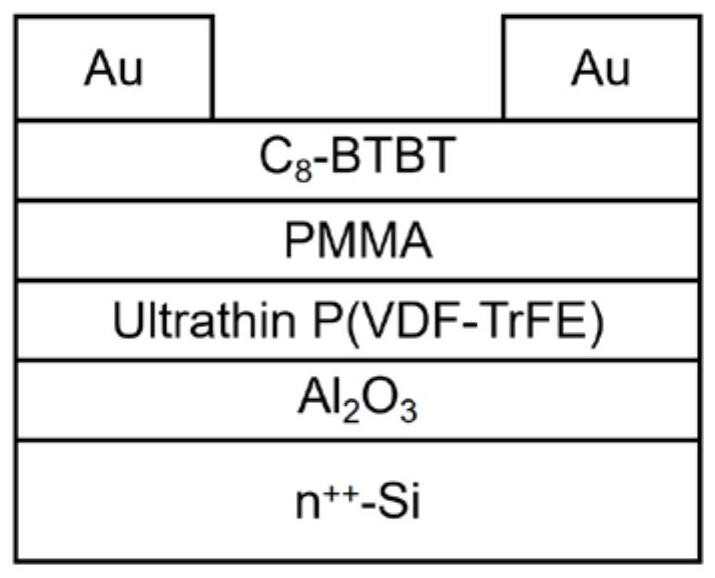

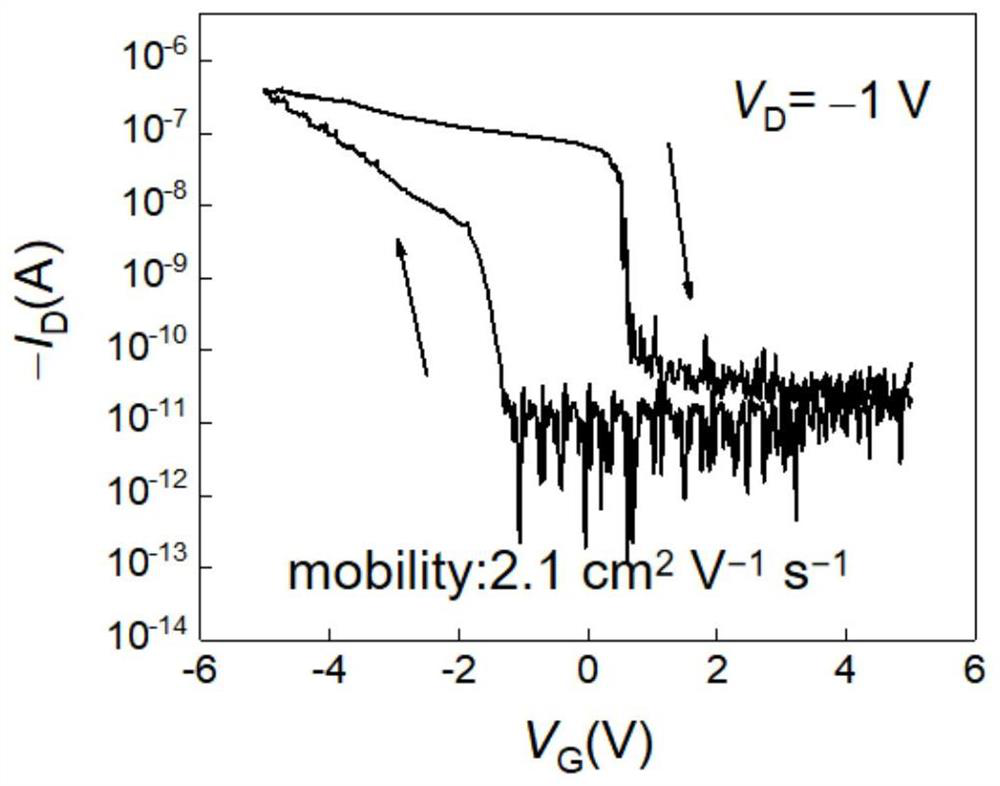

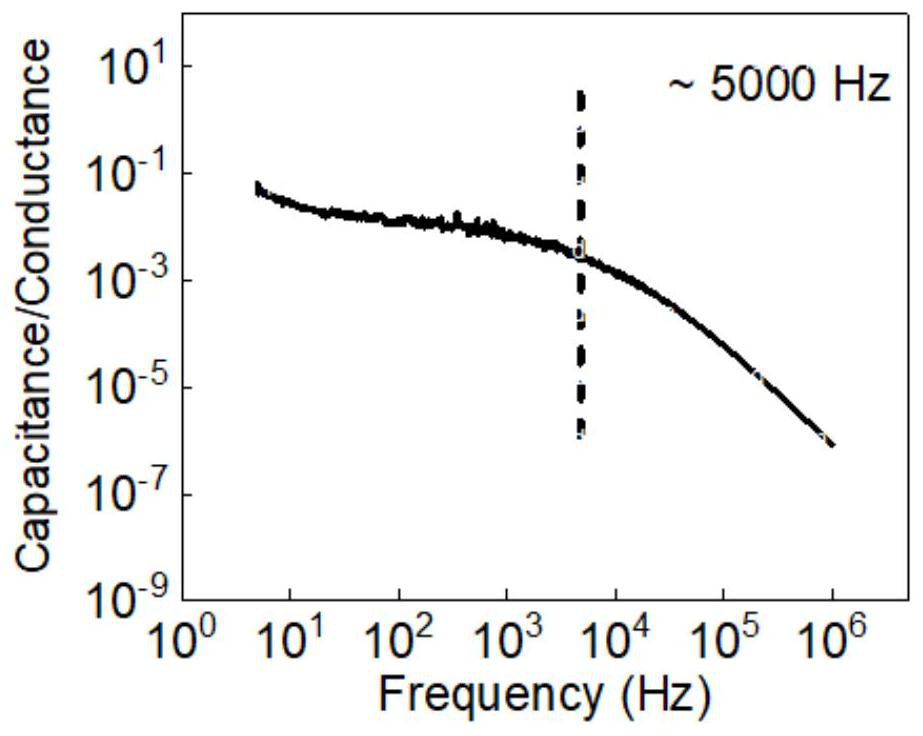

Ultra-low power consumption ferroelectric transistor memory based on two-dimensional organic functional materials and its preparation method

ActiveCN110047996BSimple deposition processGood workmanshipSolid-state devicesSemiconductor/solid-state device manufacturingOrganic field-effect transistorPolymethyl methacrylate

The invention discloses an ultra-low power consumption ferroelectric transistor memory based on a two-dimensional organic functional material and a preparation method thereof. An aluminum oxide insulating layer is grown on a substrate by an atomic beam deposition method, and then an antisolvent is used to An ultrathin crystalline ferroelectric polymer film was prepared at room temperature by assisted crystallization, and then an ultrathin layer of polymethyl methacrylate and an ultrathin layer of dioctyl Dioctylbenzothiophene benzothiophene, and finally a gold film was transferred onto the dioctylbenzothiophene benzothiophene layer as source and drain electrodes using a non-invasive gold film transfer process. The present invention uses the quasi-two-dimensional ferroelectric polymer crystalline film as the dielectric layer and the two-dimensional organic molecular crystal C 8 ‑BTBT material is used as a semiconductor layer to prepare fast transistor memory, which can greatly reduce the power consumption of ferroelectric organic field effect transistor memory, and has low-voltage operation capability and fast storage capability.

Owner:NANJING UNIV

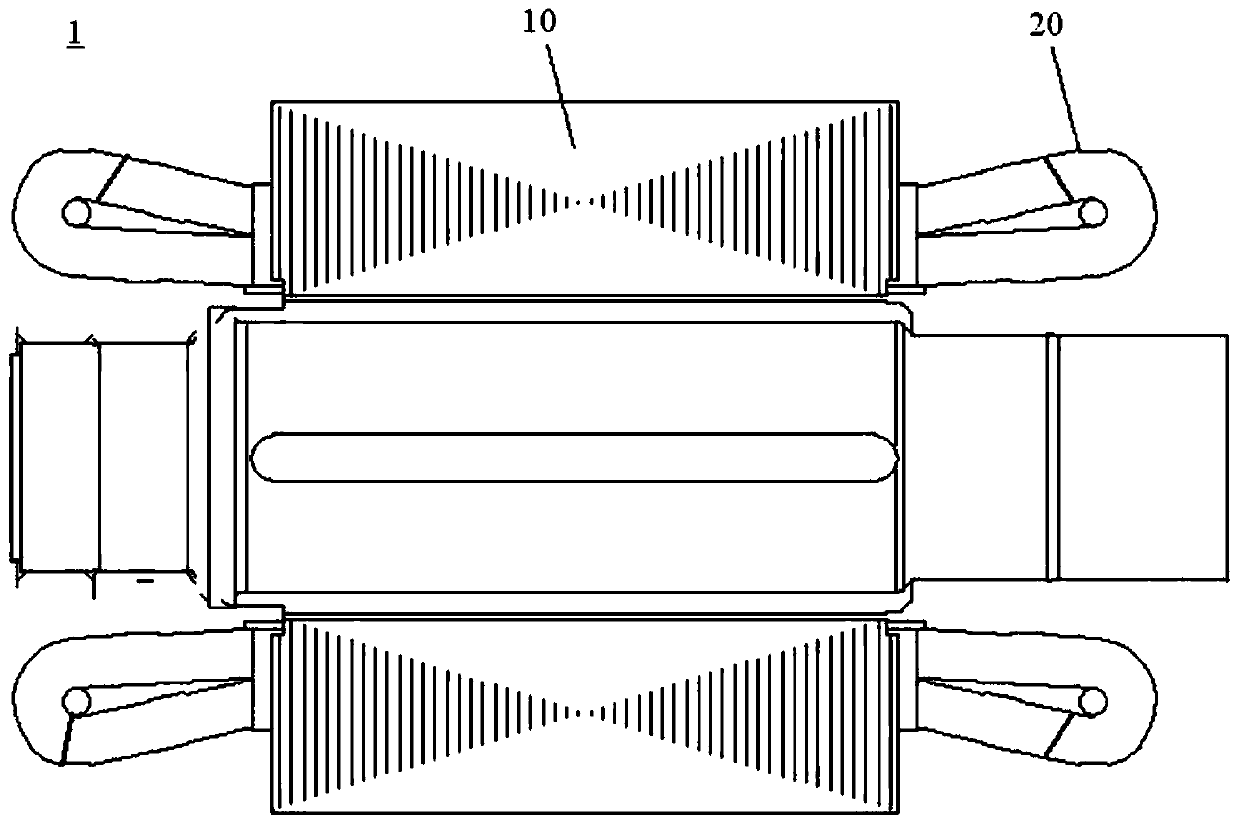

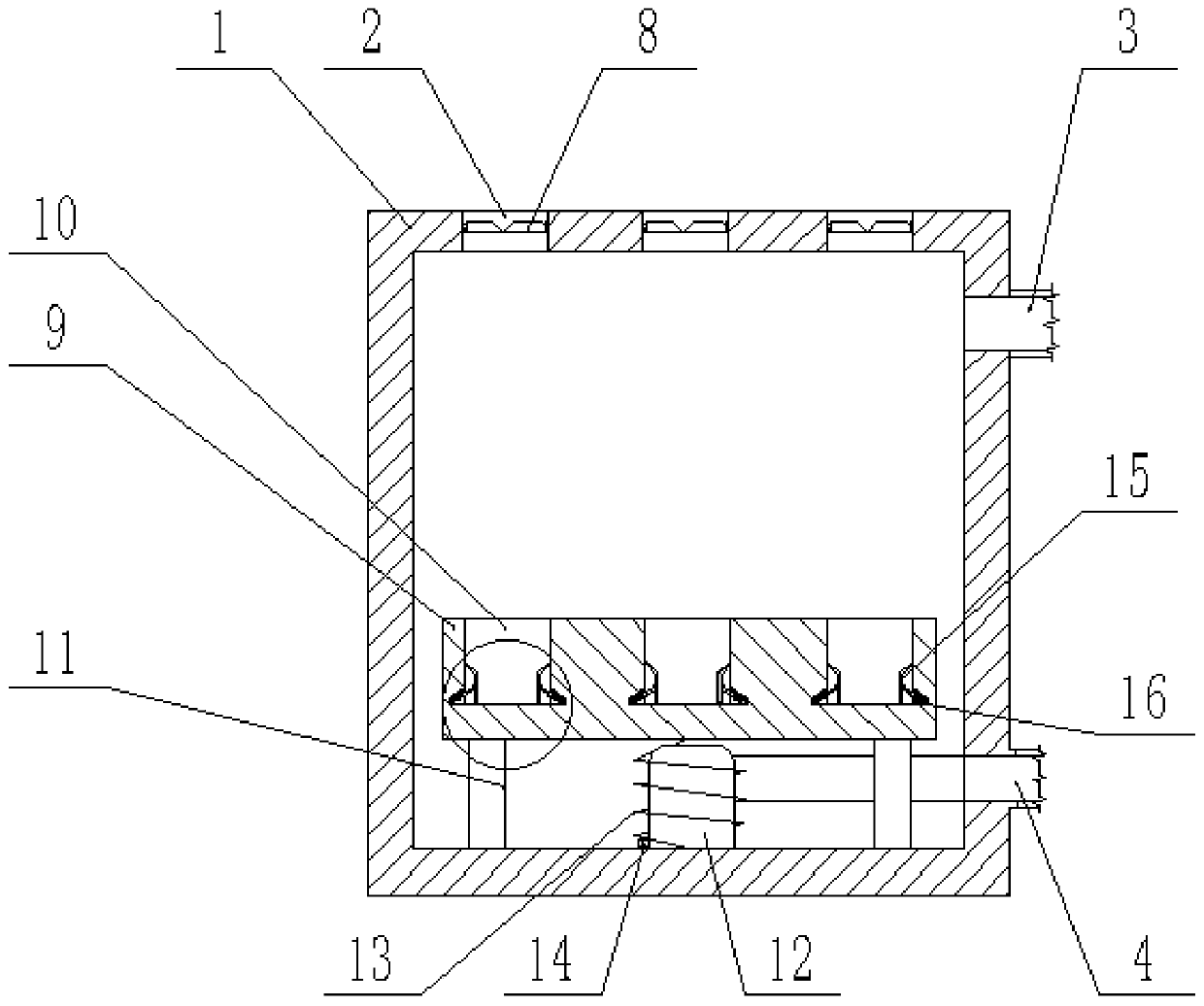

Motor manufacturing method and motor

ActiveCN107769494AImprove reliabilityGuaranteed insulation propertiesApplying solid insulationMechanical engineeringStator

The invention relates to a motor manufacturing method and a motor. The motor comprises a cylindrical stator core and a coil. The stator core is internally provided with a containing cavity. The motormanufacturing method comprises the following steps of placing the coil in the containing cavity so as to enable the coil to form a containing part contained in the containing cavity and an extending part configured to extend out of the containing cavity from the two sides of the stator iron core in the axial direction of the stator iron core; and an extending part pouring and sealing die arrangedon the outer side of the extending part in a sleeved mode and provided with an inner cavity. A containing part pouring and sealing die provided with an inner cavity is arranged in the containing cavity in a sleeved mode. The containing part is contained in the containing part pouring and sealing die. The pouring and sealing fluid is poured into the interior of the containing part pouring and sealing die and the interior of the extending part pouring and sealing die. When the pouring and sealing fluid is solidified, the containing part pouring and sealing die and the extending part pouring andsealing die are disassembled. The motor manufactured by the method is relatively high in reliability.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

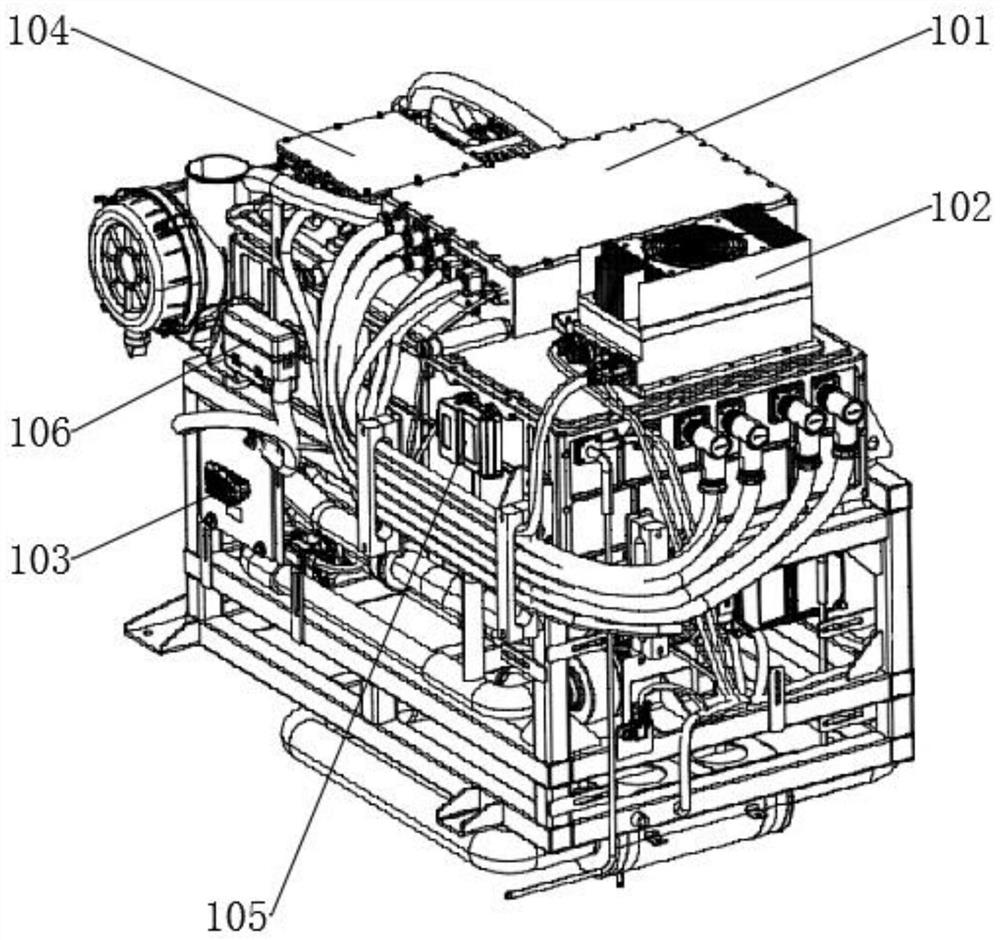

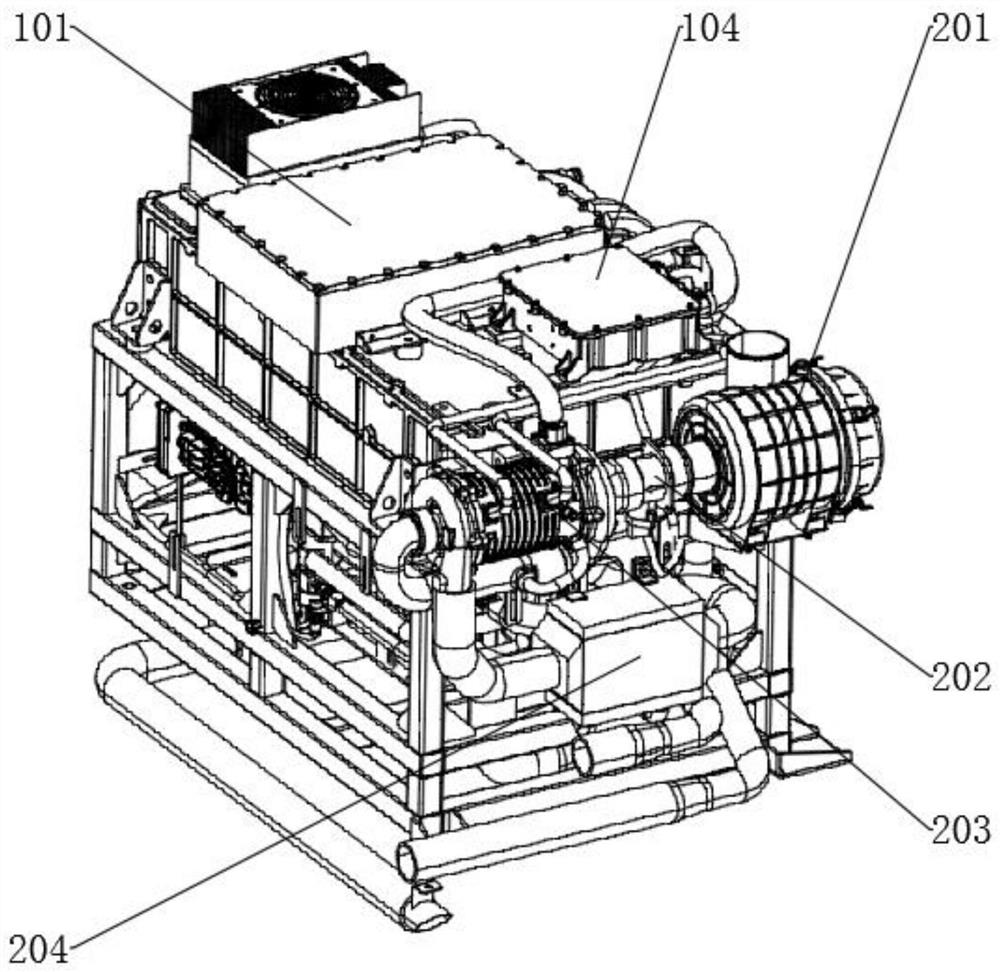

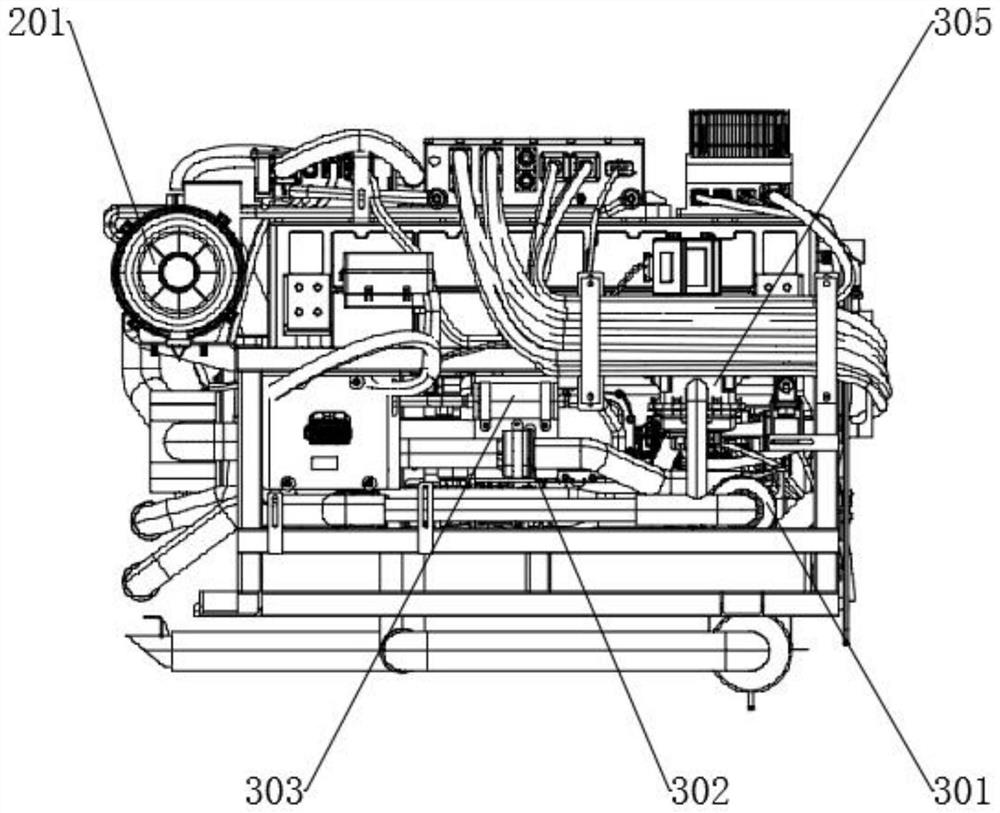

Commercial vehicle fuel cell system

PendingCN113517464AGuaranteed insulation propertiesPlay a supporting roleFuel cell heat exchangeReactant parameters controlFuel cellsNew energy

The invention discloses a commercial vehicle fuel cell system, and relates to the field of new energy vehicles. The problem that an existing system is low in integration degree and space utilization rate is solved. The system specifically comprises an integrated frame and an electric pile module. The outer wall of the top of the integrated frame is fixedly connected with a key component mechanism. The key component mechanism comprises an air treatment assembly, a hydrogen treatment assembly and a cooling assembly. The outer wall of the top of the key component mechanism is fixedly connected with a fuel cell assembly, and the top outer wall of the fuel cell assembly is fixedly connected with an electrical assembly. According to the fuel cell system, as a main framework of the system, the integrated frame is arranged and can achieve a supporting effect and fix the whole fuel cell system, and related elements can be fixed and disassembled in a detachable mode, so that assembly and maintenance of the system are greatly facilitated; and related parts can be arranged around the integrated frame, so that the integration level and the space utilization rate are improved.

Owner:重庆明天氢能科技有限公司

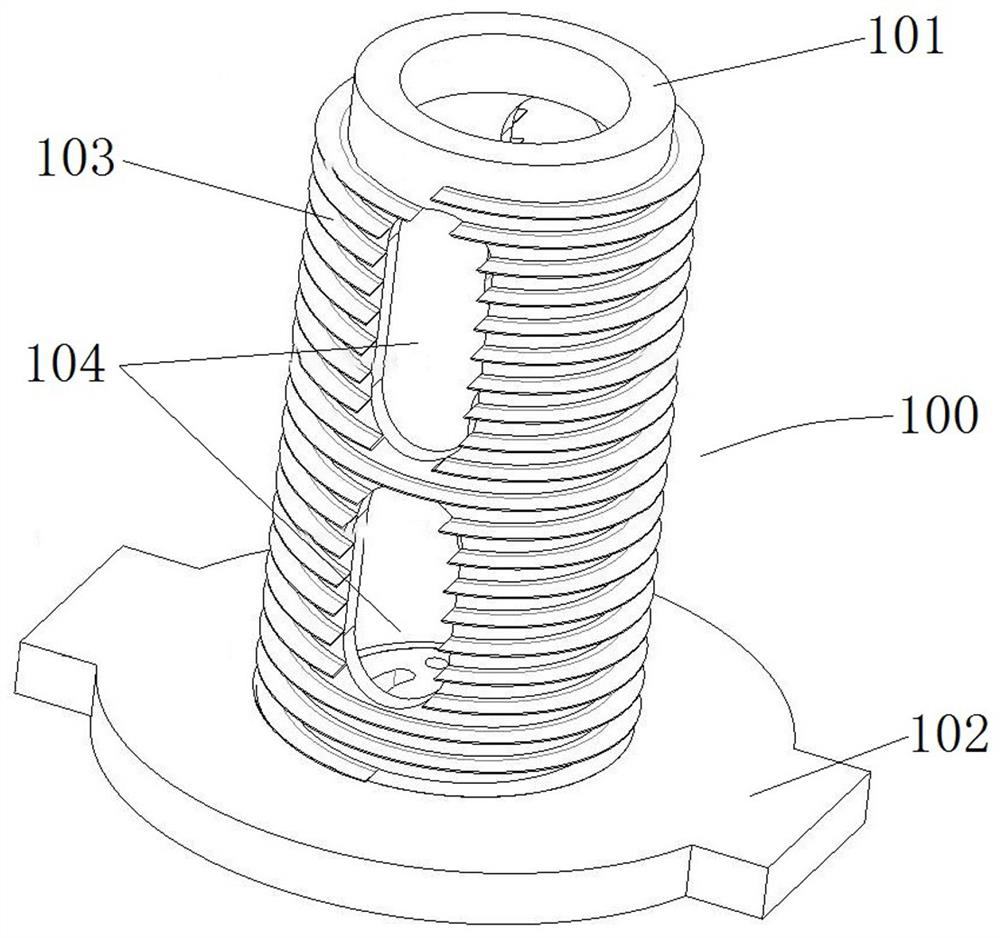

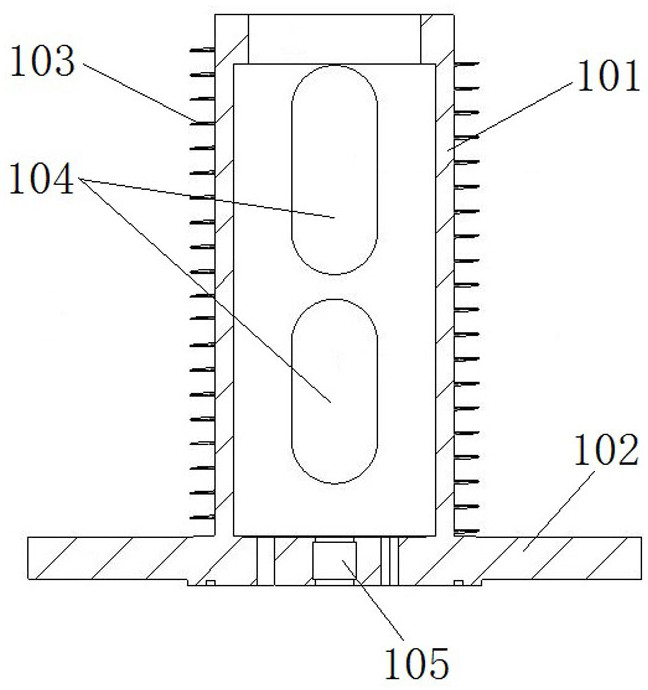

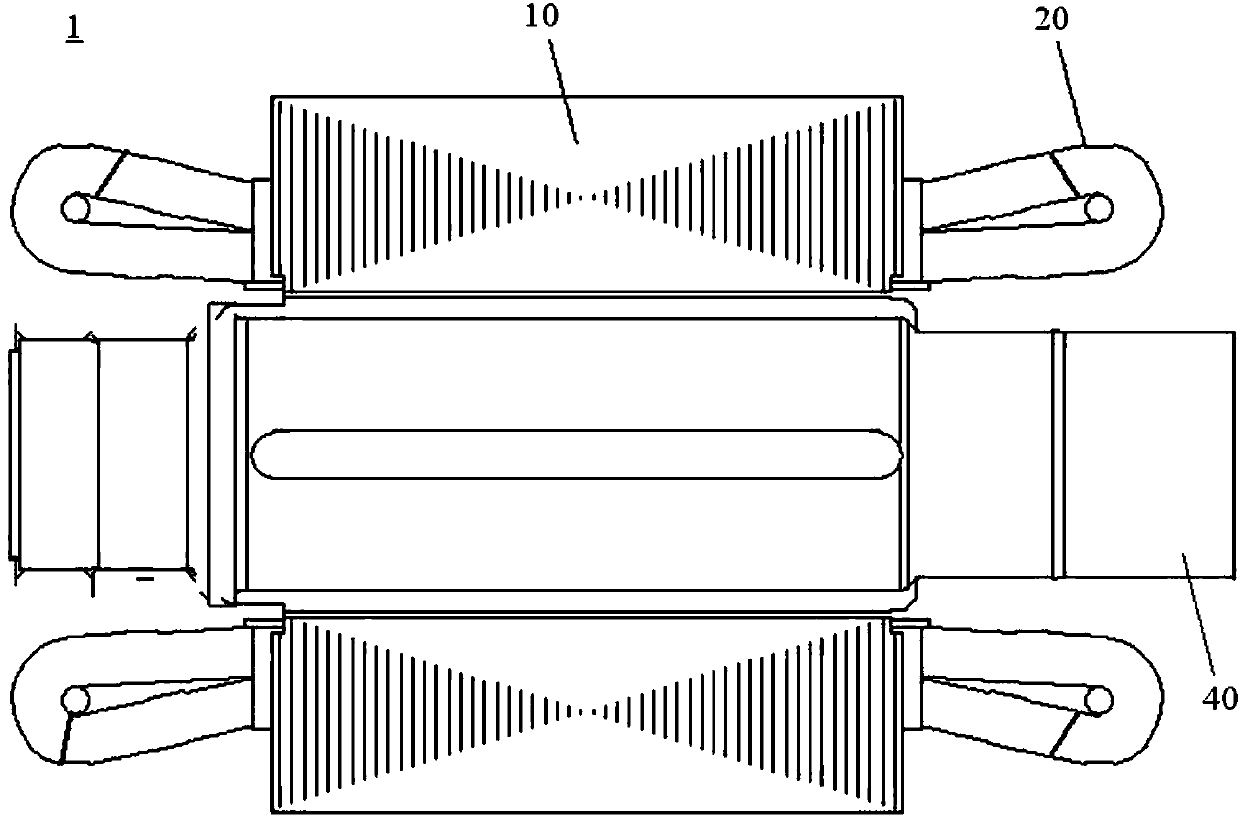

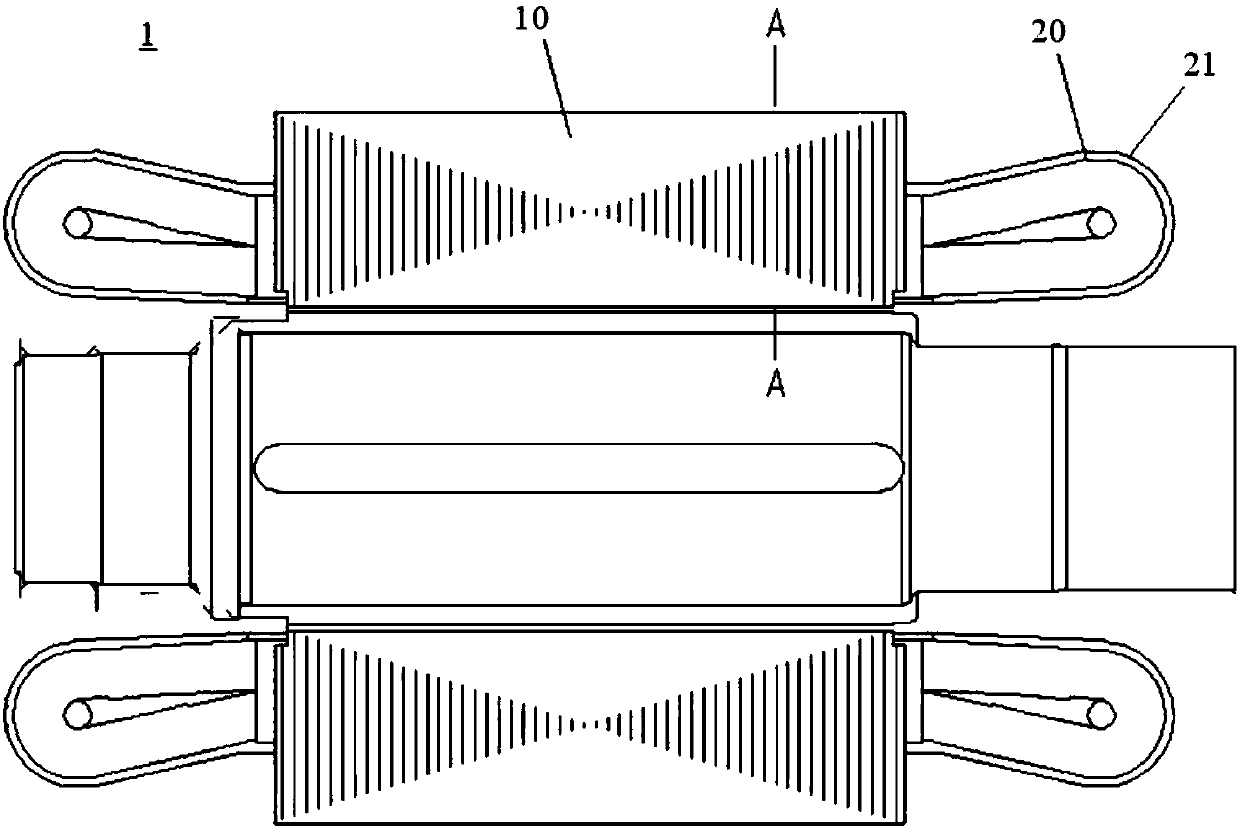

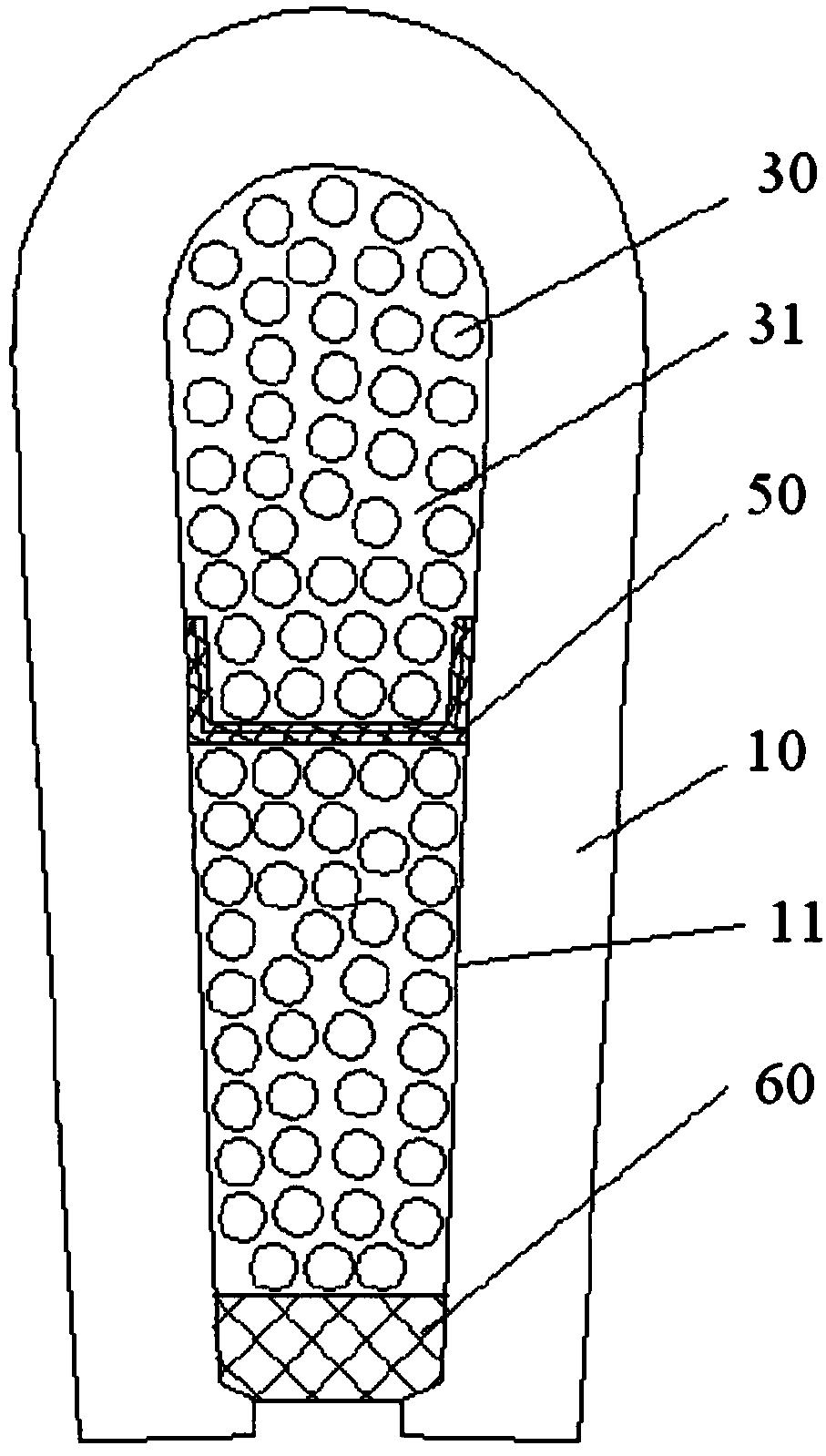

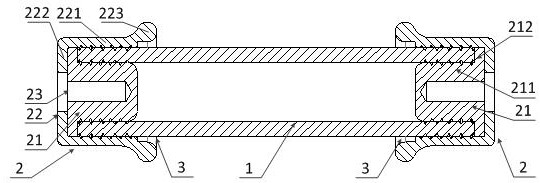

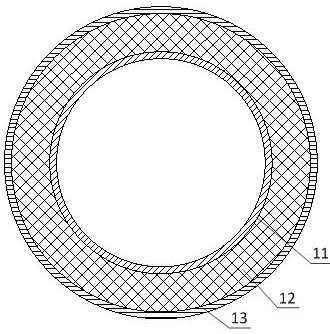

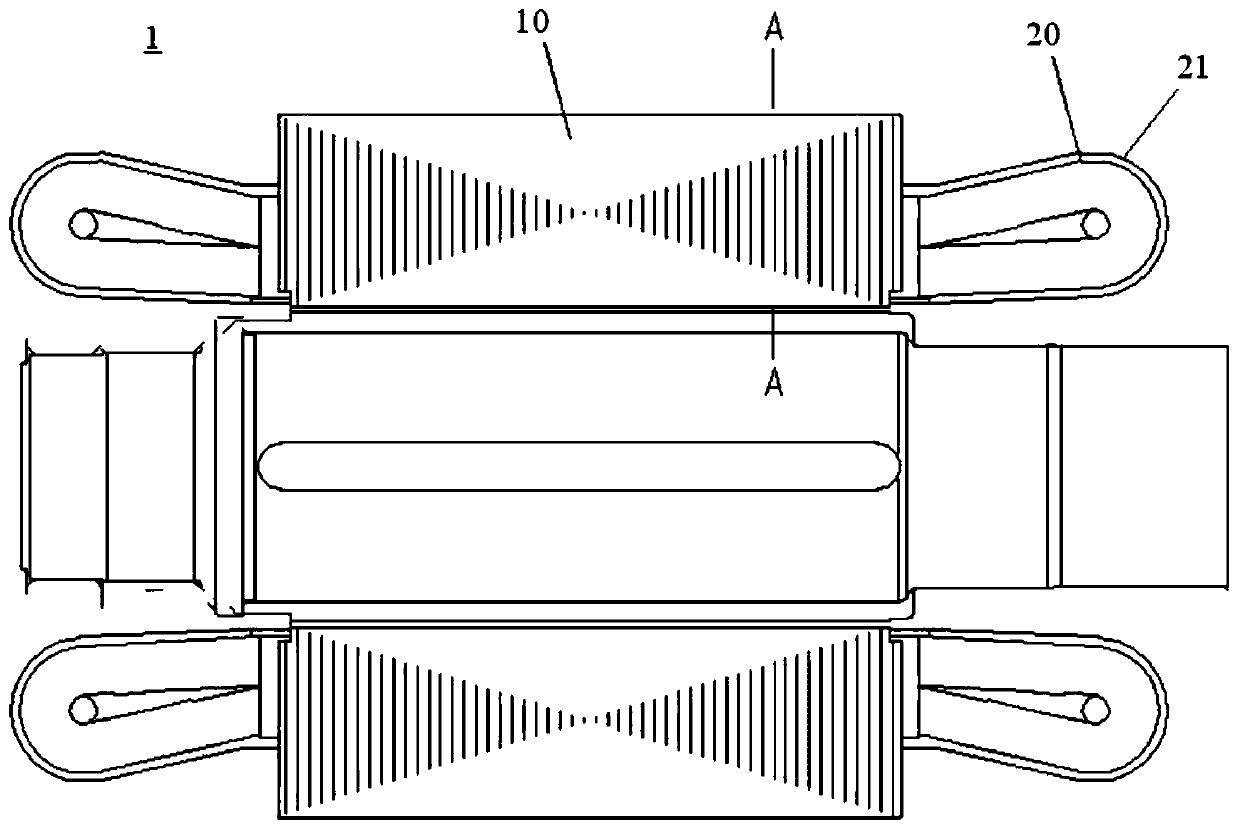

Insulating pull rod for high-voltage switchgear

PendingCN112735868AEnsure electric field uniformityGuaranteed insulation propertiesContact operating partsInsulating bodiesStructural engineeringSwitchgear

The invention provides an insulating pull rod for high-voltage switchgear. The insulating pull rod comprises an insulating tube body and two metal joints; the two ends of the insulating tube body are respectively inserted into the two metal joints, and an annular shielding gap is formed between each metal joint and the insulating tube body at the periphery of the insulating tube body and is used for shielding discharge between the insulating tube body and the metal joints. According to the insulating pull rod, the annular shielding gaps are formed between the metal joints and the insulating tube body and at the periphery of the insulating tube body, so that the discharge between the insulating tube body and the metal joints is shielded, and the partial discharge of the insulating pull rod, especially the joint of the metal joint and the insulating tube body, is avoided; therefore, the electric field uniformity of the insulating pull rod is ensured, the insulating property of the insulating pull rod is further ensured, and the insulating pull rod can work safely and reliably.

Owner:CHINA ELECTRIC POWER RES INST +3

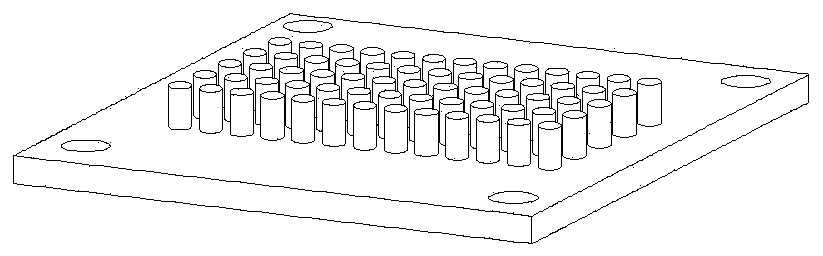

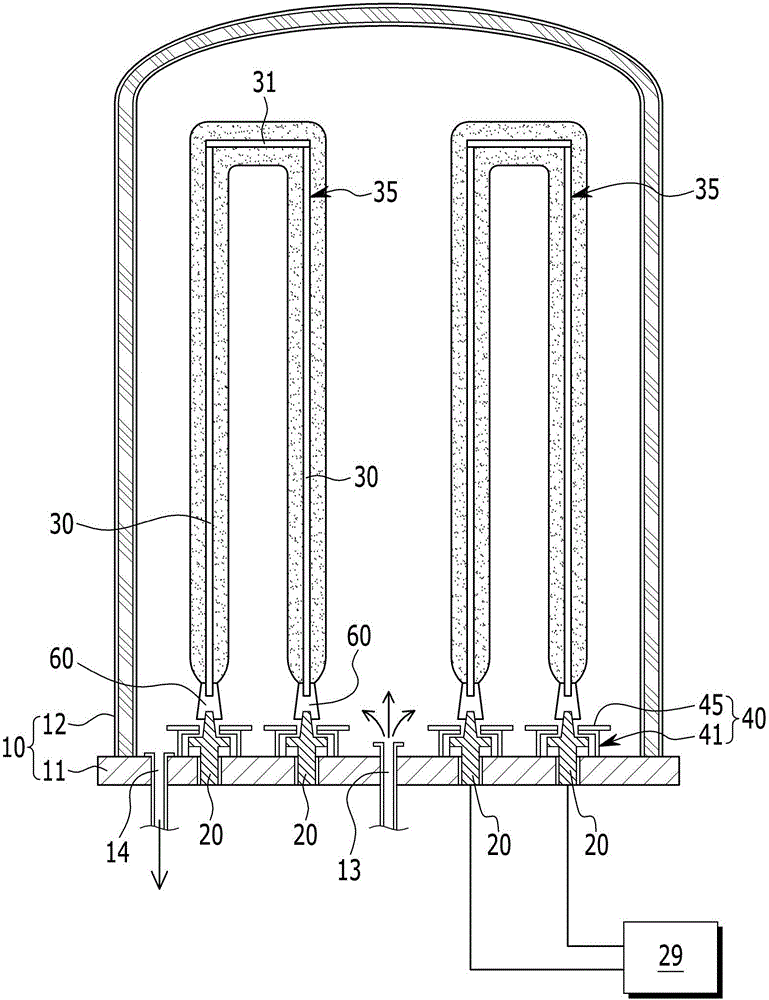

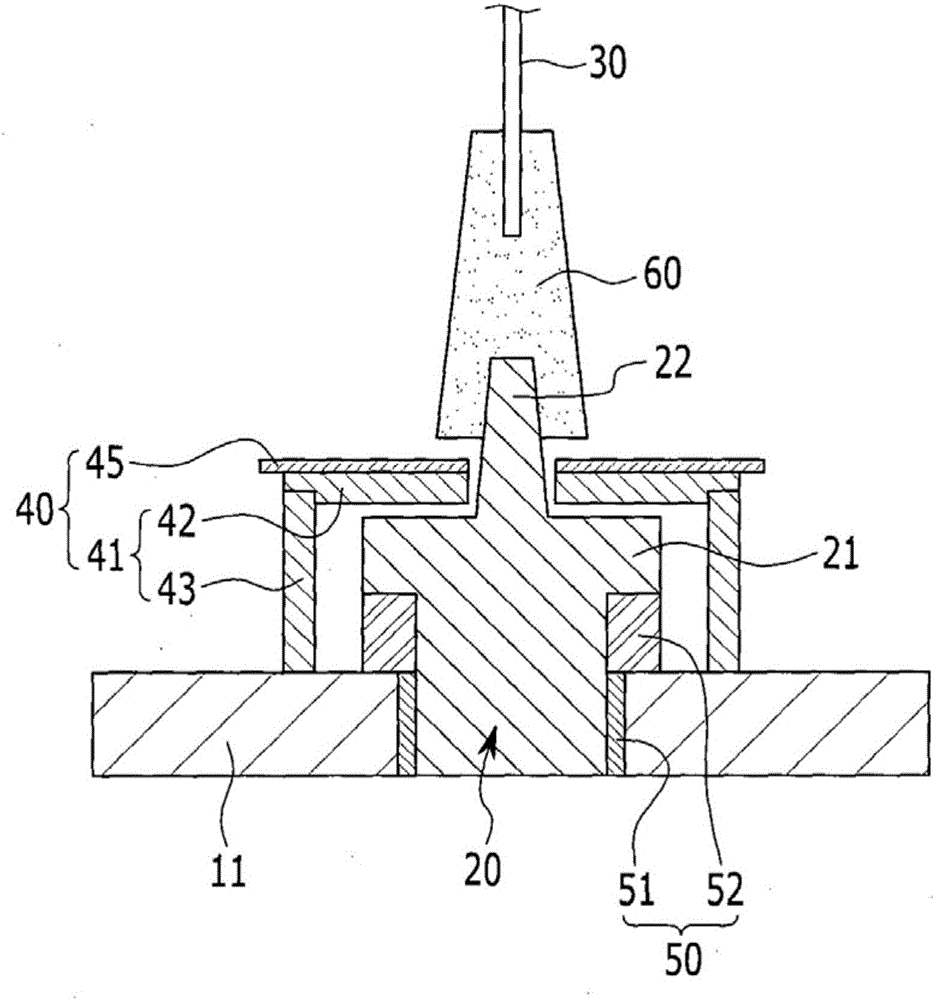

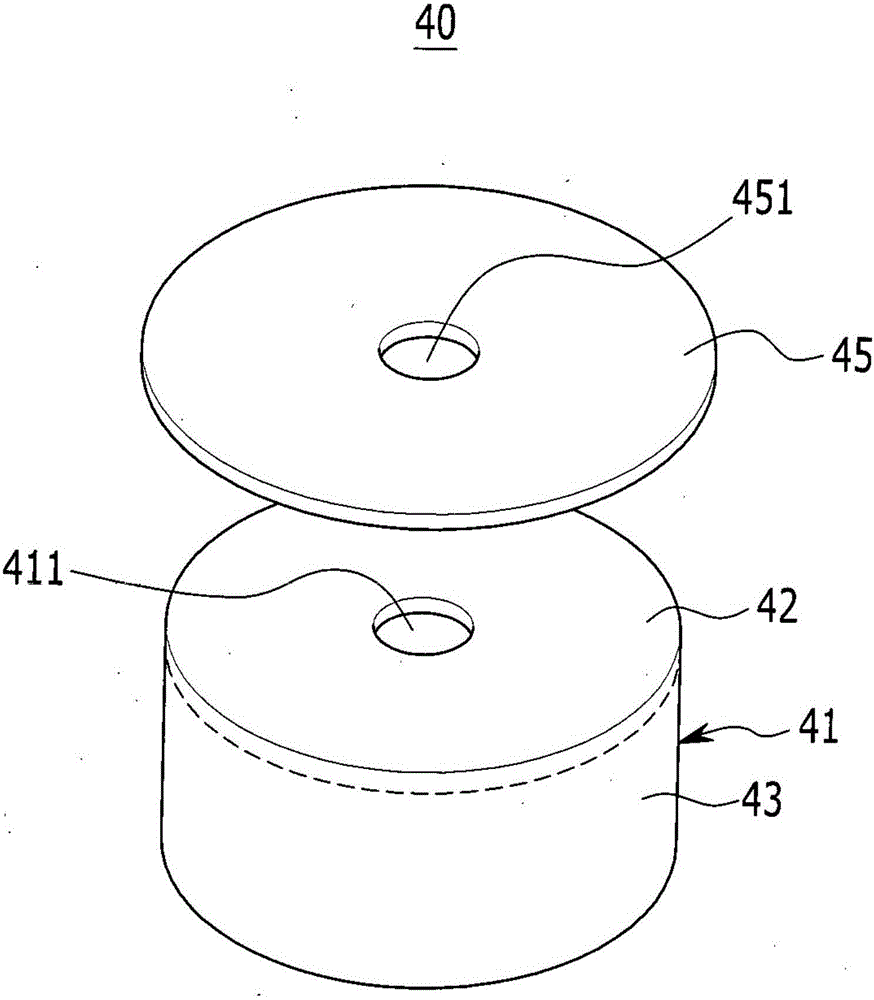

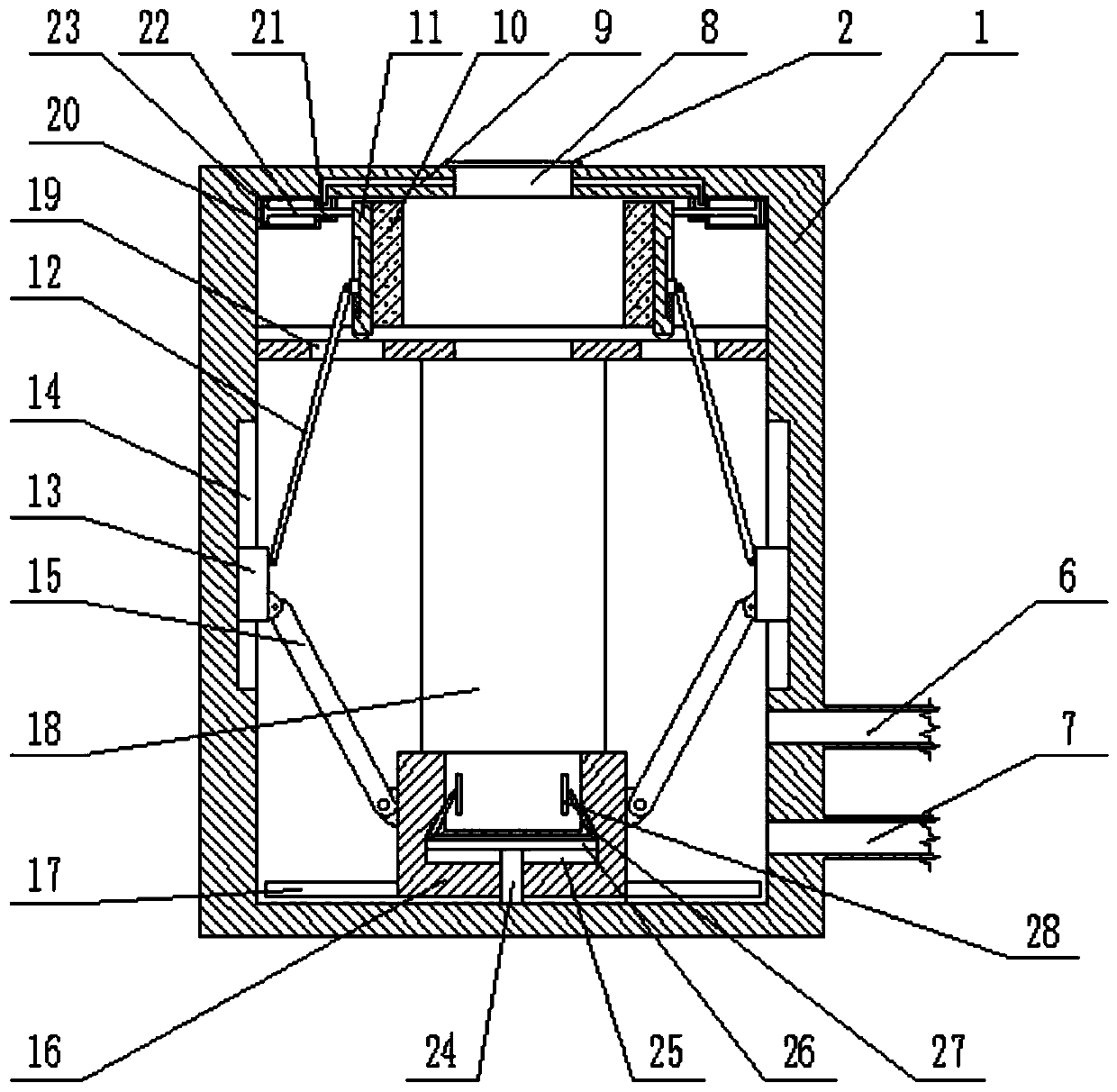

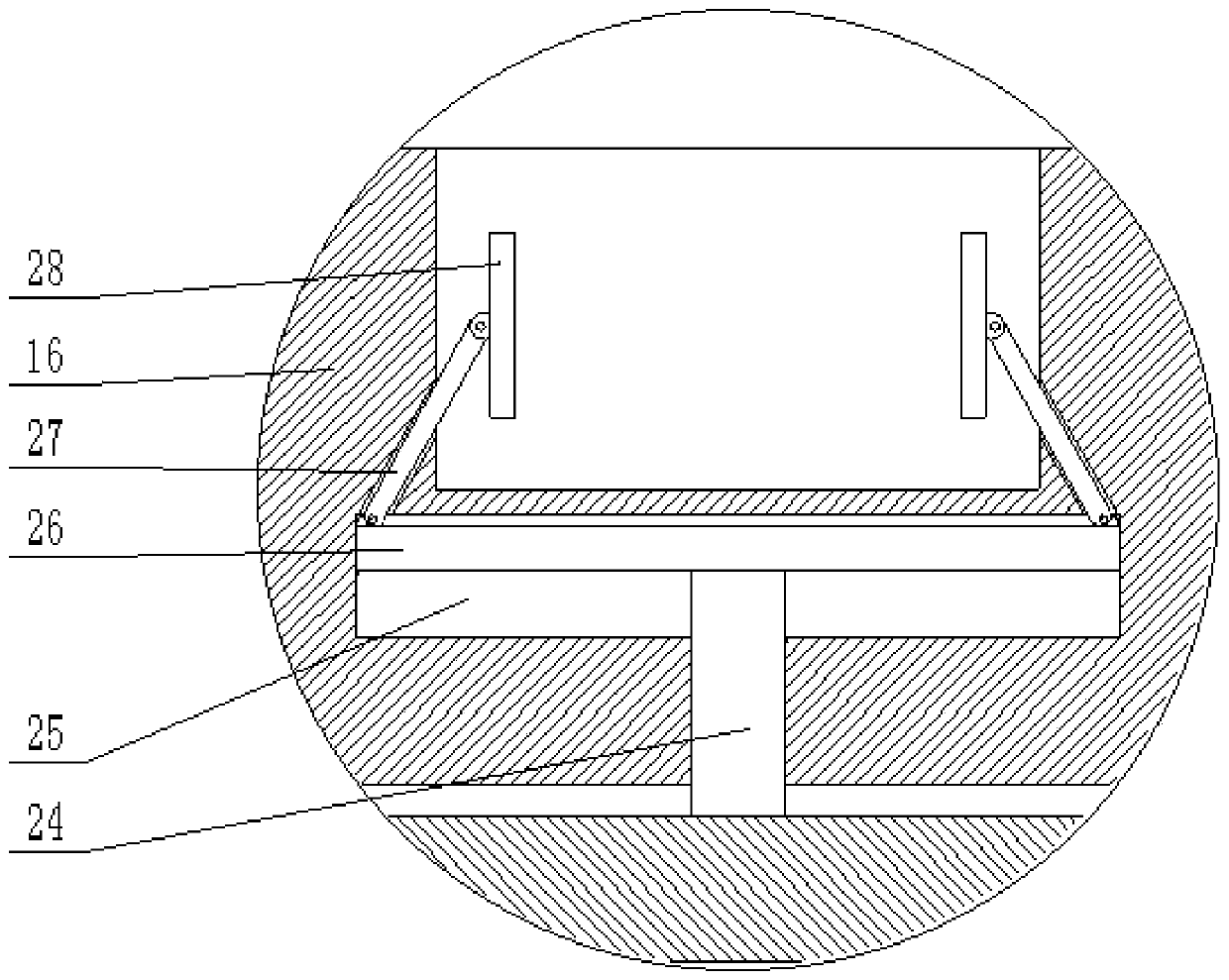

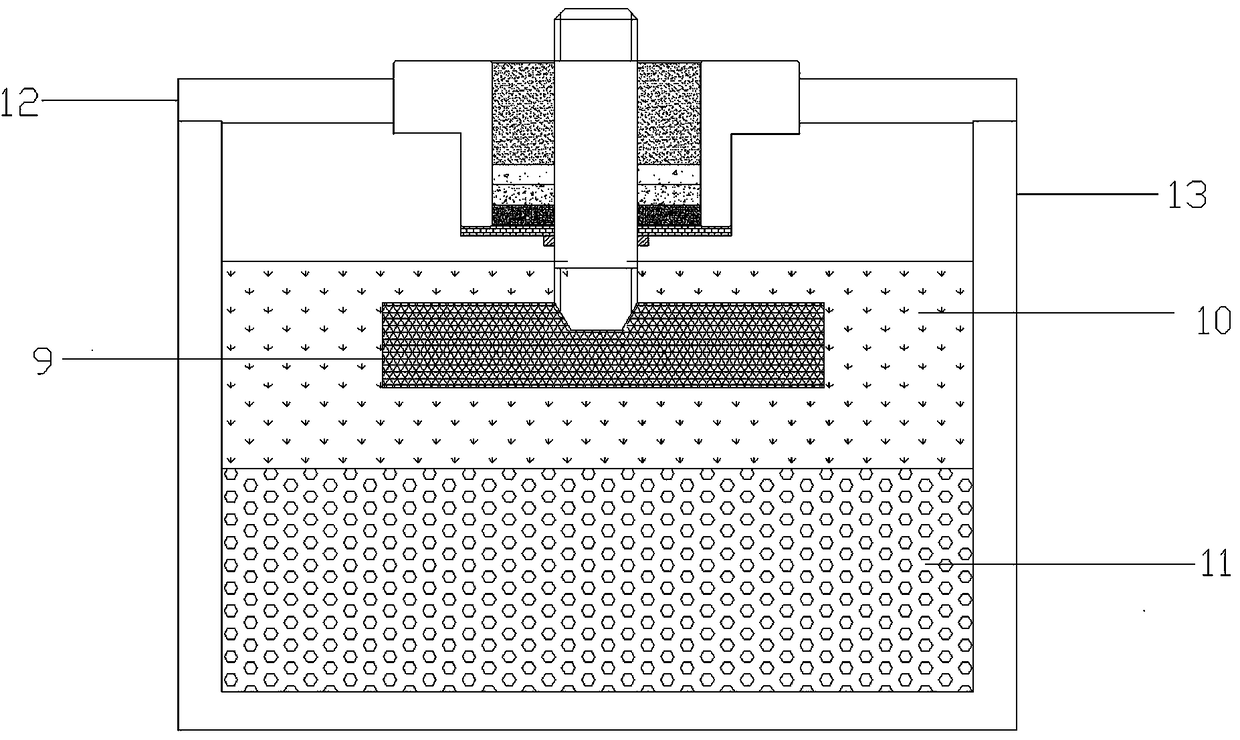

Apparatus for manufacturing polysilicon

ActiveCN105848774AOmit cleaningGuaranteed insulation propertiesSilicon hydridesChemical/physical/physico-chemical stationary reactorsChemical vapor depositionReaction chamber

An apparatus for manufacturing polysilicon using a chemical vapor deposition (CVD) reactor is provided. The apparatus for manufacturing polysilicon includes: a reaction chamber including a substrate and a reactor cover; at least a pair of electrodes installed through the substrate by an insulating member and connected with a power supply; at least a pair of filaments which are coupled with the pair of electrodes by an electrode chuck and of which upper ends are connected to each other; and a cover assembly including an electrode cover surrounding an upper surface and a side of each of the pair of electrodes on the substrate and a cover shield covering the upper surface of the electrode cover.

Owner:HANWHA CHEMICAL CORPORATION

Motor manufacturing method and motor

ActiveCN107769494BImprove reliabilityGuaranteed insulation propertiesApplying solid insulationEngineeringMechanical engineering

The invention relates to a motor manufacturing method and a motor. The motor comprises a cylindrical stator core and a coil. The stator core is internally provided with a containing cavity. The motormanufacturing method comprises the following steps of placing the coil in the containing cavity so as to enable the coil to form a containing part contained in the containing cavity and an extending part configured to extend out of the containing cavity from the two sides of the stator iron core in the axial direction of the stator iron core; and an extending part pouring and sealing die arrangedon the outer side of the extending part in a sleeved mode and provided with an inner cavity. A containing part pouring and sealing die provided with an inner cavity is arranged in the containing cavity in a sleeved mode. The containing part is contained in the containing part pouring and sealing die. The pouring and sealing fluid is poured into the interior of the containing part pouring and sealing die and the interior of the extending part pouring and sealing die. When the pouring and sealing fluid is solidified, the containing part pouring and sealing die and the extending part pouring andsealing die are disassembled. The motor manufactured by the method is relatively high in reliability.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

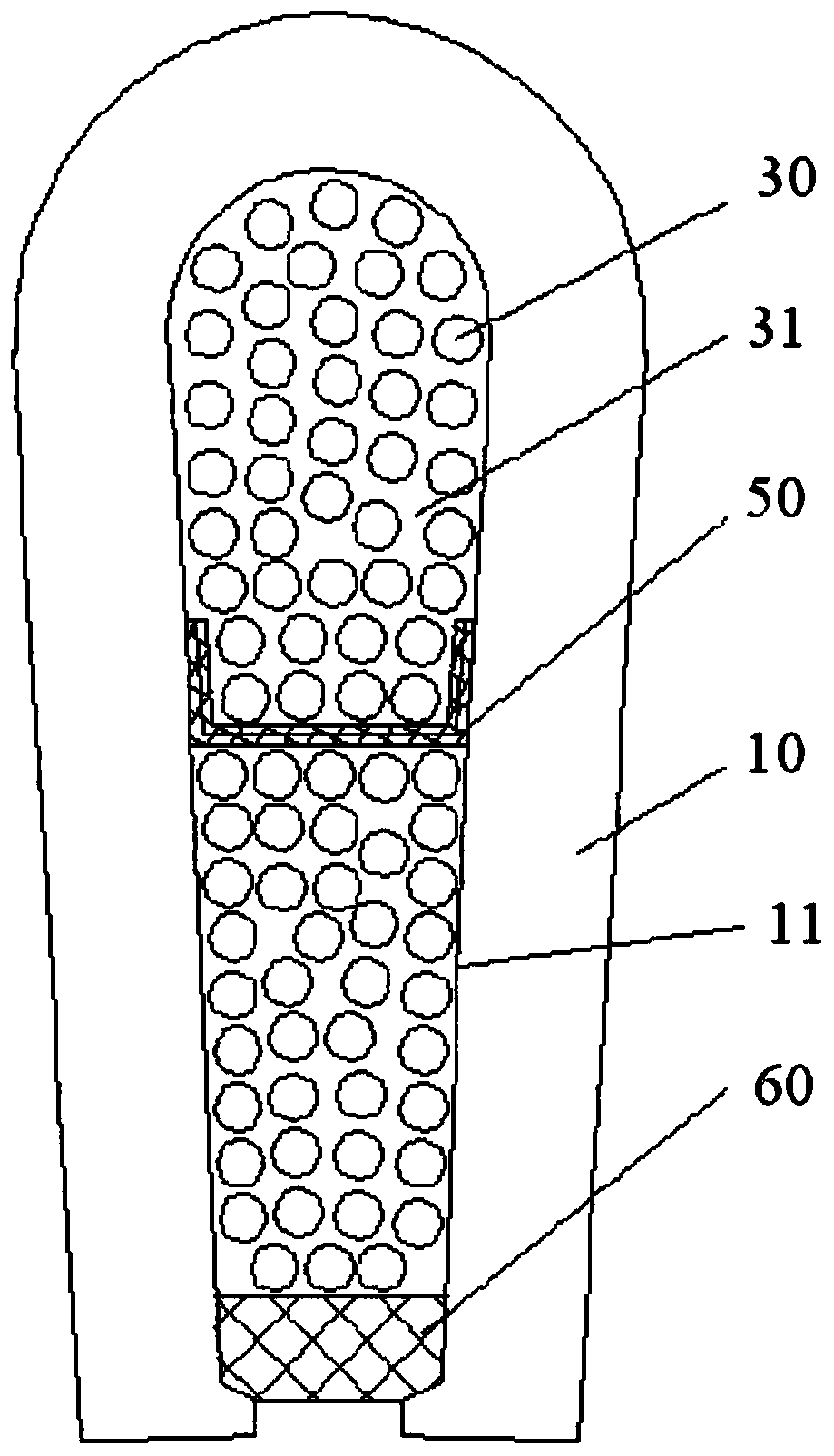

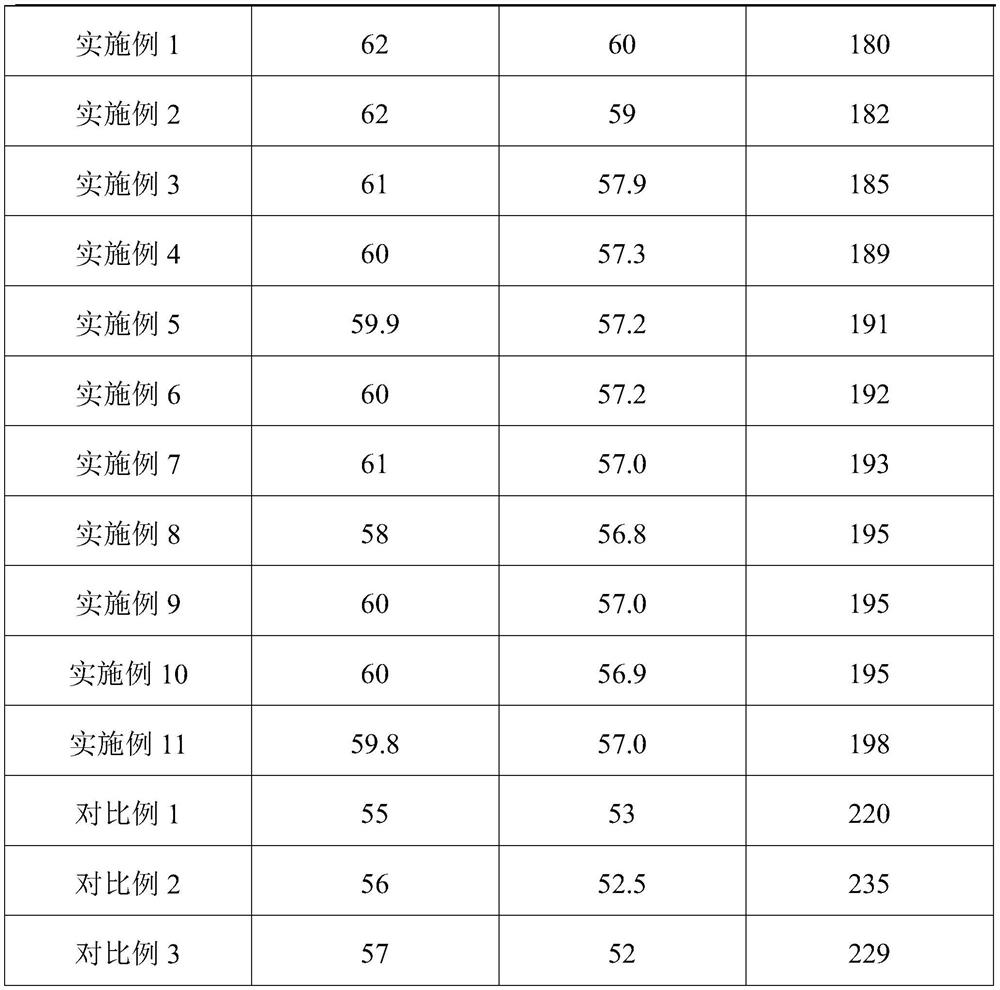

Metal magnetic powder core, preparation method and application thereof

PendingCN113744989AGuaranteed insulation propertiesImprove insulation performanceMagnetic core manufactureCores/yokesCompression moldingSurface reaction

The invention provides a metal magnetic powder core, a preparation method and application thereof. The preparation method comprises the steps that metal magnetic powder and a passivator are mixed to form slurry; after aluminum hydroxide gel and the slurry are mixed, drying and sieving are conducted in sequence; and mixing the lubricating powder with the sieved powder, carrying out compression molding, and then carrying out heating treatment to obtain the metal magnetic powder core. The method comprises the following steps: passivating the surfaces of metal magnetic powder particles by using a passivating agent, then adding aluminum hydroxide gel, and reacting the passivating agent and the aluminum hydroxide gel on the surfaces of the metal magnetic powder particles to generate an aluminum oxide insulating layer. The metal magnetic powder core provided by the invention has relatively good insulation effect and high temperature resistance, and the insulation effect among the metal magnetic powder particles is ensured, so that the eddy current loss is greatly reduced.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

A method of cooling servers through oil

ActiveCN108174583BSpeed up heat dissipationAffect normal operationHeat-exchange elementsCooling/ventilation/heating modificationsCarbon numberSide chain

The invention belongs to the technical field of special methods for cooling electric equipment, and specifically discloses a method for cooling a server through oil. The method comprises the followingsteps: (1) a cabinet and an oil circulation device are prepared, and oil raw materials, including insulating mineral oil and 2,6-di-tert-butyl-p-cresol, are prepared, wherein the carbon atoms on thealkyl side chain in the insulating ore oil account for 42-50% of the total molecular carbon number; (2) the oil raw materials prepared in step (1) are mixed to form oil; (3) a server is put in the cabinet, and the oil is put in the oil circulation device; and (4) the oil circulation device is started to make the oil enter the cabinet and go over the server, the oil absorbing heat is sucked by theoil circulation device and cooled and then enter the cabinet again, and the temperature of the cooled oil is between -10 DEG C and 20 DEG C. The invention aims to solve the problems in the prior art:the air flow carries and blows impurities into the server to cause dust accumulation during heat dissipation based on cold and hot air exchange, and the low thermal conductivity of air results in lowheat dissipation efficiency of the server.

Owner:中南信息科技(深圳)有限公司

Sealing structure for medium-high temperature battery, medium-high temperature battery and assembly method thereof

InactiveCN106159134BImprove sealingWide temperature rangeFinal product manufactureSecondary cellsEngineeringUltimate tensile strength

The invention relates to a sealing structure for a medium-high temperature battery, a medium-high temperature battery and an assembly method thereof. The sealing structure includes a metal piece for drawing current, and a closed cavity is provided inside the battery at the assembly gap where the metal piece is assembled on the battery to seal the assembly gap, and the metal piece passes through the closed cavity, and the closed cavity There are one layer, two layers, three layers or more than three layers of salt layers for liquid sealing inside, and the melting points of each salt layer decrease sequentially from the inner side of the battery to the outer side. The sealing structure of the present invention has excellent air-tightness and anti-corrosion performance, which guarantees the service life of the medium-high temperature battery when it works at 150-700°C, and also has insulation properties, which greatly reduces the mechanical strength under the condition of ensuring the mechanical strength. The volume occupied by the battery seal is reduced, saving space.

Owner:润高投资有限公司

A method for server cooling

ActiveCN108207105BGuaranteed stabilityFast coolingCooling/ventilation/heating modificationsHeat conductingLiquid surfaces

The invention belongs to the technical field of a special method for cooling electrical equipment, and specifically discloses a server cooling method. The server cooling method specifically comprisesthe following steps of 1, preparing hydrocarbon-based mineral oil, wherein the number of carbon atoms in the molecules of the hydrocarbon-based mineral oil is 17-23, and the molecular weight is 250-300, and preparing a sealed machine cabinet and an oil circulation apparatus; 2, placing a server into the machine cabinet; 3, pumping the hydrocarbon-based mineral oil into the machine cabinet until the server is immersed below the liquid surface, and performing sealing on the machine cabinet; 4, extracting high-temperature oil from the machine cabinet through the oil circulation apparatus, then cooling the oil circulation apparatus, and maintaining the cooled oil temperature to be 0-20 DEG C; and 5, pumping the cooled oil to the machine cabinet. By adoption of the server cooling method, the problem of unobvious server cooling caused by low air heat conducting coefficient in cooling through a cold and hot air exchanging mode, and the problem that the carried dust blows into the server whenthe cold air blows the server in the prior art can be solved.

Owner:ZHUZHOU PUTIAN ZHONGPU LIGHTNING PROTECTION TECH

Contact for high-speed mechanical switch and fracture structure

ActiveCN111863507AGuaranteed stabilityGuaranteed reliabilityHigh-tension/heavy-dress switchesAir-break switchesButt jointEngineering

The invention relates to a contact for a high-speed mechanical switch and a fracture structure, which can solve the problems of poor closing reliability, short service life and high production cost caused by end surface contact conduction of a moving contact and a static contact in the prior art. The contact for the high-speed mechanical switch comprises a columnar base body, one end of the columnar base body is a butt joint end matched with an adaptive contact in a butt joint mode, and the butt joint end is provided with an elastic contact finger elastically connected with the butt joint endof the adaptive contact in an abutting mode. The elastic contact finger can buffer the impact of the moving contact on the static contact through the elastic deformation of the elastic contact finger.The rigid impact between the moving contact and the static contact is converted into flexible contact, and the elastic force generated by the elastic contact finger after being pressed and deformed can drive the elastic contact finger to press the contact, so that the requirement on the output force of the operating mechanism and the holding mechanism is reduced, and the stability of the conductive connection between the moving contact and the static contact is ensured.

Owner:PINGGAO GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com