Motor manufacturing method and motor

A manufacturing method and structure technology, applied in the field of motors, can solve the problems of reducing the reliability of motors and the hidden dangers of the insulation characteristics of stator coils, etc., and achieve the effect of improving reliability and stability and ensuring insulation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

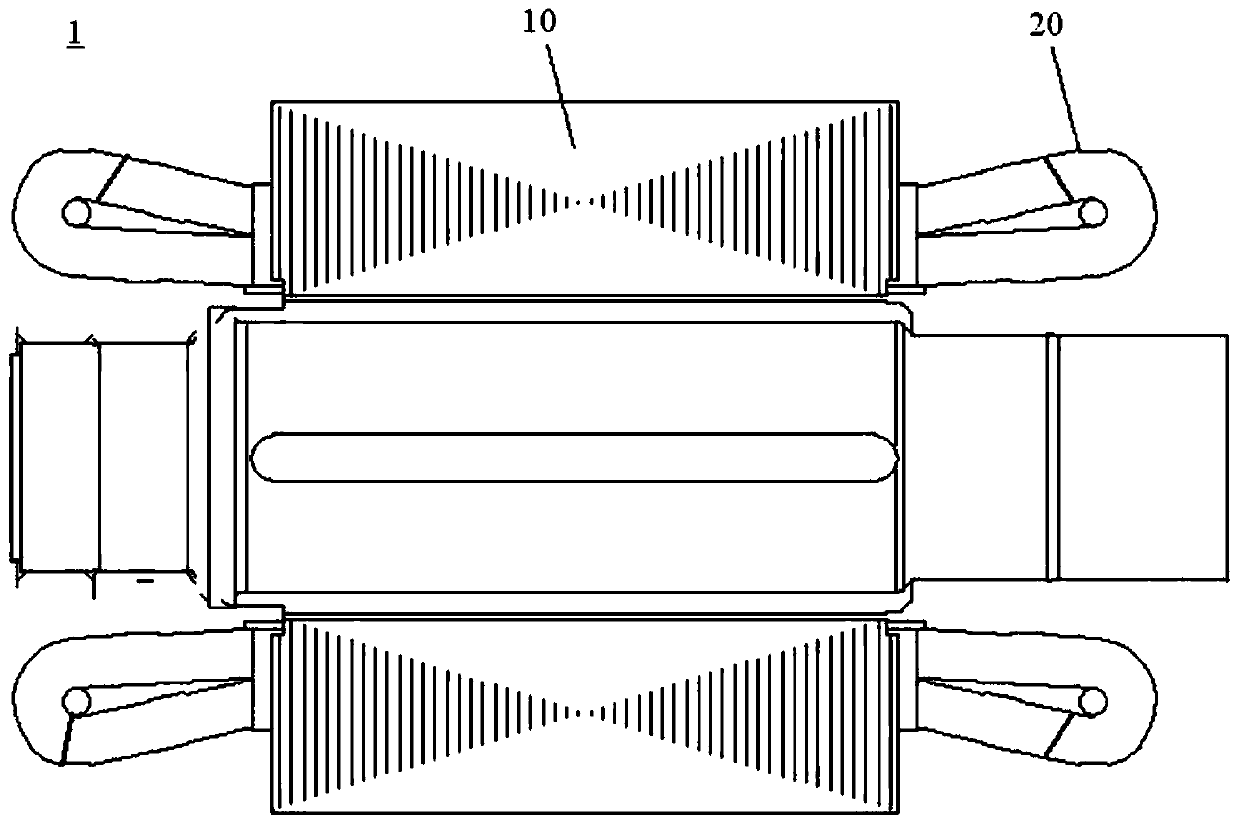

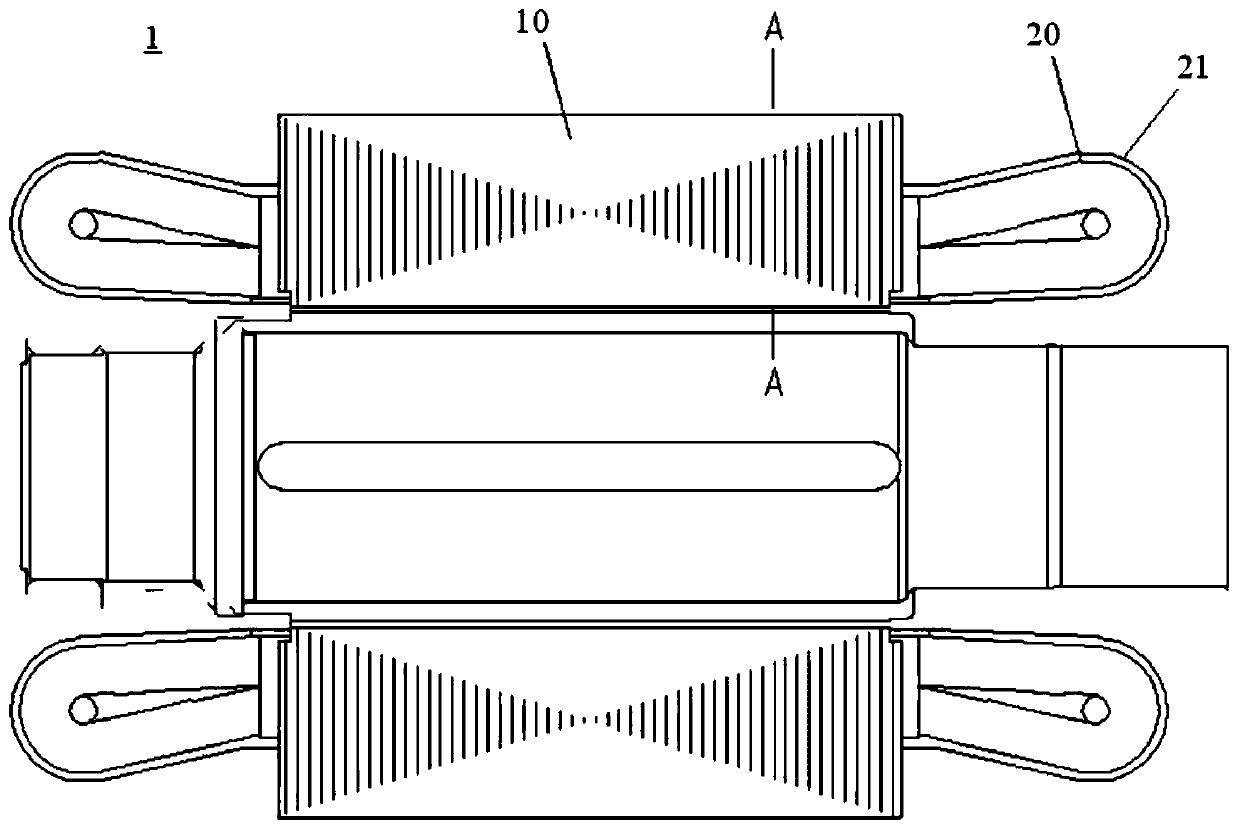

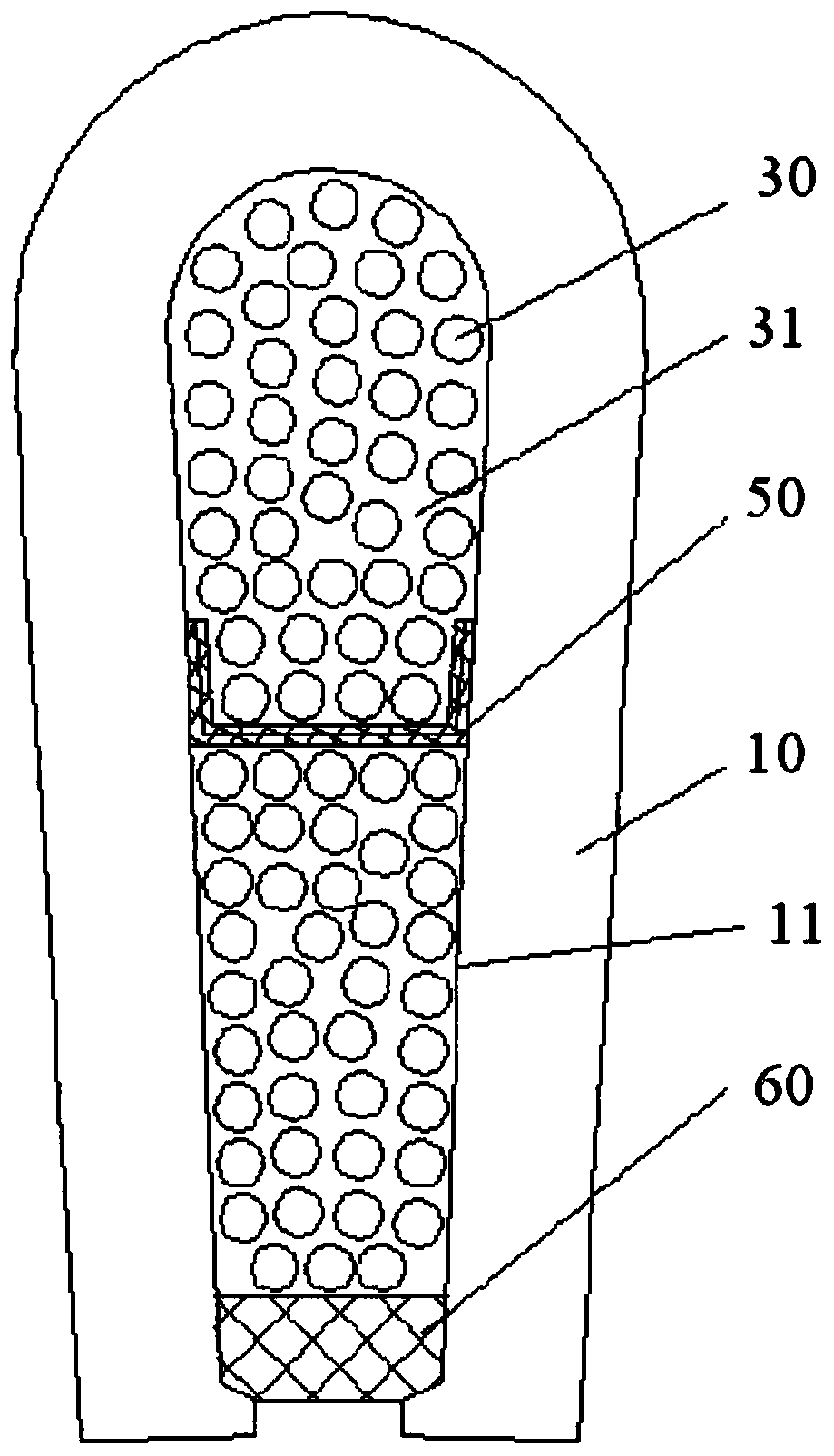

[0025] Such as figure 1 with figure 2 As shown, the motor 1 of the present invention includes a substantially cylindrical stator core 10 and coils. The stator core 10 is internally constructed with a housing cavity 11 (see image 3 ). The specific structure of the stator core and its containing cavity is well known to those skilled in the art, and will not be repeated here. Coils are pre-wound from electromagnetic wires on a shuttle machine. Keep the tension consistent throughout the winding process. The magnet wire here is preferably a corona-resistant magnet wire comprising an insulating layer containing inorganic nanomaterials.

[0026] available from figure 1 with figure 2 It can be seen from the figure that a part of the coil is accommodated in the accommodation chamber 11, and this part is called the accommodation part 30; the other part of the coil extends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com