X-ray tube

An X-ray tube and X-ray technology, applied in the field of fixed anode type X-ray tubes, can solve the problems of reducing the heat load of the anode target, increasing the cost, poor heat dissipation characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

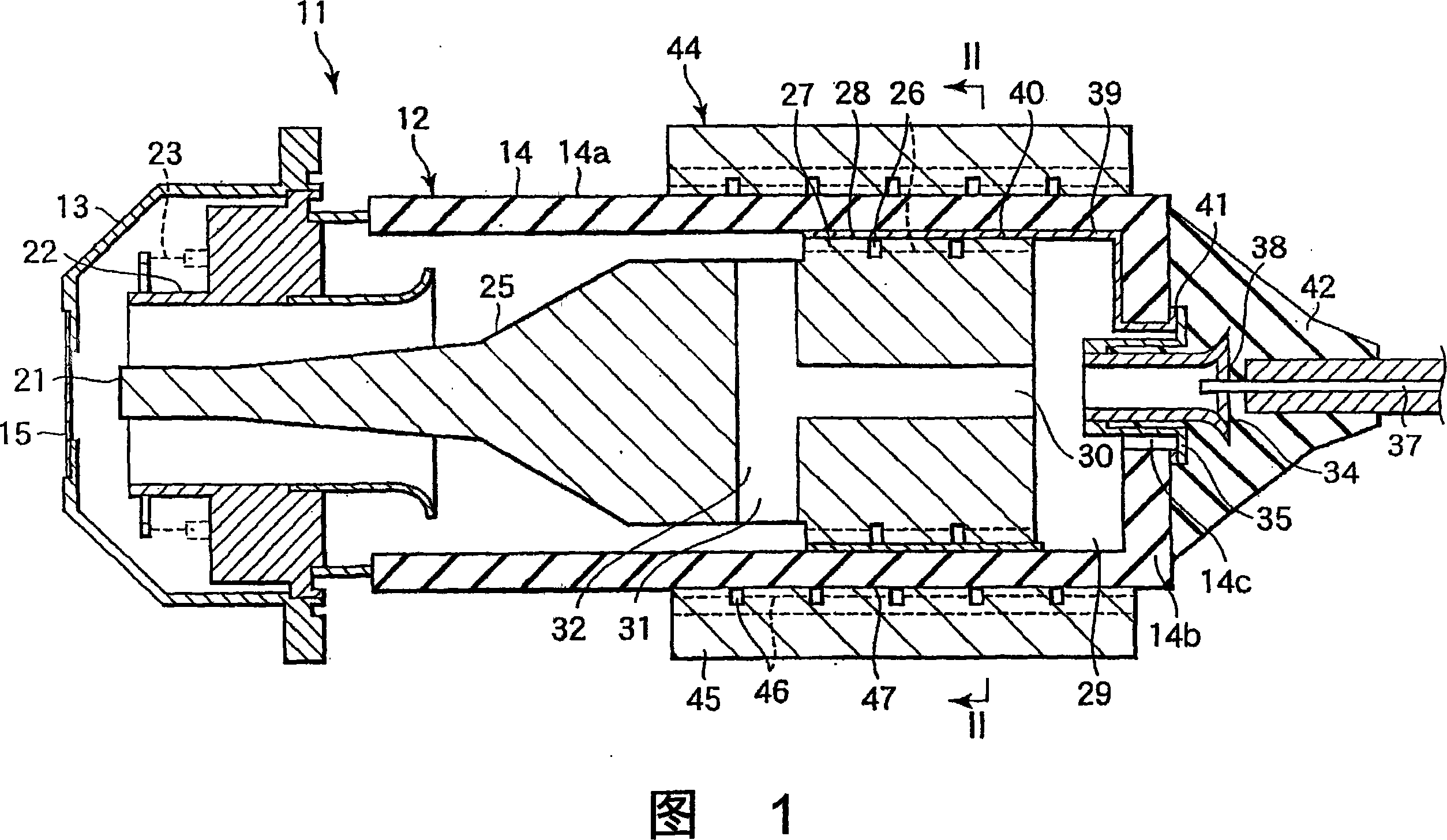

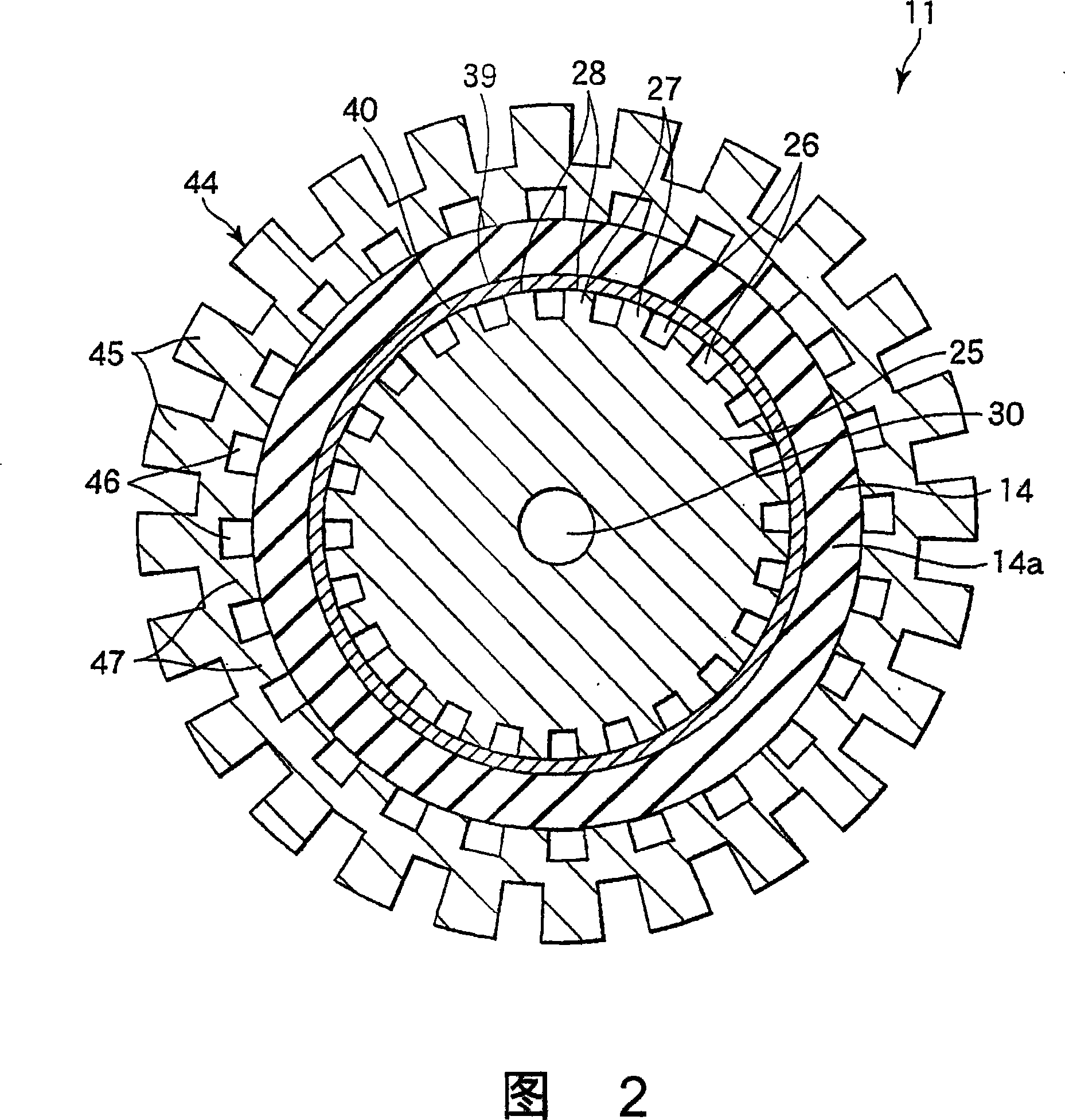

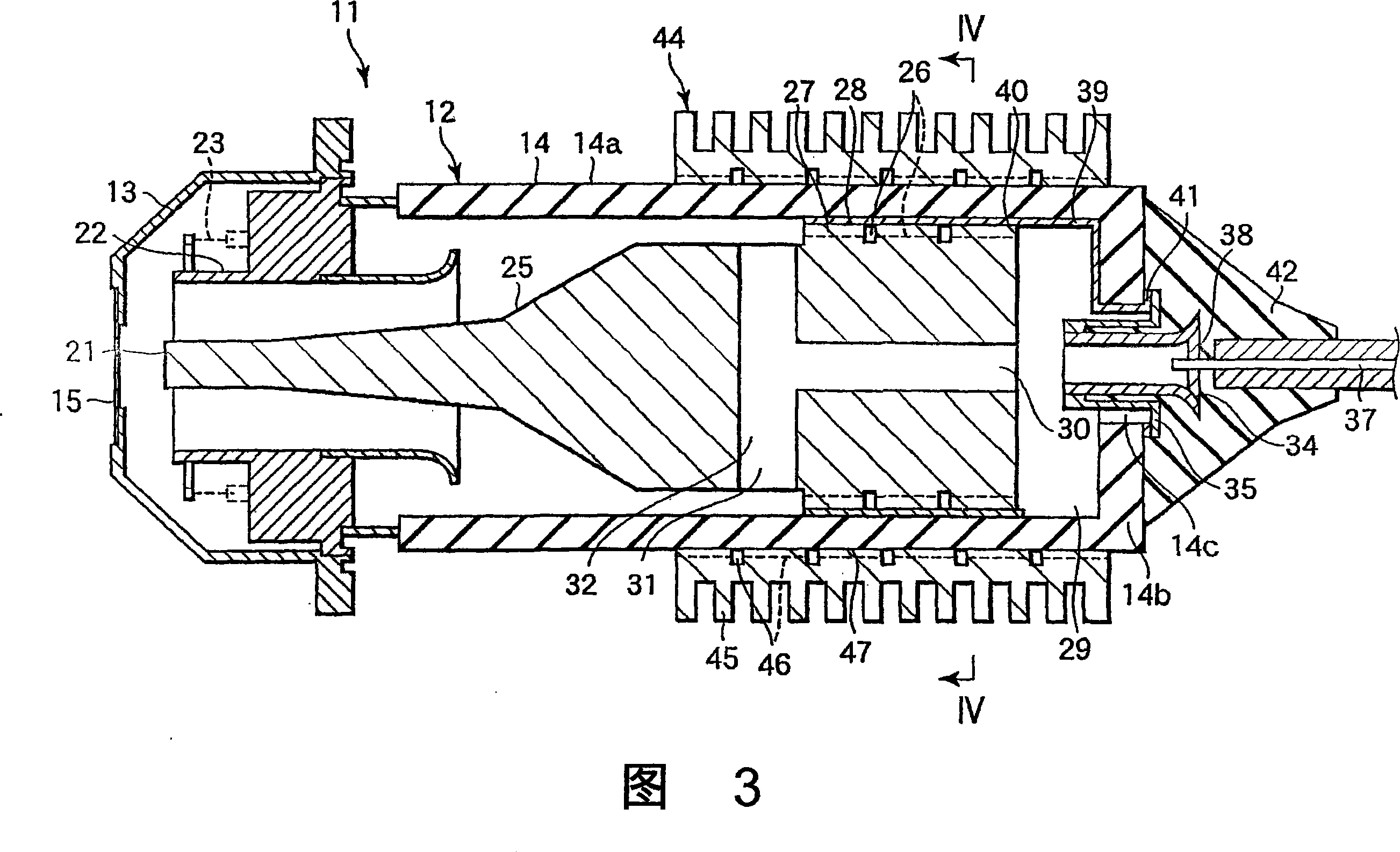

[0026] Hereinafter, a fixed anode type X-ray tube according to an embodiment of the present invention will be described with reference to the drawings.

[0027] 1 and 2 show a fixed anode type X-ray tube 11 as an X-ray tube. The X-ray tube 11 has a casing 12 that keeps the inside in a vacuum state. The casing 12 is formed by combining a first casing 13 made of metal on one end side along the axial direction of the tube axis of the X-ray tube 11 and a second casing 14 on the other end side constituting the insulating portion.

[0028] The first housing 13 is formed in a cap shape (tubular shape) whose outer diameter at the front end gradually decreases. The front end surface of the first housing 13 is formed as a flat surface. An output window 15 that transmits X-rays is provided on the flat portion. The output window 15 is made of a material that reduces the attenuation of X-rays, such as beryllium (Be), and has a thickness of about several tens to several hundreds of μm.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com