Heat dissipation system for solarlok photovoltaic interconnection system

a photovoltaic array and interconnection system technology, applied in the direction of electrical equipment, lighting and heating equipment, semiconductor devices, etc., can solve the problems of ineffective means for expulsion of heat generated by internal system electronic components, risk of heat rise sufficient to damage enclosures and/or internal components of interconnection systems, etc., to achieve the effect of eliminating heat generated and increasing heat dissipation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014]The heat dissipation system of the present invention is applied to an interconnection system for photovoltaic (PV) arrays, and preferably to a roof mounted PV array, although the PV arrays may be independently mounted on frames, building facades or other configurations.

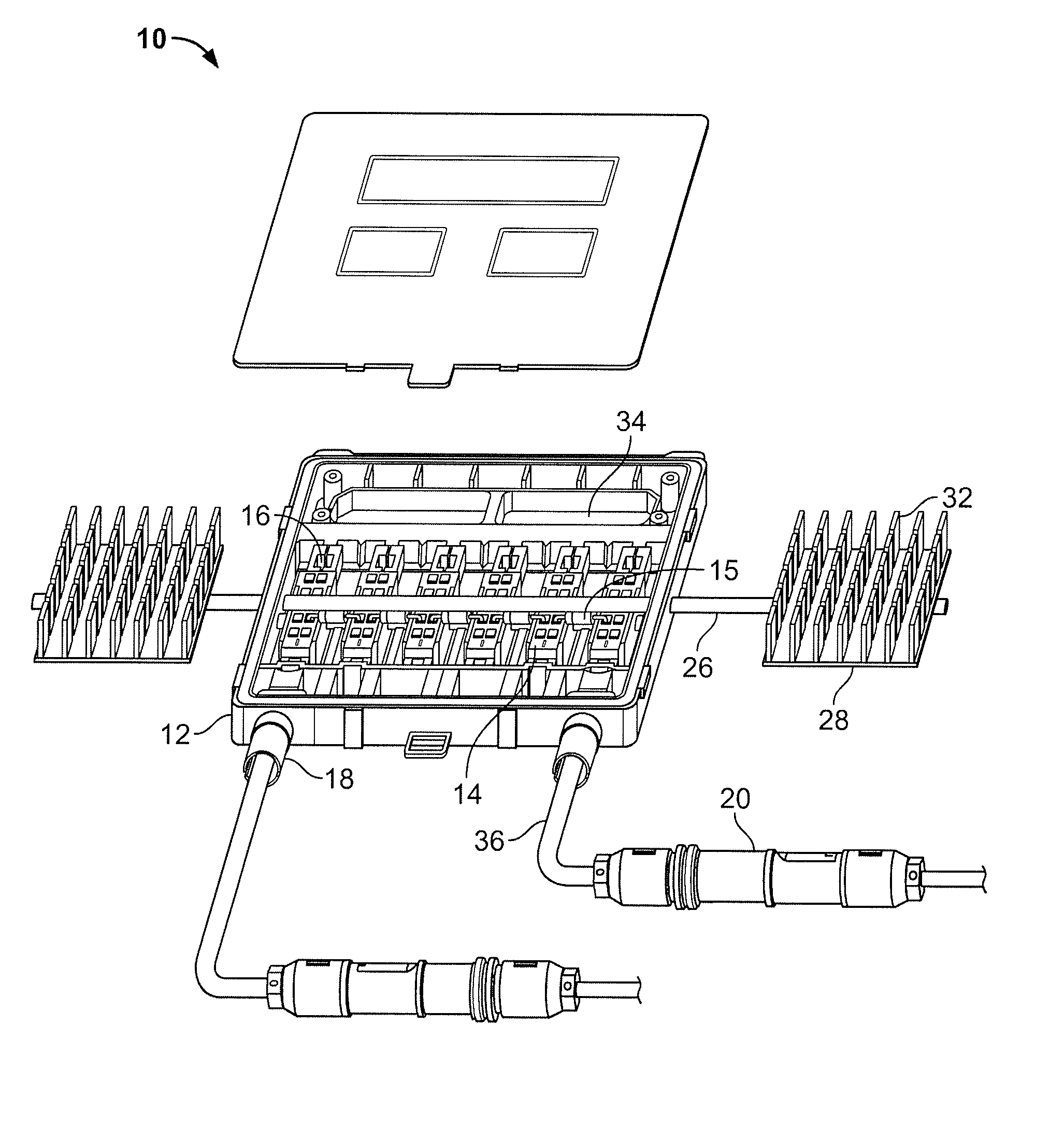

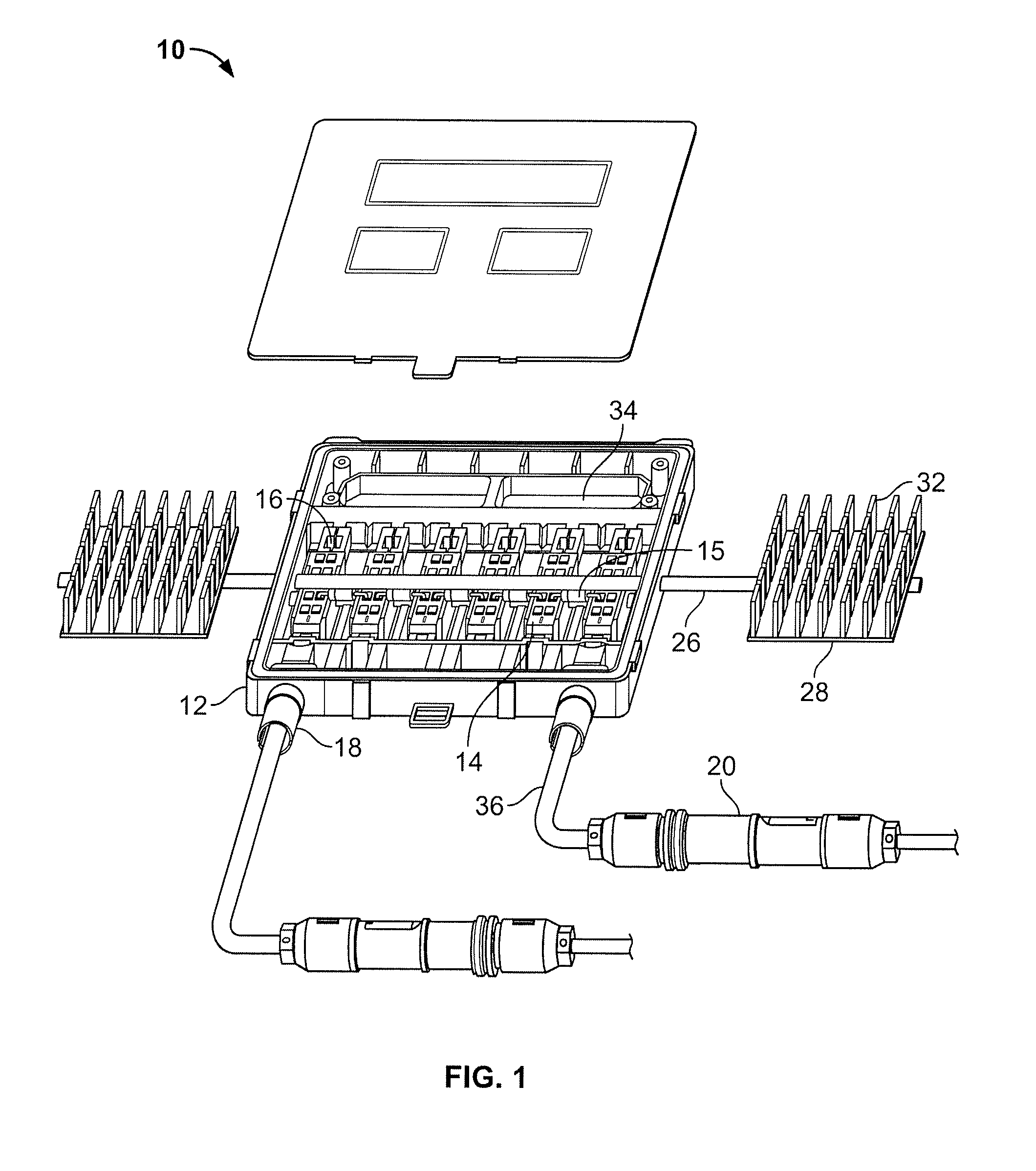

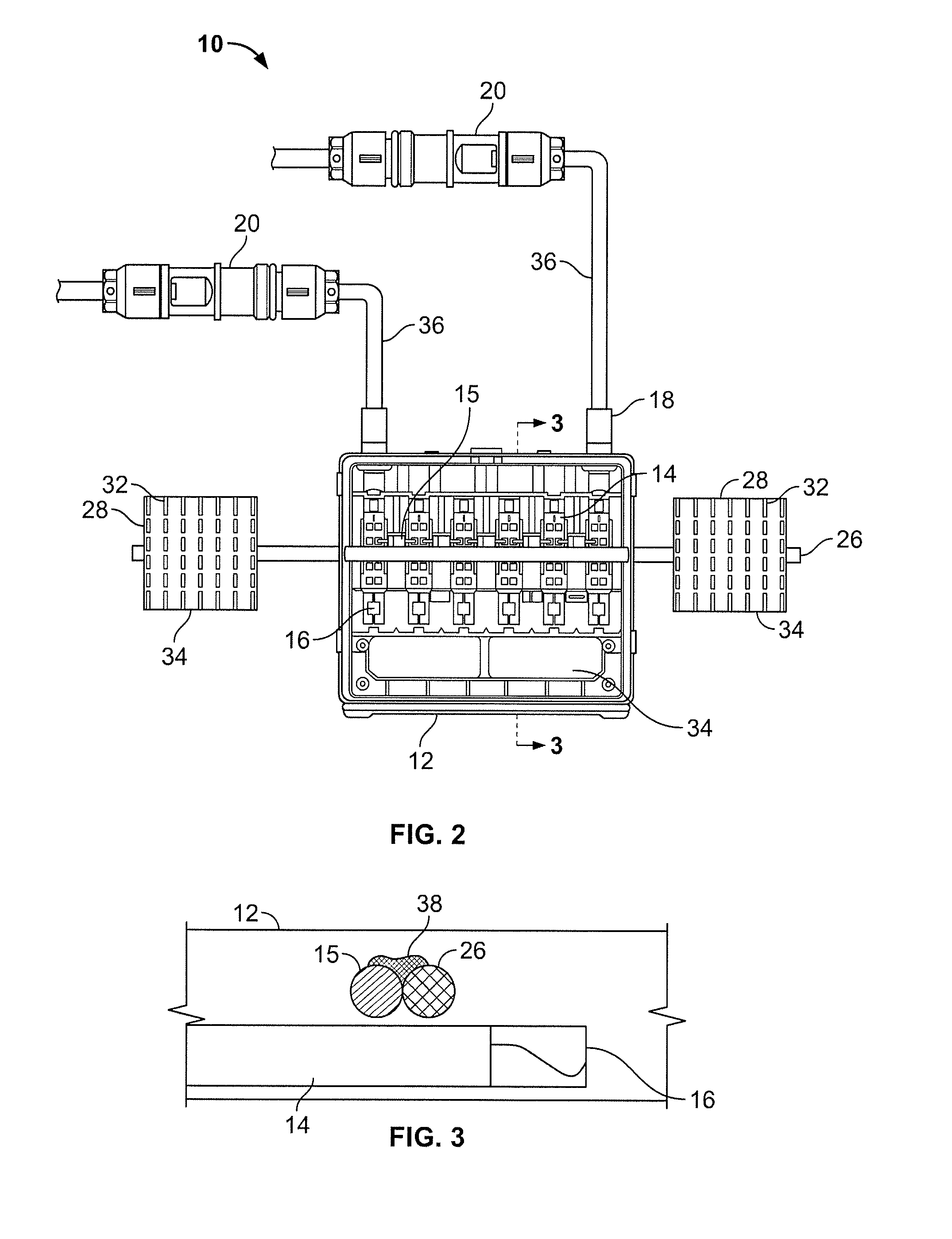

[0015]Referring to FIGS. 1-3, the interconnection system is generally designated as 10. A connection box 12 houses the components of the interconnection system 10, including a series of electrical connectors 14 for connecting conductors of the PV array (not shown). Connectors 16 are mounted to rail assemblies 14. Up to six rail assemblies 14 per connection box 12 is the preferred arrangement, although more than six rail assemblies 14 may be enclosed within a connection box suitable for larger configurations. The rail assemblies 14 provide mechanical support for the connectors 14. Connectors 16 are electrically isolated from the diode assemblies 15.

[0016]The connection box 12 has cable couplers 18, and an apertur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com