Assorted fiber felt body

A technology of mixed fibers and mats, which is applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems that the strength and stiffness of single carbon fiber mat-like fabrics are difficult to further improve, and achieve high thermal insulation properties and mechanical processing properties, ensuring heat insulation properties, improving strength and tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

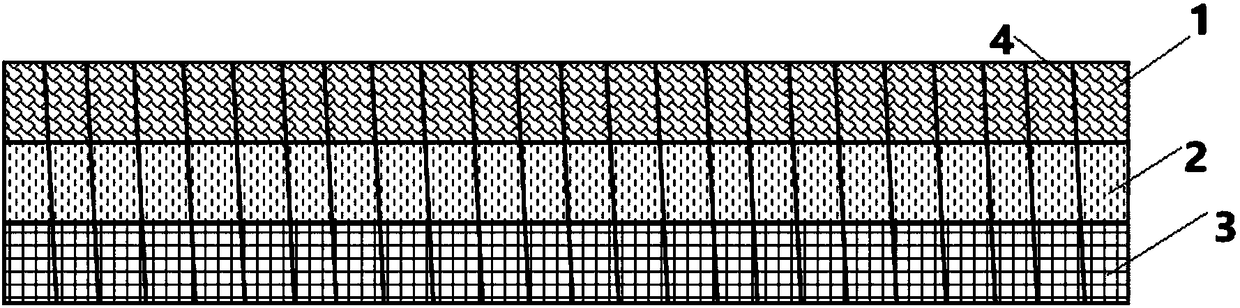

[0030] High-strength T700 carbon fiber with a chopped length of 10mm is used at 100g / m 2 Surface density carding net, preparation thickness is the surface high-strength carbon fiber mixed layer 1 of 1mm; By the boron carbide fiber of length 20mm chopped at 130g / m 2 Surface density carding, the preparation of a subsurface heat-resistant ceramic fiber layer with a thickness of 2mm; by chopping the high modulus carbon fiber M60J with a length of 50mm at 134g / m 2 The surface density was combed to prepare a middle high modulus carbon fiber layer 3 with a thickness of 1.6 mm. The final three-layer structure uses high-strength T300 carbon fiber to form an overall structure with a needle punching density of 2000 needles / square meter.

Embodiment 2

[0032] High-strength T800 carbon fiber with a chopped length of 20mm is used at 150g / m 2 Surface density carding net, the preparation thickness is the surface high-strength carbon fiber mixed layer 1 of 1mm; By the boron carbide fiber of chopping length 20mm with 133g / m 2 Surface density carding, prepare a subsurface heat-resistant ceramic fiber layer with a thickness of 2mm; by chopping high modulus carbon fiber M40J with a length of 55mm at 122g / m 2 The surface density was combed to prepare a middle high modulus carbon fiber layer 3 with a thickness of 1.7mm. The final three-layer structure uses high-strength T300 carbon fiber to form an overall structure with a needle punching density of 3000 needles / square meter.

Embodiment 3

[0034] High-strength T700 carbon fiber with a chopped length of 15mm is used at 100g / m 2 Surface density carding, the preparation of a thickness of 1mm surface high-strength carbon fiber mixed layer 1; 2 Surface density carding, prepare a subsurface heat-resistant ceramic fiber layer with a thickness of 4mm; by chopping high modulus carbon fiber M55J with a length of 50mm at 134g / m 2 The surface density was combed to prepare a middle high modulus carbon fiber layer 3 with a thickness of 1.5 mm. The final three-layer structure uses high-strength T800 carbon fiber to form an overall structure with a needle punching density of 4000 needles / square meter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com