Metal magnetic powder core, preparation method and application thereof

A magnetic powder core and metal technology, which is applied in the manufacture of magnetic cores, magnetic cores/yokes, inductors/transformers/magnets, etc., can solve problems such as uneven distribution, poor insulation effect, etc., to ensure insulation effect and good insulation effect And high temperature resistance, reduce the effect of eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

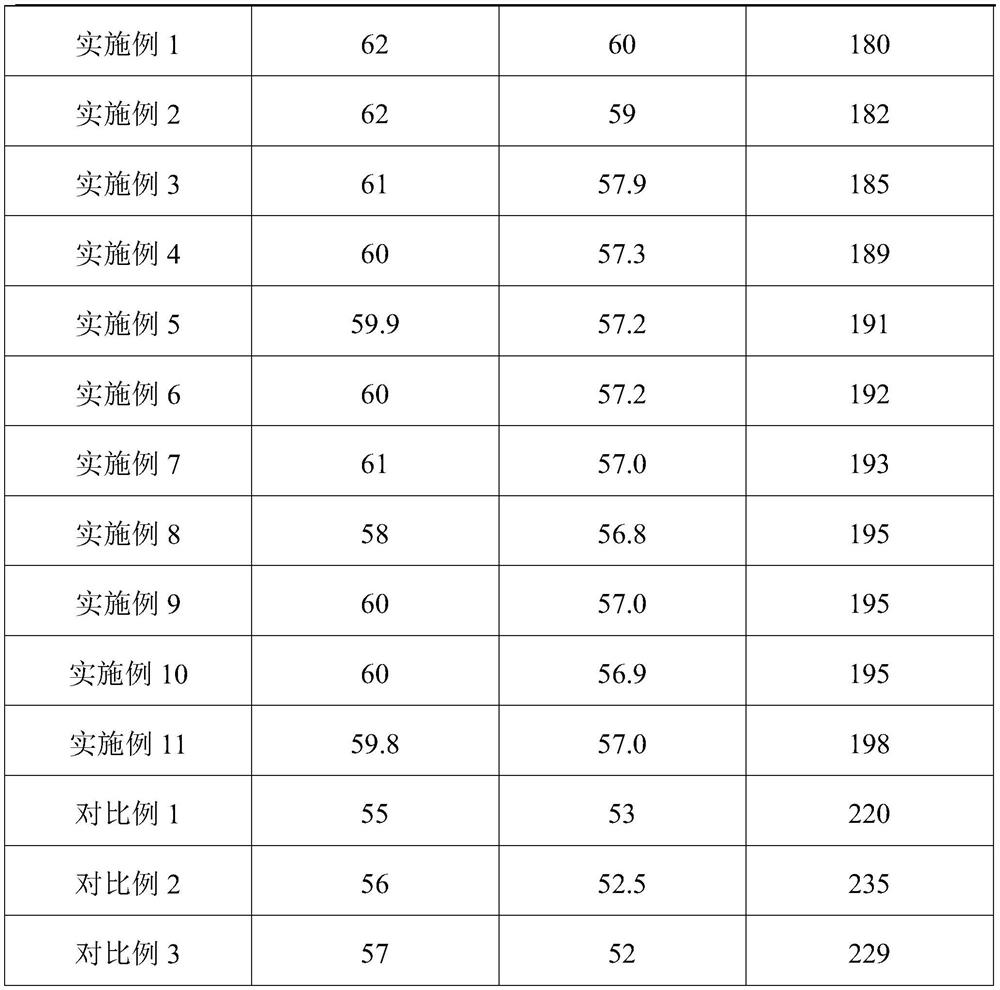

Embodiment 1

[0044] This embodiment provides a metal magnetic powder core, the surface of the powder particles of the metal magnetic powder core is covered with a passivation layer and an alumina insulating layer, and the preparation method of the metal magnetic powder core includes the following steps:

[0045] (1) stirring and mixing gas atomized iron-silicon-aluminum (FeSiAl-85-9.5-5.5, brand: sendust) powder, phosphoric acid and water to obtain slurry for 5 minutes; the average particle size of the gas-atomized iron-silicon aluminum powder is 50 μm, The addition amount of the phosphoric acid is 1.5 wt% of the aerosolized iron-silicon-aluminum powder, and the addition amount of the water is 5 wt% of the aerosolized iron-silicon-aluminum powder;

[0046] (2) After stirring and mixing the aluminum hydroxide gel with a solid content of 25wt% and the slurry described in step (1) for 5 minutes, drying at 200° C. for 2 hours in turn, and passing through a 70-mesh sieve; the addition of the alu...

Embodiment 2

[0049] This embodiment provides a metal magnetic powder core, the surface of the powder particles of the metal magnetic powder core is covered with a passivation layer and an alumina insulating layer, and the preparation method of the metal magnetic powder core includes the following steps:

[0050] (1) stirring and mixing gas atomized iron-nickel (FeNi-50-50, brand: High-Flux) powder, chromic acid and water for 10min to obtain slurry; the average particle size of the gas-atomized iron-nickel powder is 75 μm, so The addition amount of the chromic acid is 2wt% of the aerosolized iron-nickel powder, and the addition amount of the water is 7.5wt% of the aerosolized iron-nickel powder;

[0051] (2) After stirring and mixing the aluminum hydroxide gel with a solid content of 20wt% and the slurry described in step (1) for 3 minutes, drying at 150° C. for 2.5 hours in turn, and passing through a 50-mesh sieve; The addition amount is 1wt% of the aerosolized iron-nickel powder;

[005...

Embodiment 3

[0054] This embodiment provides a metal magnetic powder core, the surface of the powder particles of the metal magnetic powder core is covered with a passivation layer and an alumina insulating layer, and the preparation method of the metal magnetic powder core includes the following steps:

[0055] (1) stirring and mixing water-atomized iron-nickel-molybdenum (Fe-Ni-Mo-17-81-2, brand: MPP) powder, aluminum dihydrogen phosphate and water for 3 minutes to obtain a slurry; the water-atomized iron-nickel-molybdenum powder The average particle size of the aluminum dihydrogen phosphate is 25 μm, the addition amount of the aluminum dihydrogen phosphate is 1wt% of the water atomized iron-nickel-molybdenum powder, and the addition amount of the water is 2.5wt% of the water-atomized iron-nickel-molybdenum powder;

[0056] (2) After stirring and mixing the aluminum hydroxide gel with a solid content of 30wt% and the slurry described in step (1) for 10 minutes, drying at 250° C. for 1.5 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com