Sealing structure for medium-high temperature battery, medium-high temperature battery and assembly method thereof

A sealed structure, medium and high temperature technology, used in structural parts, sealing materials, secondary batteries, etc., can solve the problems of unsecured sealing, inability to achieve effective sealing, complex processes, etc., and achieve a wide range of operating temperatures, excellent Liquid sealing performance, the effect of avoiding seal failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The specific embodiments described herein are only for explaining the present invention.

[0031] In the present invention, the closed space enclosed by the battery casing and containing the electrolyte is the "inner" side / part of the battery, and the opposite open space separated by the battery casing is the "outer" side / part. "Up" and "down" are understood according to the upper and lower relationship depicted in the figure.

[0032] The sealing structure of the present invention is suitable for medium-high temperature energy storage batteries, for example, sodium-sulfur batteries, liquid metal batteries and the like.

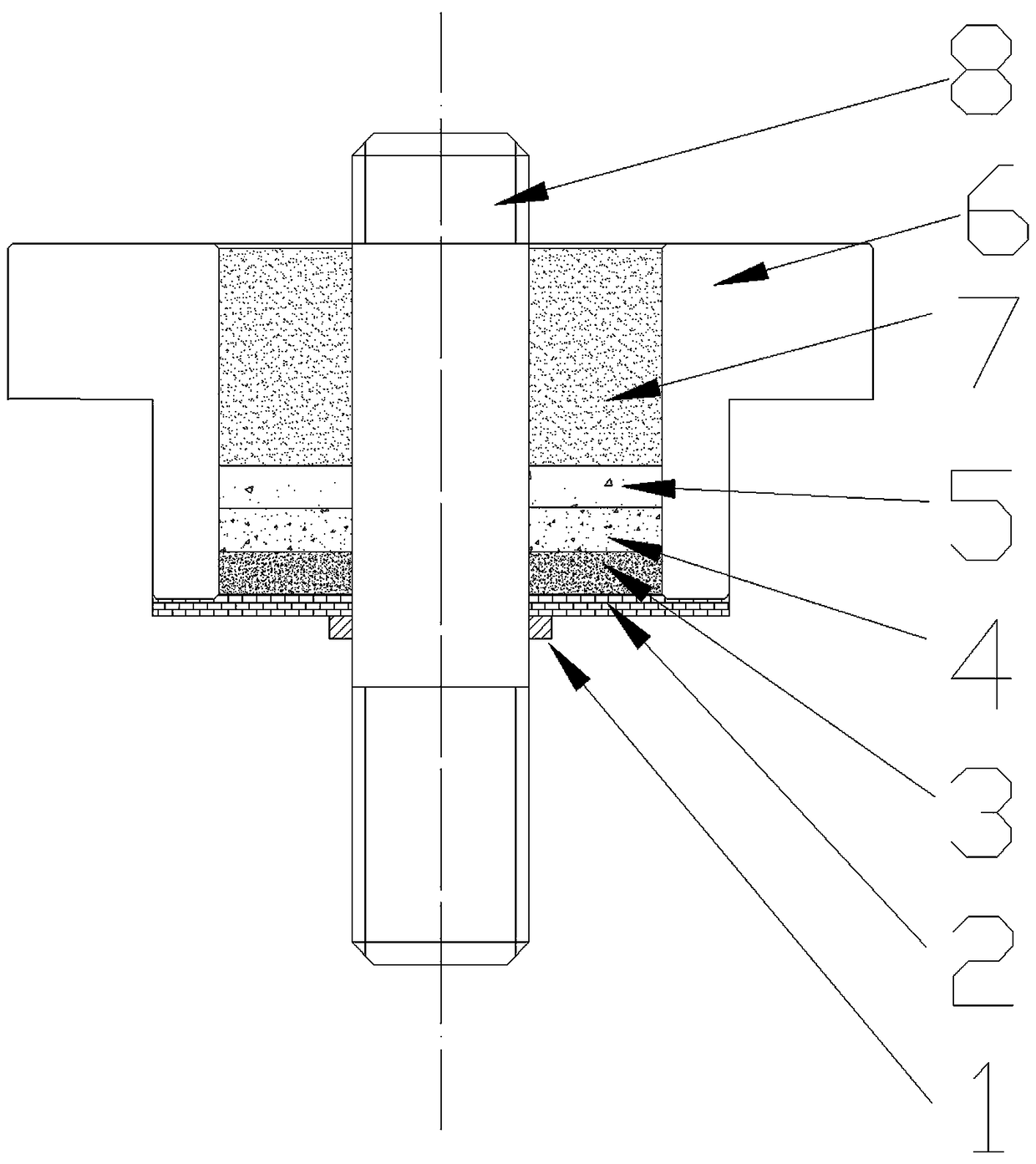

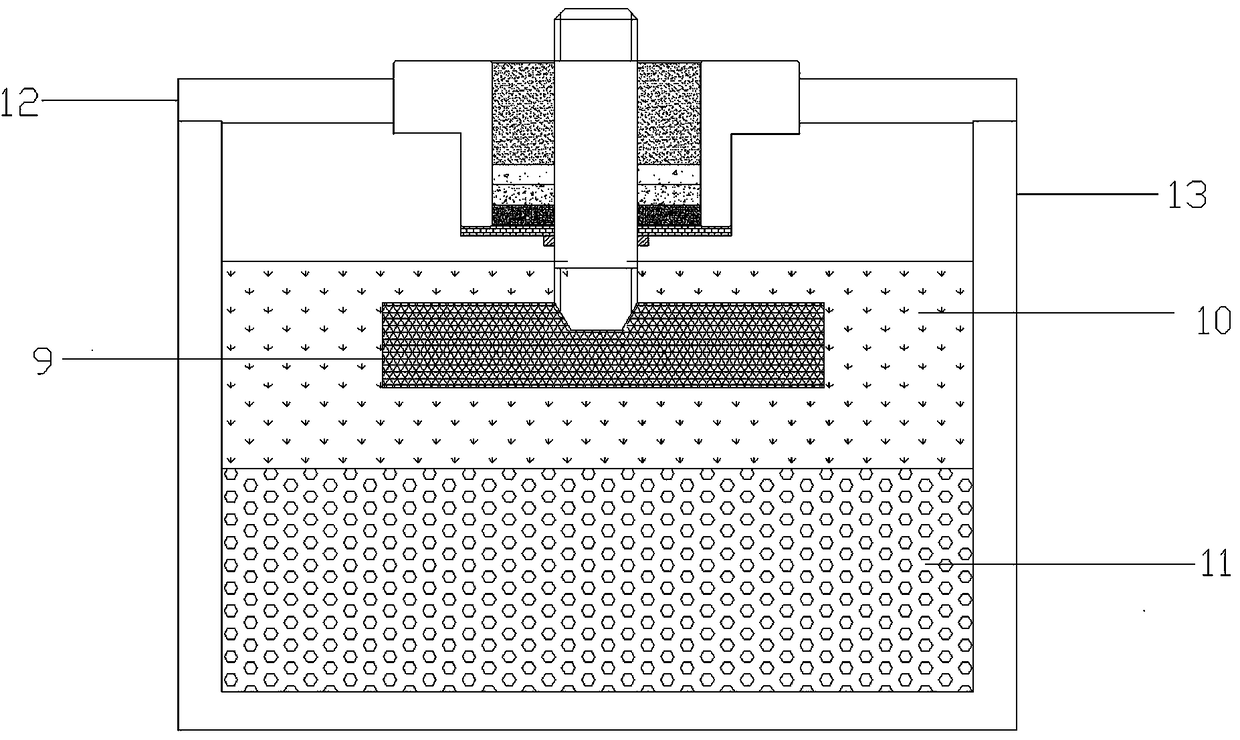

[0033] Such as figure 1 As shown, a sealing structure for a high-temperature battery in a specific embodiment of the present invention. When this structure is applied to a battery, the metal rod 8 can be connected to the pos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com