Contact for high-speed mechanical switch and fracture structure

A mechanical switch and contact technology, applied in high-voltage/high-current switches, electrical switches, high-voltage air circuit breakers, etc., can solve the problems of short service life, poor closing reliability, and high production costs, reducing production costs and ensuring Insulation properties, effect of reducing output force requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

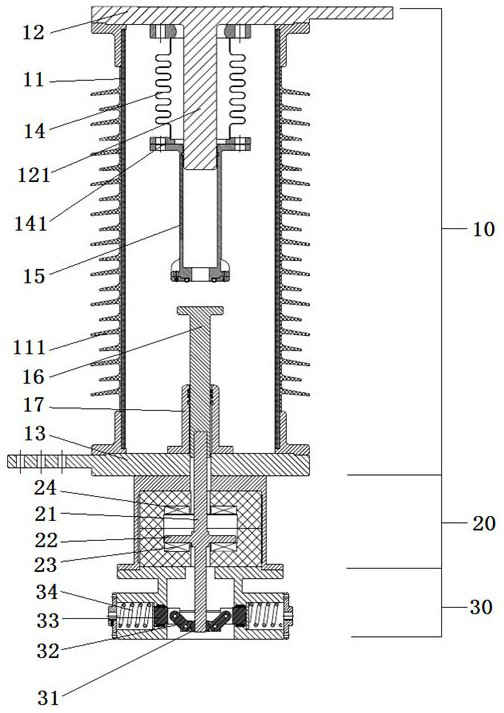

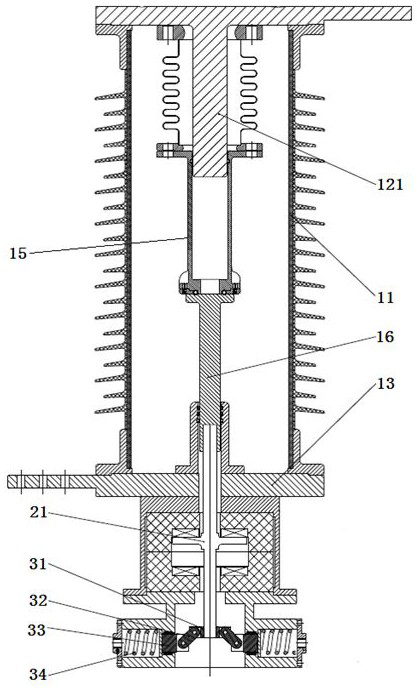

[0061] Embodiment 1 of the fracture structure of the present invention: the fracture structure in the present invention is assembled in a high-speed mechanical switch, such as figure 1 and figure 2 As shown, the high-speed mechanical switch mainly includes a fracture structure 10, an operating mechanism 20 that drives the fracture structure 10 to move, and a holding mechanism 30 that keeps the fracture structure 10 at the designed opening and closing positions. Each part of the high-speed mechanical switch is introduced in detail.

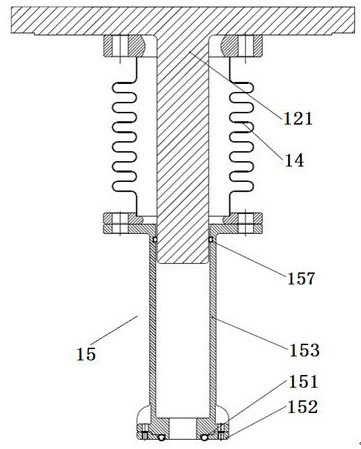

[0062] High-speed mechanical switches include along figure 1 and figure 2 The insulating cylinder 11 extending in the upper and lower directions, the outer peripheral surface of the insulating cylinder 11 is provided with an insulating shed 111, the fracture structure 10 is arranged in the inner cavity of the insulating cylinder 11, and the fracture structure 10 includes a moving contact 16 and a static contact Head 15. The openings at both e...

Embodiment 2

[0081] Embodiment 2 of the breakout structure of the present invention: the difference from the above embodiments is that in this embodiment, the elastic contact fingers are arranged on the movable contact, that is, the contact end is arranged on the butt end of the movable contact facing the static contact. Finger installation groove, the elastic contact finger is arranged in the contact finger installation groove, when the moving contact moves towards the static contact, the elastic contact finger on the moving contact contacts the static contact before the moving contact, and buffers through its own elastic deformation Impact between moving and static contacts. Or in other embodiments, coaxially arranged spring contact fingers are arranged on the end faces of the movable contact and the static contact, wherein the radial dimension of one spring contact finger is larger than that of the other spring contact finger, so that the dynamic and static contact When the heads are do...

Embodiment 3

[0082] Embodiment 3 of the interruption structure of the present invention: the difference from the above-mentioned embodiment is that in this embodiment, the elastic contact finger can adopt a bow-shaped shrapnel structure, and the two ends of the shrapnel structure are fixed to the butt end of one of the contacts. The arched part is in contact with the matching contact, and the shrapnel structure can realize the elastic contact between the two contacts through its own deformation, and is not limited to the use of spring contact fingers as elastic contact fingers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com