A method for server cooling

A server and oil temperature technology, which is applied in the field of server cooling, can solve the problems of low air thermal conductivity, not obvious server cooling, and dust blowing into the server, so as to improve cooling efficiency, avoid low ambient temperature, and reduce noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following is further described in detail through specific implementation methods:

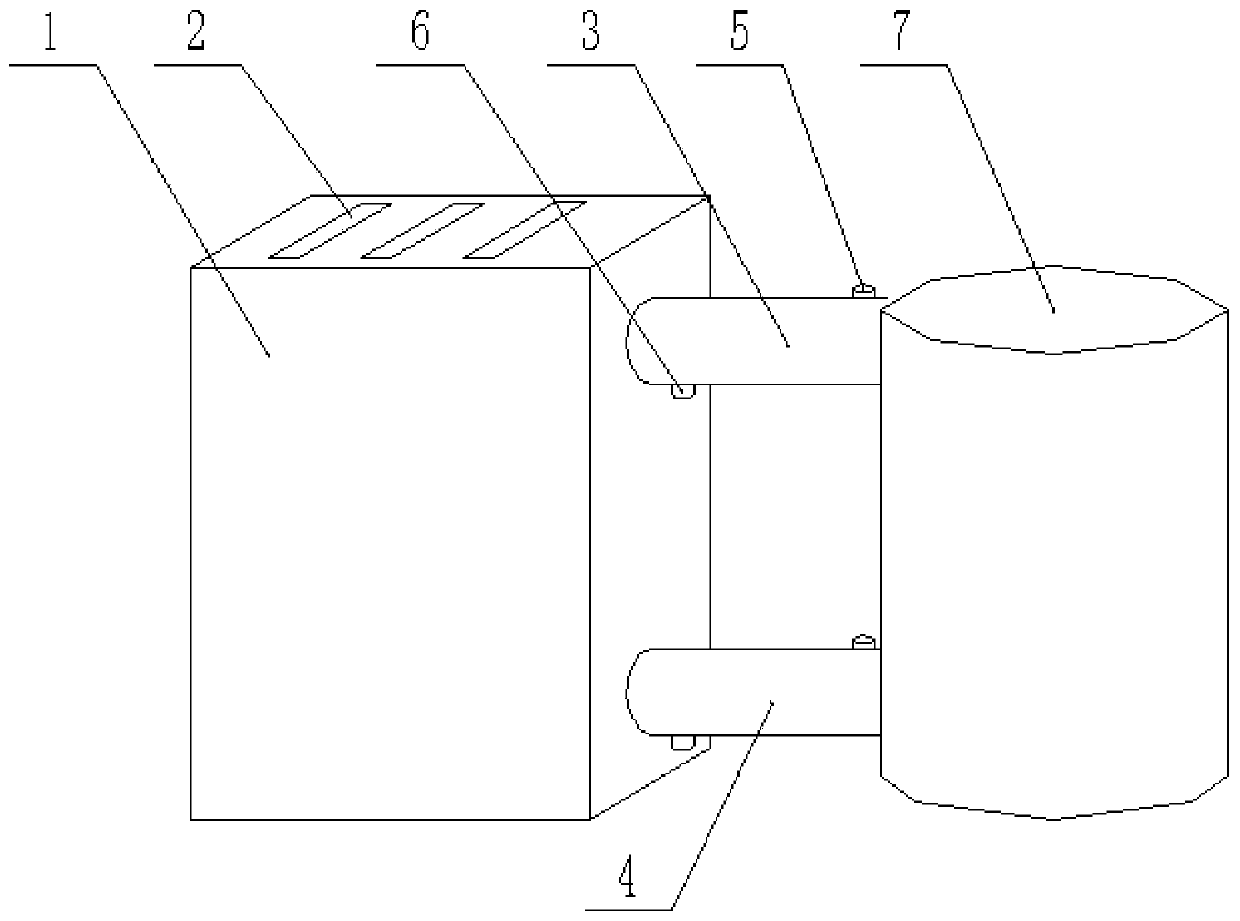

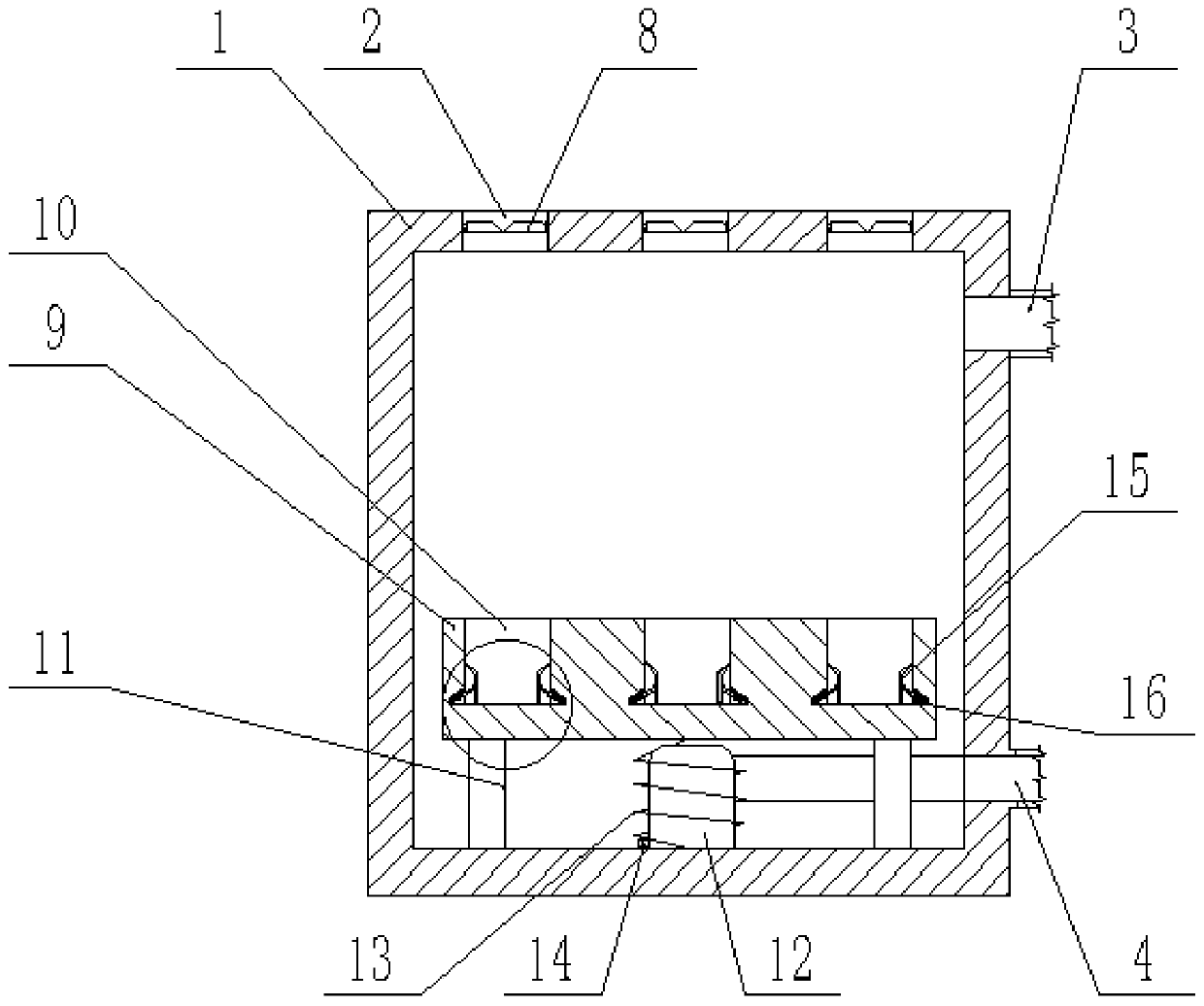

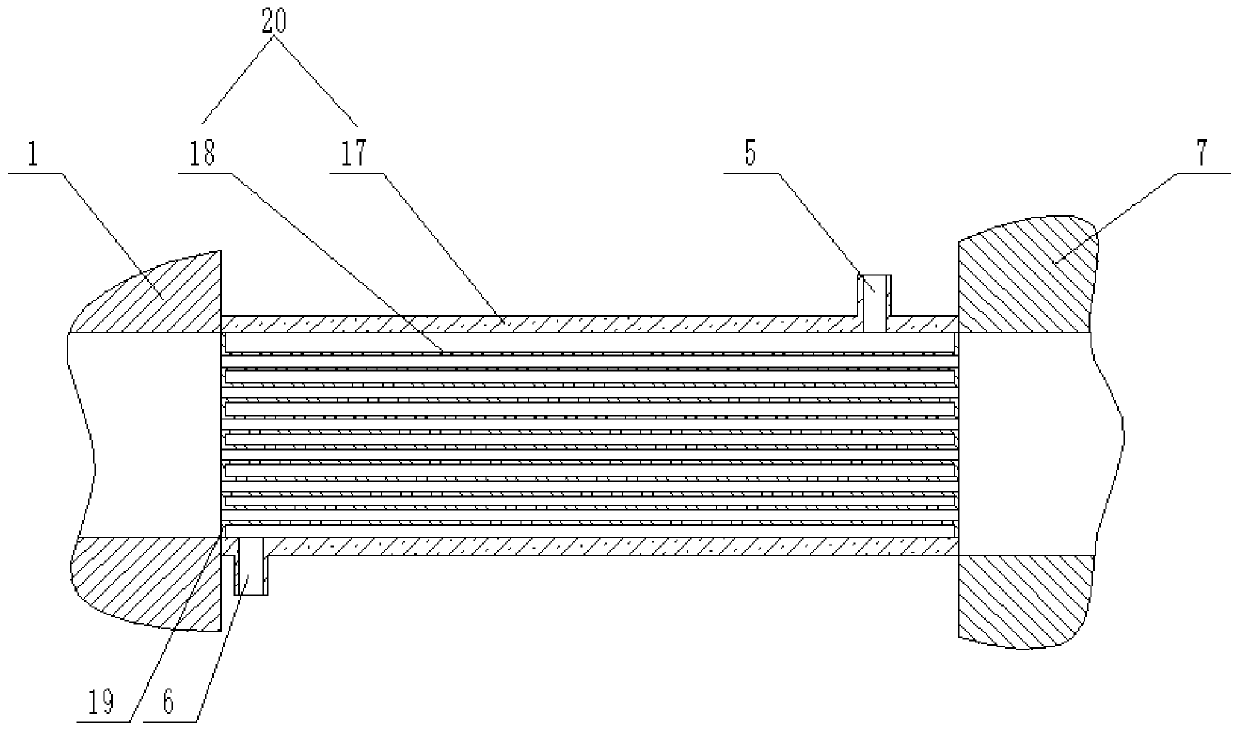

[0026] The reference signs in the accompanying drawings of the specification include: cabinet 1, access opening 2, oil outlet pipe 3, outer oil inlet pipe 4, coolant inlet 5, coolant outlet 6, circulating oil tank 7, scraper 8, positioning plate 9, positioning Groove 10, telescopic rod 11, tension column 12, first spring 13, oil outlet 14, clamping plate 15, clamping groove 16, second cooling jacket 17, thin oil outlet tube 18, separator 19, outlet Oil pipe 20, pillar 21, helical blade 22, dust removal sheet 23, dust removal chamber 24, strip hole 25, sleeve pipe 26, support rod 27, second spring 28.

[0027] The embodiment is basically as figure 1 Shown: a server cooling method, comprising the following steps:

[0028] Step 1: Prepare a server cooling system, including the cabinet 1 and the circulating oil tank 7. The cabinet 1 is a hexahedron structure formed in one piece. There ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com