Patents

Literature

35results about How to "Simple deposition process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-hardness and high-corrosion-resistance high-entropy alloy nitride coating and preparation method thereof

ActiveCN108220880AImprove corrosion resistanceIncrease productivityVacuum evaporation coatingSputtering coatingHigh entropy alloysHardness

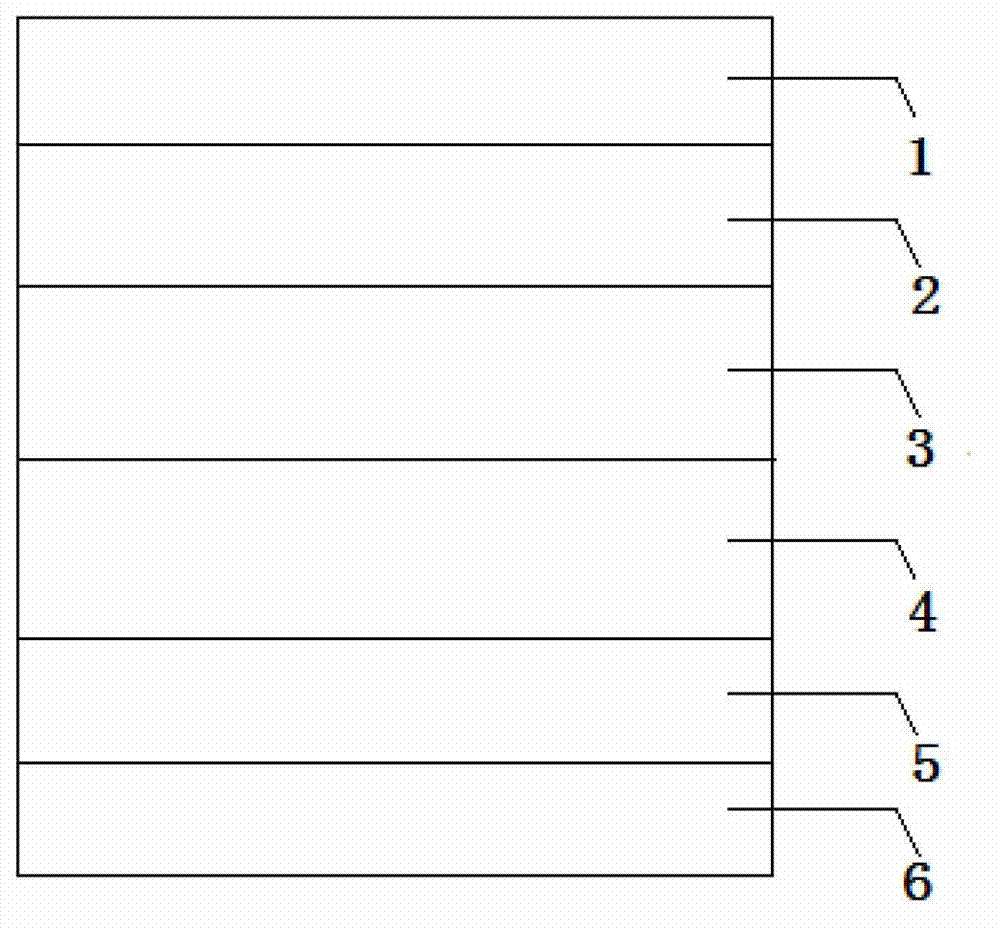

The invention provides a high-hardness high-corrosion-resistance high-entropy alloy nitride coating. The molecular formula of the high-hardness high-corrosion-resistance high-entropy alloy nitride coating is (AlCrTiZrNbV)N. The invention further provides a preparation method of the coating. The method comprises the steps of firstly, cleaning a matrix and then conducting ion cleaning; secondly, sending the treated matrix to a sputtering chamber to deposit a TiN transition coating, controlling a Ti target material through a DC cathode and depositing the TiN transition coating of 100-200 nm; andthirdly, depositing a TiAlN transition coating on the TiN transition coating and depositing the (AlCrTiZrNbV)N coating on the TiAlN transition coating. The (AlCrTiZrNbV)N coating obtained through thepreparation method has high hardness exceeding 35 GPa and also has excellent corrosion resistance. The coating has the characteristics of being simple in production process, high in deposition speed,low in cost and the like and also has the advantages of being high in production efficiency, low in energy consumption and low in equipment requirement.

Owner:SHANGHAI NEWARC COATING TECH CO LTD

Pearlescent magic color aluminum powder pigment and preparation method thereof

InactiveCN102260421ASimple processSimple equipmentInorganic pigment treatmentElectrically conductiveTitanium dioxide

The invention discloses an aluminum powder pigment with iridescent pearl luster and a preparation method thereof. The method uses aluminum powder with an average particle size of 10 μm to 150 μm and a surface coated with SiO2 film as the substrate raw material. The SiO2 film is inert, acid-resistant, heat-resistant, and transparent. The pH of the solution is 1.5-2.5 and the temperature is 60 Under the condition of ℃~80℃, deposit a layer of nano-titanium dioxide film on the transparent SiO2 film by chemical liquid phase deposition, wash and dry, and bake the pigment at 500℃~600℃ under the protection of inert gas 0.5~1.0 h, the high-gloss pearlescent aluminum powder pigment with TiO2 / SiO2 / Al-based composite film was obtained. The pigment also has excellent comprehensive properties such as the illusion interference effect of pearlescent pigments and the conductivity, high hiding power, shielding and non-toxic environmental protection of metallic aluminum powder pigments. It has unique decorative effects and can be widely used in high-end automotive topcoats and high-end decorations. Products, surface coating of high-end instruments, ink printing, children's toys, etc. The method of the invention is simple and feasible, and has industrial feasibility.

Owner:SICHUAN UNIV

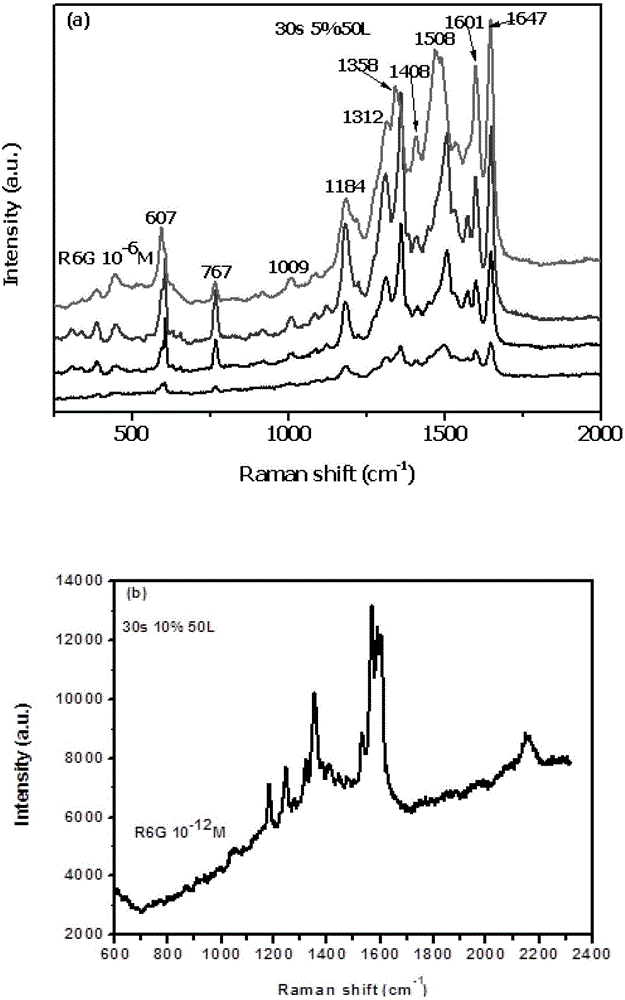

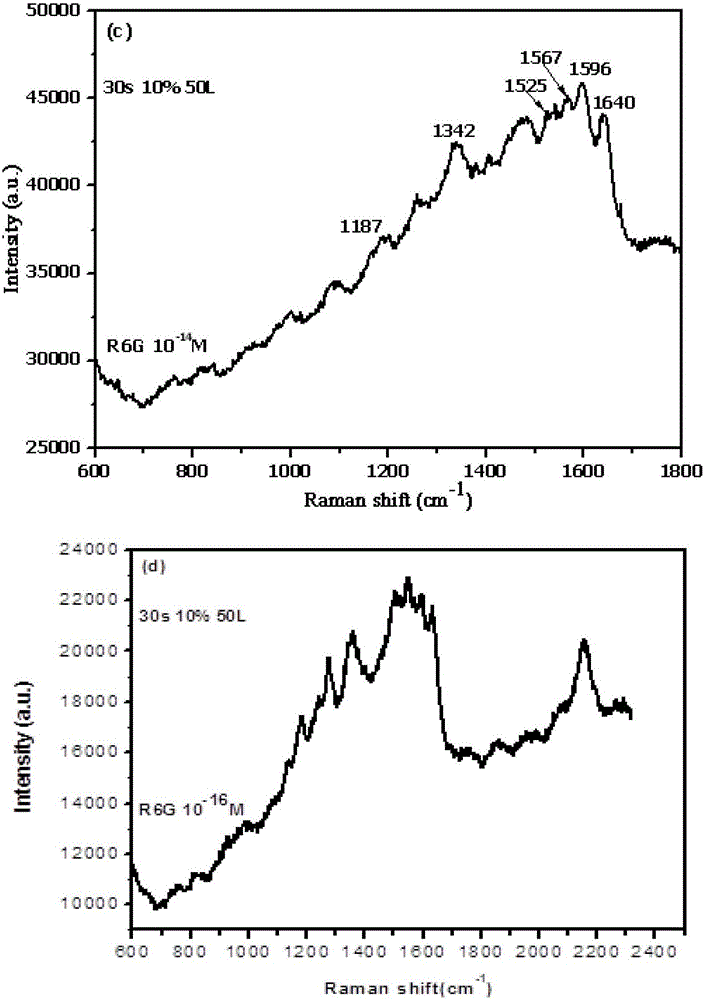

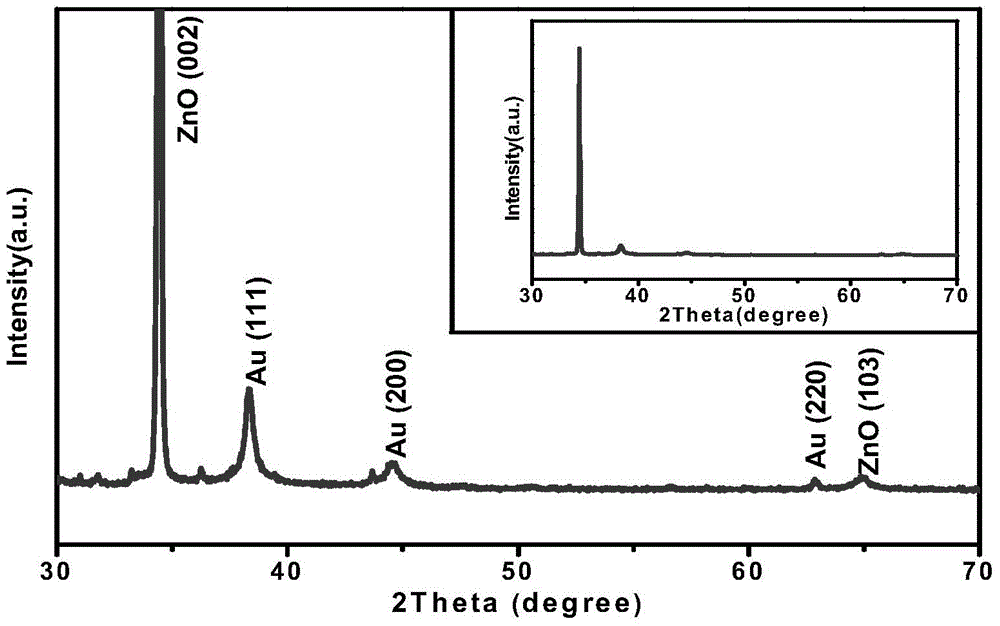

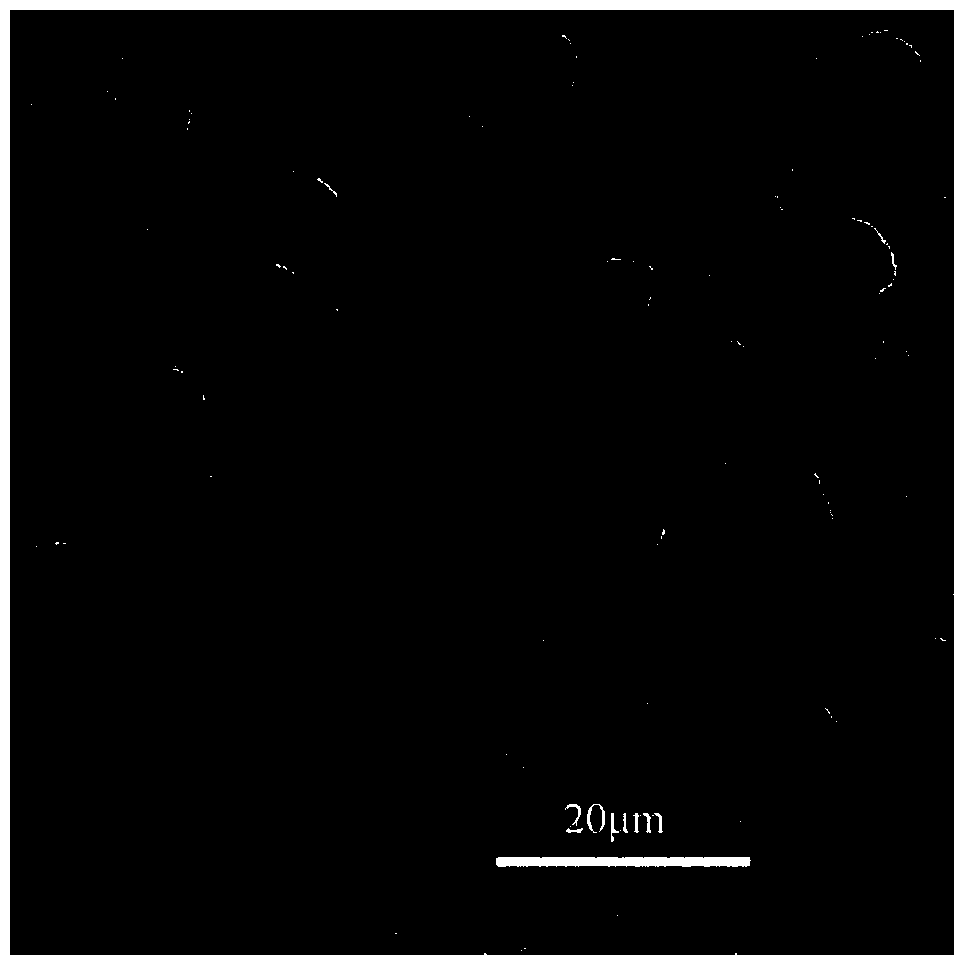

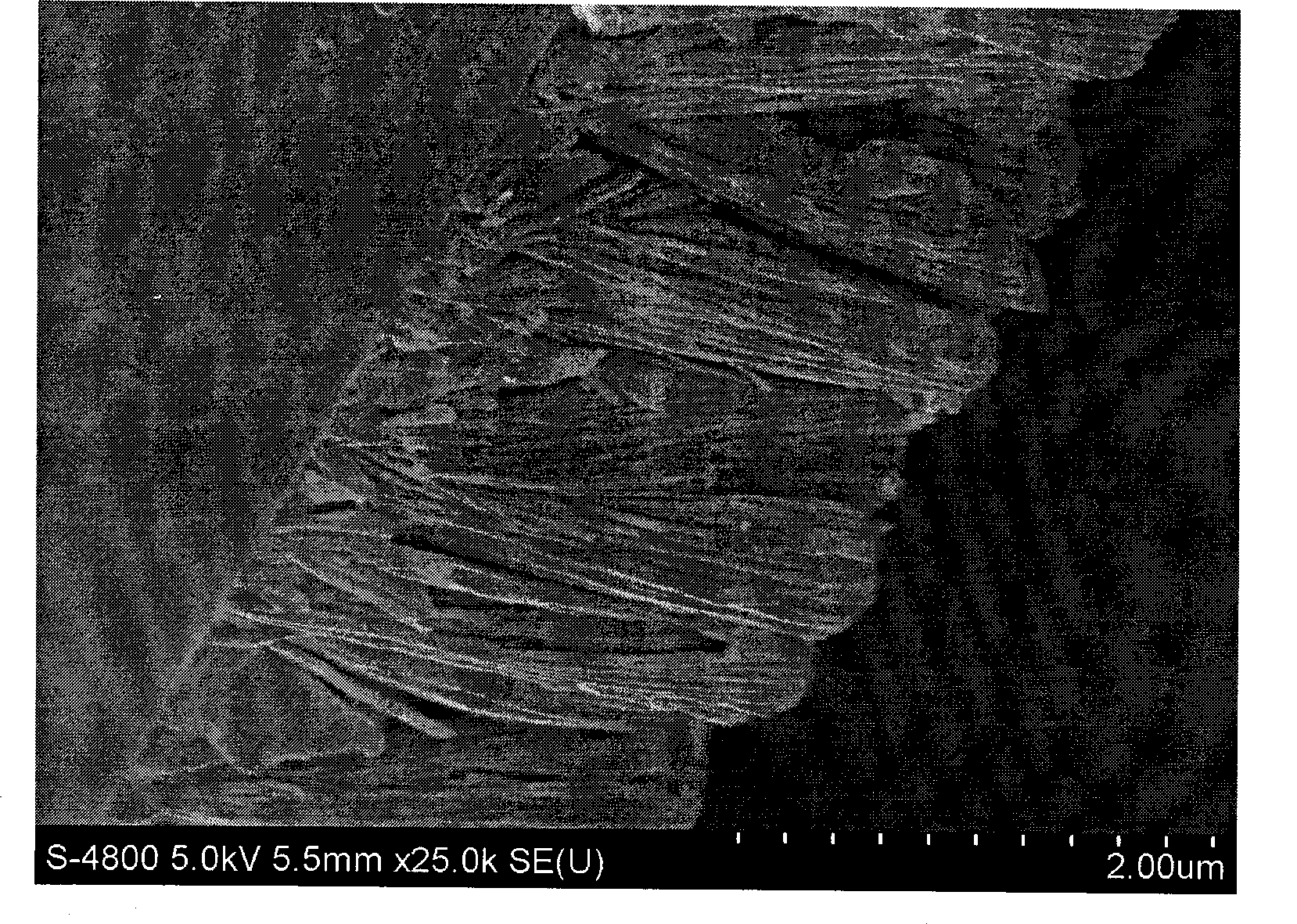

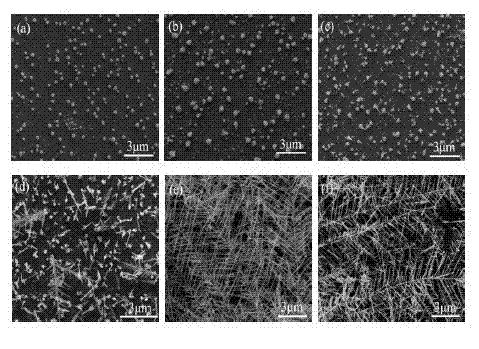

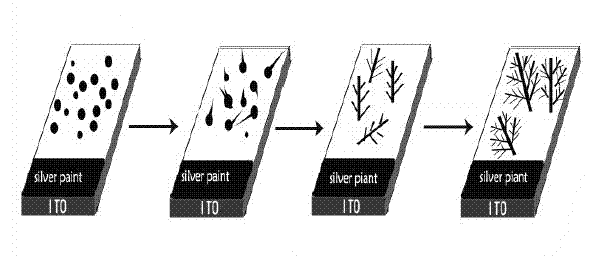

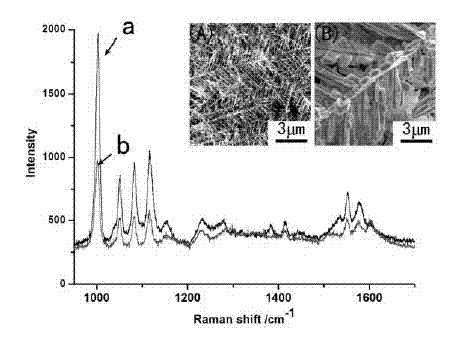

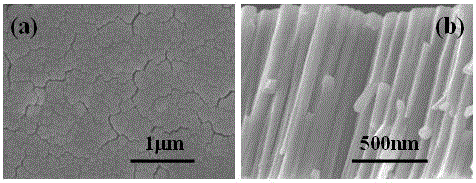

Au nano dendrites surface-reinforced Raman scattering substrate and preparation method thereof

InactiveCN105973865AUniform SERS signalSERS signal is reliableRaman scatteringPrecious metalPower flow

The invention discloses an Au nano dendrites surface-reinforced Raman scattering substrate and a preparation method thereof. The SERS active substrate is a layered micro nano structure composited by precious metal Au and a semiconductor ZnO. The preparation method employs a two-step constant current deposition method, an Au spin-coated ZnO nano rod array substrate generated on an ITO electro-conductive glass is taken as a work electrode, graphite flake is taken as a counter electrode, the Au nano dendrites can be produced. The active substrate is formed by a main part (the Au nano rod) hollow structure and a lim Au dendrite. The method has the advantages of simple process, low cost, small current, and low voltage, the Au dendrite can be transferred to a silicon chip substrate; the substrate obtained in the invention has the advantages of high stability, and ordered and controllable structure, and has high stability in the Raman spectroscopy detection.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

High temperature resistant antioxidative metal ceramic composite coating and preparation method thereof

InactiveCN103540936AFast deposition rateGood high temperature oxidation resistanceVacuum evaporation coatingSputtering coatingComposite filmOxidation resistant

The invention relates to high temperature resistant antioxidative coating materials, and particularly provides a high temperature resistant antioxidative metal ceramic composite coating and a preparation method thereof. The composite thin film is characterized in that the coating consists of refractory metal, refractory carbide and an intermetallic compound. The coating is 10-50 mu m thick. The refractory metal is one or more of molybdenum, tantalum, zirconium and hafnium, the refractory carbide consists of silicon carbide as well as one or more of tantalum carbide, zirconium carbide and hafnium carbide, and the intermetallic compound consists of one or more of molybdenum silicide, tantalum silicide, zirconium silicide, hafnium silicide, tantalum silicon carbide, zirconium silicon carbide and hafnium silicon carbide. The crystal structure of the coating consists of amorphous and / or polycrystal nanoparticles.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

Nano-particle reinforced copper-based composite material and preparation method thereof

ActiveCN103643075AExcellent mechanical and electrical propertiesSimple processMaterial nanotechnologyNanometreCrystallite

The invention discloses a nano-particle reinforced copper-based composite material and a preparation method thereof. The size of a copper matrix grain is smaller than 20 microns in the copper-based composite material; the nano-particle reinforced phase is molybdenum carbide, or molybdenum carbide and molybdenum, or molybdenum carbide and carbon; the particle size of the nano-particle reinforced phase is smaller than 200nm; the mass percent of Mo in the copper-based composite material is 0.1-15%; the mass percent of C is smaller than 1%. The nano-particle reinforced copper-based composite material disclosed by the invention is prepared by adopting an electronic beam physical vapor deposition process. The nano-particle reinforced copper-molybdenum-carbon composite material prepared by the method has excellent mechanical property and electrical property, and adopted electronic beam physical vapor deposition process is simple, low in cost and easy to control.

Owner:嘉兴市燕知网络科技有限公司

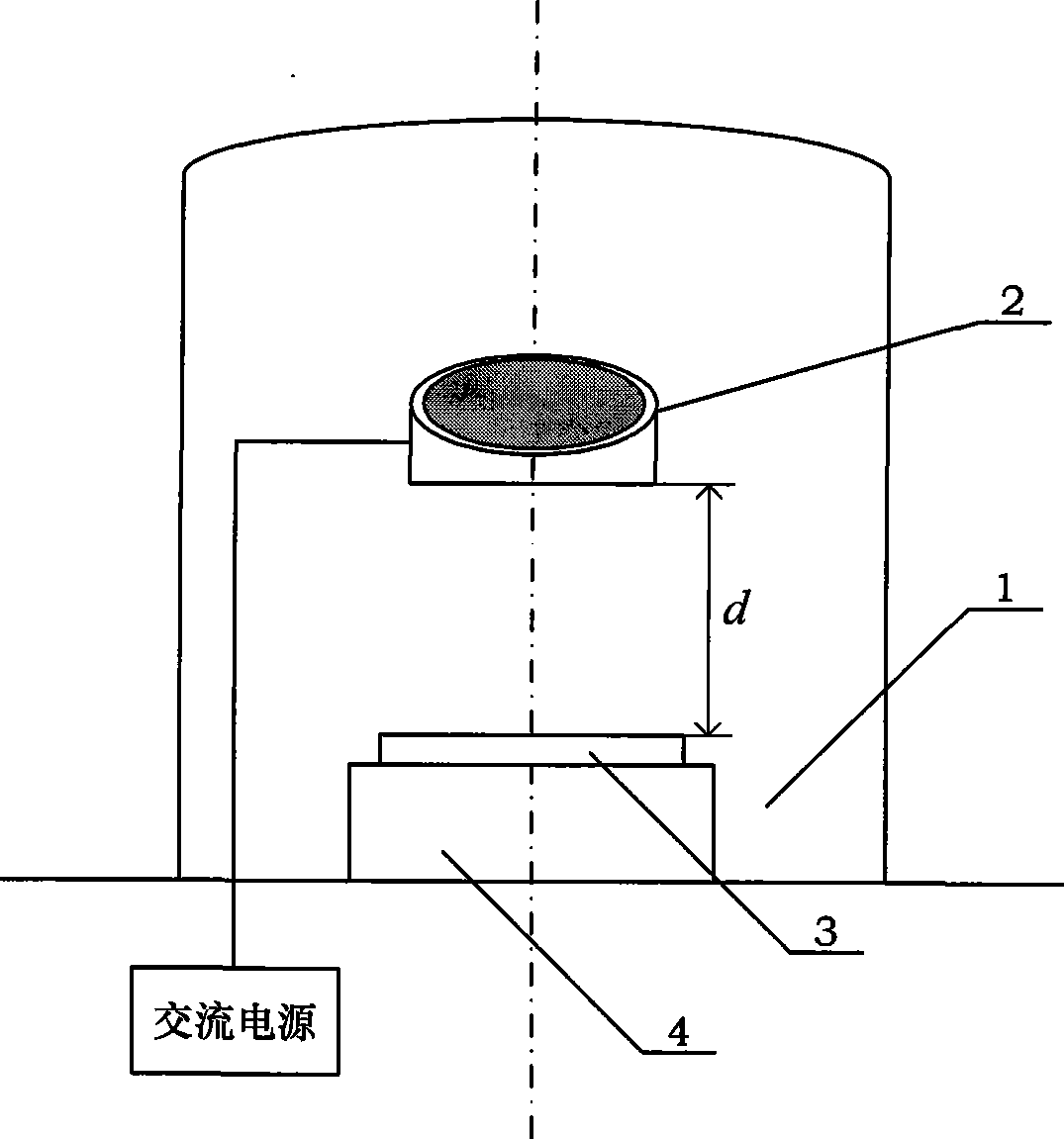

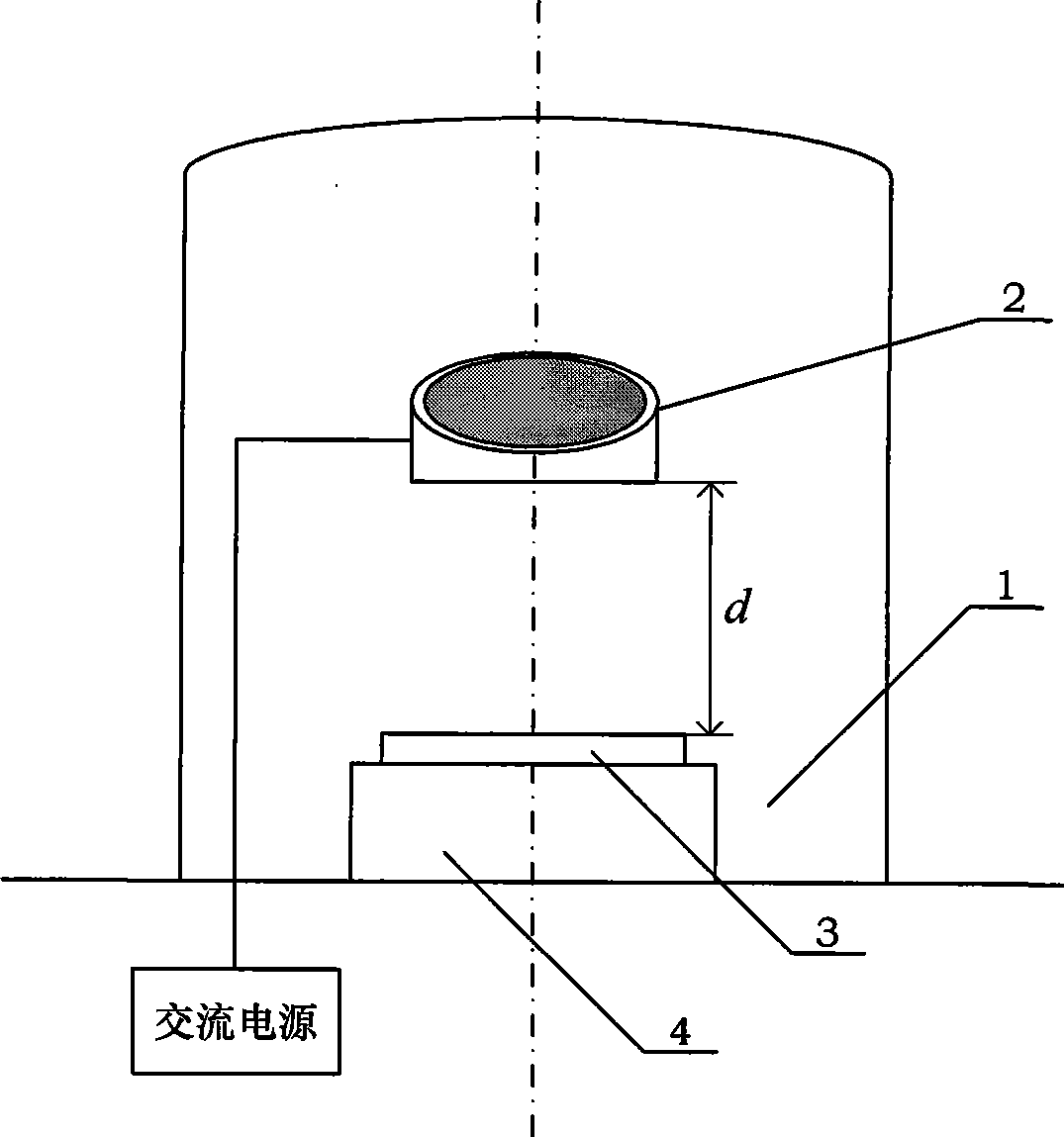

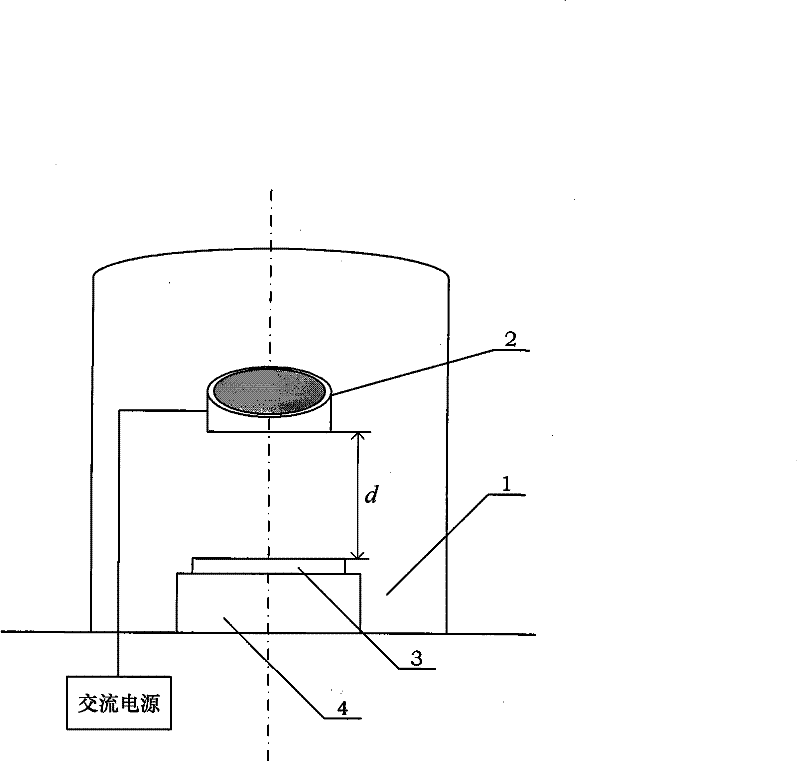

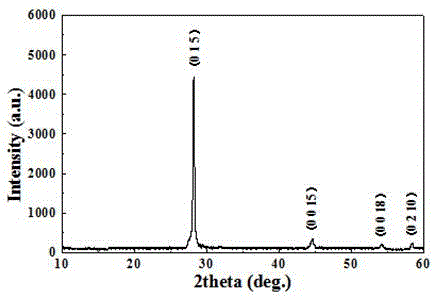

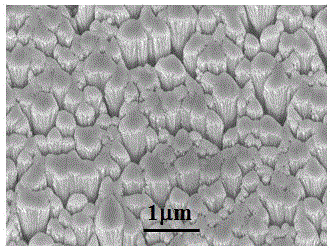

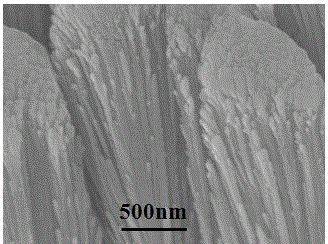

Preparation of tellurium nano-wire array based on physical vapour deposition

InactiveCN101435067AEvenly distributedUniform structureVacuum evaporation coatingSputtering coatingPower flowGas phase

The invention discloses a preparation method of tellurium nano wire array based on physical vapor deposition. By adjusting the magnitude of current output by alternative power supply and the distance of glass substrate and tungsten boat, a thin film with tellurium nano wire array structure is directly deposited on the glass substrate by thermal evaporation of tellurium material in a vacuum chamber; the whole deposition technique has simple process, low cost and easy scale production; and the obtained tellurium nano wire array has uniform structure, thus effectively guaranteeing uniform distribution of nanophase.

Owner:BEIHANG UNIV

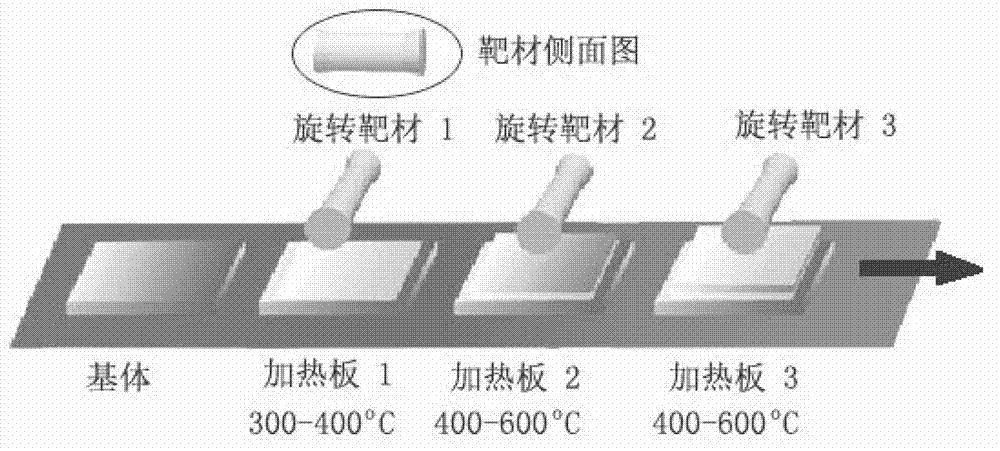

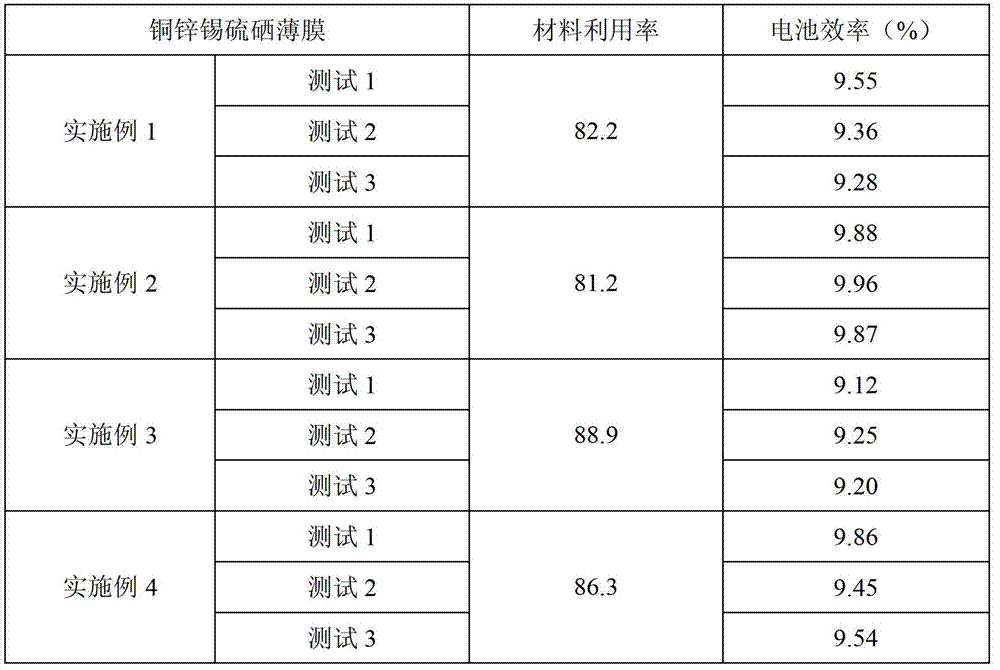

Method for preparing copper zinc tin sulfur selenium thin film by using alloy rotary target material

ActiveCN103208417AReduce manufacturing costImprove efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingSputteringSulfur

The invention discloses a method for preparing a copper zinc tin sulfur selenium thin film by using an alloy rotary target material. The method comprises the following steps of: (1) heating a substrate on which a molybdenum layer is deposited until the temperature rises to 300 to 400 DEG C, regulating sputtering power to 30 to 200 W by using a sputtering method, and sputtering to obtain a first thin film, wherein the surface of the first thin film is in a copper-poor zinc-rich state; (2) regulating the temperature of the substrate to 400 to 600 DEG C, regulating the sputtering power to 80 to 200 W by using the sputtering method, and sputtering to obtain a second thin film, wherein the surface of the second thin film is in a copper-rich state; and (3) regulating the temperature of the substrate to 400 to 600 DEG C, regulating the sputtering power to 30 to 200 W by using the sputtering method, and sputtering to obtain a third thin film, wherein the surface of the second thin film is in a copper-poor state, so that the copper zinc tin sulfur selenium thin film is prepared.

Owner:赣州优膜科技有限公司

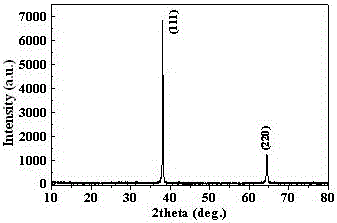

Method for preparing bismuth telluride nano-wire array by physical vapour deposition

The invention discloses a preparation method of a bismuth telluride nano-wire array by adopting a physical vapor deposition method. The method comprises the following steps: in a vacuum chamber, raw bismuth telluride is thermally evaporated and a membrane with bismuth telluride nano-wire array structure is deposited on the glass substrate by regulating the output electric current of the mains supply and the distance between the glass substrate and a tungsten boat. The whole deposition process is simple, the cost is low, and mass production is easy to be achieved; the obtained bismuth telluride nano-wire arrays are uniform in structure and the even distribution of nanophases is effectively ensured.

Owner:BEIHANG UNIV

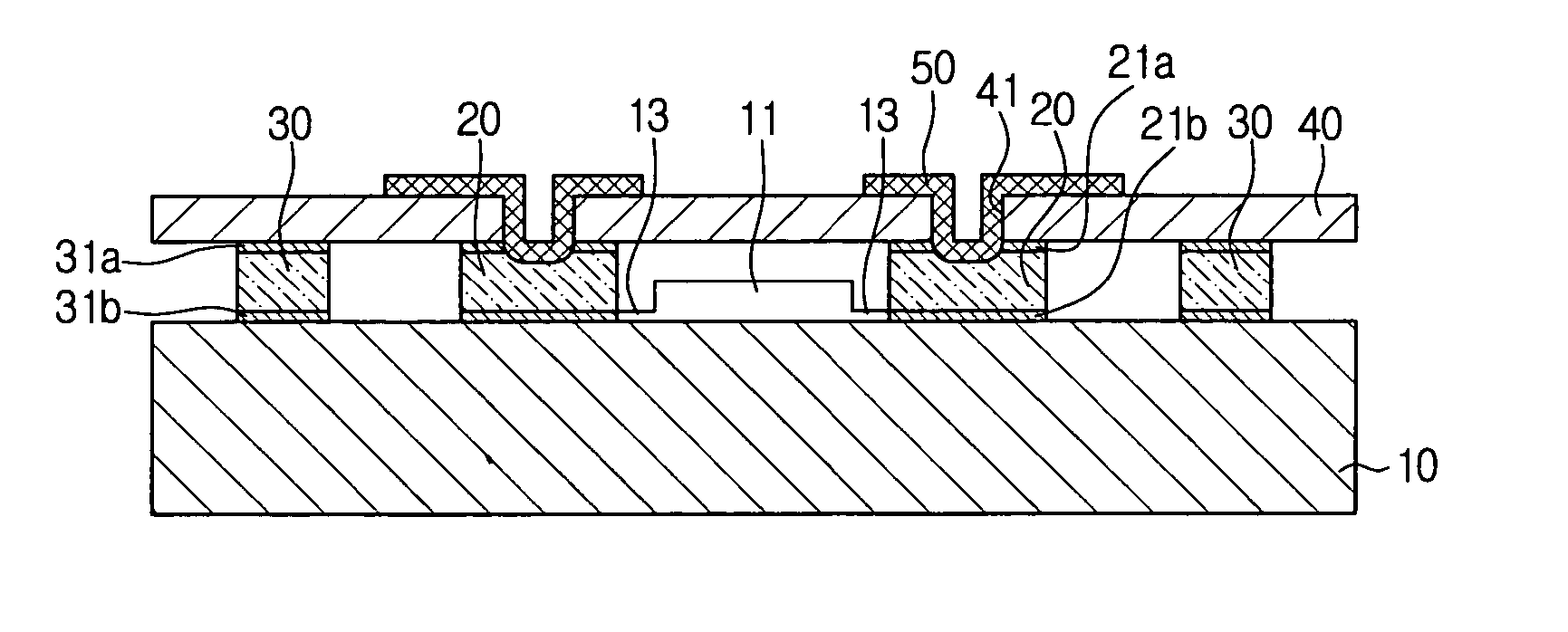

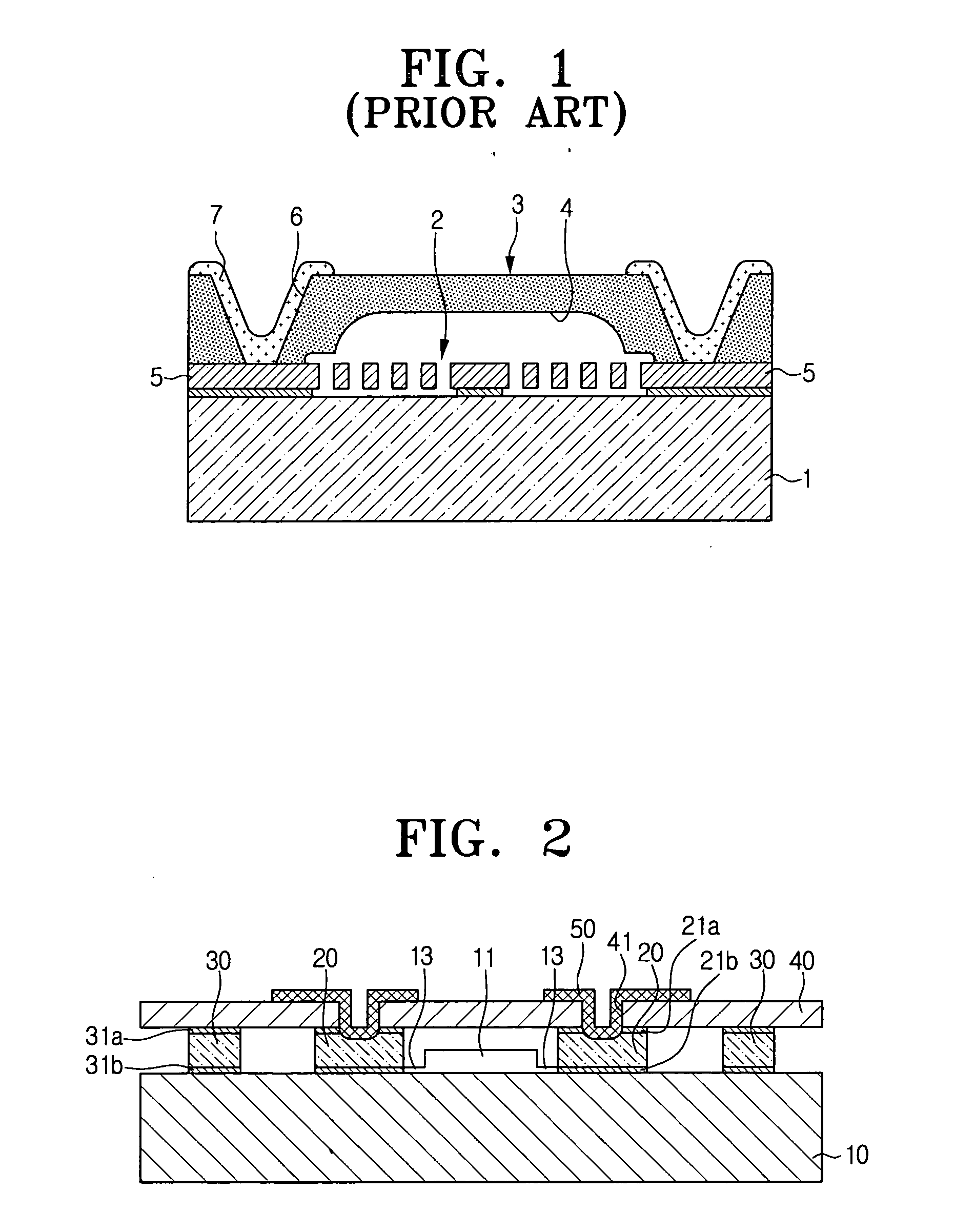

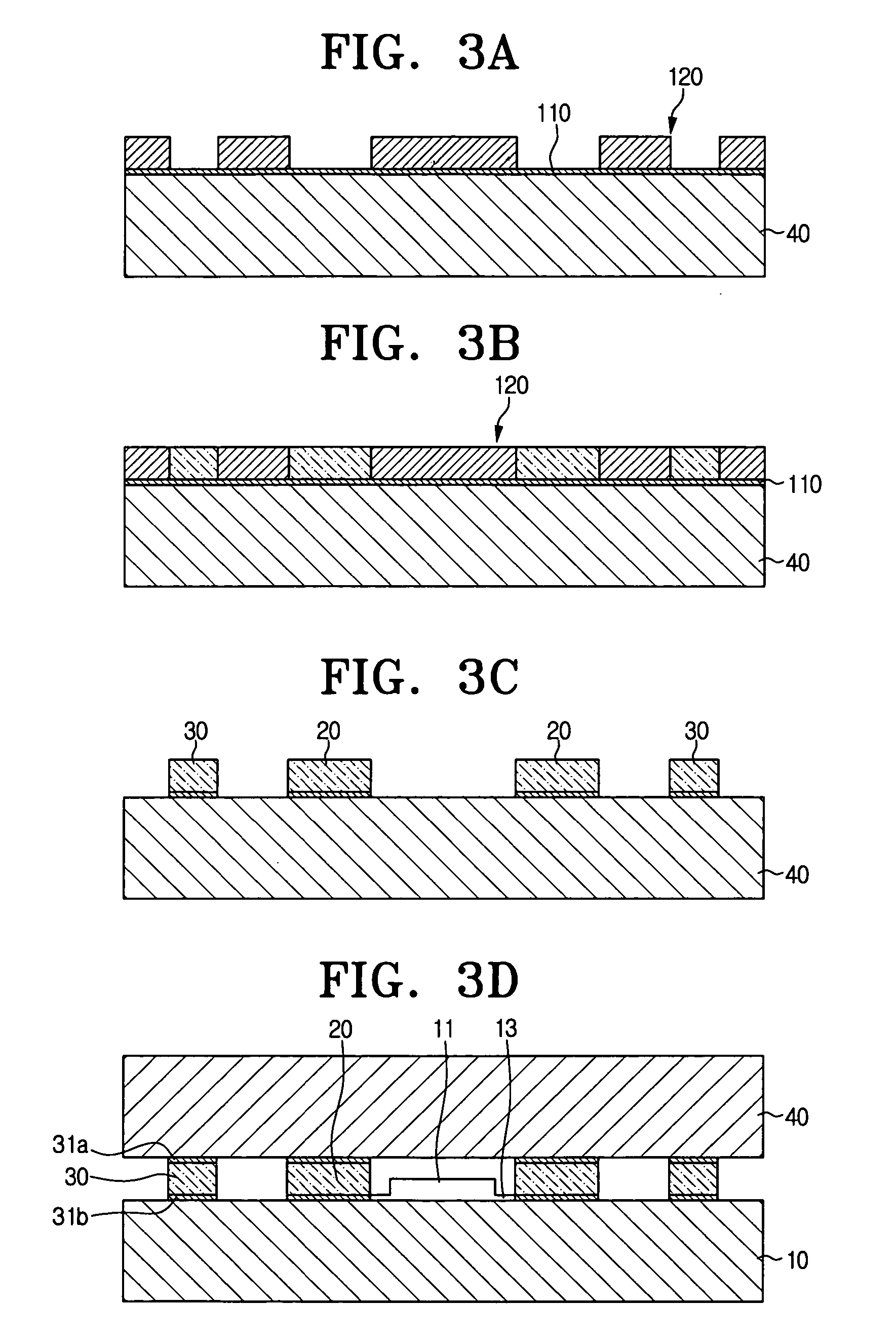

MEMS device package and method for manufacturing the same

InactiveUS20060141652A1Relieve pressureEasy to depositSemiconductor/solid-state device manufacturingMicrostructural devicesMicroelectromechanical systemsActive devices

A micro electromechanical system (MEMS) device package and a method of manufacturing the same are provided. The MEMS device package includes: a device substrate with a MEMS active device being formed on the top surface thereof; internal electrode pads, each of which is positioned on the opposite side of the MEMS active device and electrically connected to the MEMS active device; sealing pads positioned outside of the internal electrode pads; a closure substrate joined to the device substrate through the sealing pads, the closure substrate having via holes formed at the areas where the internal electrode pads are positioned; and external electrode pads formed on the top surface of the closure substrate in such a way that the external electrode pads are electrically connected to the internal electrode pads through the via holes. The internal electrode pads and the sealing pads are formed from an identical material such as Au and thus the device substrate and the closure substrate are bonded to each other with direct bonding such as Au—Au direct bonding via the sealing pads.

Owner:SAMSUNG ELECTRONICS CO LTD

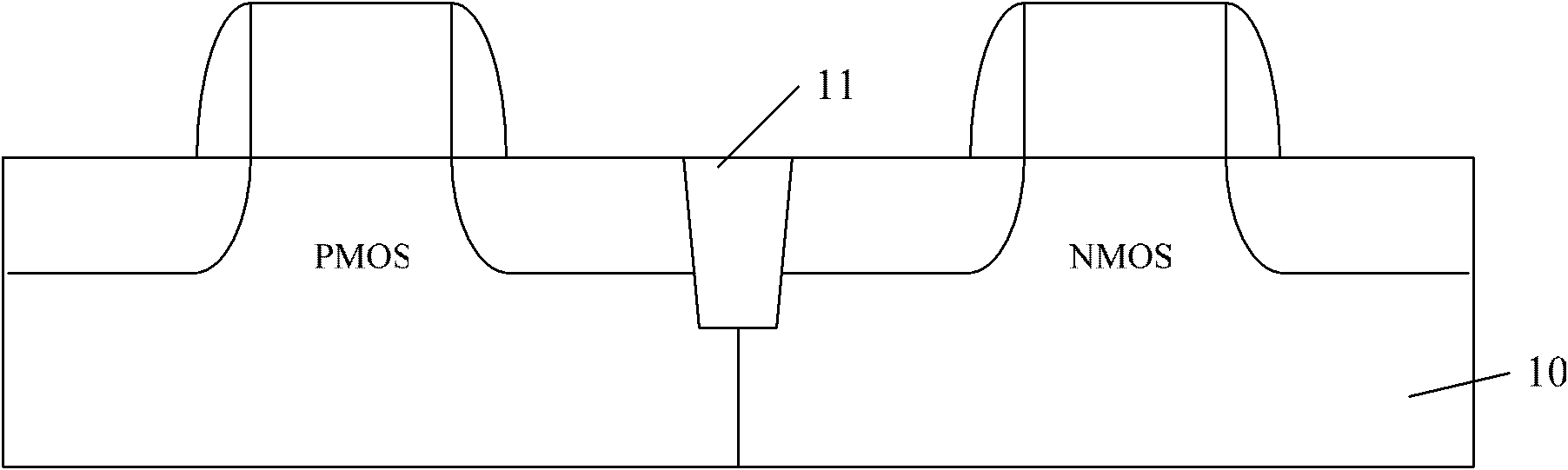

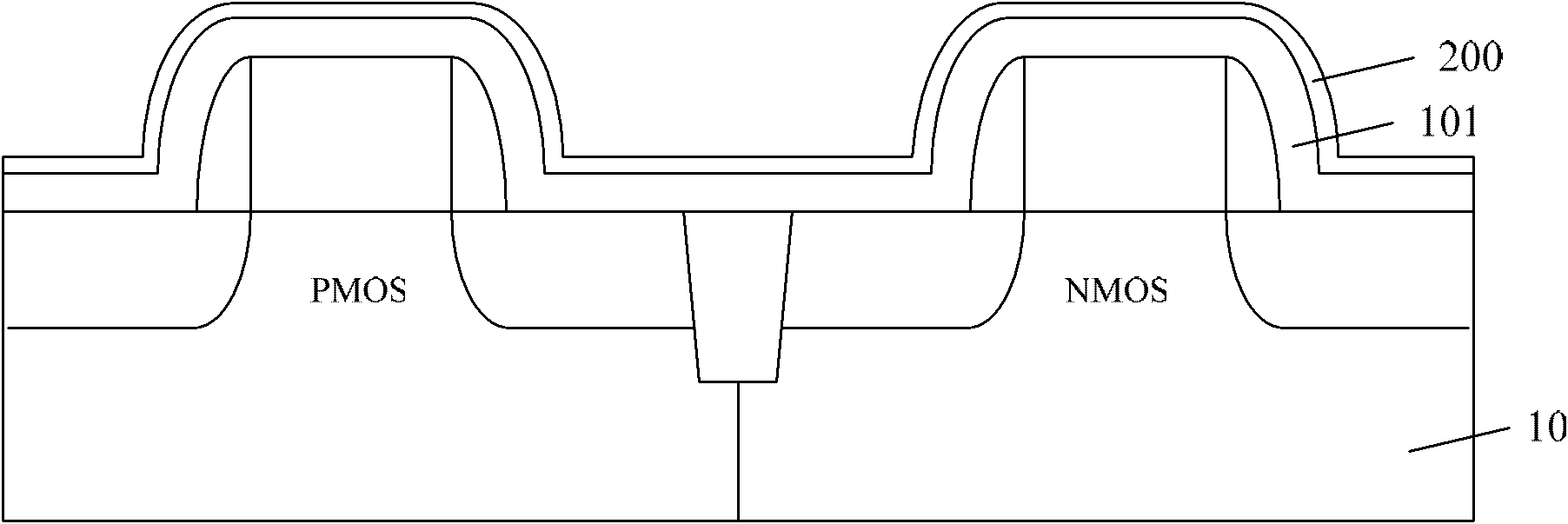

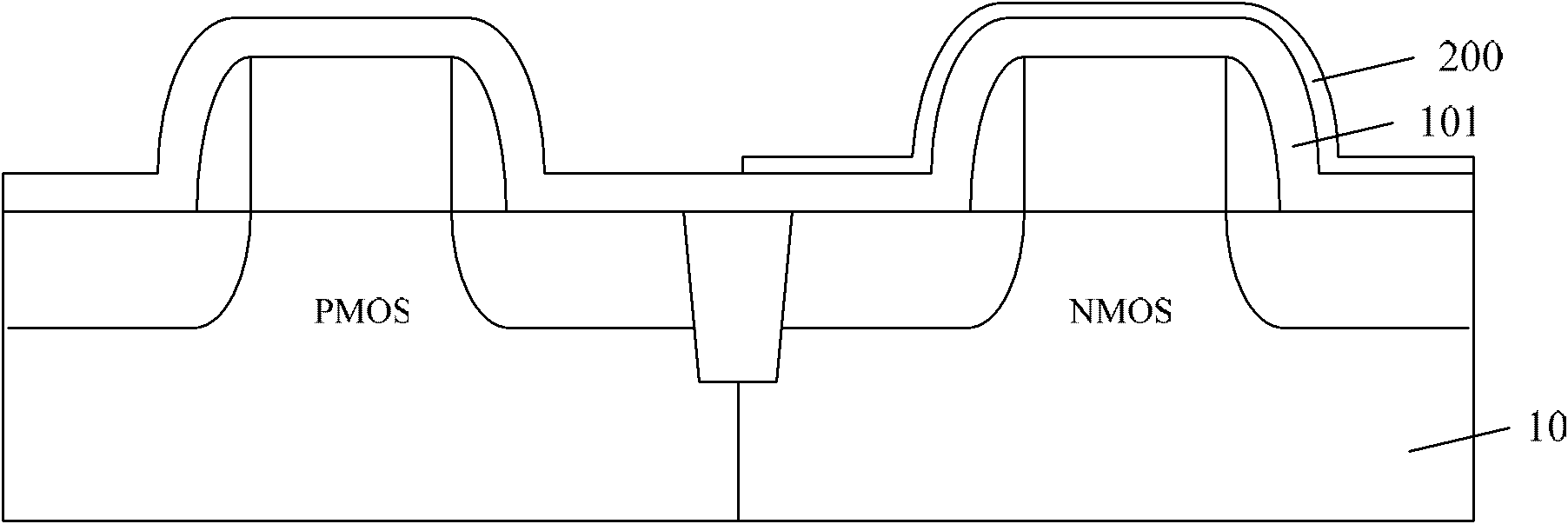

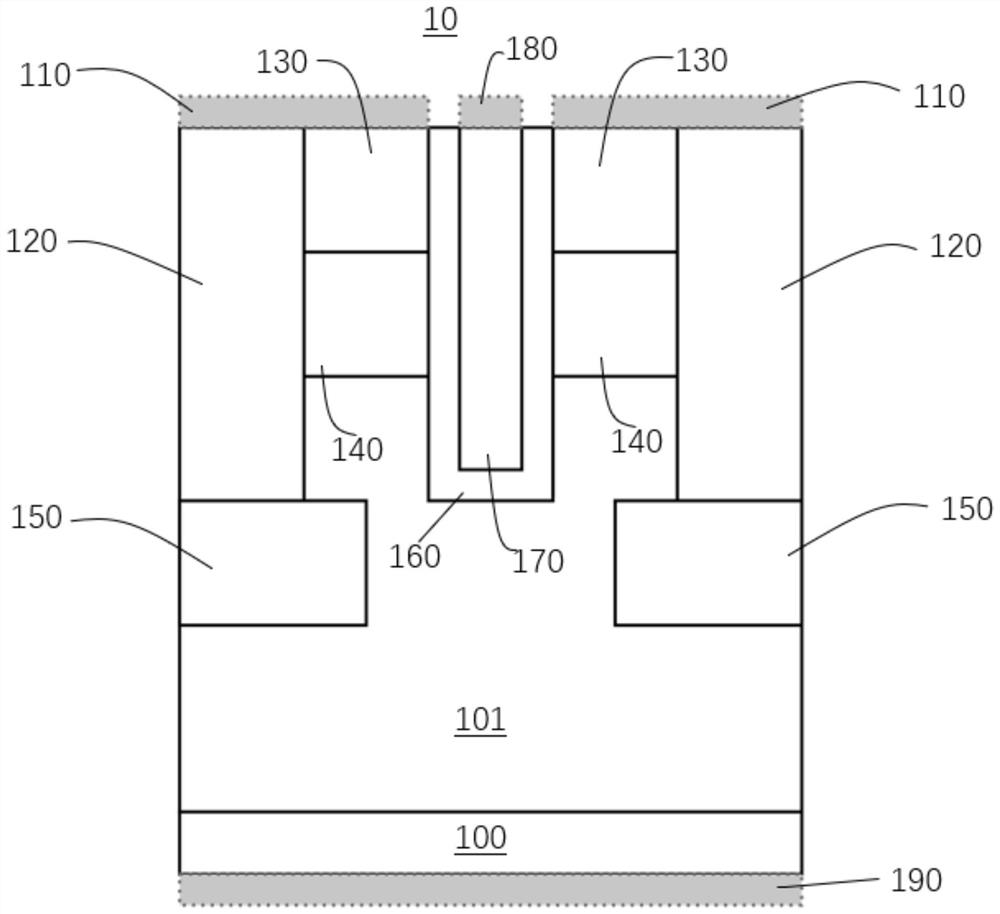

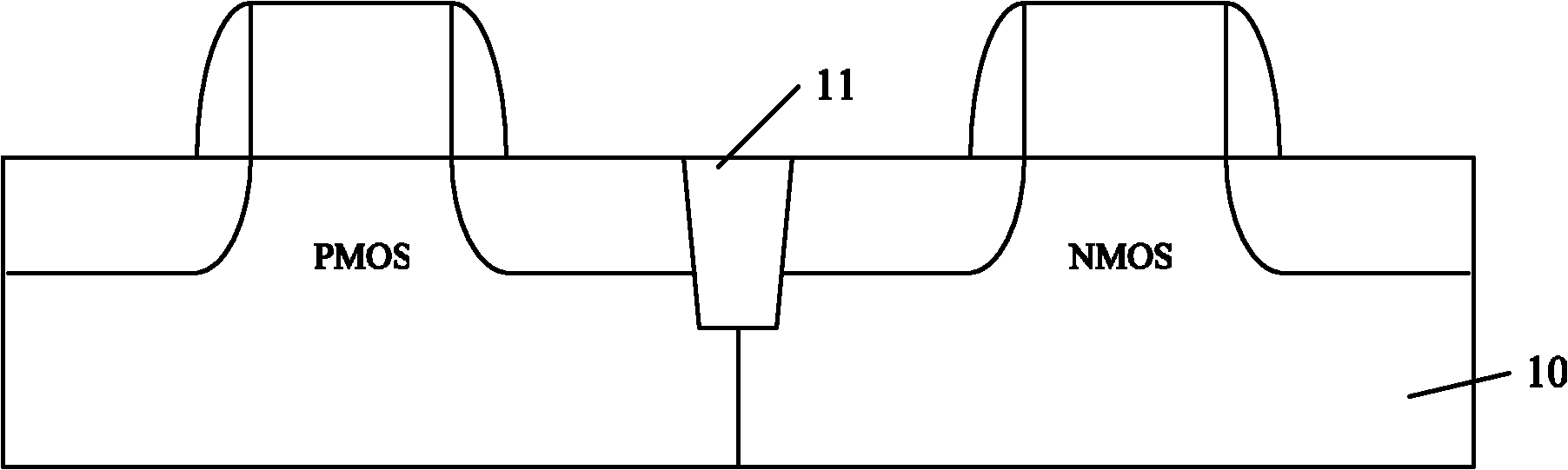

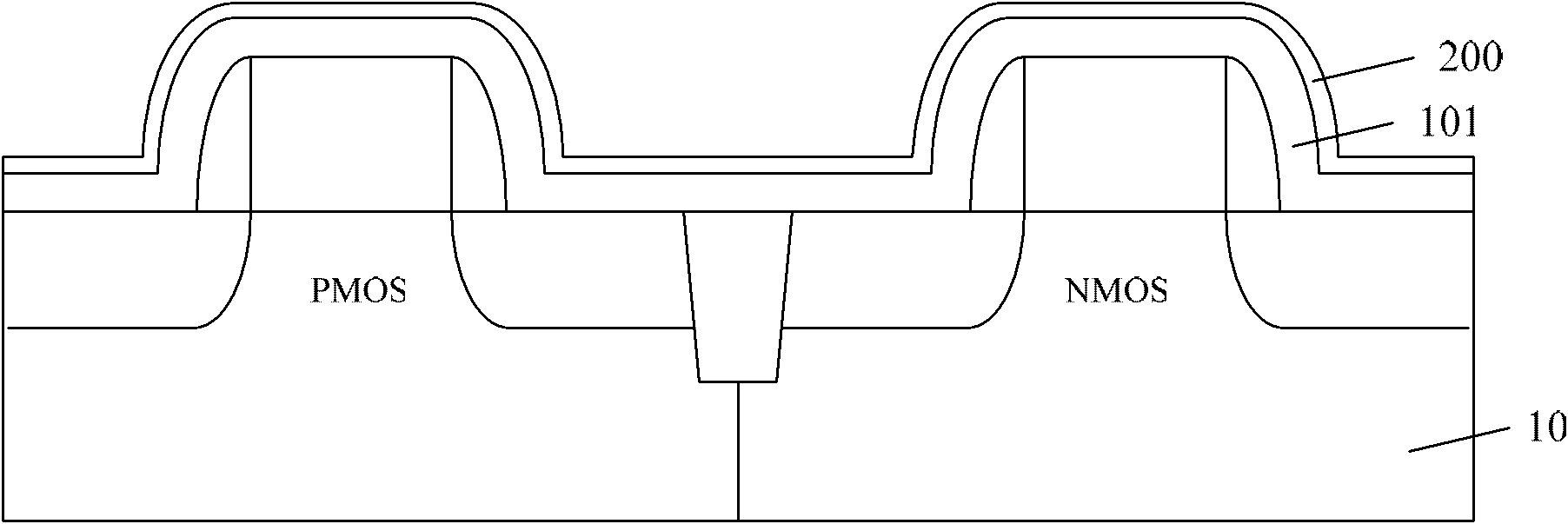

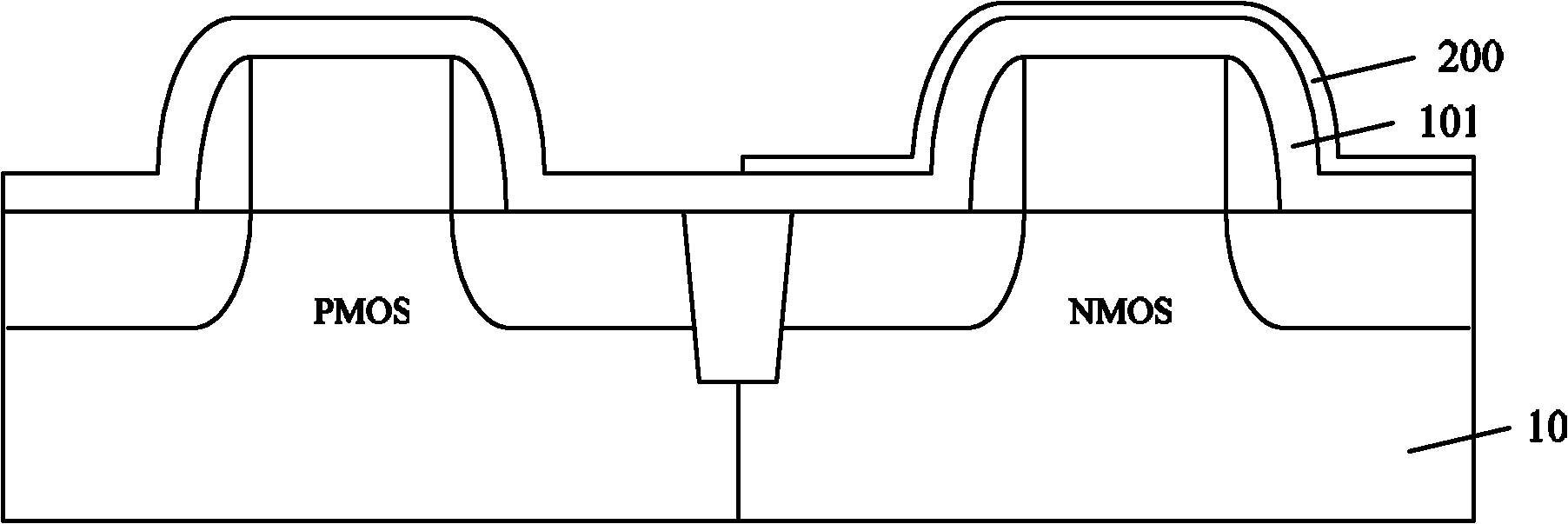

Manufacturing method of strain CMOS device

ActiveCN102487017ASimple deposition processSolve the problem of over etchingSemiconductor/solid-state device manufacturingCMOSEtching

The invention provides a manufacturing method of a strain CMOS device. The method comprises the following steps: providing a CMOS device; successively forming a first stress layer and a film oxidation layer on a CMOS device surface; imaging the film oxidation layer so as to expose a part of the first stress layer which is located in a PMOS transistor area; taking the film oxidation layer as a hard mask so as to etch the first stress layer; at least forming a sacrificial barrier layer on a film oxidation layer surface; forming a second stress layer on a formed semiconductor structure surface; taking the sacrificial barrier layer as an etching stop layer so as to etch a part of the second stress layer which is located in the NMOS transistor area; removing the sacrificial barrier layer. In the invention, through forming the sacrificial barrier layer on the film oxidation layer surface and taking the sacrificial barrier layer as the etching stop layer, a problem of over etching can be solved. Further, the sacrificial barrier layer can be amorphous carbon. A deposition technology is simple and the sacrificial barrier layer removing is easy to be performed.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

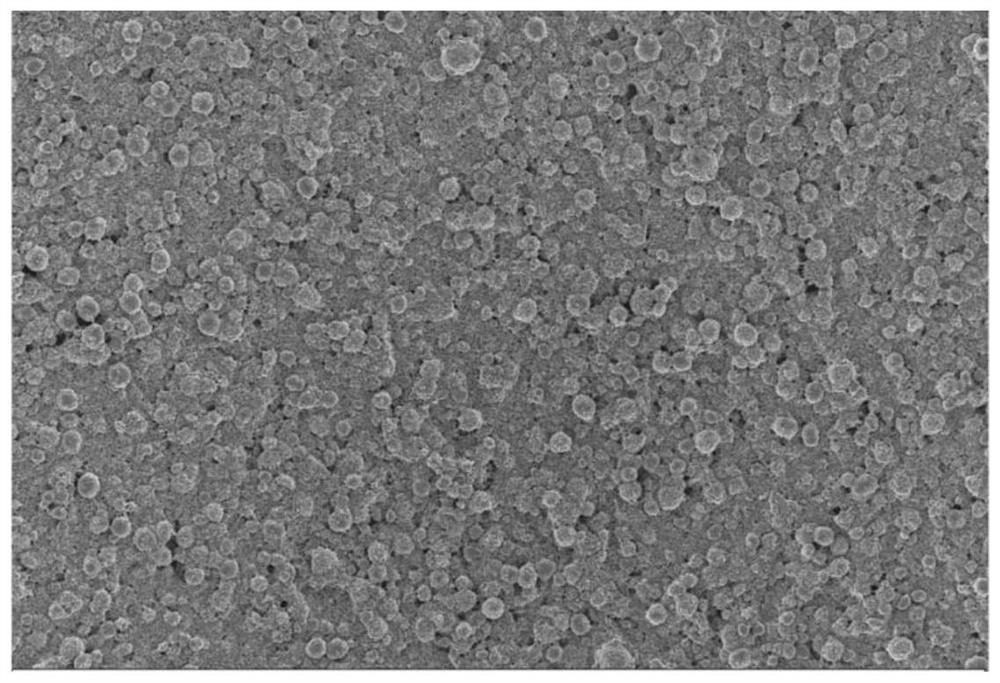

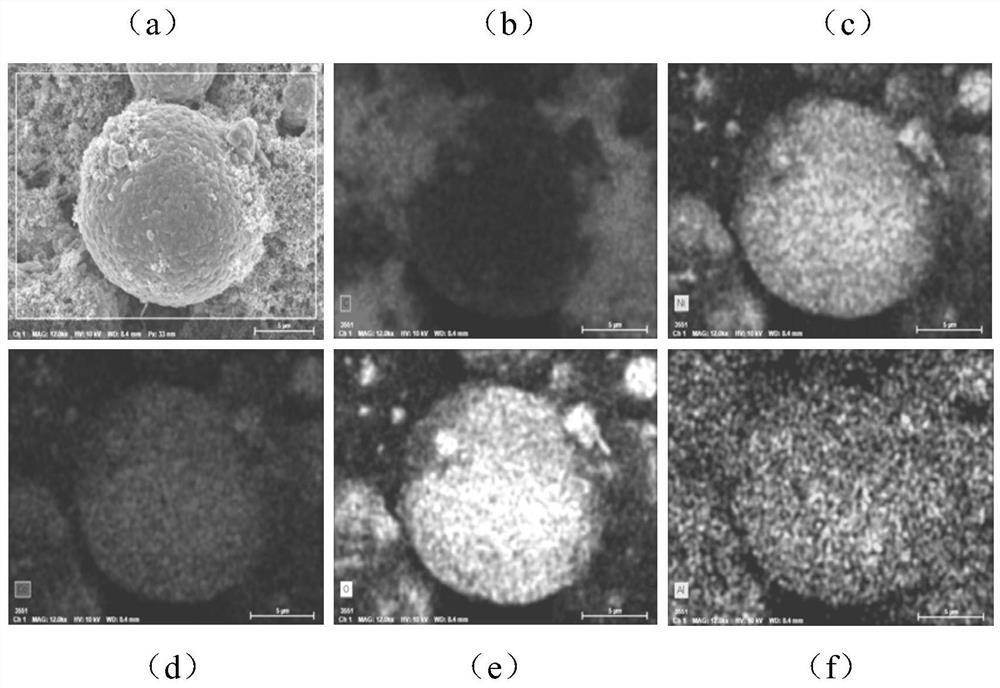

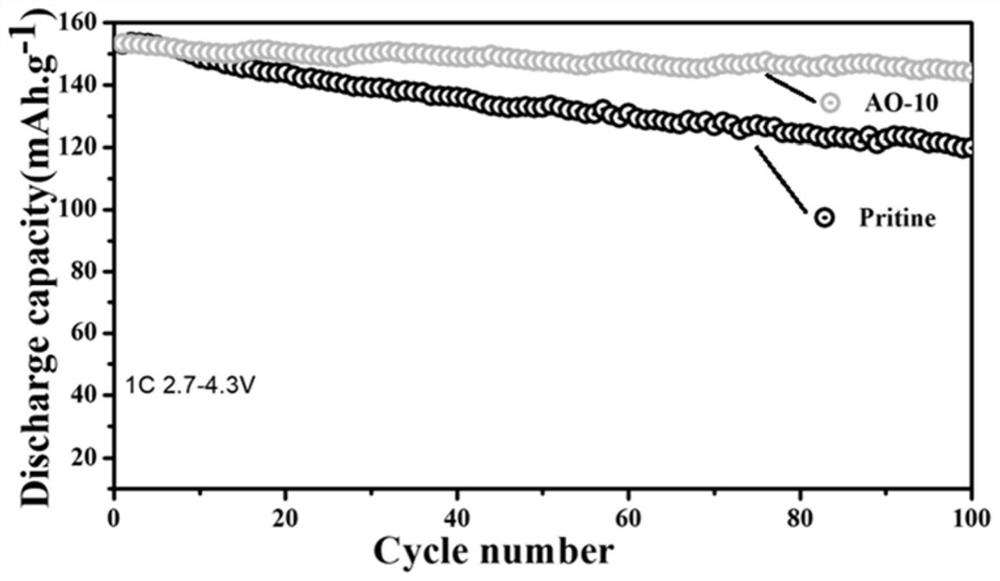

Surface coating modification method for ternary positive electrode material of lithium ion battery

PendingCN113488643ASimple processReduce energy consumptionSecondary cellsPositive electrodesElectrical batteryLithium-ion battery

The invention discloses a surface coating modification method for a ternary positive electrode material of a lithium ion battery, and belongs to the field of positive electrode materials of lithium ion batteries. The method comprises the following steps: sequentially loading an aluminum source and an oxygen source onto the surface of a ternary positive electrode plate of the lithium ion battery by using carrier gas by utilizing an atomic deposition system: adsorbing a layer of aluminum source on the surface of the ternary positive electrode plate of the lithium ion battery, and then carrying out combination reaction on the oxygen source and the adsorbed layer of aluminum source to generate an aluminum oxide layer; repeating the cycle number of the aluminum oxide layer, namely depositing an aluminum oxide film on the surface of the ternary positive electrode plate of the lithium ion battery, so as to realize coating modification on the surface of the ternary positive electrode material of the lithium ion battery. The surface coating modification method for the ternary positive electrode material of the lithium ion battery is short in preparation period, safe and simple in method, low in energy consumption, simple in required equipment and suitable for modification of various ternary positive electrode materials.

Owner:SHAANXI UNIV OF SCI & TECH

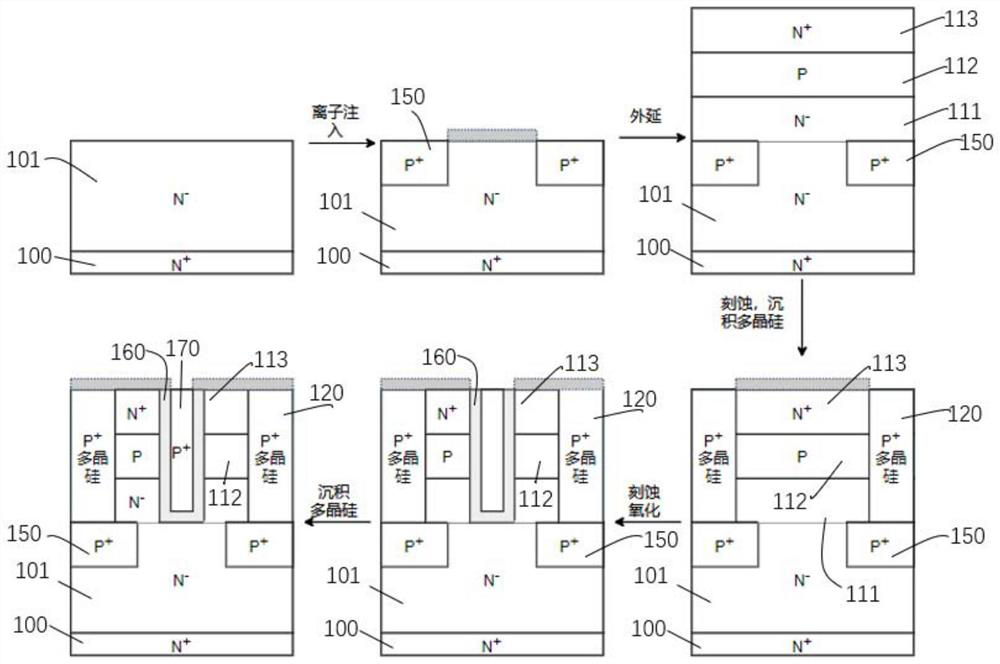

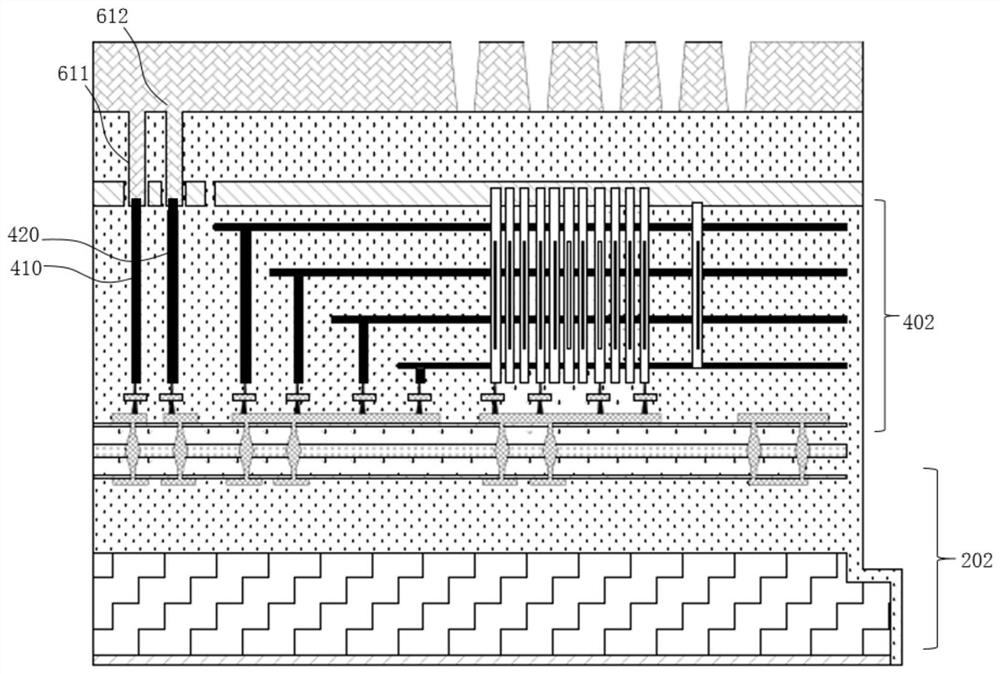

Silicon carbide semiconductor device and preparation method thereof

PendingCN113972261ASimple deposition processReduced depletion region areaSemiconductor devicesElectrical field strengthDevice material

The invention relates to a silicon carbide semiconductor device and a preparation method thereof. Two sides of a trench gate dielectric layer are respectively provided with two heavily doped polycrystalline silicon trench regions of a second conductive type. Due to the energy band structure of silicon carbide and polycrystalline silicon, the area of a depletion region of a shielding region is reduced by the polycrystalline silicon trench region. The reduction of the area of the depletion region not only can reduce the electric field intensity at the corner of the protective trench gate medium, but also can slightly hinder electron flow, thereby reducing the resistance of the drift region. The polycrystalline silicon deposition process of the second conduction type is relatively simple, and the problems of depth and transverse diffusion caused by the traditional silicon carbide ion implantation process of the second conduction type are avoided by adopting the heavily doped polycrystalline silicon trench region of the second conduction type.

Owner:SONGSHAN LAKE MATERIALS LAB +1

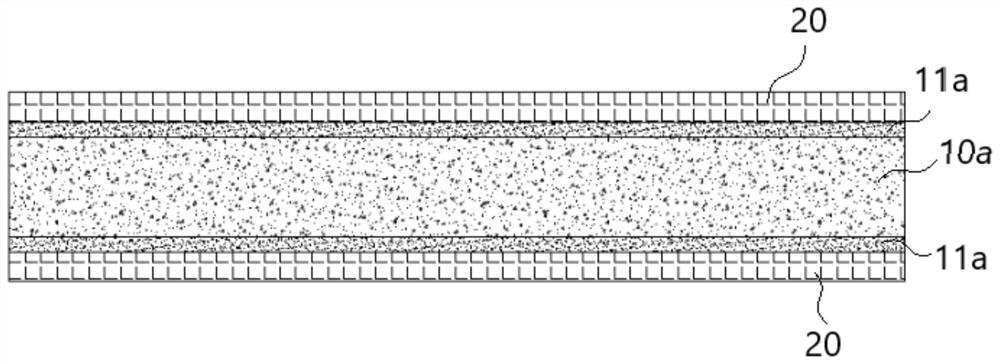

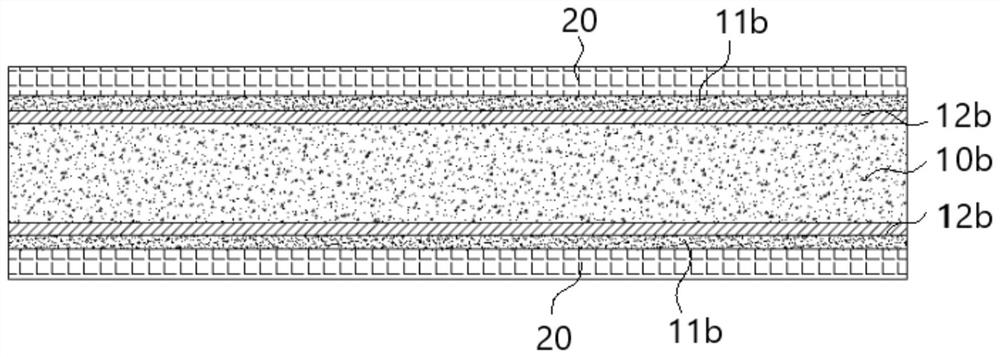

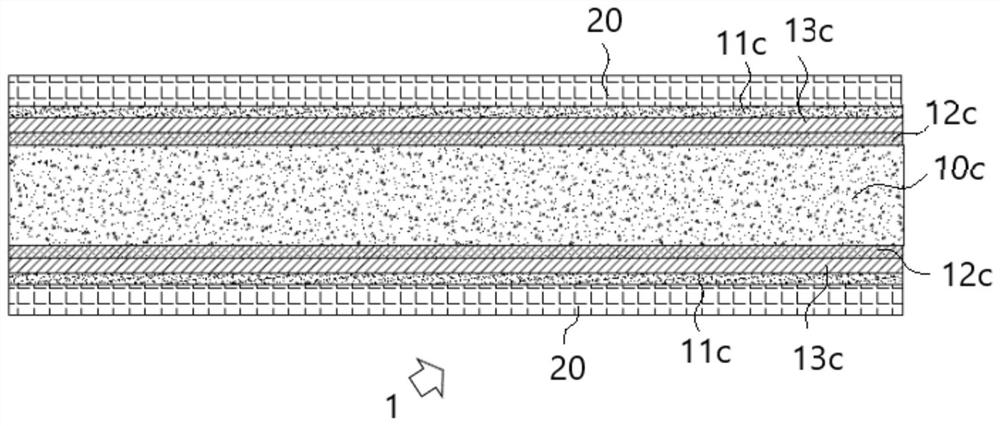

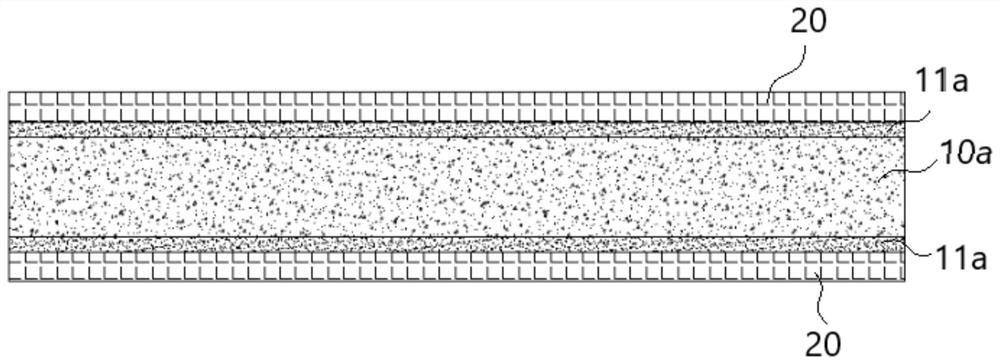

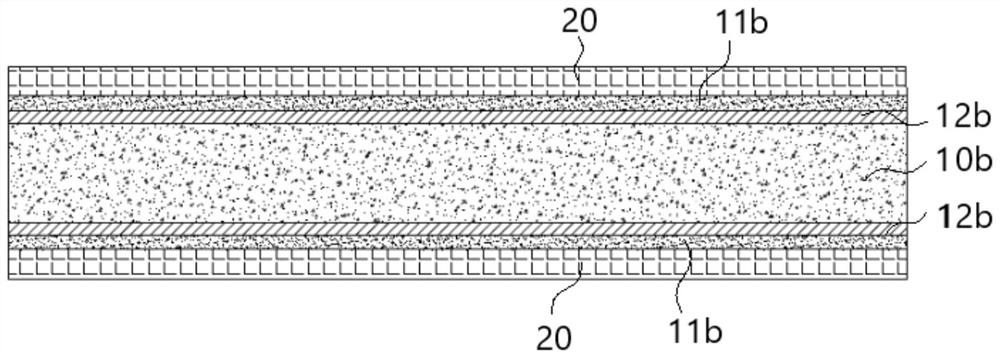

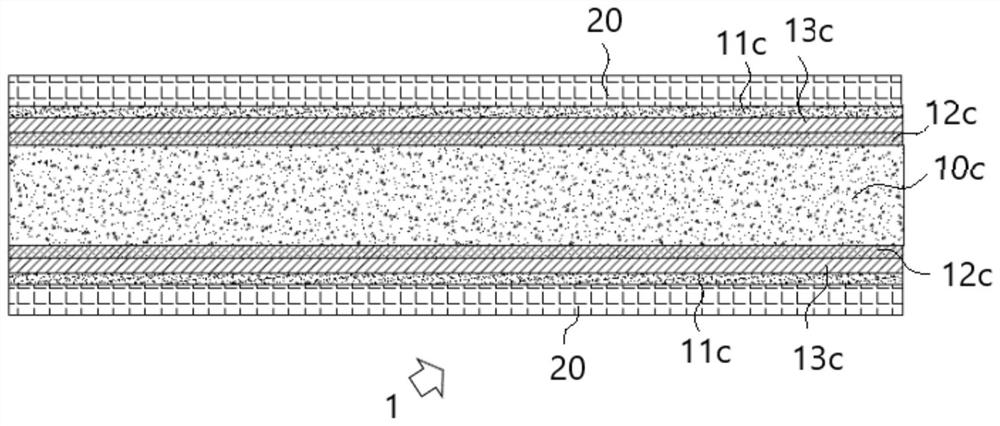

Low-contact-resistance fuel cell stack and fuel cell using same

PendingCN111769293AGuaranteed hydrophobicityGuaranteed corrosion resistanceCell electrodesFuel cellsCarbon filmInternal resistance

The invention discloses a low-contact-resistance fuel cell stack and a fuel cell using the same. Each fuel cell unit comprises an anode plate, a membrane electrode and a cathode plate which are sequentially stacked into a whole, wherein the membrane electrode is provided with gas diffusion layers on each of two sides; the cathode plate and the anode plate are silicon polar plates made of doped conductive crystalline silicon materials; the silicon polar plates are provided with front reducing agent runners and / or back oxidizing agent runners; an intermediate layer for reducing contact resistance is arranged between each silicon polar plate and the corresponding gas diffusion layer; the intermediate layer are deposition films formed by a deposition process; and each deposition film comprisesa carbon deposition film in contact with the corresponding gas diffusion layer. According to the low-contact-resistance fuel cell stack and the fuel cell using the same of the invention, the metal deposition film are adopted as the intermediate transition layers, so that the contact resistance between the carbon films and the surfaces of the silicon polar plates can be obviously reduced, so thatthe internal resistance of the fuel cell stack is obviously reduced.

Owner:浙江海晫新能源科技有限公司

A high hardness and high corrosion resistance high entropy alloy nitride coating and preparation method thereof

ActiveCN108220880BImprove corrosion resistanceIncrease productivityVacuum evaporation coatingSputtering coatingHigh entropy alloysNitride

The invention provides a high-hardness high-corrosion-resistance high-entropy alloy nitride coating. The molecular formula of the high-hardness high-corrosion-resistance high-entropy alloy nitride coating is (AlCrTiZrNbV)N. The invention further provides a preparation method of the coating. The method comprises the steps of firstly, cleaning a matrix and then conducting ion cleaning; secondly, sending the treated matrix to a sputtering chamber to deposit a TiN transition coating, controlling a Ti target material through a DC cathode and depositing the TiN transition coating of 100-200 nm; andthirdly, depositing a TiAlN transition coating on the TiN transition coating and depositing the (AlCrTiZrNbV)N coating on the TiAlN transition coating. The (AlCrTiZrNbV)N coating obtained through thepreparation method has high hardness exceeding 35 GPa and also has excellent corrosion resistance. The coating has the characteristics of being simple in production process, high in deposition speed,low in cost and the like and also has the advantages of being high in production efficiency, low in energy consumption and low in equipment requirement.

Owner:SHANGHAI NEWARC COATING TECH CO LTD

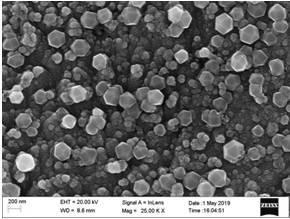

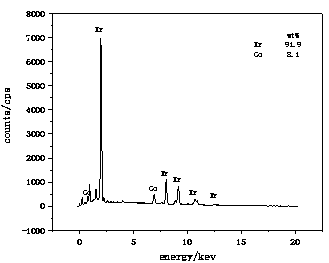

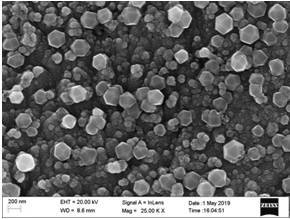

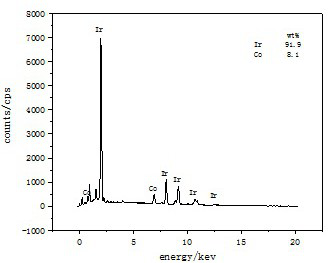

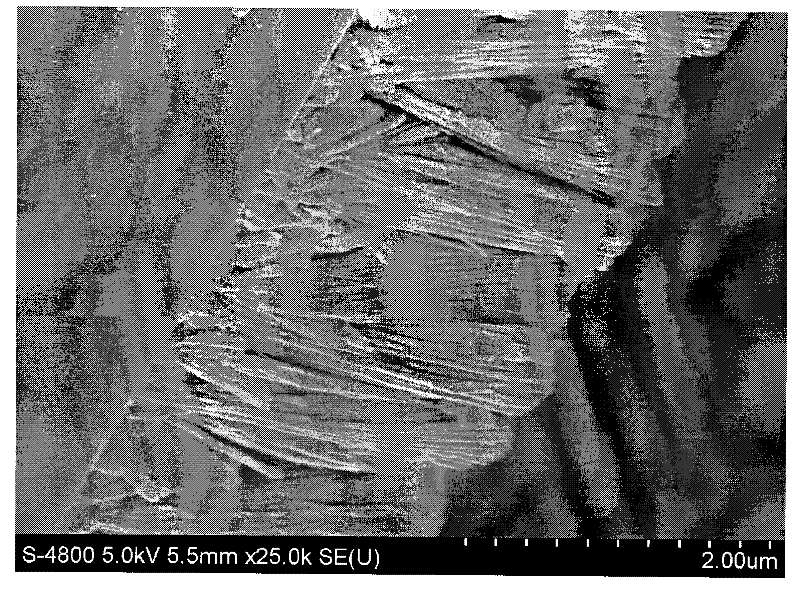

Polyhedral cobalt iridium nano particle electrolytic hydrogen evolution catalyst and plating solution formula and preparation method thereof

ActiveCN110453256ASimple deposition processSize is easy to controlElectrode shape/formsIridiumBenzotriazole

The invention discloses a polyhedral cobalt iridium nano particle electrolytic hydrogen evolution catalyst and a plating solution formula and a preparation method thereof. The cobalt iridium nano particles have octahedral and octahedral structures, the particle size is 10-250 nm, the chemical components of cobalt and iridium in the particles are uniformly distributed, the iridium content is 45-95wt%, the catalytic hydrogen evolution performance tower fresnel slope of the catalyst is 30-40 mV / decade. The plating solution formula of the catalyst is that the cobalt salt is 5-200 mmol / L of cobaltsulfamate and 1-100 mmol / L of cobalt sulfamate; the iridium salt is 10-150 mmol / L of hexa-bromo-iridium (IV) acid sodium and 1-100 mmol / L of hexa-bromo-iridium (III) acid sodium; the conductive saltis 0.1-500 mmol / L of sodium bromide and 0.1-100 mmol / L of sodium chloride; the complexing agent is 1-20 mmol / L of triammonium citrate and 1-10 mmol / L of sodium tetraborate l; and the other additives are 1-10 mmol / L of benzotriazole, 1-10 mmol / L of thiourea and 1-5 mmol / L of sodium dodecyl benzene sulfonate. The preparation method is prepared by an electrochemical deposition process, is high in efficiency and can be applied to the surface preparation of a conductive substrate with a complicated shape, and the size of the nano particles and the components of the nano particles are controllable;in addition, the catalytic performance is high, and the stability is high.

Owner:CHANGZHOU UNIV

Method for reducing carbon-silicon contact resistance

PendingCN111916783AGuaranteed hydrophobicityGuaranteed corrosion resistanceFinal product manufactureFuel cellsCarbon filmDeposition process

The invention discloses a method for reducing the contact resistance of carbon and silicon, and the method employs a silicon plate which reduces the contact resistance between the silicon plate and acarbon film. The process comprises the following operation steps: S10) preparing a silicon plate, wherein the silicon plate is made of a doped conductive crystalline silicon material; S20) obtaining atransition deposition film and a carbon deposition film on the silicon plate through a deposition process, wherein the transition deposition film and the carbon deposition film are respectively formed through a single deposition process or once formed through a single deposition process. by arranging the structural design of the transition deposition film, the contact resistance between the silicon plate and the carbon deposition film is remarkably reduced.

Owner:浙江海晫新能源科技有限公司

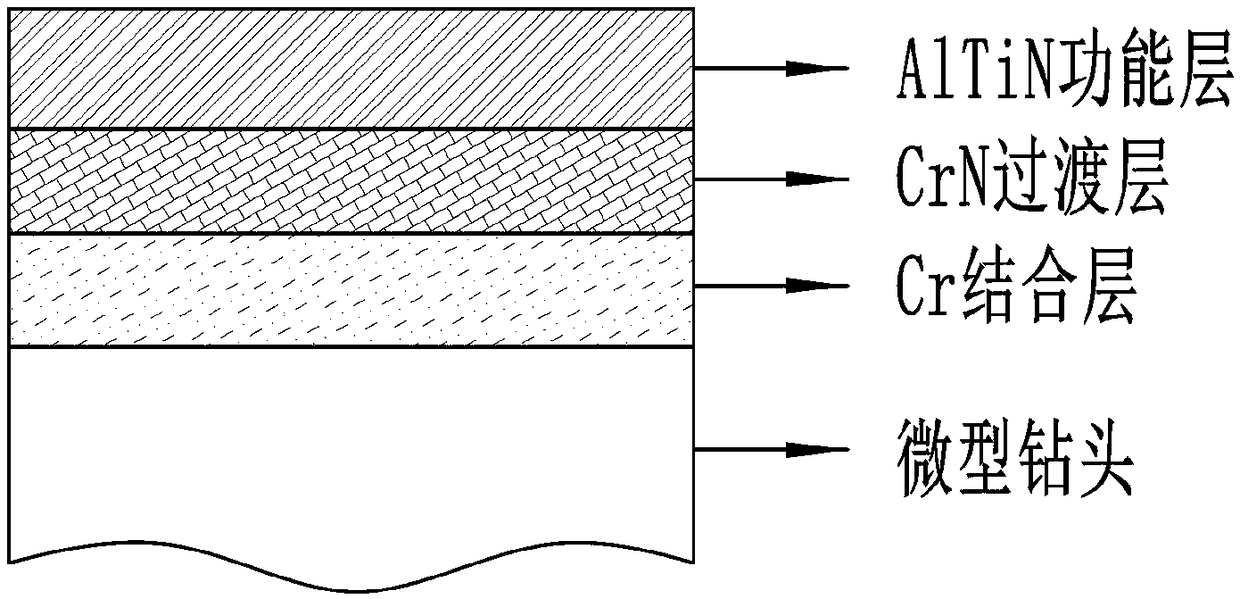

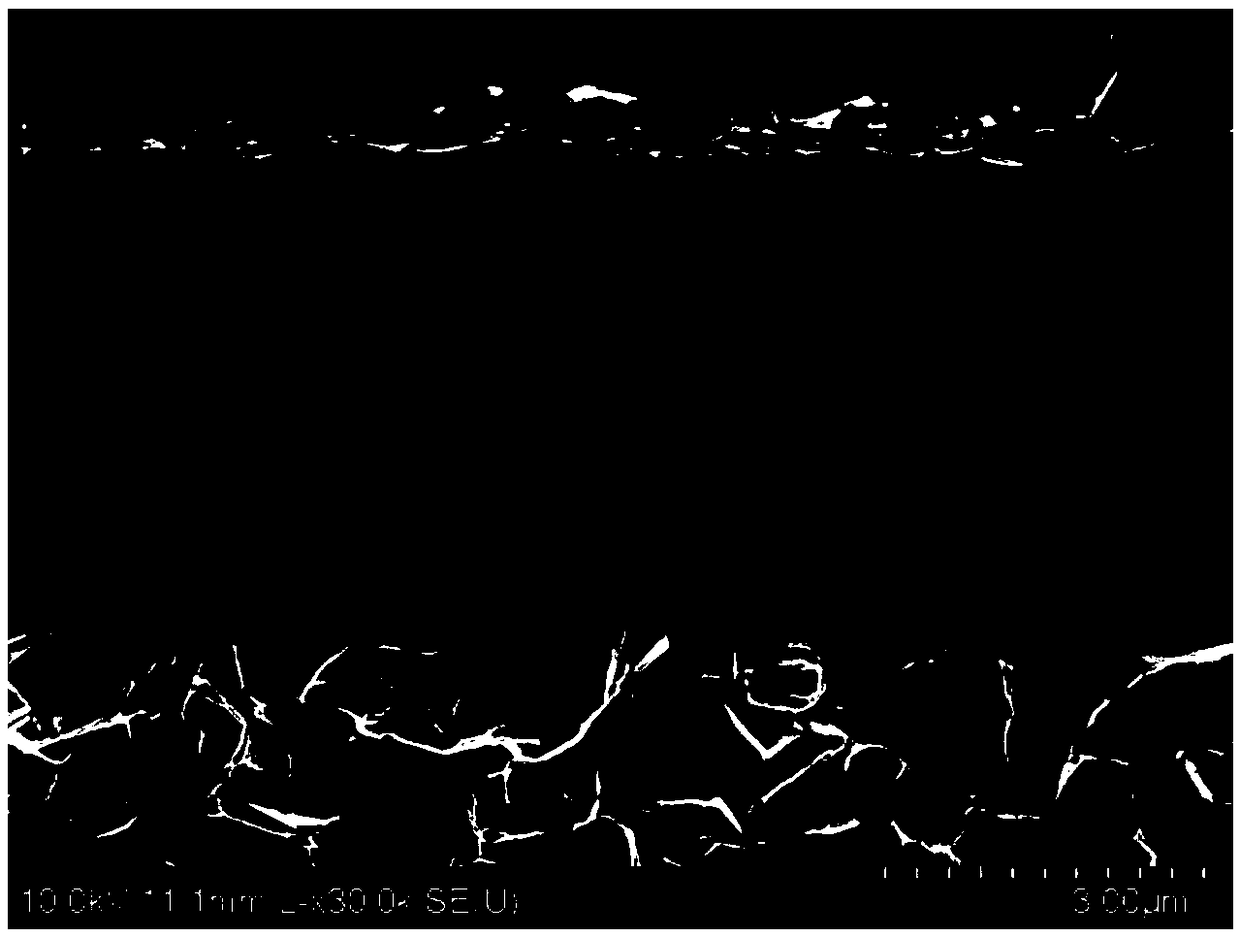

Microbit deposited with AlTiN coating, and preparation method thereof

InactiveCN109023266AImprove bindingHigh hardnessVacuum evaporation coatingSputtering coatingPeak valueNitrogen gas

The invention discloses a microbit deposited with an AlTiN coating. The microbit deposited with the AlTiN coating comprises the AlTiN coating, wherein the AlTiN coating comprises a Cr binding layer, aCrN transition layer and an AlTiN function layer stacked sequentially; and the AlTiN coating has a high binding force, can be firmly combined on the surface of the microbit, is not easy to flake, issmooth in surface, and less in large particle quantity, so that the microbit has high hardness and high temperature wearability, and can maintain the high performance during long-time high-speed operation. The invention further discloses a preparation method of the microbit deposited with the AlTiN coating. The AlTiN coating is prepared on the surface of the microbit by utilizing a plused arc technology, and a high-density plasma can be produced during the pulse discharge period through controlling the nitrogen and argon flow, the pulsed arc peak value, the duty ratio and the frequency, so that the deposition speed of the function layer is fast, and the deposition process is simple, good in repeatability, can be applied to mass production in industry, and has a favorable economic benefit.

Owner:GUANGDONG UNIV OF TECH

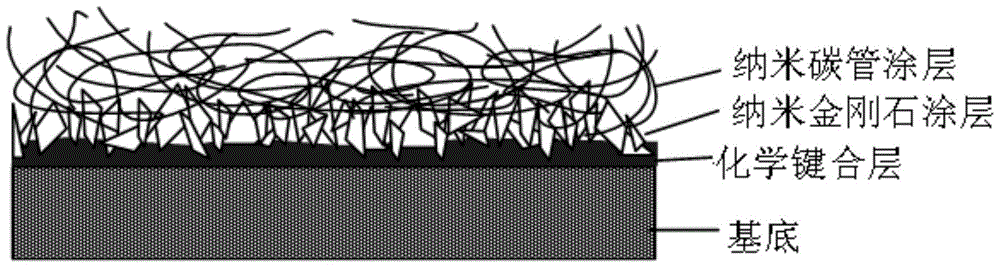

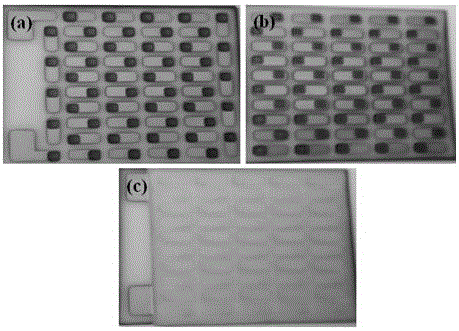

A field emission cathode with double-layer nano-carbon coating and preparation method thereof

ActiveCN104701115BSimple deposition processEasy to controlElectrolytic coatingsDischarge tube/lamp detailsCarbon nanotubeCarbon coated

The invention provides a field emission cathode with a double-layer nanocarbon coating and a preparation method. First, nanodiamond is coated on a substrate through electrophoretic deposition to form a nanodiamond coating; then nanocarbon tubes are deposited through electrophoresis. The method is coated on the nanodiamond coating to form a carbon nanotube coating; finally, heat treatment is performed in a hot wire chemical vapor deposition system to cause a chemical bonding reaction between the substrate and the nanodiamond coating to obtain a chemical bonding layer. Obtain a field emission cathode with a four-layer structure of substrate - chemical bonding layer - nanodiamond coating - nanocarbon tube coating. This field emission cathode has the advantages of both carbon nanotubes and nanodiamond and has good field emission characteristics. and field emission stability.

Owner:NORTHWEST UNIV

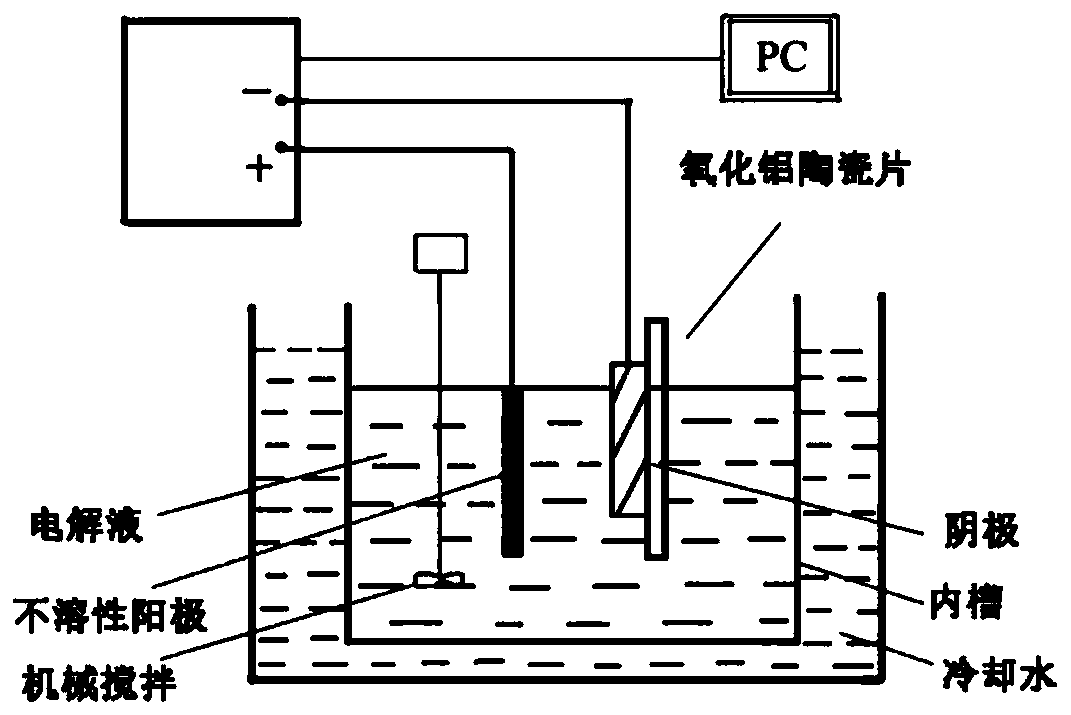

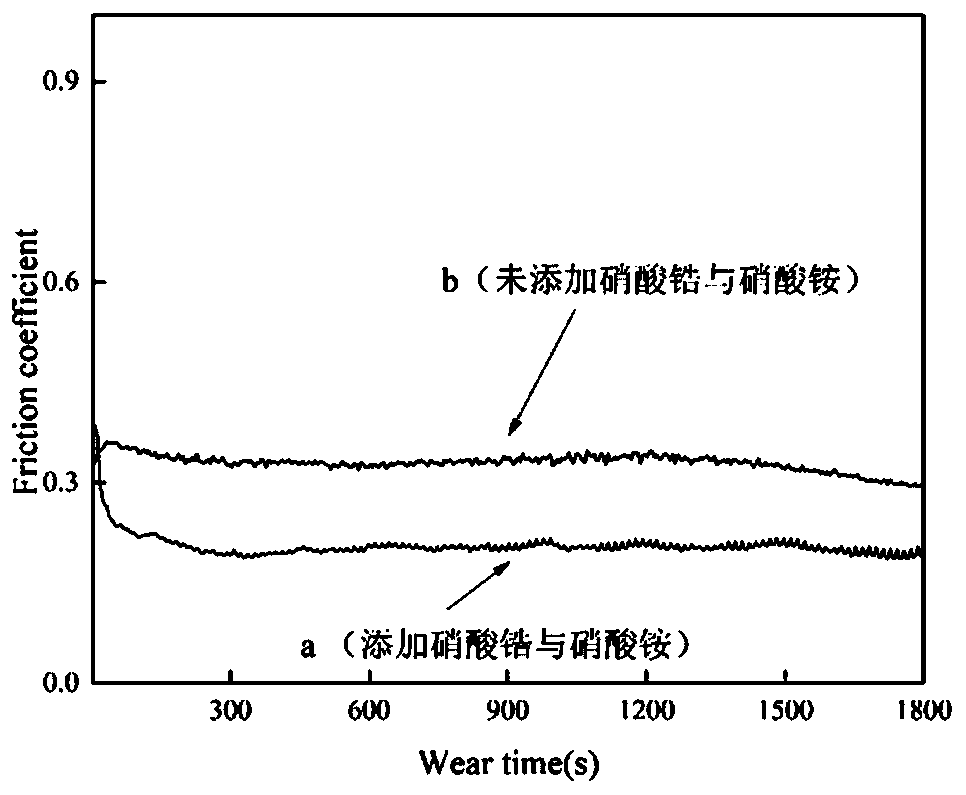

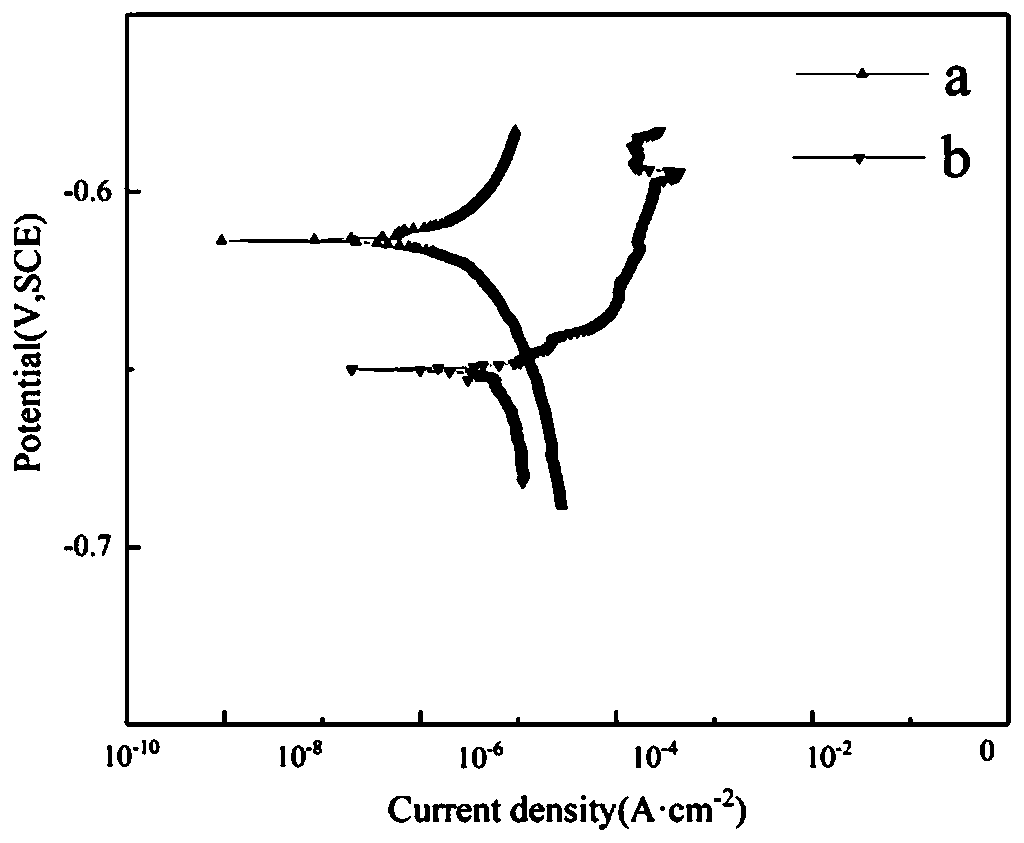

aluminum alloy surface 3 c 4 -al 2 o 3 -zro 2 Preparation method of wear-resistant composite coating

ActiveCN108441912BHigh bonding strengthSimple deposition processElectrolytic coatingsWear resistantElectrolyte

The invention discloses a preparation method of an Al3C4-Al2O3-ZrO2 wear-resistant composite coating on the surface of aluminum alloy. According to the preparation method, an electrolytic tank of a single-groove structure is adopted, and a mixed solution prepared from zirconium nitrate, urea, formamide and glycerin is used as an electrolyte. The cathode side is covered with an aluminum oxide ceramic sheet with the size similar to the size of a workpiece so that a non-conducting shielding effect can be achieved in the discharging process, electric field distortion caused by the edge effect around the cathode is reduced, and discharging of the cathode is more uniform. A direct-current voltage or a pulse voltage is applied to the electrolytic tank, so that a continuous and uniform air film israpidly formed on the surface of the cathode, continuous plasma micro-arc discharging can be caused on the surface of the aluminum alloy, and accordingly, the stable, uniform and hard ceramic coatingis formed on the surface of the aluminum alloy. By adoption of the preparation method, the wear-resistant and corrosion-resistant coating with high hardness, a small friction coefficient and a low wear rate can be prepared on the surface of the aluminum alloy, and thus, the application of the aluminum alloy in the fields of traffic, energy and the like is effectively widened.

Owner:NANJING UNIV OF SCI & TECH

Manufacturing method of strain CMOS device

ActiveCN102487017BSimple deposition processSolve the problem of over etchingSemiconductor/solid-state device manufacturingCMOSEtching

The invention provides a manufacturing method of a strain CMOS device. The method comprises the following steps: providing a CMOS device; successively forming a first stress layer and a film oxidation layer on a CMOS device surface; imaging the film oxidation layer so as to expose a part of the first stress layer which is located in a PMOS transistor area; taking the film oxidation layer as a hard mask so as to etch the first stress layer; at least forming a sacrificial barrier layer on a film oxidation layer surface; forming a second stress layer on a formed semiconductor structure surface; taking the sacrificial barrier layer as an etching stop layer so as to etch a part of the second stress layer which is located in the NMOS transistor area; removing the sacrificial barrier layer. In the invention, through forming the sacrificial barrier layer on the film oxidation layer surface and taking the sacrificial barrier layer as the etching stop layer, a problem of over etching can be solved. Further, the sacrificial barrier layer can be amorphous carbon. A deposition technology is simple and the sacrificial barrier layer removing is easy to be performed.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

A kind of welding powder for the anti-wear layer of the water-cooled wall of the circulating fluidized bed boiler

The invention discloses a low-cost circulating fluidized bed boiler water wall anti-wear plate anti-wear layer welding powder, which is composed of the following raw materials in weight percentage: 65%-70% high-carbon ferrochrome, 8%-12% boron Iron, 5%-20% ferronickel, 2%-3% silicon carbide and 0-15% ferromanganese, the cladding powder is made of raw material grade powder, the cost is low, and it is used for cladding to manufacture easy-to-weld double-layer structure water cooling The wall anti-wear plate will further promote the application of grid-type steady flow anti-wear technology in the anti-wear of circulating fluidized bed boiler water wall, and improve the service life of circulating fluidized bed boiler water wall.

Owner:上海炳晟机电科技有限公司

A polyhedral cobalt-iridium nanoparticle hydrogen evolution electrocatalyst and its plating solution and preparation method

The invention discloses a polyhedral cobalt-iridium nanoparticle electrolytic water hydrogen evolution electrocatalyst and its plating solution and preparation method. The cobalt-iridium nanoparticle has octahedral and decahedral structures, the particle size is 10-250nm, and the chemical composition of cobalt and iridium in the particle is The components are evenly distributed, the iridium content is 45-95wt%, and the Tafel slope of the catalytic hydrogen evolution performance of the catalyst is 30-40mV / decade. Catalyst plating solution: cobalt salt is cobalt sulfate 5-200mmol / L, cobalt sulfamate 1-100mmol / L, iridium salt is sodium hexabromoiridium (IV) 10-150mmol / L, hexabromoiridium (III 1-100mmol / L of sodium nitrite, 0.1-500mmol / L of sodium bromide as conductive salt, 0.1-100mmol / L of sodium chloride, 1-20mmol / L of triammonium citrate as 1-20mmol / L of complexing agent, 1-10mmol of sodium tetraborate / L, other additives are benzotriazole 1-10mmol / L, thiourea 1-10mmol / L, sodium dodecylbenzenesulfonate 1-5mmol / L. The invention is prepared by an electrochemical deposition process, has high efficiency, can be applied to the surface preparation of conductive substrates with complex shapes, has controllable size and composition of nano particles, and has high catalytic performance and strong stability.

Owner:CHANGZHOU UNIV

Method for preparing bismuth telluride nano-wire array by physical vapour deposition

The invention discloses a preparation method of a bismuth telluride nano-wire array by adopting a physical vapor deposition method. The method comprises the following steps: in a vacuum chamber, raw bismuth telluride is thermally evaporated and a membrane with bismuth telluride nano-wire array structure is deposited on the glass substrate by regulating the output electric current of the mains supply and the distance between the glass substrate and a tungsten boat. The whole deposition process is simple, the cost is low, and mass production is easy to be achieved; the obtained bismuth telluride nano-wire arrays are uniform in structure and the even distribution of nanophases is effectively ensured.

Owner:BEIHANG UNIV

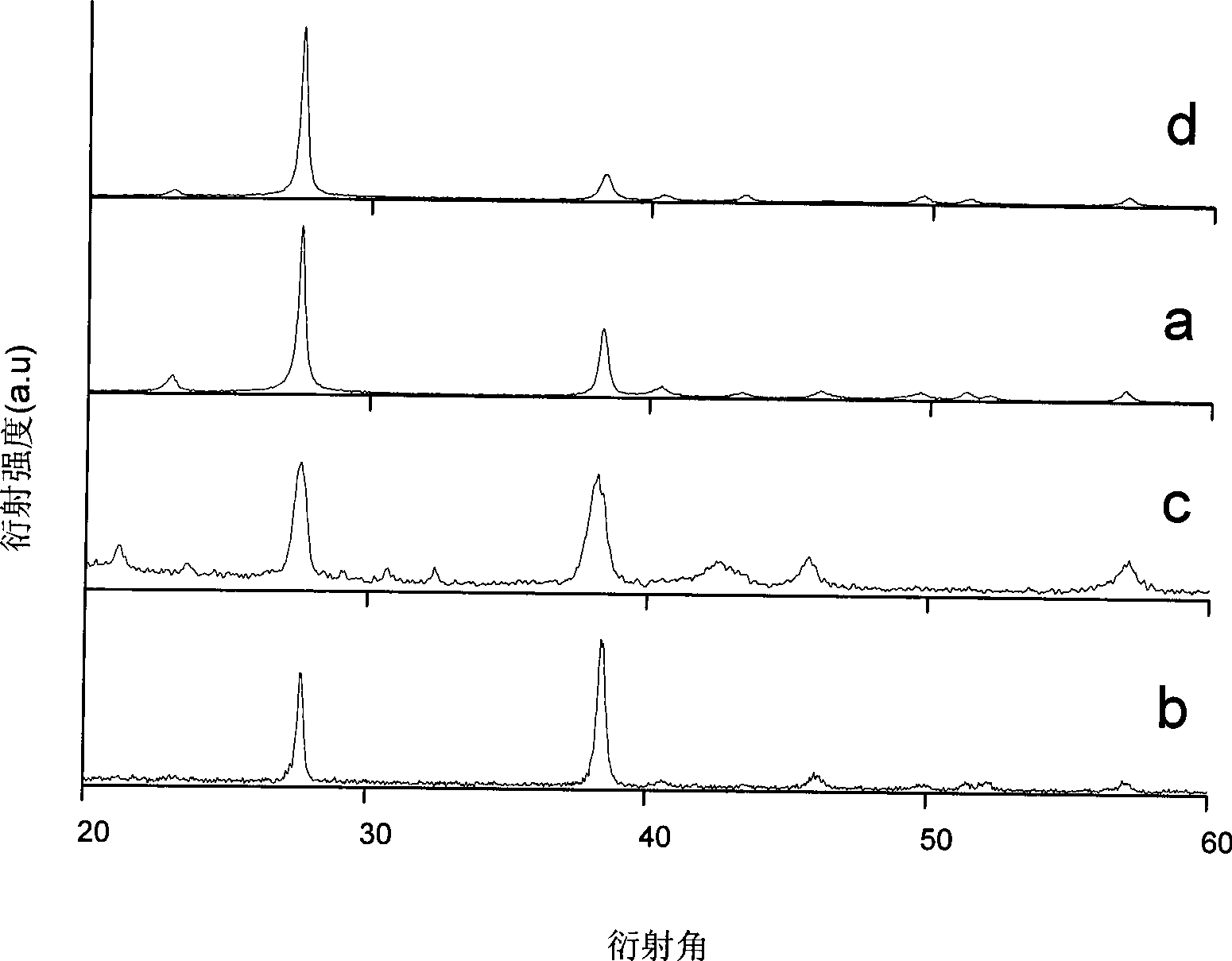

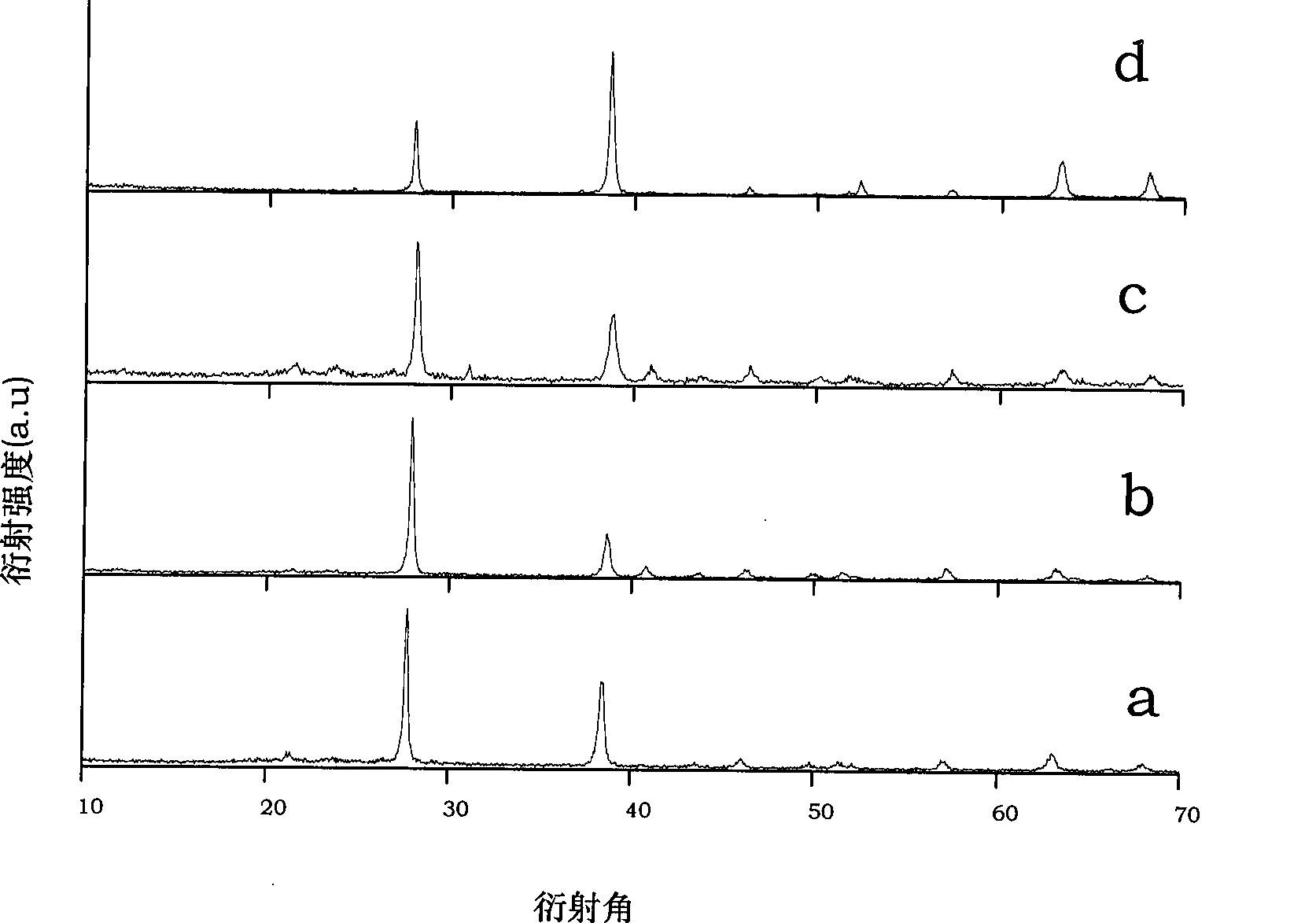

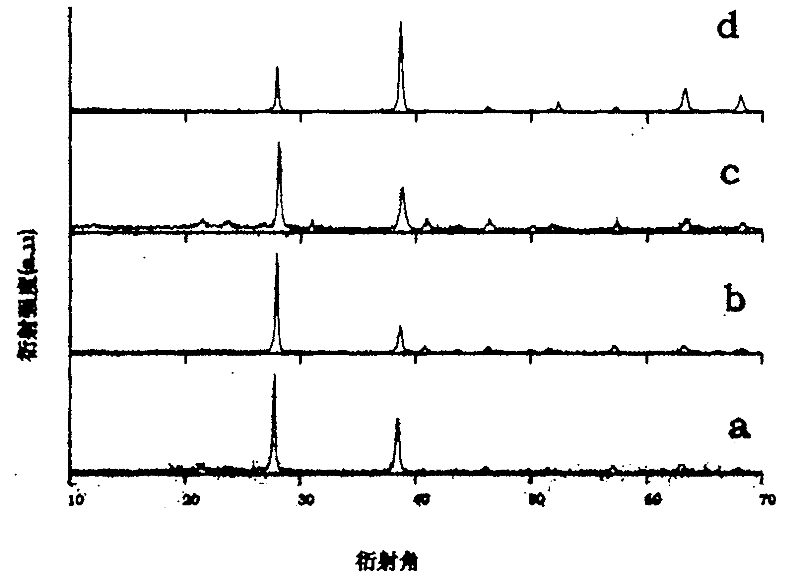

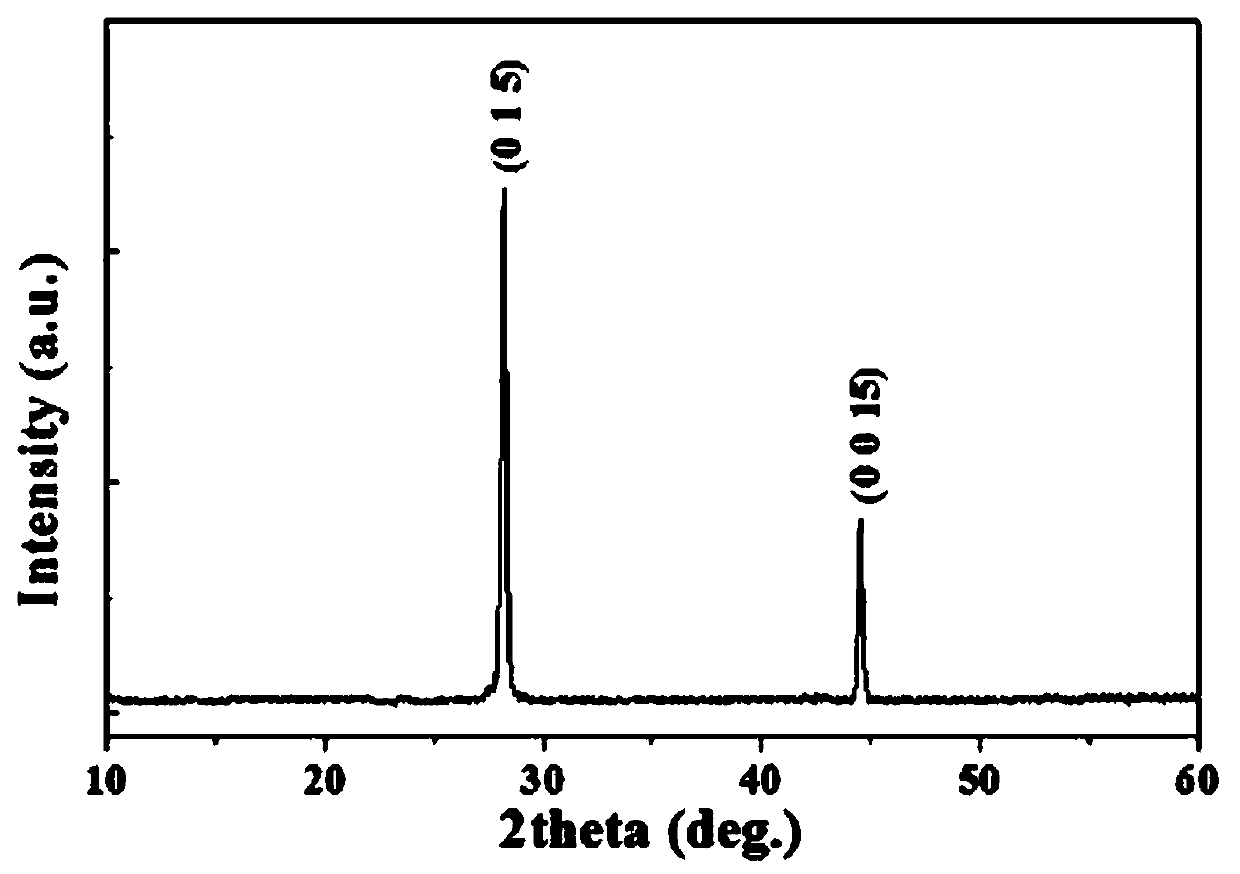

A Method for Controllable Preparation of Structure Gradient Oriented Growth Sb-bi-te Film by Vacuum Evaporation Coating

InactiveCN108103439BLow thermal conductivityClear structural gradientVacuum evaporation coatingSputtering coatingAlcoholPhysical chemistry

The invention relates to a method for preparing a structural gradient oriented growth Sb-Bi-Te membrane by using vacuum evaporation coating. The method comprises the following steps: (1) evenly mixing(Bi0.2Sb0.8)2Te3 and Te powder (in a mass ratio of 10 to (0.8 to 1.2)), and pressing the mixed material of (Bi0.2Sb0.8)2Te3 and Te under a pressure of 8-10MPa into a block; (2) performing ultrasoniccleaning on a substrate in acetone, absolute ethyl alcohol and deionized water respectively, and blow drying with nitrogen; (3) putting 0.1-0.2g of the block obtained by pressing the mixed material of(Bi0.2Sb0.8)2Te3 and Te into a tungsten boat of a vacuum chamber of a vacuum coating machine; (4) introducing nitrogen into the vacuum chamber for 2-5min; (5) when the vacuum degree reaches 2.0*10<-4> to 5.0*10<-4>Pa, turning on a heating temperature control power supply, and setting the heating temperature at 100-200 DEG C to start heating the substrate; (6) after the temperature rises to the preset temperature 100-200 DEG C, depositing on a PID controller according to the set deposition rate; (7) adjusting the output current to 160-170A; starting the deposition preparation of a structural gradient oriented growth (Bi0.2Sb0.8)2Te3 membrane on the substrate. The method provided by the invention has the advantages of easiness in preparation and remarkable effect.

Owner:TIANJIN UNIV OF SCI & TECH

Silver nanodendrite surface enhanced Raman scattering (SERS) substrate, and preparation method and application thereof

InactiveCN102181891BUniform shapeSize is easy to controlRaman scatteringNanotechnologyElectrolytic agentIndium

Owner:WENZHOU UNIV

Nanoparticle-reinforced copper-based composite material and preparation method thereof

ActiveCN103643075BImprove mechanical propertiesImprove electrical performanceMaterial nanotechnologyCarbon compositesElectron beam physical vapor deposition

The invention discloses a nano-particle reinforced copper-based composite material and a preparation method thereof. The size of a copper matrix grain is smaller than 20 microns in the copper-based composite material; the nano-particle reinforced phase is molybdenum carbide, or molybdenum carbide and molybdenum, or molybdenum carbide and carbon; the particle size of the nano-particle reinforced phase is smaller than 200nm; the mass percent of Mo in the copper-based composite material is 0.1-15%; the mass percent of C is smaller than 1%. The nano-particle reinforced copper-based composite material disclosed by the invention is prepared by adopting an electronic beam physical vapor deposition process. The nano-particle reinforced copper-molybdenum-carbon composite material prepared by the method has excellent mechanical property and electrical property, and adopted electronic beam physical vapor deposition process is simple, low in cost and easy to control.

Owner:嘉兴市燕知网络科技有限公司

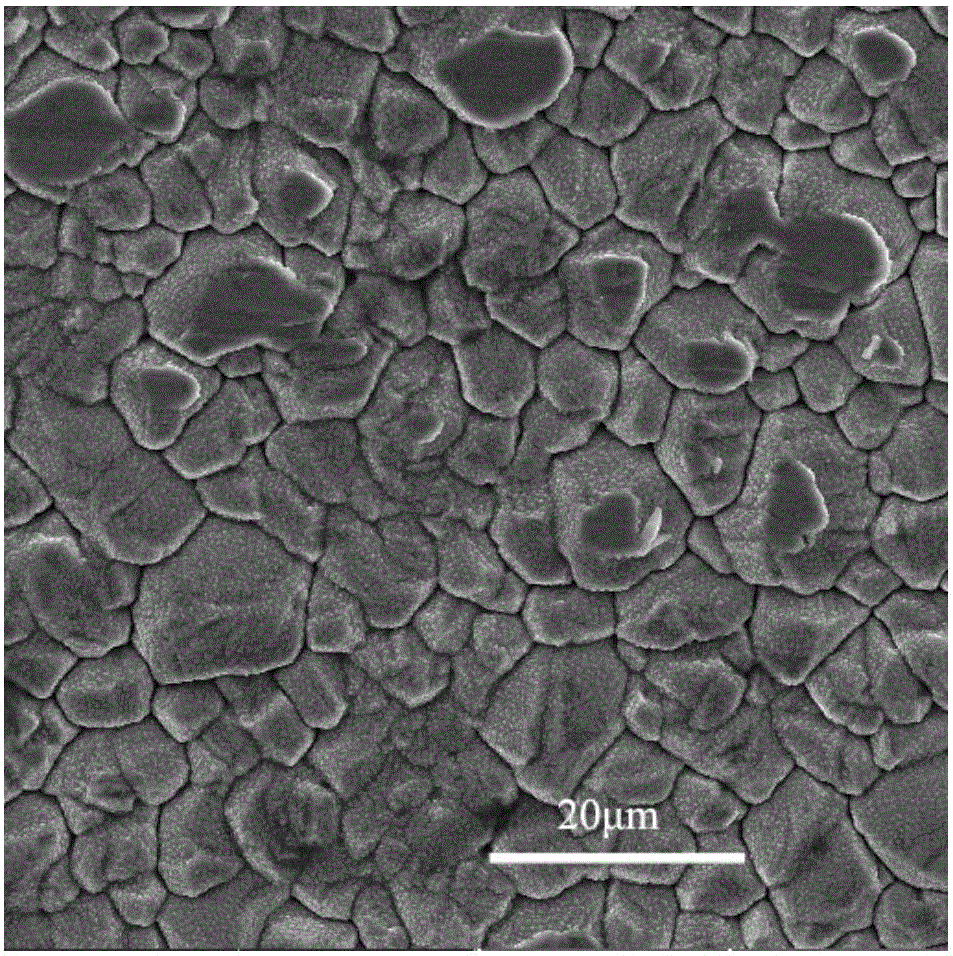

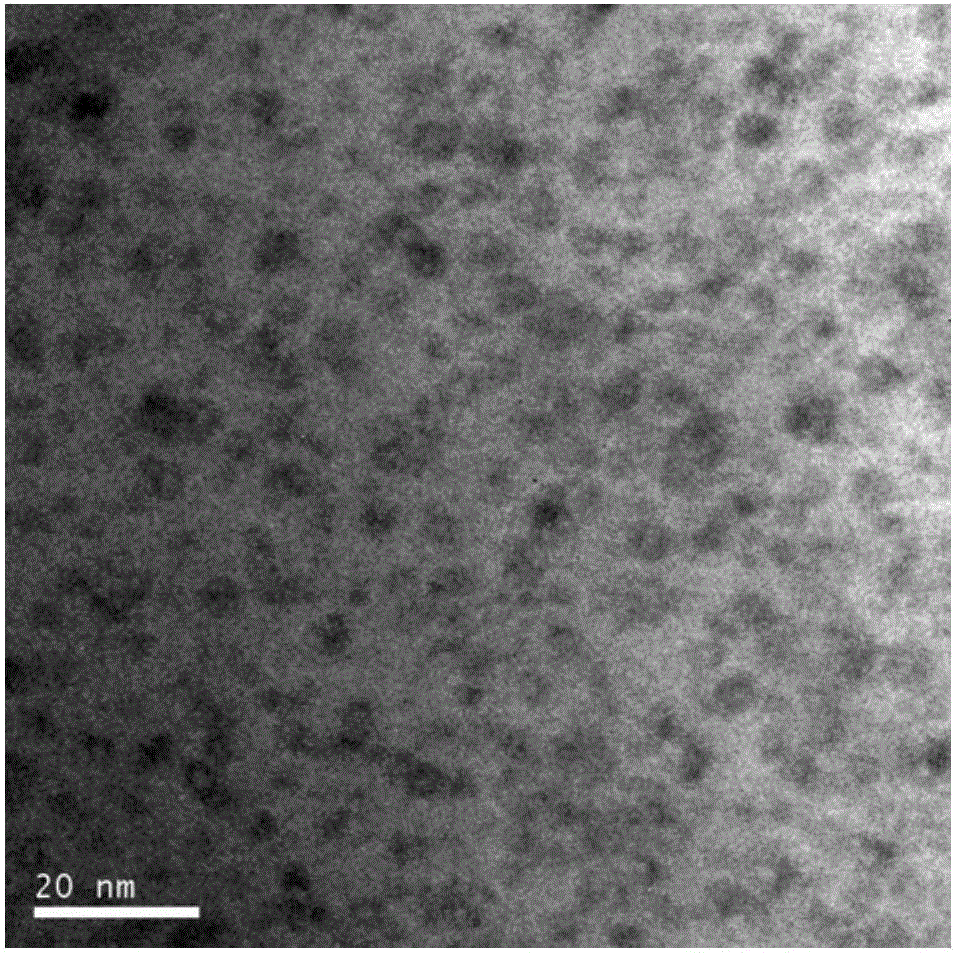

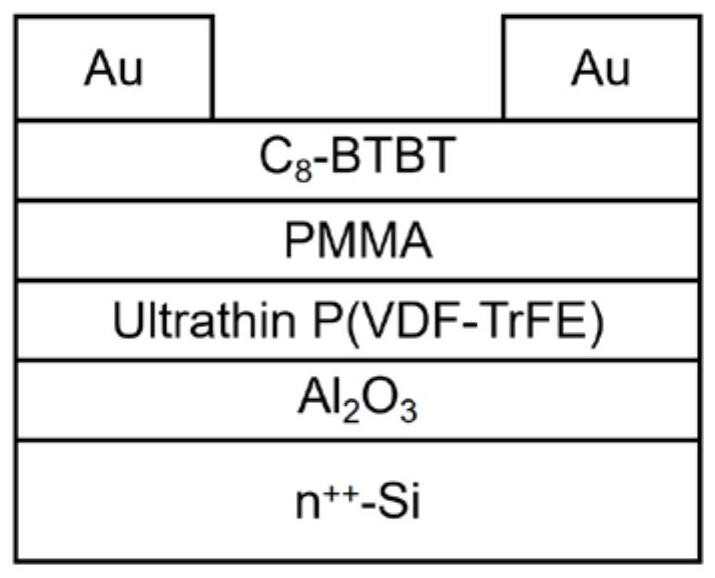

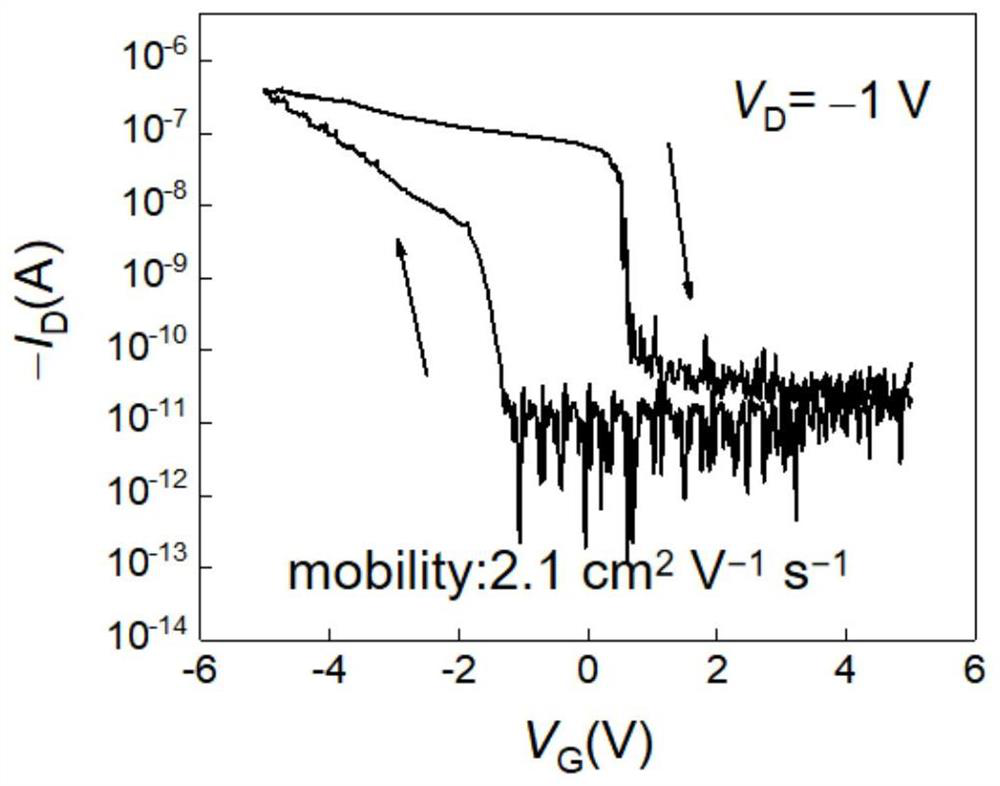

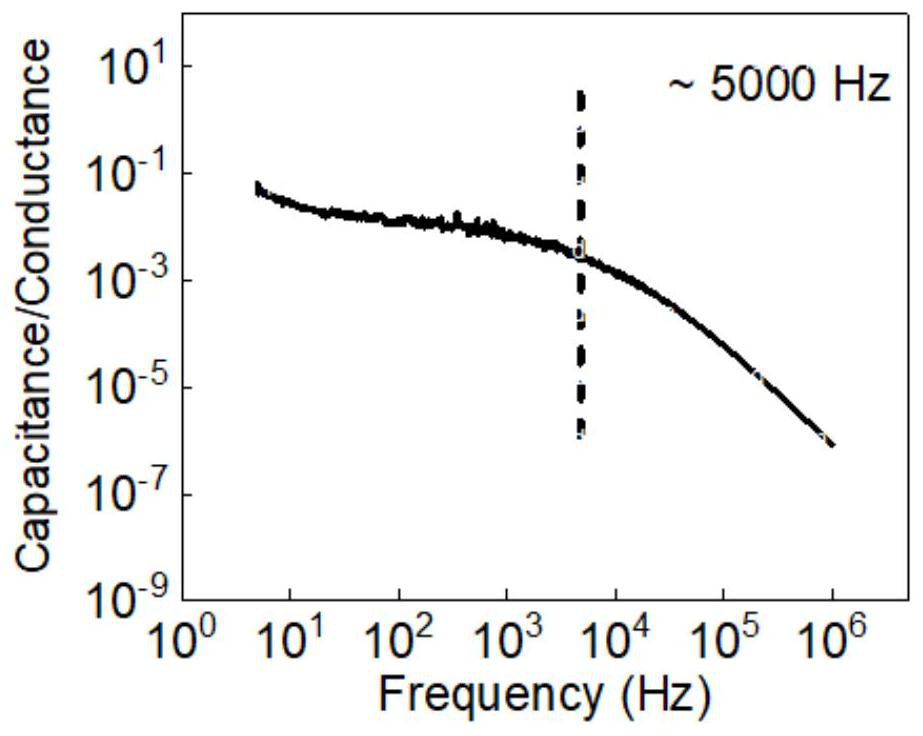

Ultra-low power consumption ferroelectric transistor memory based on two-dimensional organic functional materials and its preparation method

ActiveCN110047996BSimple deposition processGood workmanshipSolid-state devicesSemiconductor/solid-state device manufacturingOrganic field-effect transistorPolymethyl methacrylate

The invention discloses an ultra-low power consumption ferroelectric transistor memory based on a two-dimensional organic functional material and a preparation method thereof. An aluminum oxide insulating layer is grown on a substrate by an atomic beam deposition method, and then an antisolvent is used to An ultrathin crystalline ferroelectric polymer film was prepared at room temperature by assisted crystallization, and then an ultrathin layer of polymethyl methacrylate and an ultrathin layer of dioctyl Dioctylbenzothiophene benzothiophene, and finally a gold film was transferred onto the dioctylbenzothiophene benzothiophene layer as source and drain electrodes using a non-invasive gold film transfer process. The present invention uses the quasi-two-dimensional ferroelectric polymer crystalline film as the dielectric layer and the two-dimensional organic molecular crystal C 8 ‑BTBT material is used as a semiconductor layer to prepare fast transistor memory, which can greatly reduce the power consumption of ferroelectric organic field effect transistor memory, and has low-voltage operation capability and fast storage capability.

Owner:NANJING UNIV

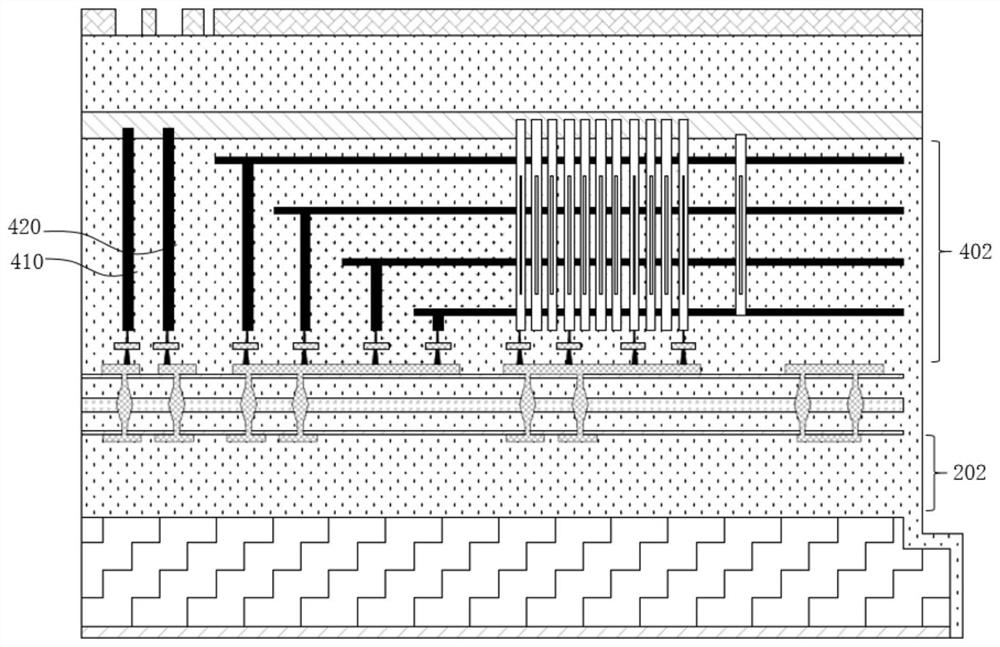

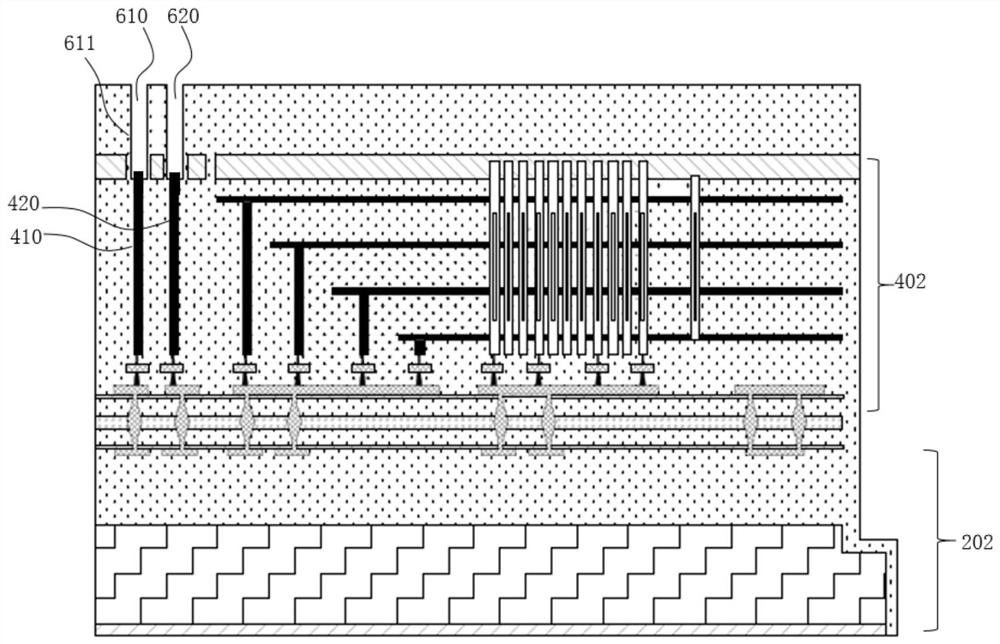

Three-dimensional memory and manufacturing method thereof

PendingCN113990804AAnd deposition process simplificationSimple deposition processSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

The invention provides a manufacturing method of a three-dimensional memory. The method comprises the steps: forming a mask layer on an insulating layer, wherein the mask layer comprises a first opening and a second opening, the first opening penetrates through the mask layer, and the bottom of the second opening is provided with the mask layer with a preset thickness; executing first etching which has a first etching selection ratio for the insulating layer and the mask layer with the preset thickness, etching the insulating layer to the bottom through the first opening, etching the mask layer through the second opening, and exposing at least part of the insulating layer; and executing second etching which has a second etching selection ratio for the semiconductor layer and the insulating layer, etching the semiconductor layer through the first opening and form a first contact hole penetrating through the insulating layer and the semiconductor layer, and simultaneously etching the insulating layer through the second opening and form a second contact hole exposing at least part of the semiconductor layer. A first through contact, a second through contact and an isolation structure can be formed at the same time, and the manufacturing process is simplified.

Owner:YANGTZE MEMORY TECH CO LTD

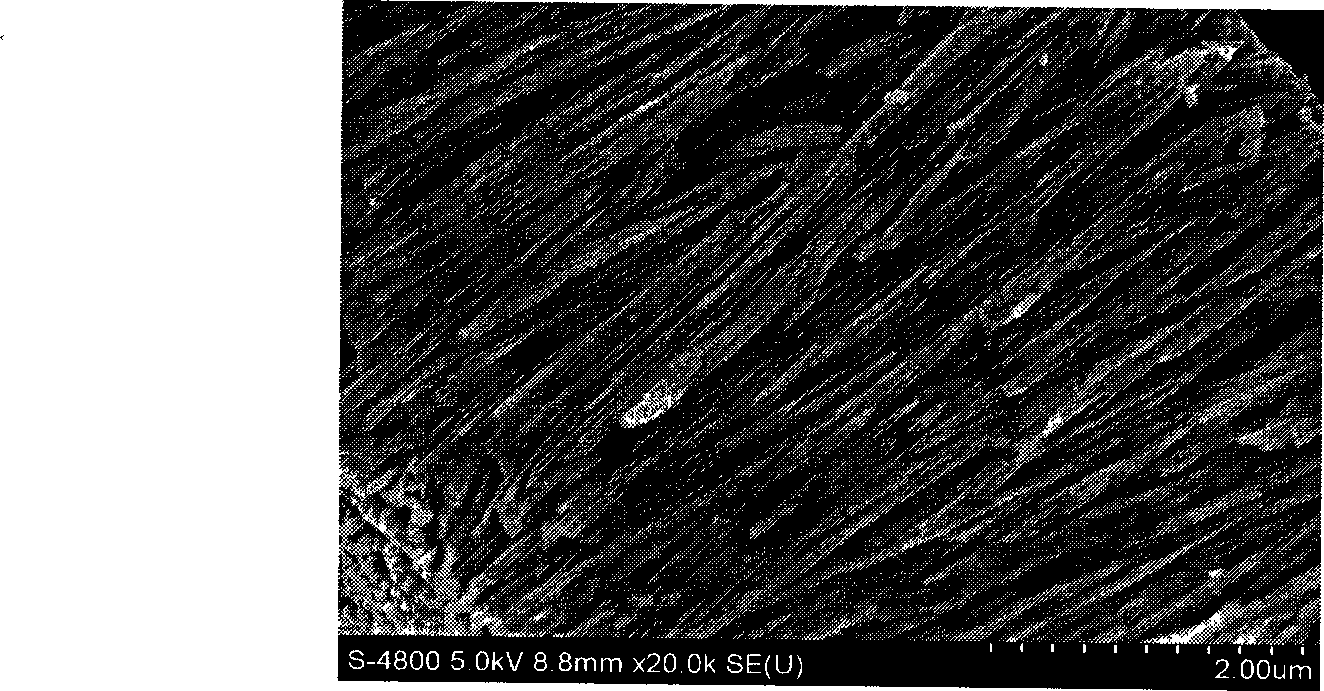

Method for preparing ag nanowire array electrodes by magnetron sputtering-mask-assisted deposition

InactiveCN104805409BUniform structureImprove performanceThermoelectric device manufacture/treatmentVacuum evaporation coatingSputteringThermoelectric materials

Owner:TIANJIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com