Method for preparing copper zinc tin sulfur selenium thin film by using alloy rotary target material

A copper-zinc-tin-sulfur-selenium and rotating target technology, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., can solve the problem of high zinc-tin vapor pressure and difficulty in obtaining copper-poor-rich zinc-rich large particle crystals Interfacial copper-zinc-tin-sulfur-selenium thin films and other issues can achieve the effects of saving heating costs, optimizing film deposition processes, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

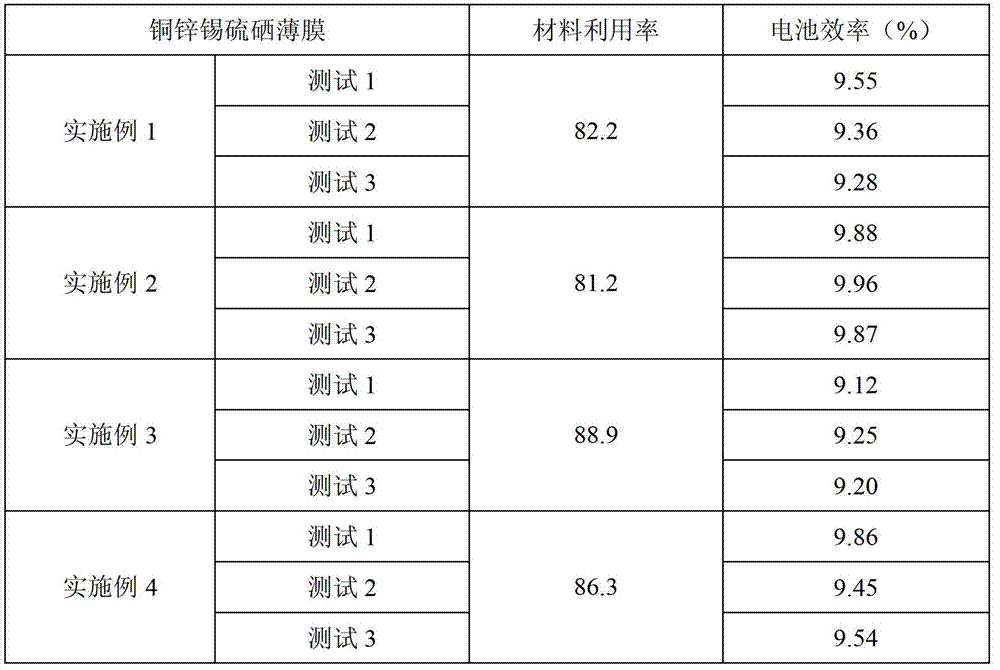

Embodiment 1

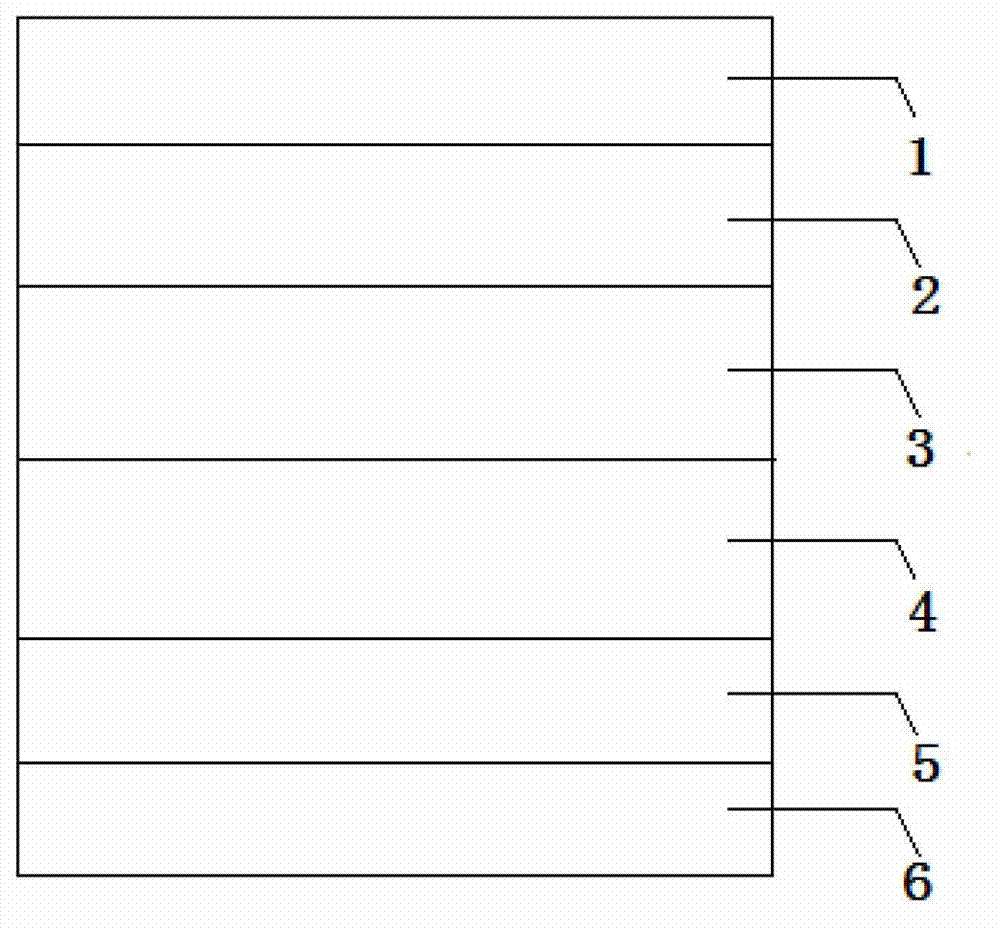

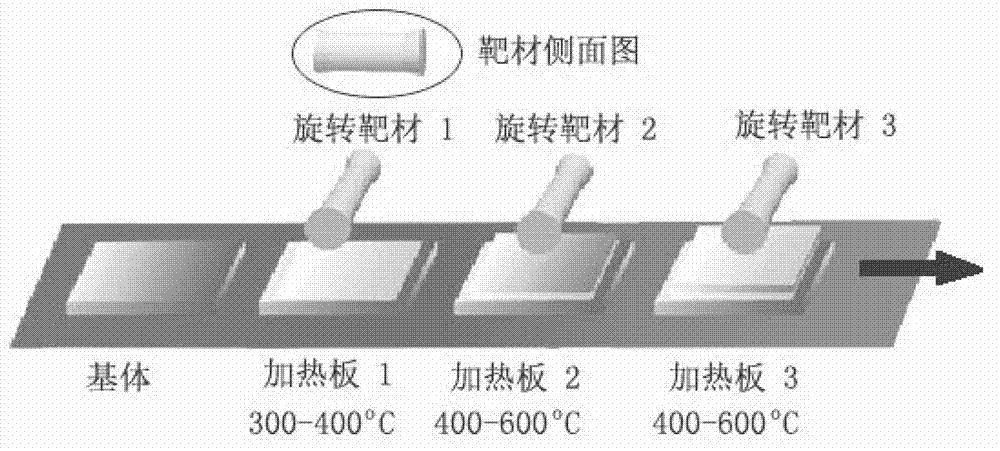

[0021] The rotating target material 1 used in the first step sputtering of the present invention is Cu 1.5 ZnSnS(Se) 4 , the rotating target 2 used in the second sputtering step is Cu 2 ZnSnS(Se) 4 , the rotating target 3 used in the third step of sputtering is Cu 1.8 ZnSnS(Se) 4 , the length of the three targets is 160 cm, the outer diameter is 14 cm, the inner diameter is 13 cm, and the thickness is 1 cm. The atomic number ratio of the three targets is 2:0.5:0.5:4. The method comprises the steps of:

[0022] (1) Using the sputtering method, coat a molybdenum layer on a soda-lime glass substrate with a thickness of 2mm, and the sputtering condition is that the initial vacuum degree is 10 -6 Torr, feed 20SCCM of argon to make the vacuum pressure reach 6mTorr, sputtering power 150W, sputtering time 45min, the thickness of the molybdenum layer is 200nm, and the resistivity of the molybdenum layer is 5 ohm centimeters;

[0023] (2) Heat the soda-lime glass substrate deposit...

Embodiment 2

[0028] The rotating target material 1 used in the first step sputtering of the present invention is Cu 1.5 ZnSnS(Se) 4 , the rotating target 2 used in the second sputtering step is Cu 2 ZnSnS(Se) 4 , the rotating target 3 used in the third step of sputtering is Cu 1.8 ZnSnS(Se) 4 , the length of the three targets is 160 centimeters, the outer diameter is 14 centimeters, the inner diameter is 13 centimeters, and the thickness is 0.5 centimeters. The atomic number ratio of the three kinds of targets is 1.5:1.5:1.5:4. The method includes the following steps:

[0029] (1) Using the sputtering method, a molybdenum layer is coated on a soda-lime glass substrate with a thickness of 4 mm, and the sputtering condition is that the initial vacuum degree is 10 -6 Torr, feed the argon gas of 20SCCM so that the vacuum pressure reaches 6mTorr, sputtering power 150W, sputtering time 45min, the thickness of the molybdenum layer is 800nm, and the resistivity of the molybdenum layer is 3 ohm...

Embodiment 3

[0035] The rotating target material 1 used in the first step sputtering of the present invention is Cu 1.5 ZnSnS(Se) 4 , the rotating target 2 used in the second sputtering step is Cu 2 ZnSnS(Se) 4 , the rotating target 3 used in the third step of sputtering is Cu 1.8 ZnSnS(Se) 4 , the length of the three targets is 160 centimeters, the outer diameter is 14 centimeters, the inner diameter is 13 centimeters, and the thickness is 1.5 centimeters. The atomic number ratio of the three kinds of targets is 1.5:1:1:4. The method includes the following steps:

[0036] (1) Using the evaporation method, a molybdenum layer is plated on a plastic sheet substrate with a thickness of 6 mm, and the evaporation condition is an initial vacuum degree of 10 -6 Torr, voltage 7KV, current 20mA, evaporation time 30min, the thickness of the molybdenum layer is 1000nm, the resistivity of the molybdenum layer is 1 ohm cm; the plastic sheet is polyimide plastic;

[0037] (2) Heat the plastic sheet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com