Surface coating modification method for ternary positive electrode material of lithium ion battery

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, positive electrodes, electrical components, etc., can solve problems such as limited performance improvement, by-product pollution of the environment, and fast performance decay, achieving fewer deposition cycles and rapid large-scale The effect of short production and reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

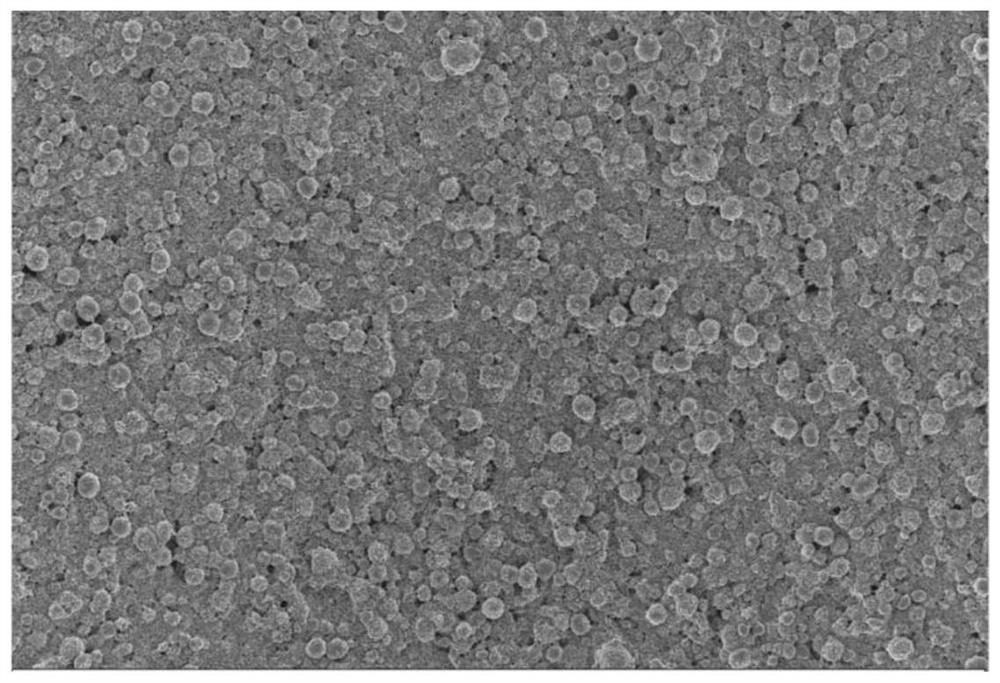

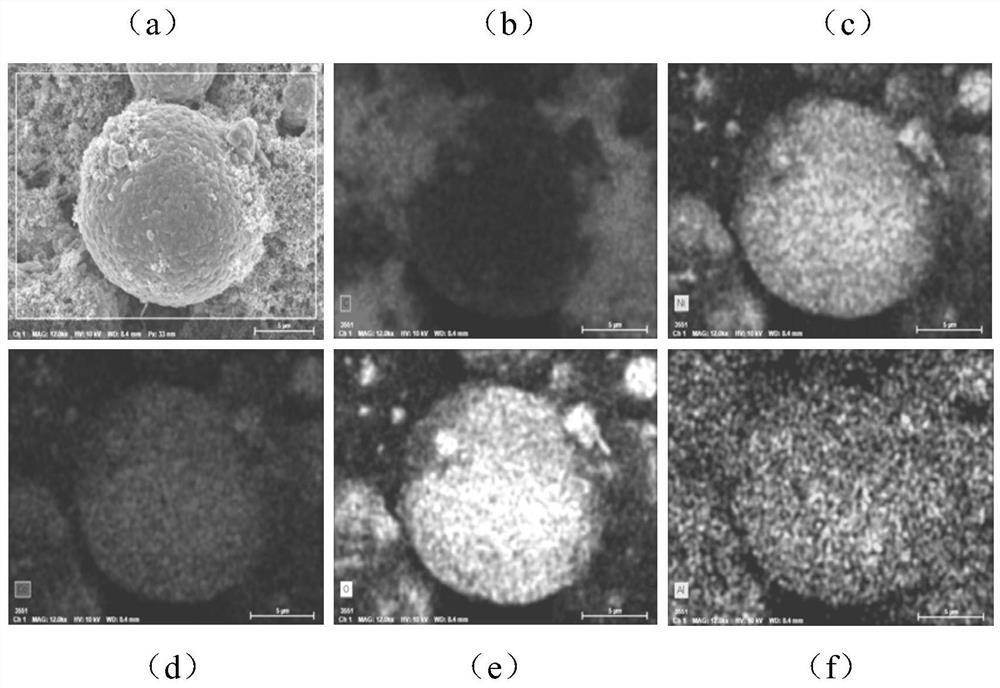

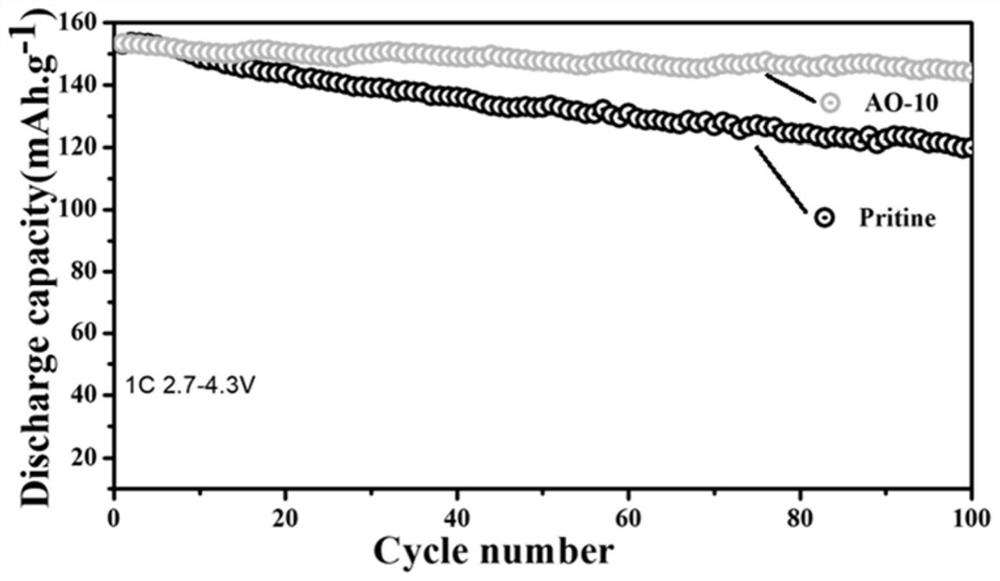

[0042] Put the prepared lithium-ion battery NCM811 electrode sheet into the chamber of the atomic deposition system, and the reaction temperature is 110°C. Use nitrogen as a carrier gas to pass trimethylaluminum into the cavity for 0.02s, exposure time is 8s, nitrogen purge time is 25s, deionized water is introduced for 0.1s, exposure time is 8s, nitrogen purge The time is 40s. The oxygen source reacts with the aluminum source adsorbed on the surface of the positive electrode to generate alumina. This is a cycle. If this cycle is repeated 10 times, a certain thickness of aluminum oxide protective film layer (denoted as AO-10) is deposited on the electrode. ).

Embodiment 2

[0044] Put the prepared lithium-ion battery NCM811 electrode sheet into the chamber of the atomic deposition system, and the reaction temperature is 110°C. Use nitrogen as a carrier gas to pass trimethylaluminum into the cavity for 0.02s, exposure time is 8s, nitrogen purge time is 20s, deionized water is introduced for 0.1s, exposure time is 8s, nitrogen purge The time is 40s. The oxygen source reacts with the aluminum source adsorbed on the surface of the positive electrode to form alumina. This is a cycle. If the cycle is repeated 10 times, a certain thickness of aluminum oxide protective film is deposited on the electrode.

Embodiment 3

[0046]Put the prepared lithium-ion battery NCM811 electrode sheet into the chamber of the atomic deposition system, and the reaction temperature is 110°C. Use nitrogen as the carrier gas to pass trimethylaluminum into the cavity for 0.02s, exposure time is 8s, nitrogen purge time is 30s, deionized water is introduced for 0.1s, exposure time is 8s, nitrogen purge The time is 40s. The oxygen source reacts with the aluminum source adsorbed on the surface of the positive electrode to form alumina. This is a cycle. If the cycle is repeated 10 times, a certain thickness of aluminum oxide protective film is deposited on the electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com