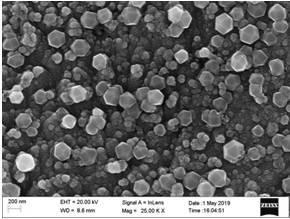

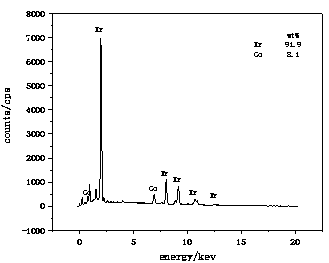

Polyhedral cobalt iridium nano particle electrolytic hydrogen evolution catalyst and plating solution formula and preparation method thereof

A nanoparticle, electrocatalyst technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of underutilization of Ir, large amount of precious metal Ir, long catalyst production time, etc., and achieve good commercial application prospects and cost. Inexpensive, time-consuming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] First configure 20mL of electroplating solution cobalt sulfate heptahydrate 25mmol / L, sodium hexabromoiridium (IV) 50mmol / L, sodium bromide 0.3mol / L, triammonium citrate 10 mmol / L, and triazole 2 mmol / L, thiourea 2 mmol / L, sodium dodecylbenzenesulfonate 5 mmol / L. Put the weighed chemicals into the glass container for electroplating. Add 15mL of deionized water to the glass container with a pipette, stir and dissolve with a magnetic stirrer, and the stirring speed is 250rpm; adjust the temperature of the water bath to 70°C, and then dropwise add sodium hydroxide solution, adjust the pH to around 3.0. The substrate is made of foamed copper (10mm x 10mm x 3mm), first soaked in acetone solution for 1h, then ultrasonically cleaned in acetone for 10min, then cleaned in 50% nitric acid for 5~10s, and washed and dried. The reference electrode is Ag / AgCl / saturated KCl, and the anode is a platinum sheet; the nitrogen valve is opened, the plating solution is deoxygenated by nit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com