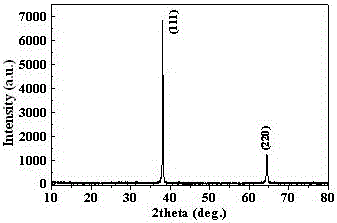

Method for preparing ag nanowire array electrodes by magnetron sputtering-mask-assisted deposition

A technology of nanowire array and magnetron sputtering, which is applied in the direction of sputtering coating, manufacturing/processing of thermoelectric devices, ion implantation plating, etc., can solve the problem of not using mask-assisted deposition of Ag nanowire array to introduce devices, nano Linear performance is average, it is difficult to form large-scale production, etc., to achieve significant practical value and economic benefits, the production environment conditions are relaxed, and it is easy to achieve large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

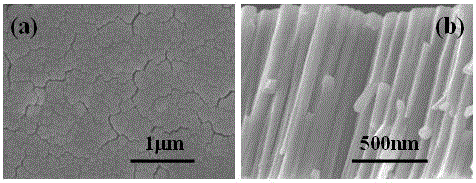

Embodiment 1

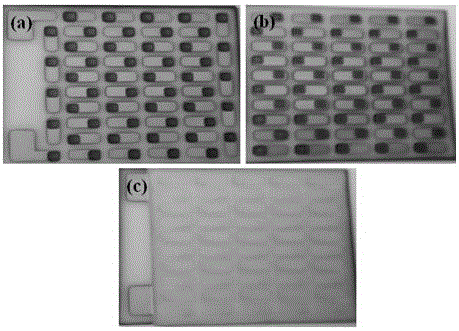

[0045] Fabrication of Ag nanowire arrays and 50 pairs of Ag nanowire array electrodes by magnetron sputtering-mask assisted deposition on AlN substrates p-n Device:

[0046] (1) The substrate was ultrasonically cleaned in acetone, absolute ethanol and deionized water for 10 minutes, then taken out, dried with high-purity nitrogen, and quickly placed in a sputtering vacuum chamber;

[0047] (2) Put the Ag target with a mass percentage purity of 99.99% into the magnetron sputtering vacuum chamber, adjust the distance between the substrate and the sputtering target source = 4, and start vacuuming;

[0048] (3) Vacuum up to 2.0×10 -4 Turn on the heating and temperature control power supply at Pa, set the heating temperature to 400°C, start to heat up the substrate, at the same time turn on the gas flow controller and the sputtering power supply to preheat, and turn on the sample stage to rotate (15 rpm);

[0049] (4) After the temperature rises to the predetermined temperature o...

Embodiment 2

[0060] Fabrication of Ag nanowire arrays and 50 pairs of Ag nanowire array electrodes by magnetron sputtering-mask-assisted deposition on AlN substrates p-n Device:

[0061] (1) The substrate was ultrasonically cleaned in acetone, absolute ethanol, and deionized water for 8 minutes, then taken out, dried with high-purity nitrogen, and quickly placed in a sputtering vacuum chamber;

[0062] (2) Put the Ag target with a mass percentage purity of 99.99% into the magnetron sputtering vacuum chamber, adjust the distance between the substrate and the sputtering target source = 3.5, and start vacuuming;

[0063] (3) Vacuum up to 3.0×10 -4 Turn on the heating and temperature control power supply at Pa, set the heating temperature to 350°C, start to heat up the substrate, and at the same time turn on the gas flow controller and the sputtering power supply to preheat, and turn on the sample stage to rotate (12 rpm);

[0064] (4) After the temperature rises to the predetermined tempera...

Embodiment 3

[0072] Preparation of columnar structure Ag film and 50 pairs of columnar structure Ag film electrodes on AlN substrate by magnetron sputtering-mask assisted deposition p-n Device:

[0073] (1) The substrate was ultrasonically cleaned in acetone, absolute ethanol, and deionized water for 8 minutes, then taken out, dried with high-purity nitrogen, and quickly placed in a sputtering vacuum chamber;

[0074] (2) Put the Ag target with a mass percentage purity of 99.99% into the magnetron sputtering vacuum chamber, adjust the distance between the substrate and the sputtering target source = 5, and start vacuuming;

[0075] (3) Vacuum up to 3.0×10 -4 Turn on the heating and temperature control power supply at Pa, set the heating temperature to 300°C, start to heat up the substrate, at the same time turn on the gas flow controller and the sputtering power supply to preheat, and turn on the sample stage to rotate (10 rpm);

[0076] (4) After the temperature rises to the predetermin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com