A method for the controllable preparation of multi-level bi-sb-te tilted column arrays by evaporative coating

A technology of evaporation coating and column array, which is applied in vacuum evaporation coating, chemical instruments and methods, sputtering coating, etc., can solve the problem of no inclined growth, etc., and achieve the effect of low cost, significant practical value, and large economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

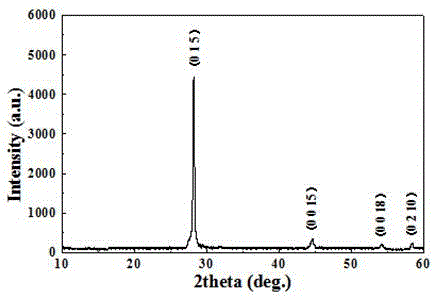

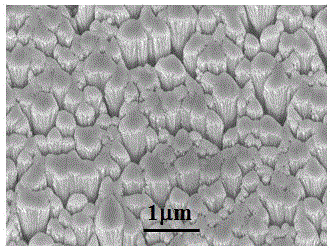

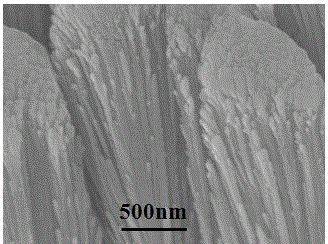

[0039] Fabrication of Multi-level Bi by Evaporation Coating on Glass Substrates 1.5 Sb 0.5 Te 3 array of tilted columns;

[0040] (1) Bi with mass percent purity of 99.99% 1.5 Sb 0.5 Te 3 The powder was pressed under 8MPa pressure to make Bi 1.5 Sb 0.5 Te 3 block; the Bi 1.5 Sb 0.5 Te 3 The average particle size of the powder is less than 50 μm;

[0041] (2) The glass substrate (or glass plate) is ultrasonically cleaned in acetone, absolute ethanol and deionized water for 5 minutes, then taken out, and dried with high-purity nitrogen (mass percentage purity 99.999%);

[0042] (3) Add 0.1g of Bi 1.5 Sb 0.5 Te 3 Put the block into the tungsten boat in the vacuum chamber of the vacuum coating machine, place the glass substrate in the center of the sample stage, and adjust the angle between the sample stage and the horizontal plane θ =5 ° ;Adjust the distance d=15cm between the center of the glass substrate and the tungsten boat;

[0043] (4) Fill the vacuum cham...

Embodiment 2

[0051] Fabrication of Multi-level Bi by Evaporation Coating on Glass Substrates 1.5 Sb 0.5 Te 3 array of tilted columns;

[0052] (1) Bi with mass percent purity of 99.99% 1.5 Sb 0.5 Te 3 The powder was pressed under 10MPa pressure to make Bi 1.5 Sb 0.5 Te 3 block; the Bi 1.5 Sb 0.5 Te 3 The average particle size of the powder is less than 50 μm;

[0053] (2) The glass substrate (or glass plate) was ultrasonically cleaned in acetone, absolute ethanol and deionized water for 8 minutes, then taken out, and dried with high-purity nitrogen (mass percentage purity 99.999%);

[0054] (3) Add 0.1g of Bi 1.5 Sb 0.5 Te 3 Put the block into the tungsten boat in the vacuum chamber of the vacuum coating machine, place the glass substrate in the center of the sample stage, and adjust the angle between the sample stage and the horizontal plane θ =30 ° ;Adjust the distance d=15 cm between the center of the glass substrate and the tungsten boat;

[0055] (4) Fill the vacuum ...

Embodiment 3

[0063] Fabrication of Multi-level Bi by Evaporation Coating on Glass Substrates 1.5 Sb 0.5 Te 3 array of tilted columns;

[0064] (1) Bi with mass percent purity of 99.99% 1.5 Sb 0.5 Te 3 The powder was pressed under 9MPa pressure to make Bi 1.5 Sb 0.5 Te 3 block; the Bi 1.5 Sb 0.5 Te 3 The average particle size of the powder is less than 50 μm;

[0065] (2) The glass substrate (or glass plate) was ultrasonically cleaned in acetone, absolute ethanol and deionized water for 8 minutes, then taken out, and dried with high-purity nitrogen (mass percentage purity 99.999%);

[0066] (3) Add 0.1g of Bi 1.5 Sb 0.5 Te 3 Put the block into the tungsten boat in the vacuum chamber of the vacuum coating machine, place the glass substrate in the center of the sample stage, and adjust the angle between the sample stage and the horizontal plane θ =45 ° ;Adjust the distance d=15 cm between the center of the glass substrate and the tungsten boat;

[0067] (4) Fill the vacuum c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com