Low-contact-resistance fuel cell stack and fuel cell using same

A fuel cell stack and low contact resistance technology, which is applied in the direction of fuel cells, battery electrodes, circuits, etc., can solve the problems of large contact resistance, undetected, and reduced output power of the stack, and achieve high durability power density, The effect of ensuring corrosion resistance and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

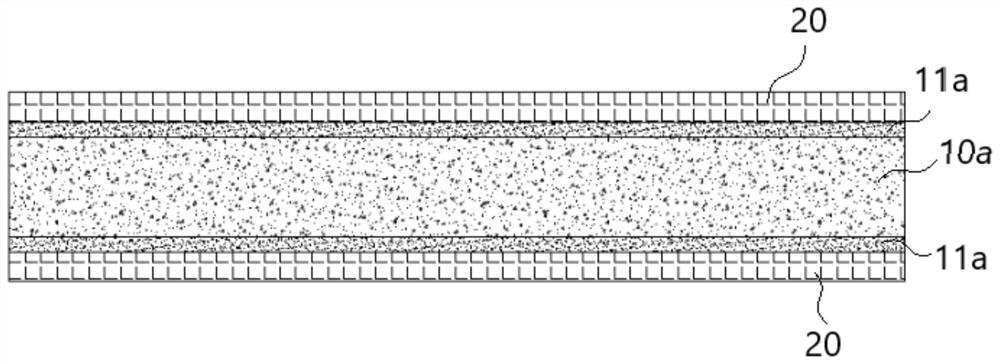

[0037] Embodiment 1: A fuel cell stack, comprising not less than 3 fuel cell units connected in series and stacked as one; each fuel cell unit includes anode plates stacked in sequence, with Membrane electrode and cathode plate of the gas diffusion layer (made of carbon fiber); wherein,

[0038] The cathode plate and the anode plate are silicon plates made of doped conductive crystalline silicon material;

[0039] The silicon plate has an internal cooling medium flow channel, a front reducing agent flow channel and / or a reverse oxidant flow channel, and the internal cooling medium flow channel, the front reducing agent flow channel and / or the reverse oxidant flow channel are respectively provided with silicon Plate import and export combination;

[0040] Preferably, in this embodiment, the silicon plate includes 2 or more silicon chips, and the silicon chips have single-sided or double-sided flow channels; wherein, conductive materials are used between the surface areas of th...

Embodiment 2

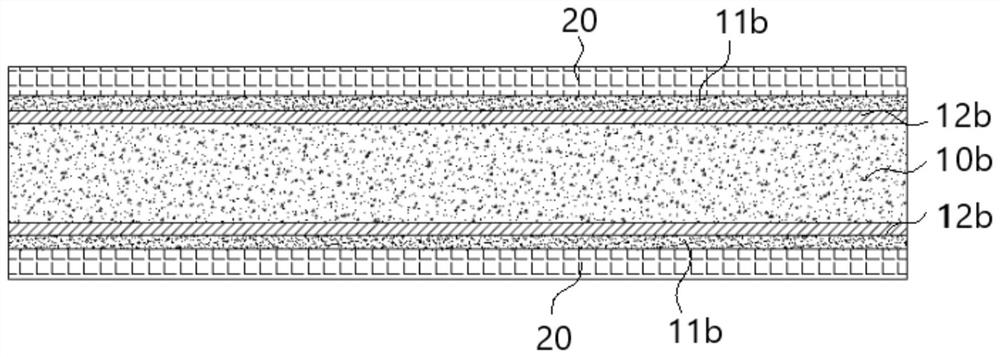

[0052] Embodiment 2: The remaining technical solutions of this embodiment 2 are the same as those of embodiment 1, the difference is that this embodiment 2 proposes a fuel cell stack with low contact resistance, between the silicon pole plate 10b and its corresponding gas diffusion layer 20 There is an intermediate layer used to reduce the contact resistance, and the intermediate layer is a deposited film formed by a deposition process; the contact resistance between the deposited film, the silicon plate and the gas diffusion layer is not greater than 10mΩ*cm 2 ; while the deposited film includes a carbon deposited film 11b in contact with its corresponding gas diffusion layer; wherein,

[0053] See figure 2 As shown, in this embodiment 2, the deposited film includes depositing the contacted carbon deposited film 11b and the metal deposited film 12b respectively, wherein, specifically, the deposition process of the metal deposited film 12b can adopt evaporation deposition or ...

Embodiment 3

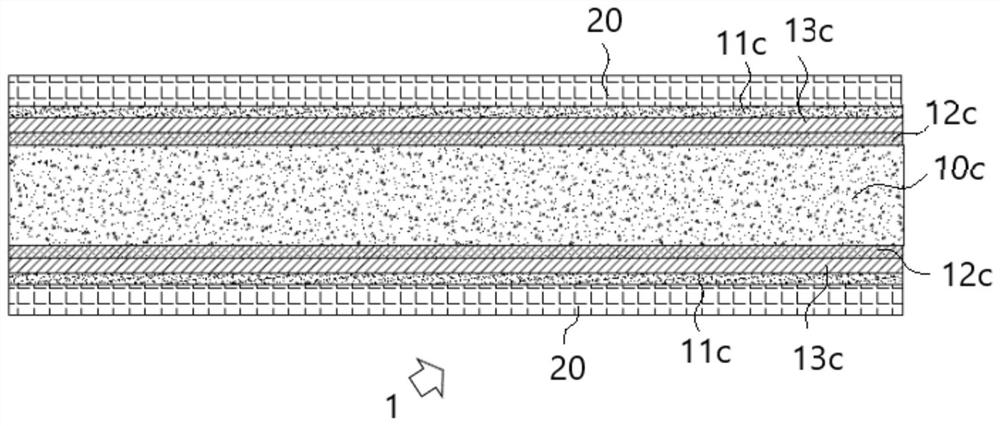

[0066] Embodiment 3: the remaining technical solutions of this embodiment 3 are the same as embodiment 2, the difference is that please refer to image 3 As shown, in this embodiment 3, the metal deposition film (material selection titanium) located on the silicon pole plate 10c is alloyed and heat-treated under the protection of an inert gas to form a metal-silicon alloy layer, and the silicon pole plate is transformed into an alloy for fuel cells Siliconized pole plate 1 is used to reduce the contact resistance between the silicon pole plate 10c and the carbon deposition film 11c; further specifically, in this embodiment 3, the surface of the silicon pole plate 10c is provided with a metal deposition film, and the surface of the silicon pole plate 10c is provided with a metal deposition film. The plate 10c is heat-treated so that the metal deposition film on the surface of the silicon pole plate 10c is alloyed (that is, the metal deposition film part is alloyed) to form a met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com