Preparation of tellurium nano-wire array based on physical vapour deposition

A technology of physical vapor deposition and tellurium nanowires, which is applied in ion implantation plating, metal material coating process, coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

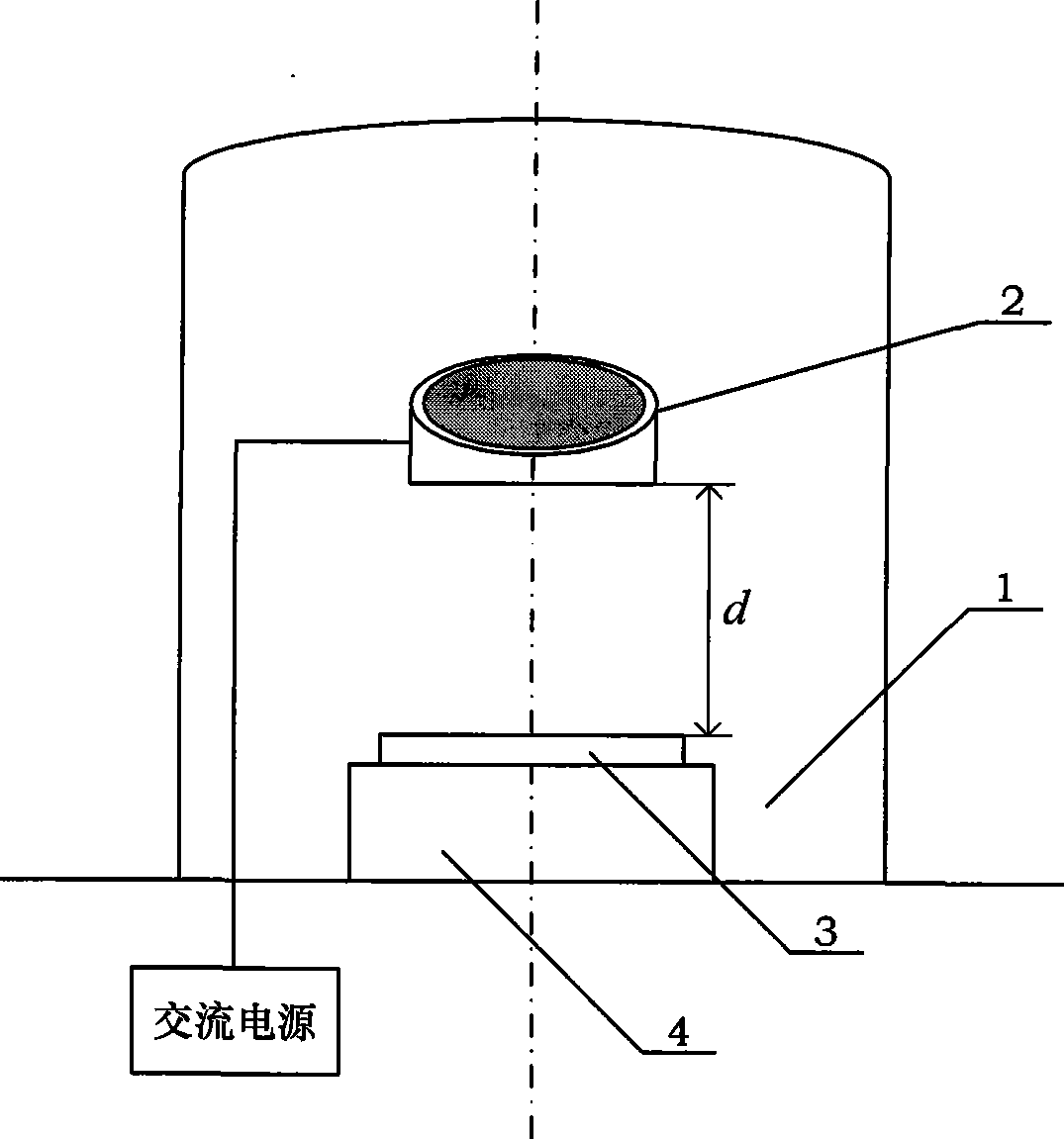

[0021] Put the tellurium Te elemental powder with a particle size of 5-10 μm into the tungsten boat 2 of the vacuum chamber 1 of the vacuum coating machine, place the glass substrate 3 on the sample stage 4, and adjust the distance d=10cm between the glass substrate 3 and the tungsten boat 2 ;

[0022] Seal the vacuum chamber 1, fill the vacuum chamber 1 with nitrogen for 3 minutes and stop (the nitrogen can be filled twice), then vacuumize the vacuum chamber 1 to make the vacuum degree in the vacuum chamber 1 reach 2.0×10 -4 Pa;

[0023] Set the deposition rate on the vacuum coating machine to 4nm / min, and the deposition time to 8h;

[0024] Turn on the AC power supply, adjust the output current to 165A; begin to deposit tellurium nanowire array films on the glass substrate 3 by physical vapor phase deposition.

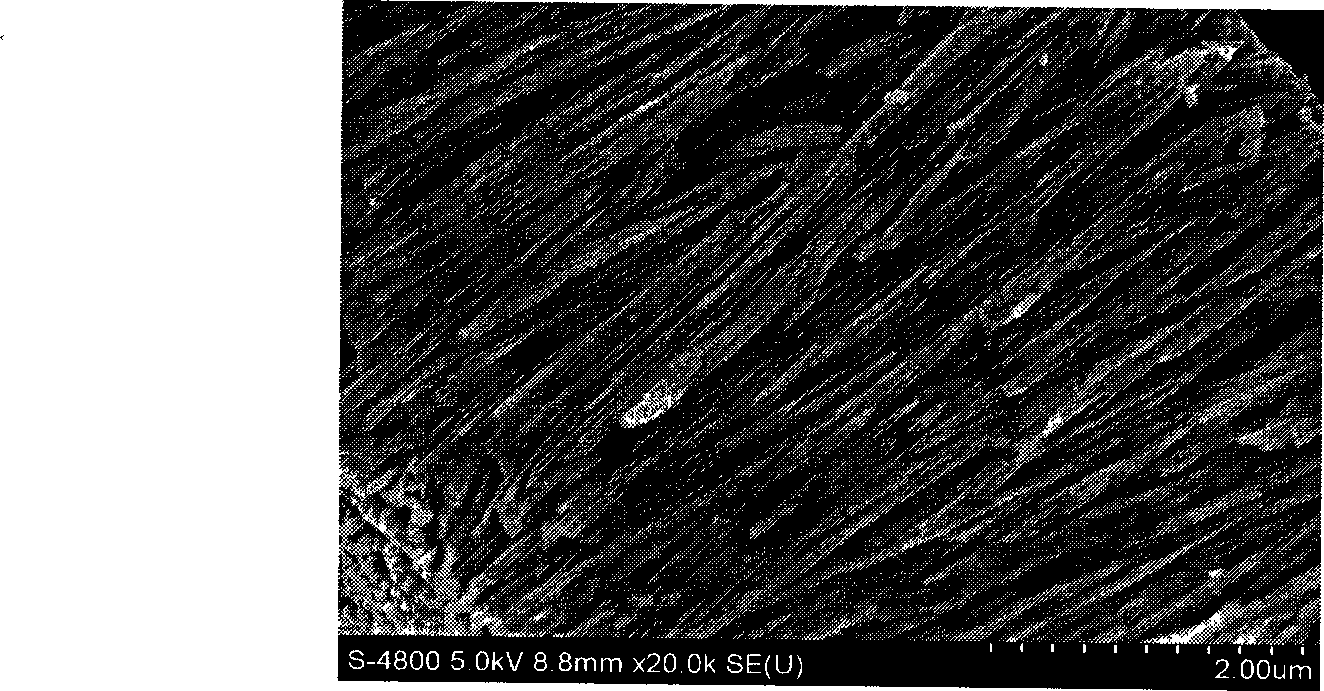

[0025] After the preparation is completed, the AC power is turned off, and after natural cooling to room temperature, the glass substrate 3 with the tellurium nano...

Embodiment 2

[0029] Put the tellurium powder with a particle size of 5-20 μm into the tungsten boat 2 of the vacuum chamber 1 of the vacuum coating machine, place the glass substrate 3 on the sample stage 4, and adjust the distance d=6cm between the glass substrate 3 and the tungsten boat 2;

[0030] Seal the vacuum chamber 1, fill the vacuum chamber 1 with nitrogen for 5 minutes and then stop, then evacuate the vacuum chamber 1 to make the vacuum degree in the vacuum chamber 1 reach 3.0×10 -4 Pa;

[0031] Set the deposition rate on the vacuum coating machine to 8nm / min, and the deposition time to 5h;

[0032] Turn on the AC power supply, adjust the output current to 175A; begin to deposit and prepare the tellurium nanowire array thin film on the glass substrate 3 .

[0033] After the preparation is completed, the AC power is turned off, and after natural cooling to 28° C., the glass substrate 3 with the tellurium nanowire array thin film is taken out.

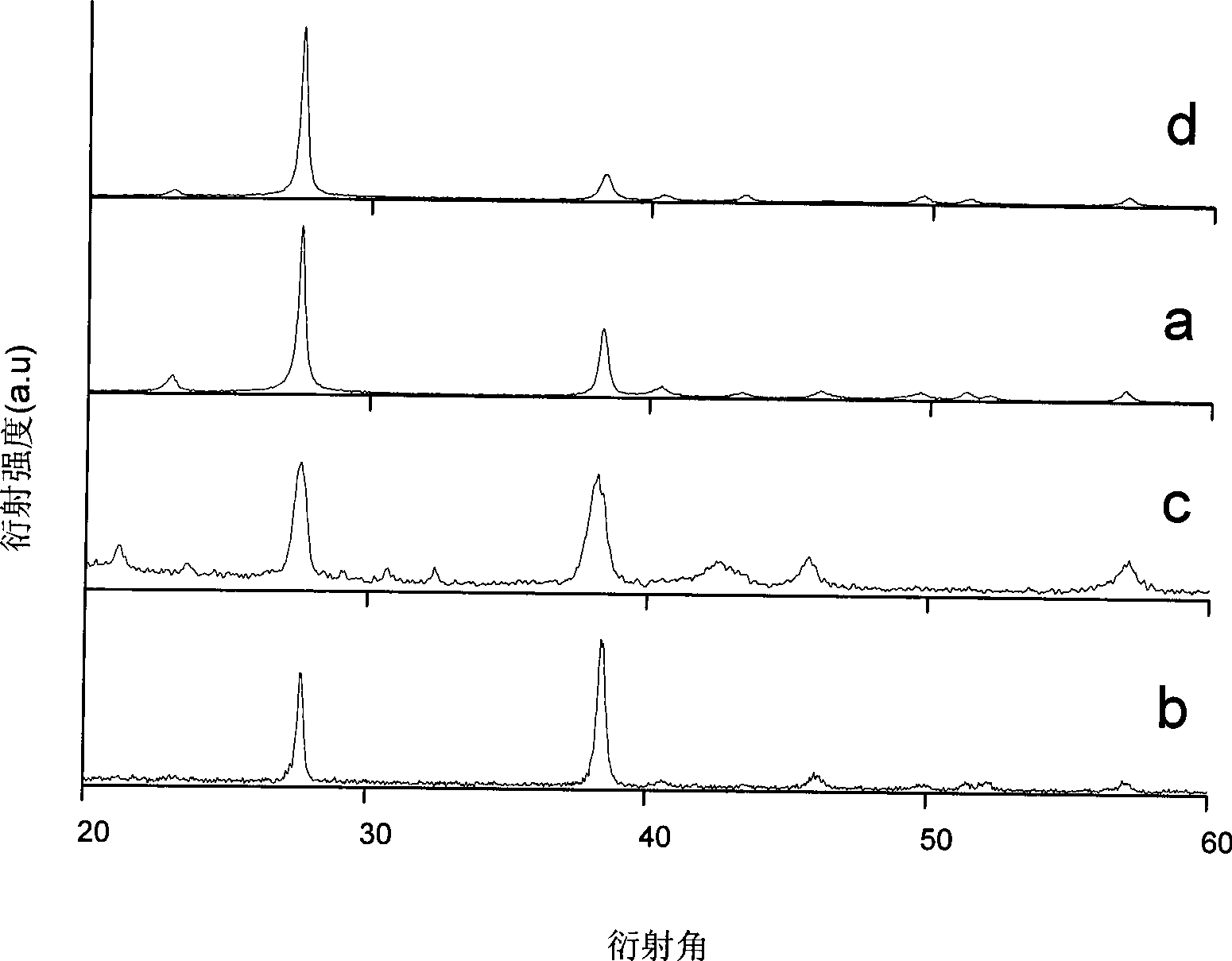

[0034] Adopt X-ray diffractometer...

Embodiment 3

[0037] Put the tellurium powder with a particle size of 10-20 μm into the tungsten boat 2 of the vacuum chamber 1 of the vacuum coating machine, place the glass substrate 3 on the sample stage 4, and adjust the distance d=9cm between the glass substrate 3 and the tungsten boat 2;

[0038] Seal the vacuum chamber 1, fill the vacuum chamber 1 with nitrogen for 3 minutes and then stop, then evacuate the vacuum chamber 1 to make the vacuum degree in the vacuum chamber 1 reach 5.0×10 -5 Pa;

[0039] Set the deposition rate on the vacuum coating machine to 12nm / min, and the deposition time to 6h;

[0040] Turn on the AC power supply, adjust the output current to 170A; begin to deposit and prepare the tellurium nanowire array thin film on the glass substrate 3 .

[0041] After the preparation is completed, the AC power is turned off, and after natural cooling to 22° C., the glass substrate 3 with the tellurium nanowire array thin film is taken out.

[0042] Adopt X-ray diffractomet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com