A kind of welding powder for the anti-wear layer of the water-cooled wall of the circulating fluidized bed boiler

A circulating fluidized bed and wear-resistant plate technology, which is applied in the directions of fluidized bed combustion equipment, cover/lining, fuel burning in a molten state, etc., can solve the problems of poor weldability of wear-resistant plates, etc., and achieve easy welding and good resistance. High temperature oxidation performance and the effect of wide process window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

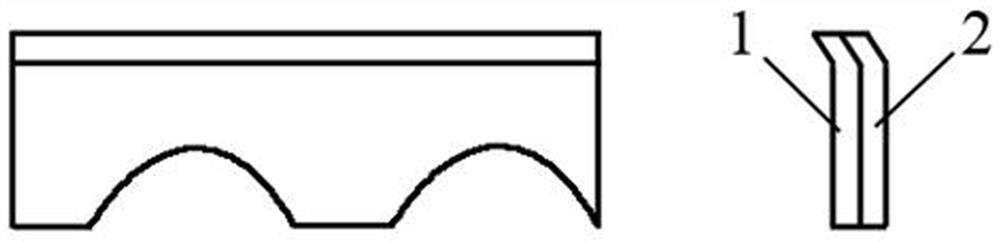

Image

Examples

Embodiment 1

[0032] Disclosed is a welding powder for the wear-resistant layer of the water-cooled wall of a circulating fluidized bed boiler, which is composed of the following raw materials in weight percentage: 70% high-carbon ferrochrome, 8% ferroboron, 20% ferronickel and 2% silicon carbide.

[0033] The welding powder can be melted by 120-150A current to form a flat welding layer. The hardness of the cladding layer is about HRC58, and the impact toughness is 4-5J / cm 2 . 900 ℃ 10 hours heat preservation oxidation test, no oxidation weight gain of the sample was detected.

[0034] This embodiment is a high chromium and high nickel formula, which has good wear resistance, corrosion resistance, high temperature oxidation resistance, good toughness, good welding processability, and slightly higher cost.

Embodiment 2

[0036] A circulating fluidized bed boiler water wall anti-wear plate anti-wear layer welding powder, which is composed of the following raw materials in weight percentage: 70% high carbon ferrochrome, 12% ferroboron, 5% ferronickel, 3% silicon carbide and 10 % ferromanganese.

[0037] Welding powder requires 170-200A current to form a smooth cladding layer. The hardness of the cladding layer is HRC60-63, and the impact toughness is 2J / cm 2 about. 900 ℃ 10 hours heat preservation oxidation test, no oxidation weight gain of the sample was detected.

[0038] This embodiment is a high chromium and low nickel formula, which has good wear resistance, high temperature oxidation resistance, good corrosion resistance, good manufacturability and low cost.

Embodiment 3

[0040] A circulating fluidized bed boiler water wall anti-wear plate anti-wear layer welding powder, which is composed of the following raw materials in weight percentage: 65% high carbon ferrochrome, 12% ferroboron, 5% ferronickel, 3% silicon carbide and 15% % ferromanganese.

[0041] The welding powder is melted by 160-180A current to form a flat welding layer. The hardness of the cladding layer is HRC56-58, and the impact toughness is 2-3J / cm 2 . 900 ℃ 10 hours heat preservation oxidation test, no oxidation weight gain of the sample was detected.

[0042] This embodiment is a low-chromium and low-nickel formula, which has good wear resistance, corrosion resistance and high temperature oxidation resistance, good manufacturability and low cost.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com