A Method for Controllable Preparation of Structure Gradient Oriented Growth Sb-bi-te Film by Vacuum Evaporation Coating

A sb-bi-te, structural gradient technology, applied in vacuum evaporation plating, sputtering plating, ion implantation plating and other directions, can solve problems such as unseen patents and literature reports, and achieve easy large-scale production, method Simple, significant practical value and economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

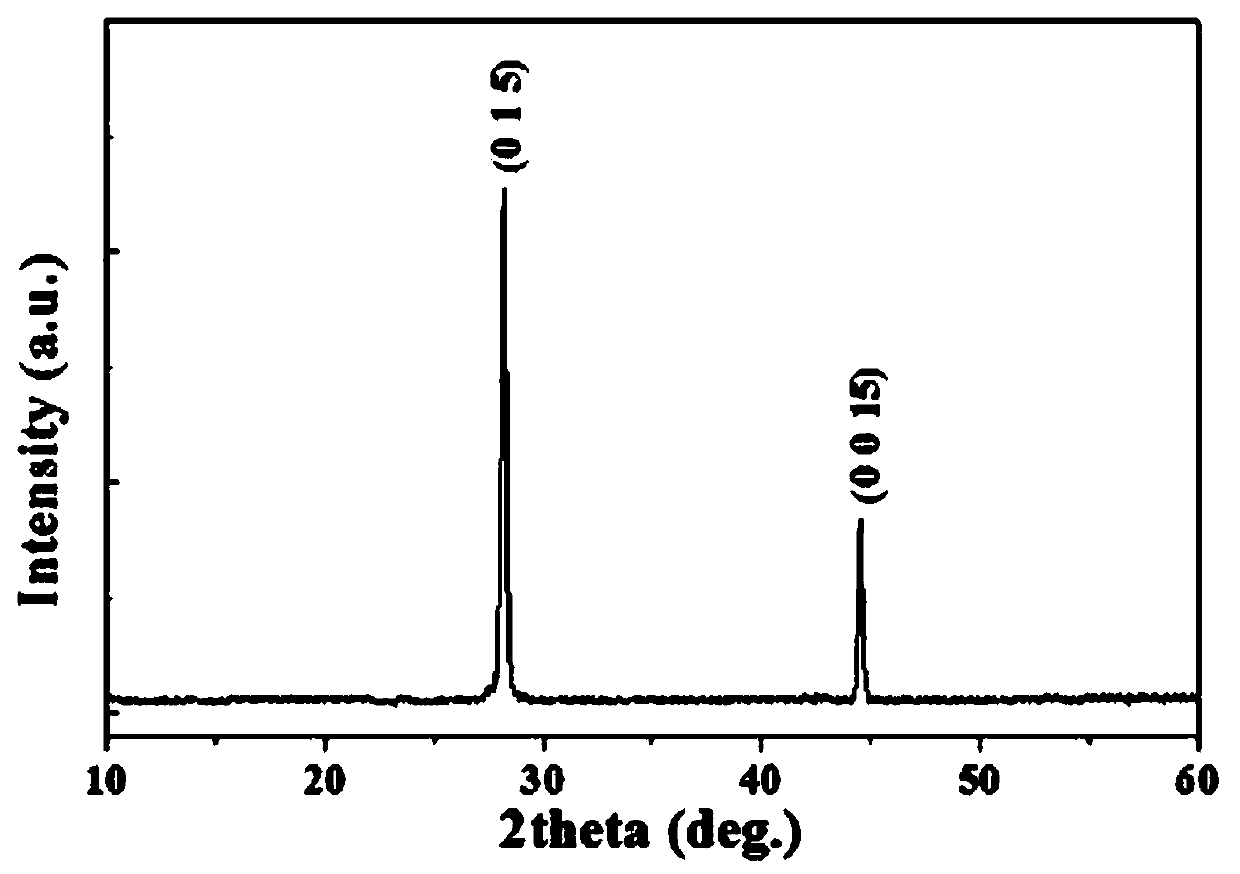

[0044] Fabrication of structural gradients (Bi 0.2 Sb 0.8 ) 2 Te 3 membrane:

[0045] (1) the mass percent purity is all 99.99% (Bi 0.2 Sb 0.8 ) 2 Te 3 and Te powder (mass ratio (Bi 0.2 Sb 0.8 ) 2 Te 3 : Te=10:0.8 evenly mixed) pressed under 8MPa pressure (Bi 0.2 Sb 0.8 ) 2 Te 3 and Te mixed material into a block; the (Bi 0.2 Sb 0.8 ) 2 Te 3 and the average particle size of Te powder is less than 50 μm;

[0046] (2) The substrate was ultrasonically cleaned in acetone, absolute ethanol and deionized water for 5 minutes, then taken out, and dried with high-purity 99.999% nitrogen;

[0047] (3) 0.15g of (Bi 0.2 Sb 0.8 ) 2 Te 3 Put the block made of mixed material with Te into the tungsten boat in the vacuum chamber of the vacuum coating machine, place the substrate on the sample stage, and adjust the distance d=4cm between the substrate and the tungsten boat;

[0048] (4) Fill the vacuum chamber with nitrogen for 4 minutes and then stop, then evacuate the ...

Embodiment 2

[0056] Fabrication of structural gradients (Bi 0.2 Sb 0.8 ) 2 Te 3 Membrane: (preferred implementation)

[0057] (1) the mass percent purity is all 99.99% (Bi 0.2 Sb 0.8 ) 2 Te 3 and Te powder (mass ratio (Bi 0.2 Sb 0.8 ) 2 Te 3 : Te=10:1 evenly mixed) pressed under 9MPa pressure (Bi 0.2 Sb 0.8 ) 2 Te 3 and Te mixed material into a block; the (Bi 0.2 Sb 0.8 ) 2 Te 3 and the average particle size of Te powder is less than 50 μm;

[0058] (2) The substrate was ultrasonically cleaned in acetone, absolute ethanol and deionized water for 6 minutes, then taken out, and dried with high-purity 99.999% nitrogen;

[0059] (3) 0.15g of (Bi 0.2 Sb 0.8 ) 2 Te 3 Put the block made of the mixed material with Te into the tungsten boat in the vacuum chamber of the vacuum coating machine, place the substrate on the sample stage, and adjust the distance d=5cm between the substrate and the tungsten boat;

[0060] (4) Fill the vacuum chamber with nitrogen for 5 minutes and ...

Embodiment 3

[0068] Fabrication of structural gradients (Bi 0.2 Sb 0.8 ) 2 Te 3 membrane:

[0069] (1) the mass percent purity is all 99.99% (Bi 0.2 Sb 0.8 ) 2 Te 3 and Te powder (mass ratio (Bi 0.2 Sb 0.8 ) 2 Te 3 : Te=10:1.2 evenly mixed) pressed under 9MPa pressure (Bi 0.2 Sb 0.8 ) 2 Te 3 and Te mixed material into a block; the (Bi 0.2 Sb 0.8 ) 2 Te 3 and the average particle size of Te powder is less than 50 μm;

[0070] (2) The substrate was ultrasonically cleaned in acetone, absolute ethanol and deionized water for 8 minutes, then taken out, and dried with high-purity 99.999% nitrogen;

[0071] (3) 0.18g of (Bi 0.2 Sb 0.8 ) 2 Te 3 Put the block made of mixed material with Te into the tungsten boat in the vacuum chamber of the vacuum coating machine, place the substrate on the sample stage, and adjust the distance d=6cm between the substrate and the tungsten boat;

[0072] (4) Fill the vacuum chamber with nitrogen for 4 minutes and then stop, then evacuate the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com