aluminum alloy surface 3 c 4 -al 2 o 3 -zro 2 Preparation method of wear-resistant composite coating

A technology of aluminum alloy surface and composite coating, applied in the field of metal surface treatment, can solve the problems of low surface hardness, poor wear resistance and high friction coefficient of aluminum and aluminum alloys, and achieve good bonding strength, uniform cathode discharge and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

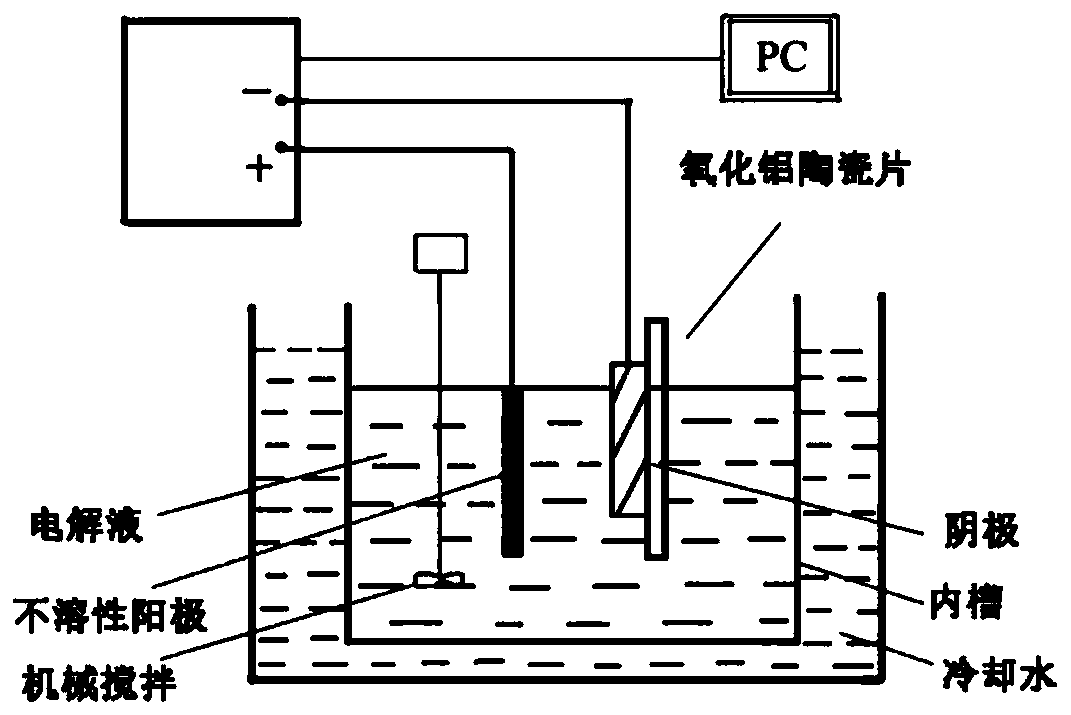

[0024] (1) use figure 1 For the electrolytic cell structure shown in the figure, the aluminum alloy parts pre-treated by plasma electrolytic deposition are sanded smooth, and the polished aluminum alloy is immersed in an ethanol solution for ultrasonic treatment and dried to obtain a pretreated aluminum alloy;

[0025] (2) One side of the aluminum alloy surface is covered with an alumina ceramic sheet and placed on the cathode. A round hole is punched on the upper part of the aluminum alloy and the ceramic sheet, and fixed by double nuts on the left and right, so that the workpiece and the ceramic sheet are tightly combined. Control the distance between cathode and anode at 70mm, and control the area ratio at 7;

[0026] (3) adopt urea-glycerol system as electrolyte, the concentration of urea is 325g / L, the concentration of formamide is 190g / L, the concentration of glycerol is 125g / L, the concentration of zirconium nitrate is 17g / L, The concentration of ammonium nitrate is 4g...

Embodiment 2

[0030] (1) use figure 1 For the electrolytic cell structure shown in the figure, the aluminum alloy parts pre-treated by plasma electrolytic deposition are sanded smooth, and the polished aluminum alloy is immersed in an ethanol solution for ultrasonic treatment and dried to obtain a pretreated aluminum alloy;

[0031] (2) One side of the aluminum alloy surface is covered with an alumina ceramic sheet and placed on the cathode. A round hole is punched on the upper part of the aluminum alloy and the ceramic sheet, and fixed by double nuts on the left and right, so that the workpiece and the ceramic sheet are tightly combined. Control the distance between cathode and anode at 60mm, and control the area ratio at 6;

[0032] (3) adopt urea-glycerol system as electrolyte, the concentration of urea is 300g / L, the concentration of formamide is 180g / L, the concentration of glycerol is 100g / L, the concentration of zirconium nitrate is 15g / L, The concentration of ammonium nitrate is 3g...

Embodiment 3

[0036] (1) use figure 1 For the electrolytic cell structure shown in the figure, the aluminum alloy parts pre-treated by plasma electrolytic deposition are sanded smooth, and the polished aluminum alloy is immersed in an ethanol solution for ultrasonic treatment and dried to obtain a pretreated aluminum alloy;

[0037] (2) One side of the aluminum alloy surface is covered with an alumina ceramic sheet and placed on the cathode. A round hole is punched on the upper part of the aluminum alloy and the ceramic sheet, and fixed by double nuts on the left and right, so that the workpiece and the ceramic sheet are tightly combined. Control the distance between cathode and anode at 80mm, and control the area ratio at 8;

[0038] (3) adopt urea-glycerol system as electrolyte, the concentration of urea is 350g / L, the concentration of formamide is 200g / L, the concentration of glycerol is 150g / L, the concentration of zirconium nitrate is 20g / L, The concentration of ammonium nitrate is 5g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com