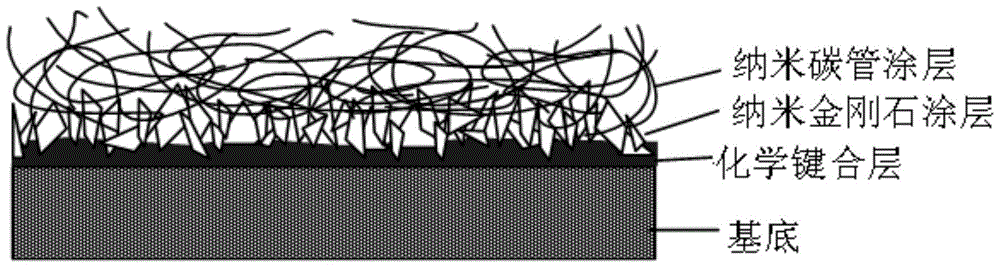

A field emission cathode with double-layer nano-carbon coating and preparation method thereof

A field emission cathode and nanocarbon technology, which is applied in cold cathode manufacturing, coating, electrode system manufacturing, etc., can solve the problems of limited growth area and complex film growth process, and achieve high production yield, good field emission characteristics, Simple effect of electrophoretic deposition process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

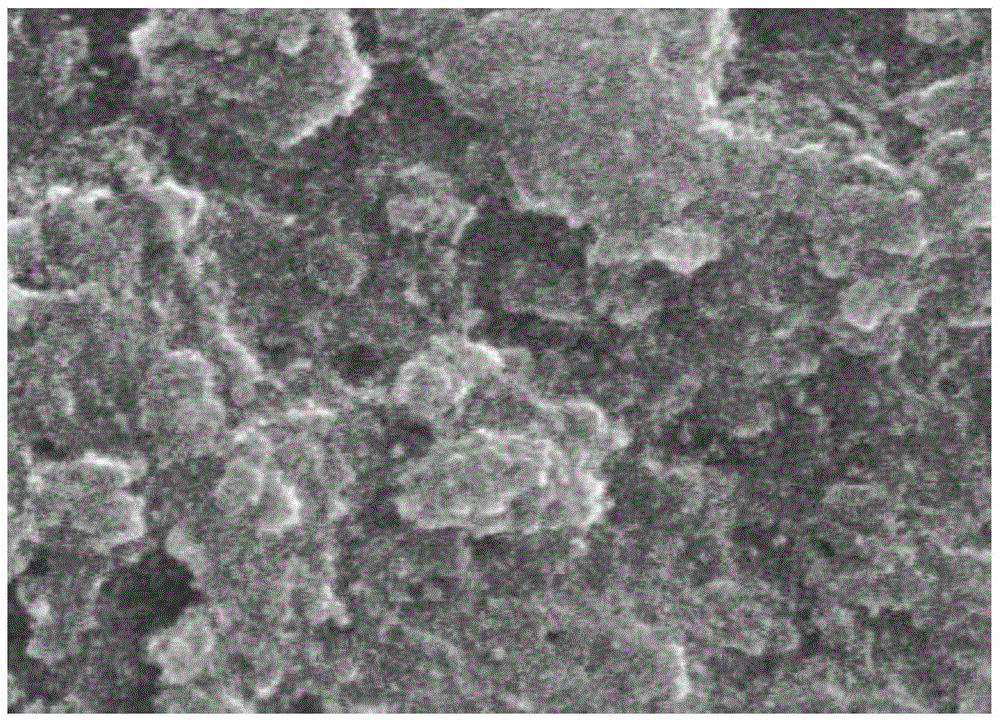

[0035] The present embodiment provides a kind of preparation method of the field emission cathode with double-layer nano-carbon coating as described above, the method specifically comprises the following steps:

[0036] Step 1: select a metal titanium sheet as the substrate, grind and polish one side of the metal titanium sheet, place it in acetone for ultrasonic cleaning, then rinse with deionized water and then dehydrate with ethanol;

[0037] Step 2, configure nano-diamond electrophoretic fluid: select a mixture with a mass ratio of nano-diamond: iodine = 1:2 as a solute; select a mixture with a volume ratio of deionized water: acetone: isopropanol = 1:1:20 as a solvent , so that the nano-diamond content is 0.23mg / ml;

[0038] After mixing the solute and solvent, carry out ultrasonic dispersion, ultrasonic power 99W, ultrasonic time 30min, ultrasonic temperature 30 ℃ ~ 40 ℃, to form a uniformly mixed nano-diamond powder electrophoretic fluid;

[0039] Step 3, the polished ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com