Method for preparing bismuth telluride nano-wire array by physical vapour deposition

A physical vapor deposition and bismuth telluride nanotechnology, which is applied in the field of preparing bismuth telluride nanowire arrays, can solve the problems that the line density cannot fully meet the density requirements of micro-refrigeration devices, influence, and high template quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

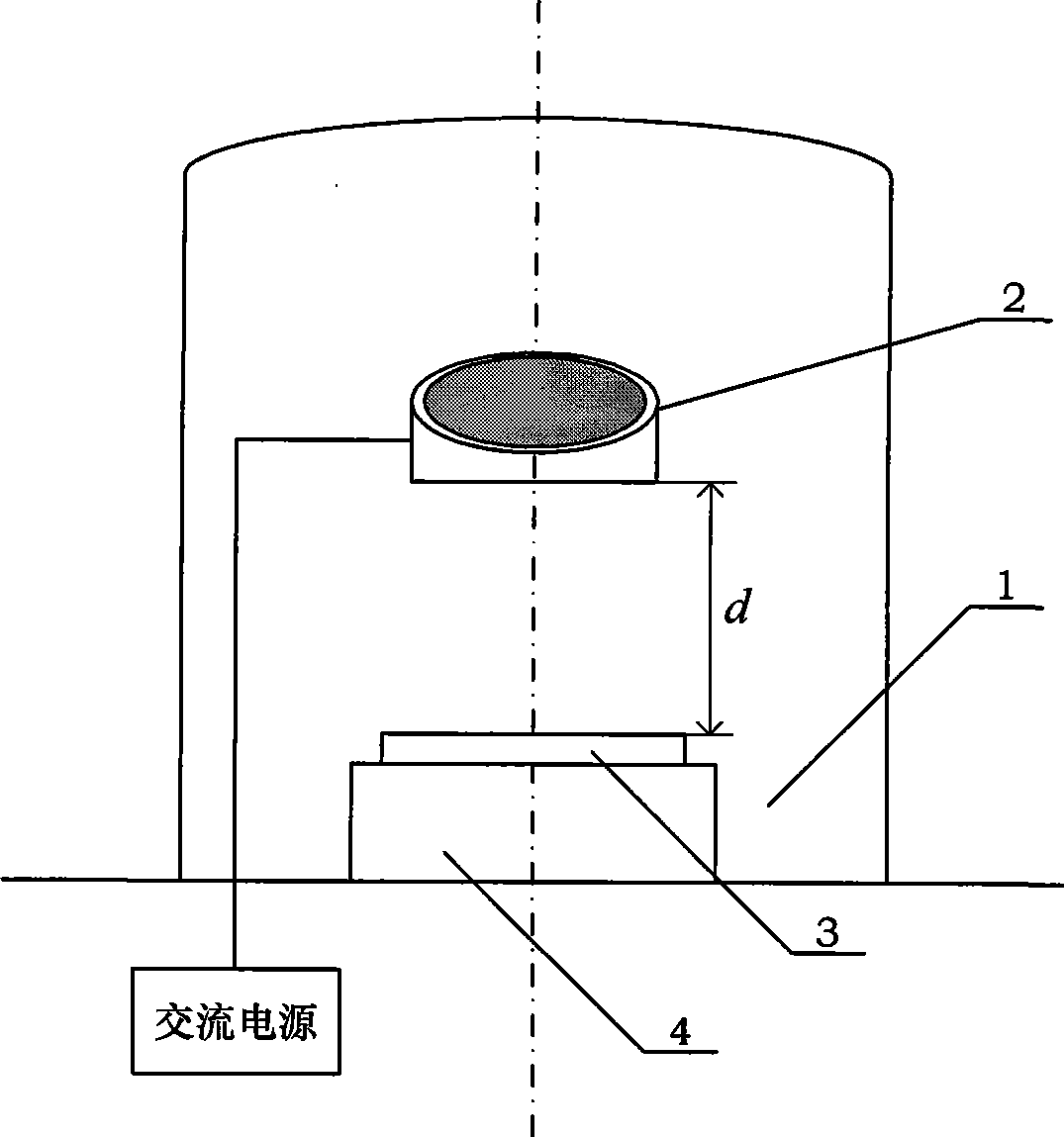

[0021] Put the bismuth telluride elemental powder with a particle size of 5-10 μm into the tungsten boat 2 of the vacuum chamber 1 of the vacuum coating machine, place the glass substrate 3 on the sample stage 4, and adjust the distance d between the glass substrate 3 and the tungsten boat 2 = 10cm;

[0022] Seal the vacuum chamber 1, fill the vacuum chamber 1 with nitrogen for 3 minutes and stop (the nitrogen can be filled twice), then vacuumize the vacuum chamber 1 to make the vacuum degree in the vacuum chamber 1 reach 2.0×10 -4 Pa;

[0023] Set the deposition rate on the vacuum coating machine to 0.7nm / min, and the deposition time to 8h;

[0024] Turn on the AC power supply, adjust the output current to 165A; begin to deposit the bismuth telluride nanowire array thin film on the glass substrate 3 by physical vapor phase deposition.

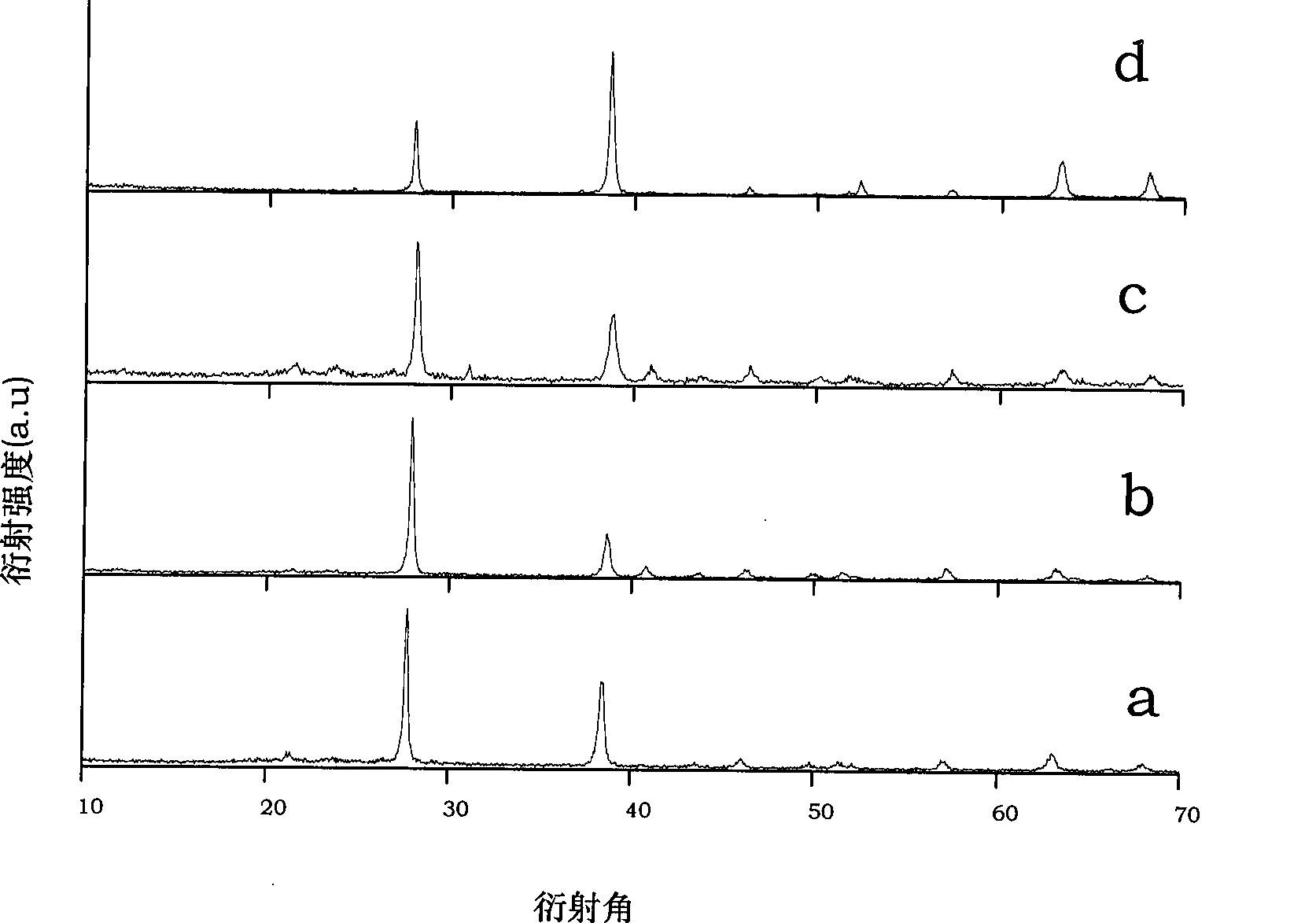

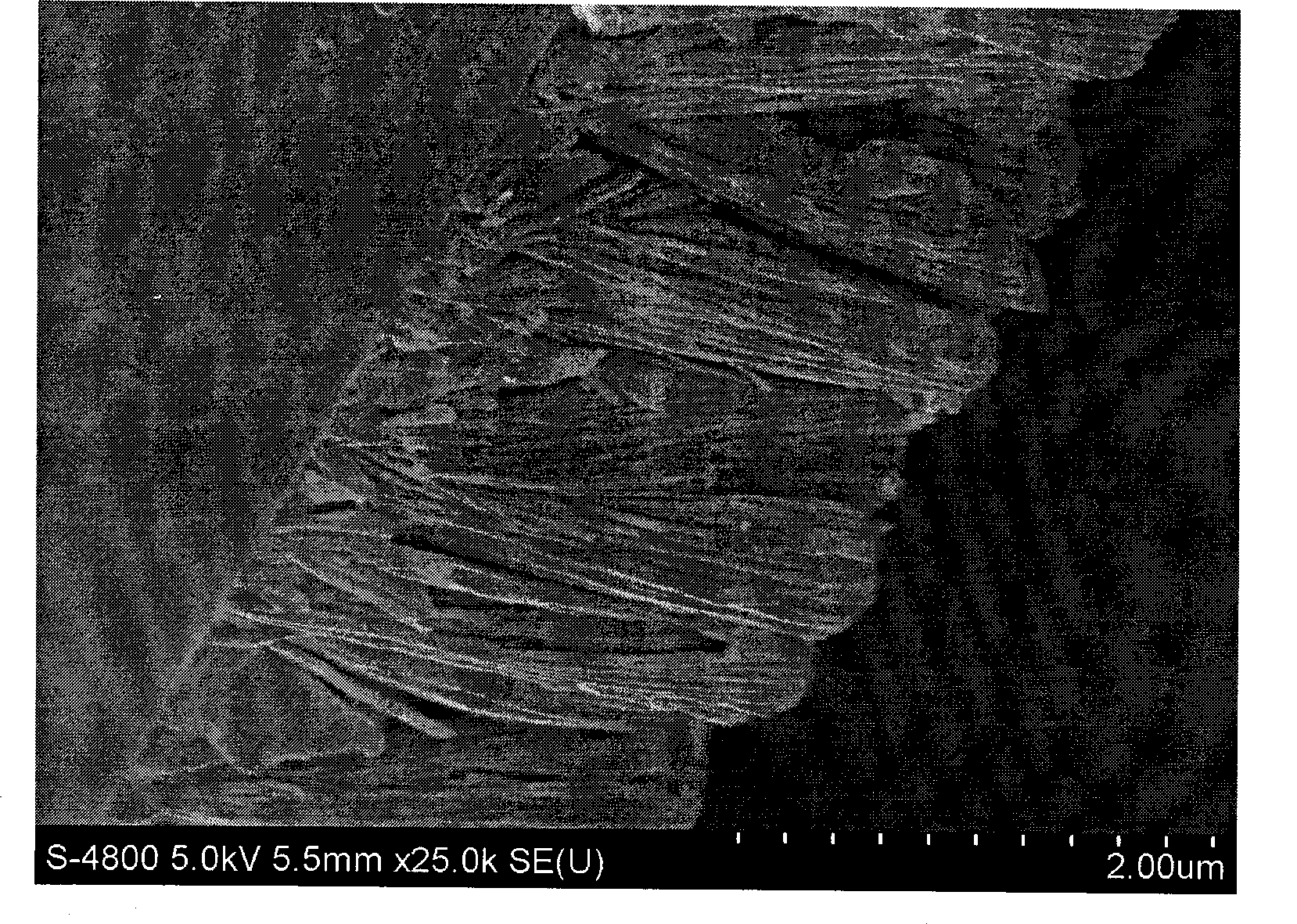

[0025] After the preparation is completed, the AC power is turned off, and after natural cooling to room temperature, the glass substrate 3...

Embodiment 2

[0029] Put the bismuth telluride powder with a particle size of 5-20 μm into the tungsten boat 2 of the vacuum chamber 1 of the vacuum coating machine, place the glass substrate 3 on the sample stage 4, and adjust the distance d=6cm between the glass substrate 3 and the tungsten boat 2 ;

[0030] Seal the vacuum chamber 1, fill the vacuum chamber 1 with nitrogen for 5 minutes and then stop, then evacuate the vacuum chamber 1 to make the vacuum degree in the vacuum chamber 1 reach 3.0×10 -4 Pa;

[0031] Set the deposition rate on the vacuum coating machine to 1.8nm / min, and the deposition time to 5h;

[0032] Turn on the AC power supply, adjust the output current to 175A; begin to deposit and prepare the bismuth telluride nanowire array thin film on the glass substrate 3 .

[0033] After the preparation is completed, the AC power is turned off, and after natural cooling to 28° C., the glass substrate 3 with the bismuth telluride nanowire array thin film is taken out.

[0034...

Embodiment 3

[0037] Put the bismuth telluride powder with a particle size of 10-20 μm into the tungsten boat 2 of the vacuum chamber 1 of the vacuum coating machine, place the glass substrate 3 on the sample stage 4, and adjust the distance d=9cm between the glass substrate 3 and the tungsten boat 2 ;

[0038] Seal the vacuum chamber 1, fill the vacuum chamber 1 with nitrogen for 3 minutes and then stop, then evacuate the vacuum chamber 1 to make the vacuum degree in the vacuum chamber 1 reach 5.0×10 -5 Pa;

[0039] Set the deposition rate on the vacuum coating machine to 4nm / min, and the deposition time to 6h;

[0040] Turn on the AC power supply, adjust the output current to 170A; begin to deposit and prepare the bismuth telluride nanowire array thin film on the glass substrate 3 .

[0041] After the preparation is completed, the AC power is turned off, and after natural cooling to 22° C., the glass substrate 3 with the bismuth telluride nanowire array thin film is taken out.

[0042]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com