Method for cooling server through oil

A server, oil cooling technology, applied in chemical instruments and methods, cooling/ventilation/heating transformation, heat exchange materials, etc., can solve the problems of dust accumulation, low server heat dissipation efficiency, low air thermal conductivity, etc., to achieve chemical stability High performance, low freezing point and high dielectric strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is further described in detail through specific implementation methods:

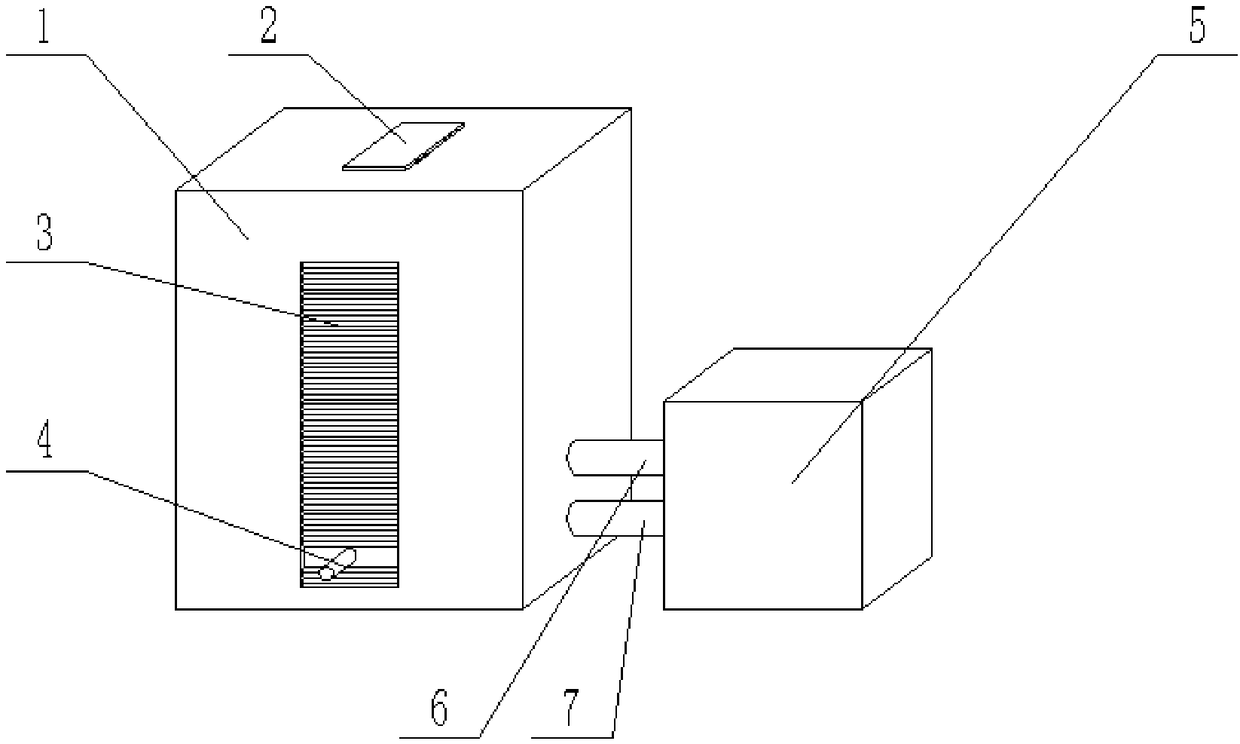

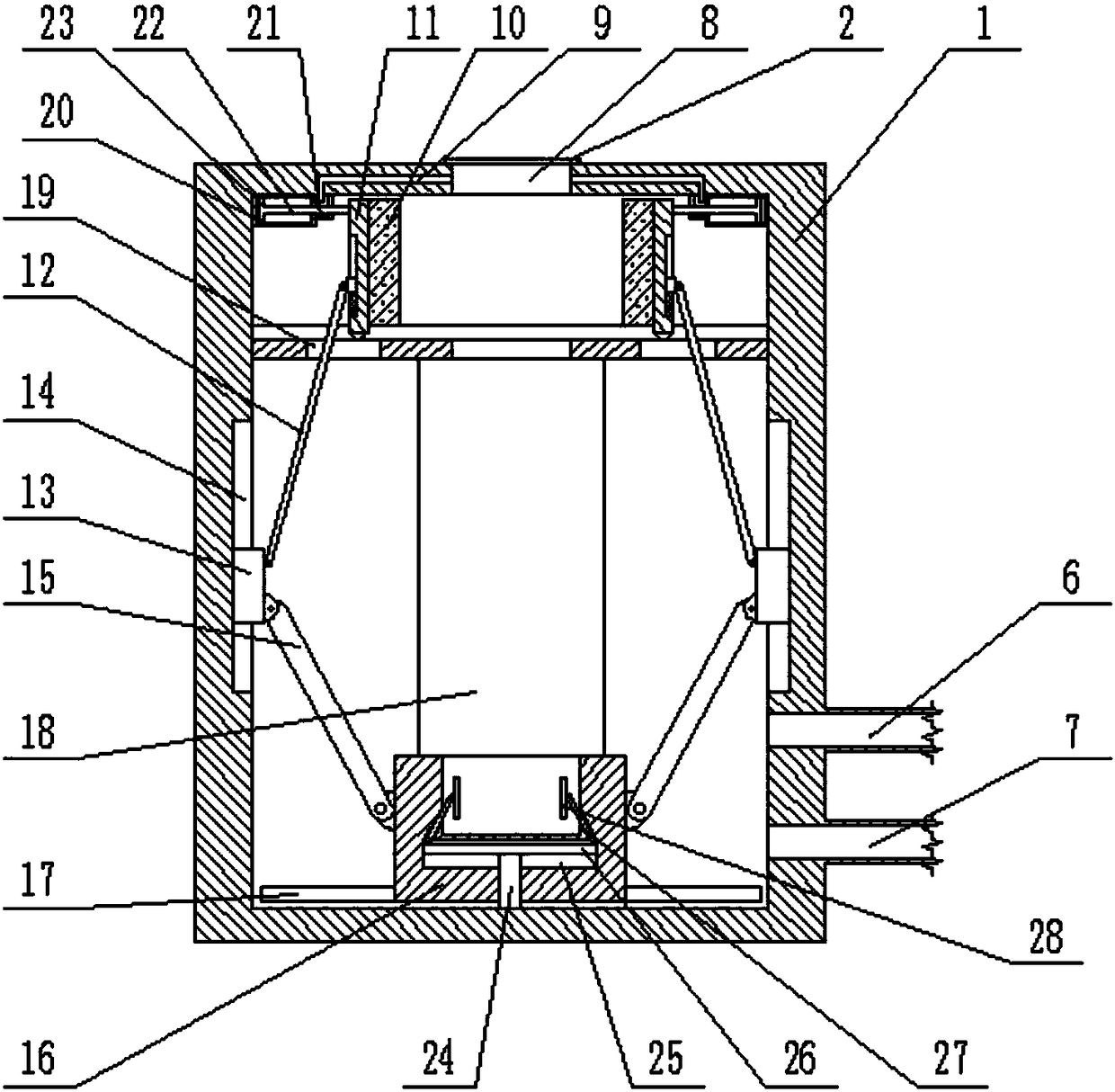

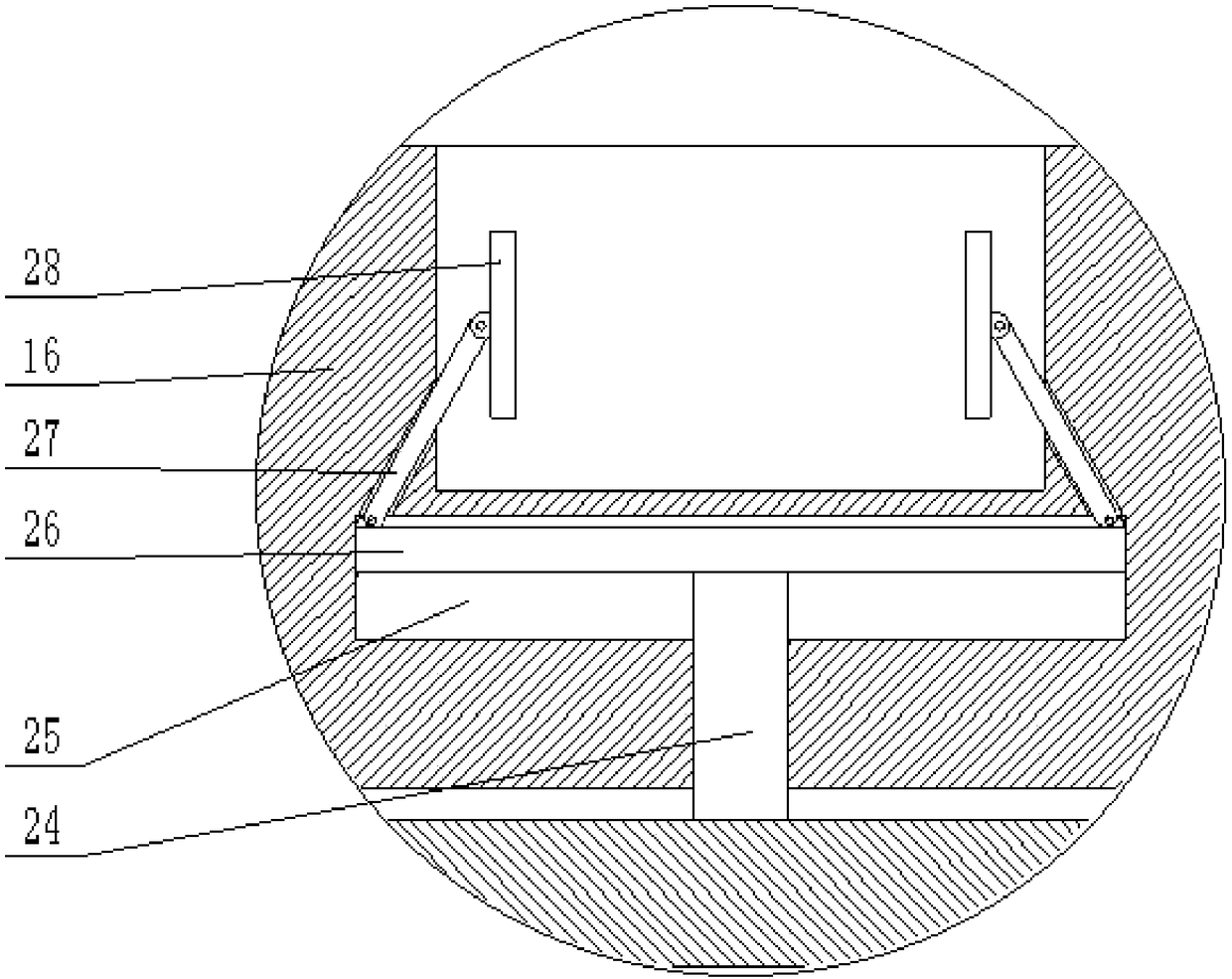

[0023] The reference signs in the drawings of the specification include: cabinet 1, cover plate 2, folding sealing layer 3, handle 4, oil circulation device 5, oil inlet pipe 6, oil outlet pipe 7, access port 8, air outlet pipe 9, oil suction block 10. Mounting plate 11, second connecting rod 12, first slider 13, first chute 14, first connecting rod 15, positioning platform 16, miscellaneous net 17, limit groove 18, through hole 19, cylinder 20, suction pipe 21, piston rod 22, piston plate 23, positioning pin 24, slide cavity 25, slide rod 26, support rod 27, hold down plate 28.

[0024] The embodiment is basically as figure 1 , figure 2 with image 3 Shown: A method of cooling a server through oil comprising the following steps:

[0025] Step 1: Prepare a server heat dissipation system, including cabinet 1. There is a rectangular access opening 8 on the upper end of cabinet 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com