Lamp

A technology of LED lamp and LED lamp body, which is applied in the cooling/heating device of lighting device, lighting device, light source, etc., which can solve the problems of LED lamp chip attenuation, loss of use value, and increase in heat generation, and achieve reasonable structure and good effect Dramatic, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

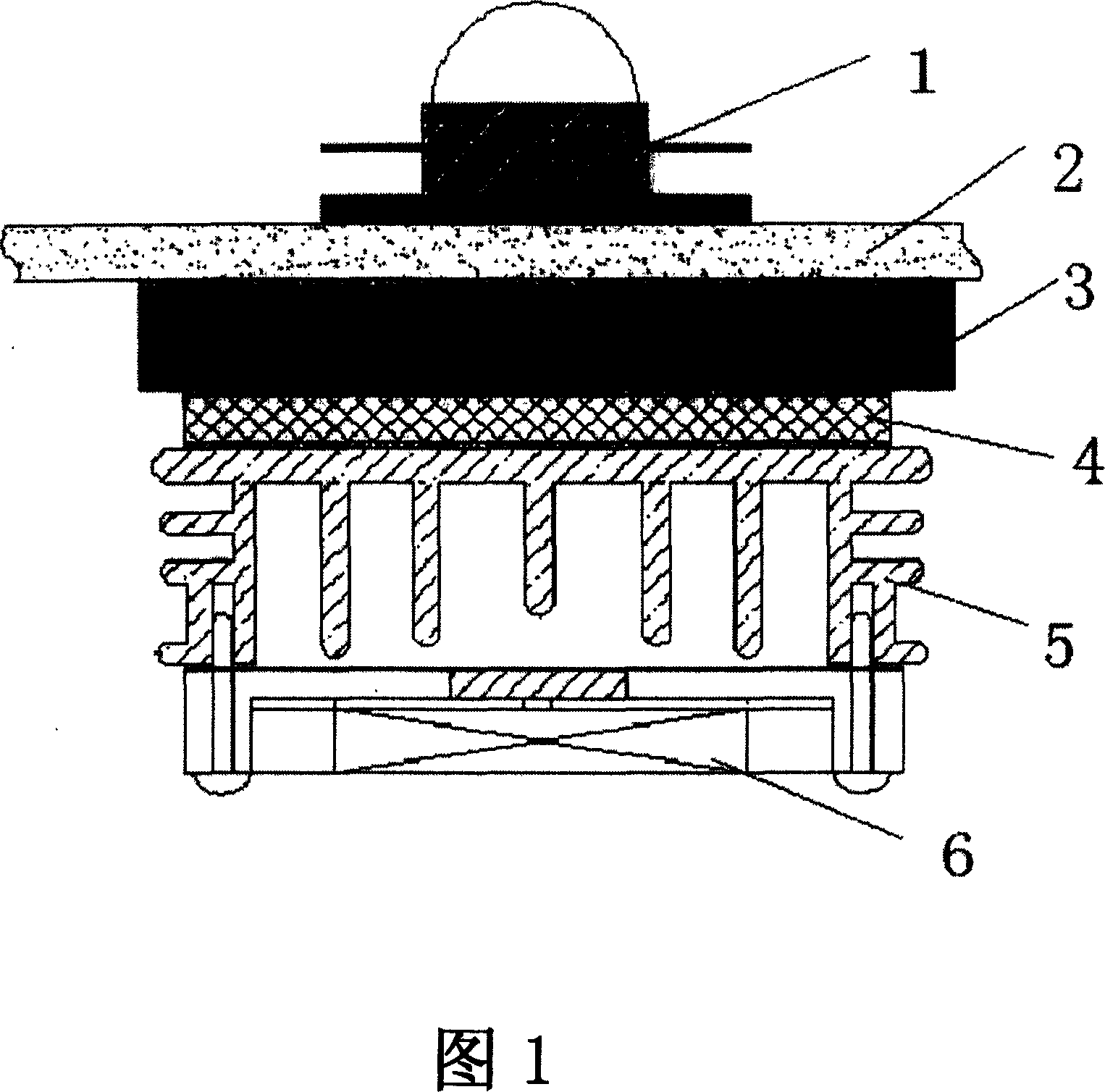

[0009] The LED lamp of the present invention is composed of an LED lamp body (1), a metal substrate (2), a heat container (3), a semiconductor refrigeration sheet (4), a cooling fin (5) and a cooling fan (6). The LED lamp body (1) is composed of LED chips and brackets, and is a commercially available high-power LED lamp; the metal substrate (2) is a connecting body of the shell, made of copper plate or aluminum plate, and has a certain heat dissipation effect; The container (3) can be selected from copper or aluminum or other materials with good thermal conductivity. The semiconductor refrigeration sheet (4) is a commercially available semiconductor refrigeration sheet. The heat sink (5) and cooling fan (6) are manufactured using the prior art. LED The lamp can be assembled and manufactured using existing technologies.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com