High-temperature-resistant composite ceramic insulating coating and preparation method thereof

A composite ceramic and insulating coating technology, applied in the direction of coating, metal material coating technology, high-efficiency propulsion technology, etc., can solve the problems of easy aging of resin-based sealing layer, insufficient reliability, low high temperature oxidation resistance, etc. To ensure insulation and service life, improve environmental adaptability and durability, improve density and surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

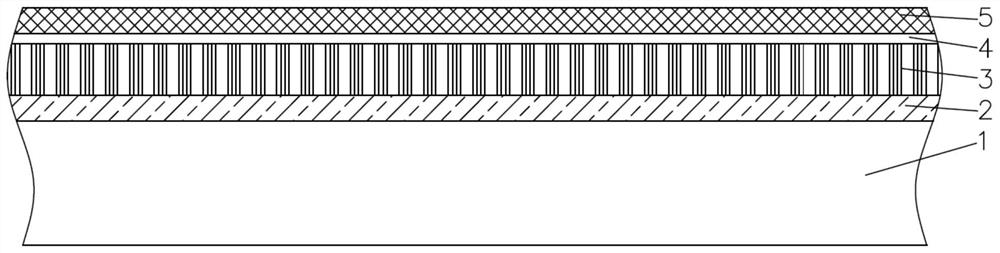

[0029] NiCrAlY is used as the material of transition layer 2 and metal layer 4, and Al 2 o 3 As the intermediate layer 3 material, Al 2 o 3 +13%TiO 2 As the surface layer 5 material, a composite ceramic insulating coating is prepared on the surface of the stainless steel substrate; the specific steps are:

[0030] S001. Pretreatment of the substrate: first soak the stainless steel substrate in acetone to remove oil stains, then perform ultrasonic cleaning of the stainless steel substrate with anhydrous ethanol as the cleaning medium, and finally dry it; then use brown corundum with a particle size of 40 mesh as the sandblasting material The surface of the stainless steel substrate is sandblasted; finally, the stainless steel substrate is preheated, the preheating temperature is 200 ° C, and the time is 3 minutes;

[0031] S002, preparation of the transition layer 2: prepare the transition layer 2 of NiCrAlY by plasma spraying, the spraying power is 20kW, and the spraying d...

Embodiment 2

[0038] A mixed alloy of NiCrAlY and NiCoCrAlY is used as the transition layer 2 and metal layer 4 materials, and ZrO 2 As the intermediate layer 3 material, Al 2 o 3 +28%TiO 2 As the surface layer 5 material, a composite ceramic insulating coating is prepared on the surface of the aluminum alloy substrate; the specific steps are:

[0039] S001. Pretreatment of the substrate: first soak the aluminum alloy substrate with acetone to remove oil stains, then perform ultrasonic cleaning of the aluminum alloy substrate with absolute ethanol as the cleaning medium, and finally dry it; then use white corundum with a particle size of 80 mesh as sandblasting The material is sand blasted on the surface of the aluminum alloy substrate; finally, the aluminum alloy substrate is preheated, the preheating temperature is 250 ° C, and the time is 5 minutes;

[0040] S002, preparation of transition layer 2: adopt plasma spraying to prepare the transition layer 2 of the mixed alloy of NiCrAlY a...

Embodiment 3

[0047] NiCoCrAlY is used as the material of transition layer 2 and metal layer 4, and Al 2 o 3 As the intermediate layer 3 material, Al 2 o 3 +40%TiO 2 As the surface layer 5 material, a composite ceramic insulating coating is prepared on the surface of the titanium alloy substrate; the specific steps are:

[0048] S001. Pretreatment of the substrate: first soak the titanium alloy substrate with acetone to remove oil stains, then perform ultrasonic cleaning of the titanium alloy substrate with anhydrous ethanol as the cleaning medium, and finally dry it; then use brown corundum with a particle size of 40 mesh as sandblasting The material is sand blasted on the surface of the titanium alloy substrate; finally, the titanium alloy substrate is preheated, the preheating temperature is 200 ° C, and the time is 3 minutes;

[0049] S002, preparation of the transition layer 2: prepare the transition layer 2 of NiCoCrAlY by plasma spraying, the spraying power is 30kW, and the spray...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com