Commercial vehicle fuel cell system

A fuel cell system and fuel cell technology, applied in fuel cells, fuel cell additives, fuel cell control, etc., can solve the problems of reducing integration, consuming pipelines, inconvenient overall maintenance, etc., achieving convenient assembly and maintenance, guaranteeing Insulation properties, the effect of improving integration and space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

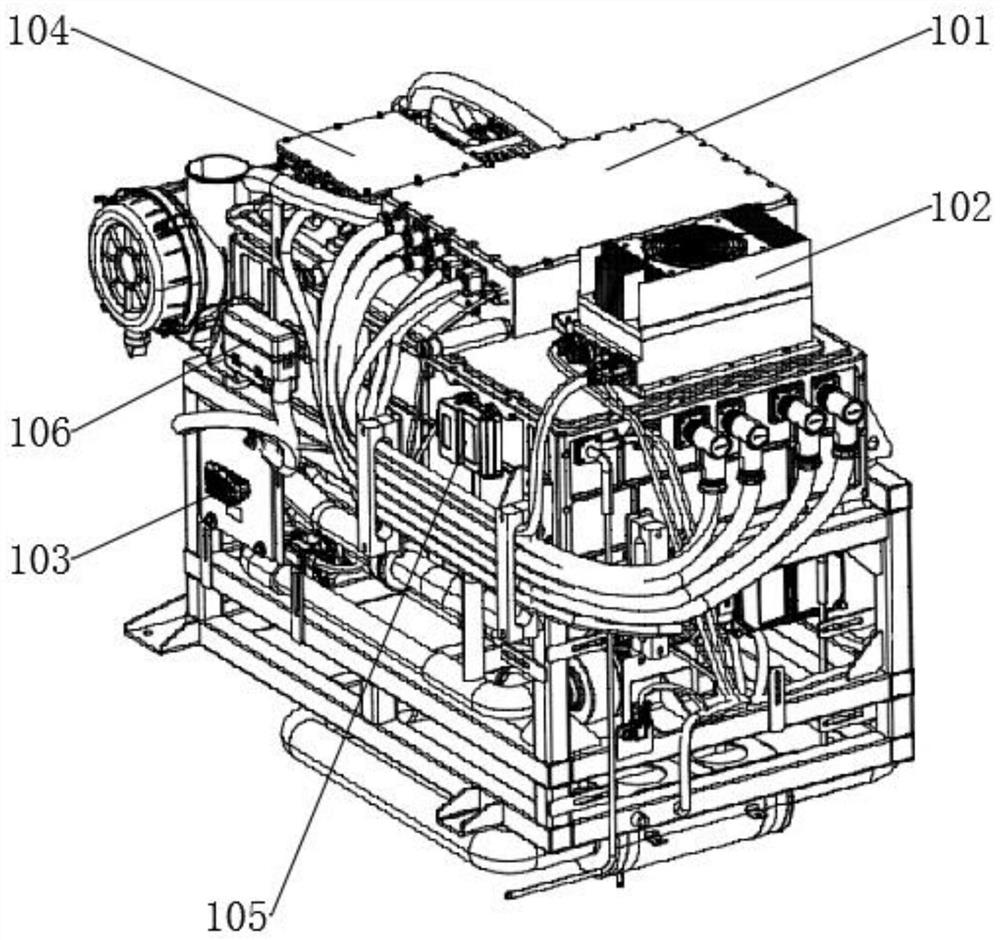

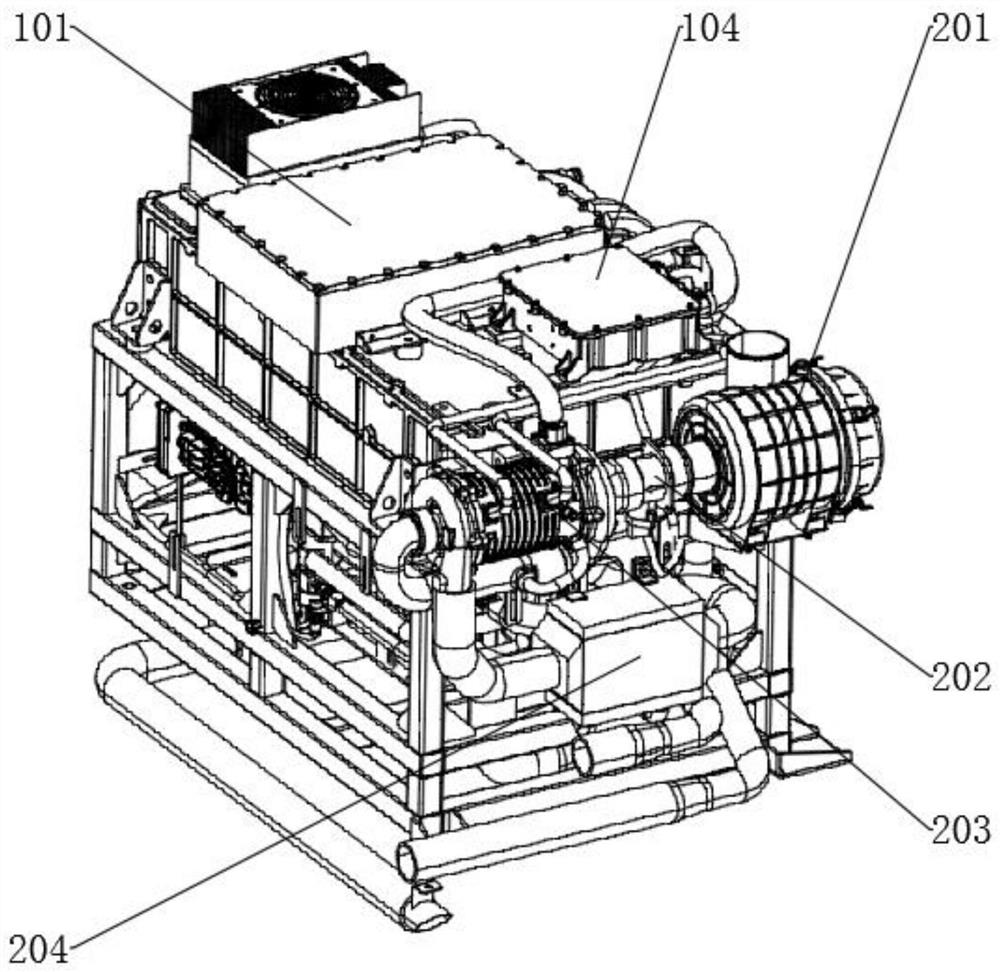

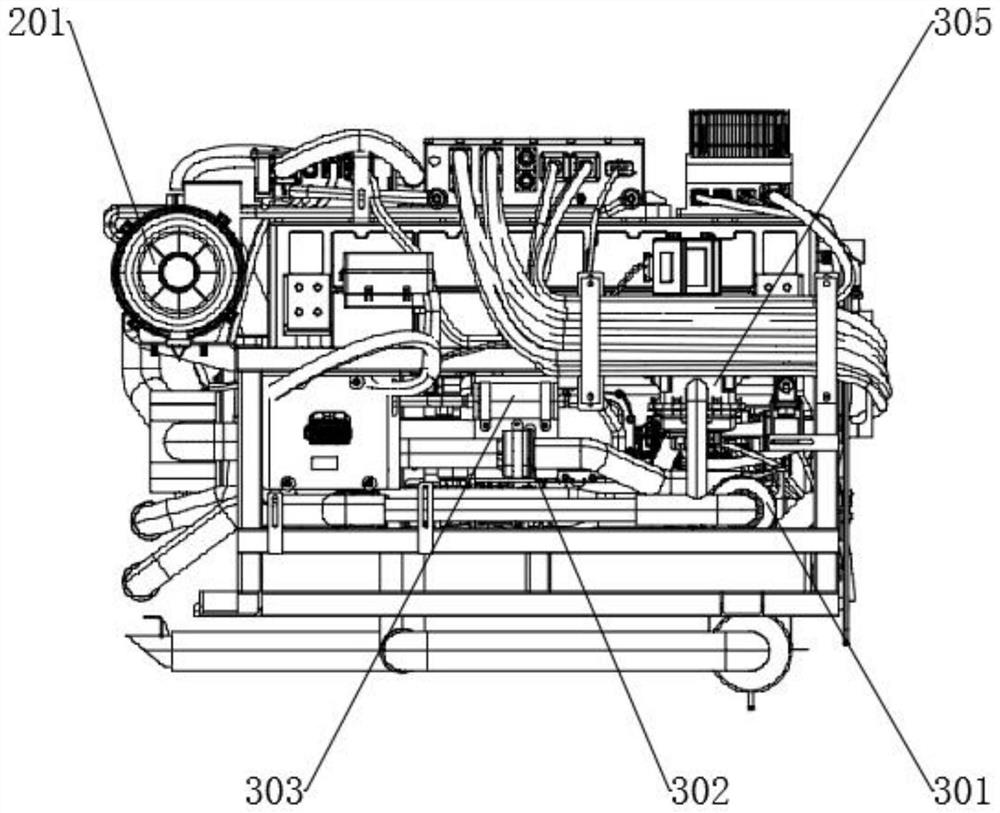

[0035] A commercial vehicle fuel cell system such as Figure 1-8 As shown, it includes an integrated frame and a stack module; the top outer wall of the integrated frame is fixedly connected with a key component mechanism, and the key component mechanism includes an air treatment assembly, a hydrogen processing assembly and a cooling assembly, and the top outer wall of the key component mechanism is fixedly connected with a fuel cell assembly , the top outer wall of the fuel cell assembly is fixedly connected with electrical components, and the partial bottom outer wall of the fuel cell assembly is set on the top outer wall of the integrated frame. The outer wall is provided with a forklift lifting frame; the outer wall of the stack module is provided with the side of the high-voltage plug-in as the first reference plane, the opposite surface of the first reference plane as the second reference plane, and the left-view direction of the first reference plane as the third referen...

Embodiment 2

[0043] A commercial vehicle fuel cell system, including an integrated water separator 403, which is the integrated water separator 403 described in Embodiment 1, and the integrated water separator 403 includes a gas-water separator core 4031, Exhaust solenoid valve 4032 and heated drain solenoid valve 4033, exhaust solenoid valve 4032 and heated drain solenoid valve 4033 are connected to the gas-water separator core 4031 through pipelines, and the outlet end of exhaust solenoid valve 4032 is connected to the hydrogen circulation pump through pipelines 404, one end of the outlet of the heated drain solenoid valve 4033 is connected to the mixer 208 through a pipeline; when in use, the integrated air-water separator 403 is composed of an air-water separator 4031, an exhaust solenoid valve 4032, and a heated drain solenoid valve 4033. On the one hand, it separates hydrogen from water vapor, and the separated hydrogen enters the stack again through the hydrogen circulation pump 404 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com