Electromagnetic relay

A technology of electromagnetic relays and electromagnetic units, applied in the direction of electromagnetic relays, relays, detailed information of electromagnetic relays, etc., can solve the problems of reducing productivity, reducing the number of turns of coil winding, reducing switching characteristics, etc., to prevent productivity decline and maintain switching characteristics , Guarantee the effect of insulating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

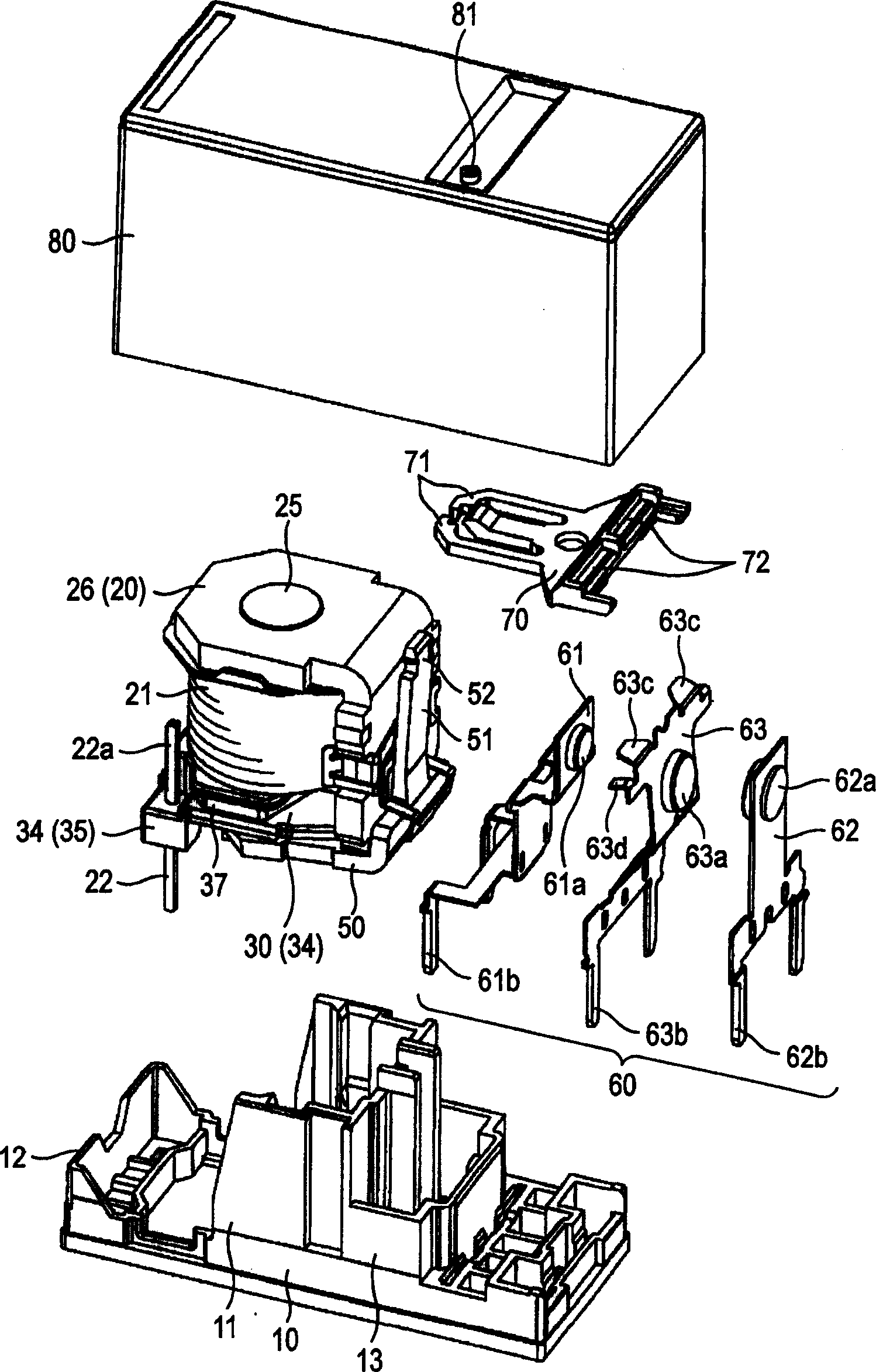

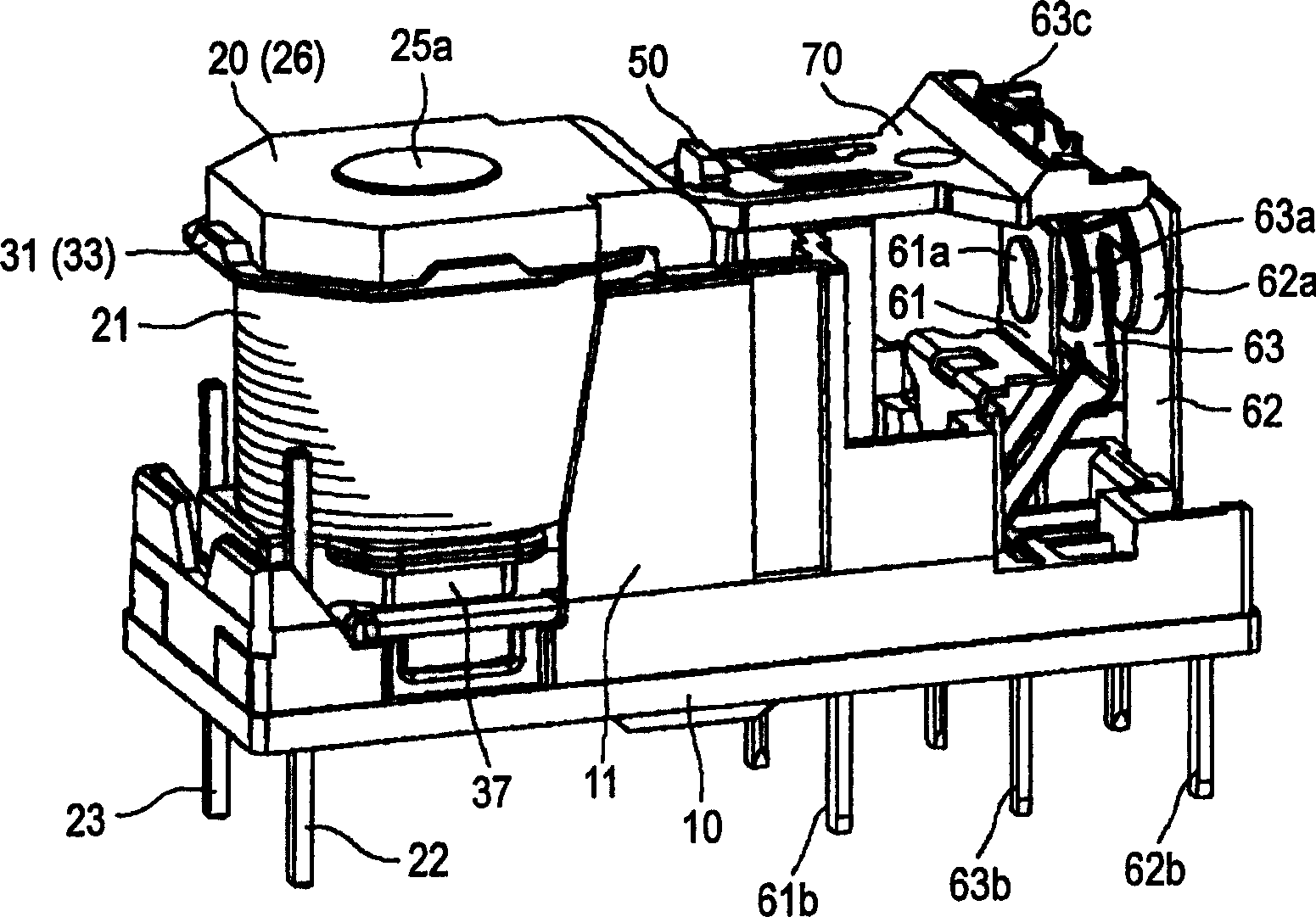

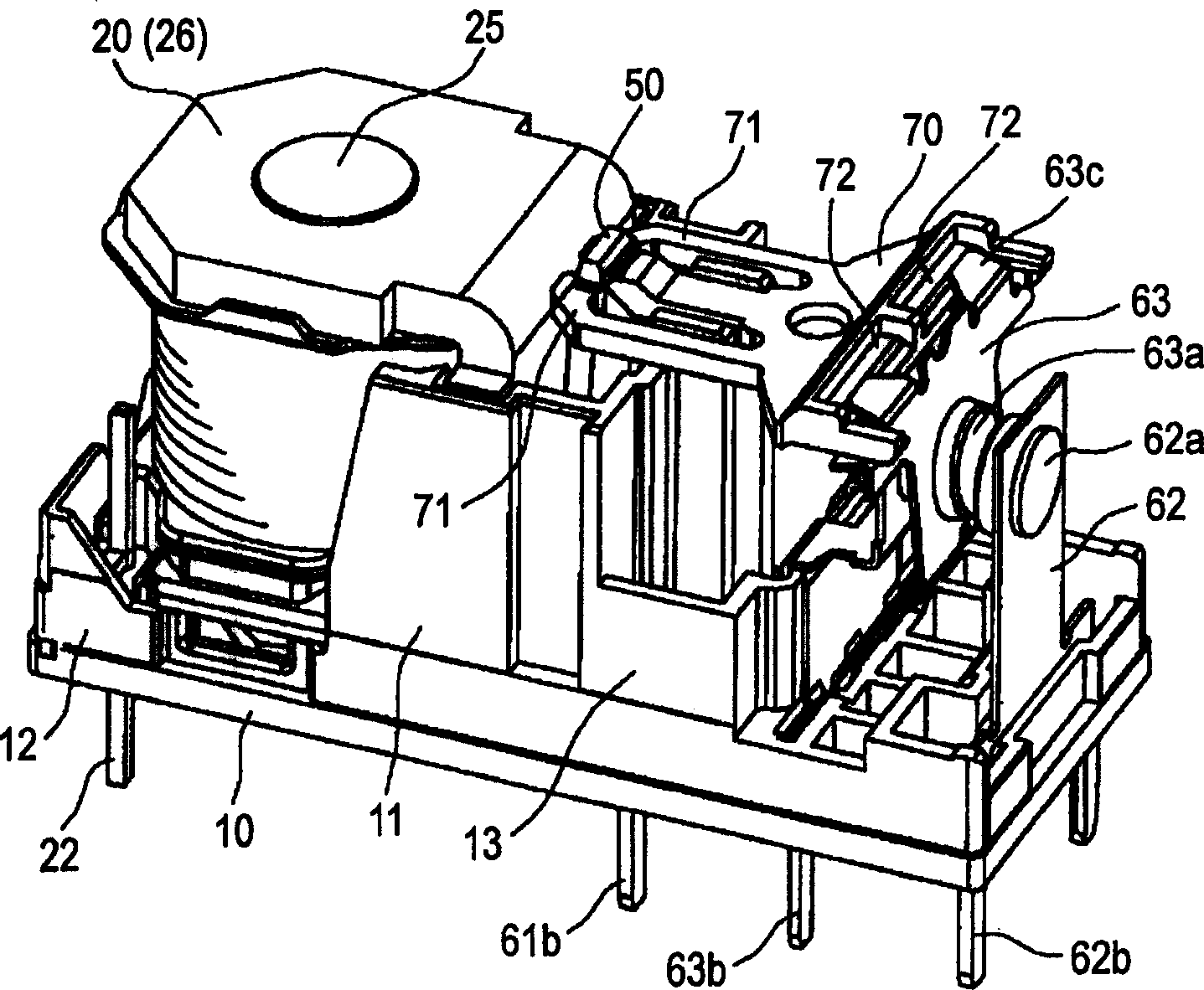

[0016] Refer to the attached figure 1 to 6 describe the embodiment modes of the present invention.

[0017] Such as figure 1 As shown, the implementation mode of the electromagnetic relay of the present invention is schematically composed of a base 10 , an electromagnetic unit 20 , a contact mechanism 60 , a card 70 and a cover 80 .

[0018] In the base 10 , the first insulating wall 11 is substantially square-bracket-shaped in plan view, and protrudes at the center of the upper surface of the base 10 . Furthermore, the second insulating wall 13 protrudes behind the first insulating wall 11 . On the other hand, a sealing wall 12 protrudes along an edge portion on one side of the upper surface of the base 10 to prevent the sealant from entering. The electromagnetic unit 20 is provided between the first insulating wall 11 and the second insulating wall 13 . On the other hand, the contact mechanism 60 is provided behind the first insulating wall 11 .

[0019] Such as image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com