A method for insulating and wrapping FeSiAl soft magnetic alloy powder

A technology of iron-silicon-aluminum alloy and soft magnetic alloy, used in magnetic objects, magnetic materials, transportation and packaging, etc., can solve the problem that the pressing stress of the magnetic core cannot be eliminated well, and the insulating layer material has no high temperature resistance and cannot be very good. Optimize the magnetic domain structure and other issues to achieve excellent DC superposition characteristics, reduce operating procedures, and reduce material yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

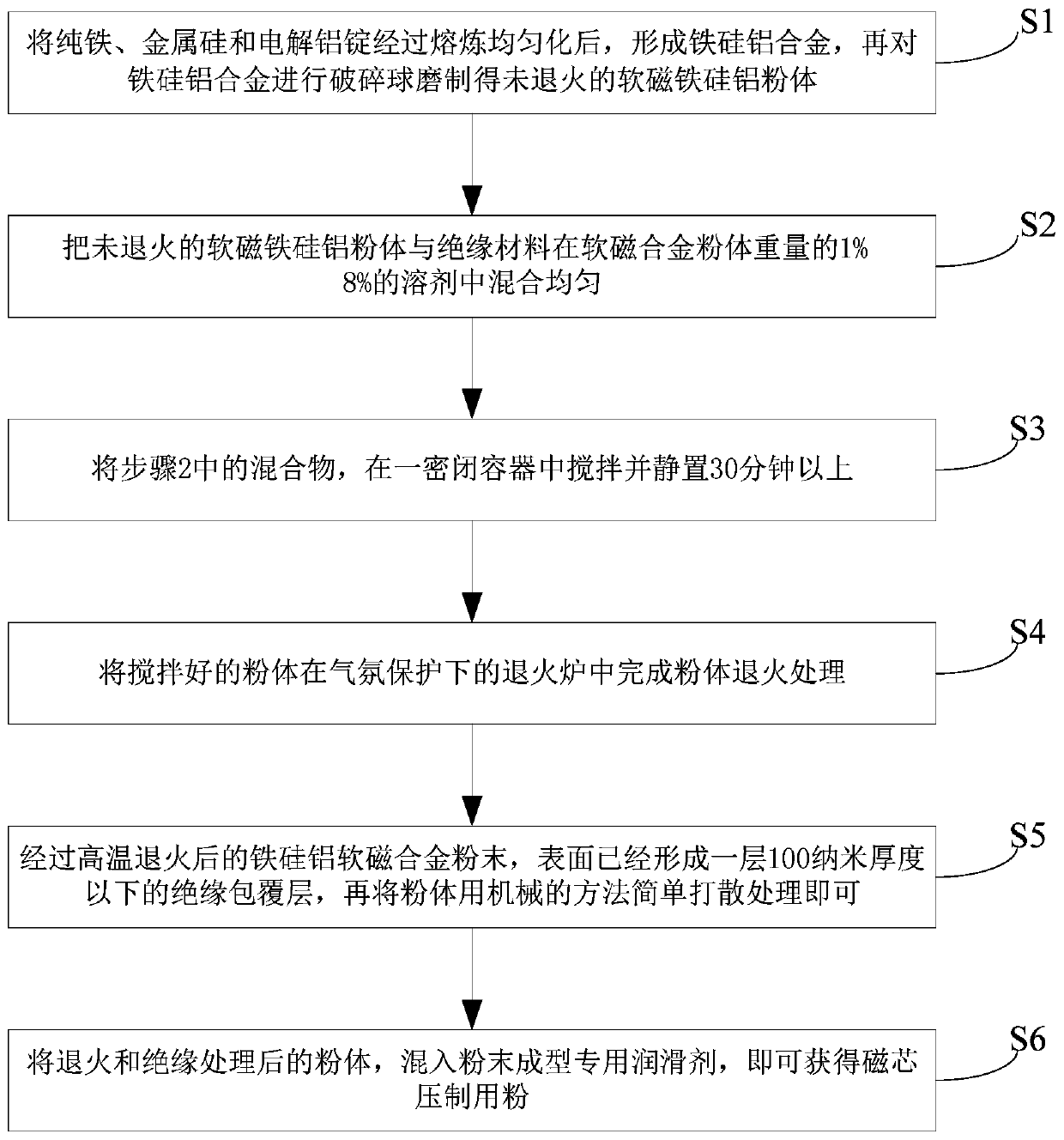

[0032] Such as figure 1 As shown, the insulation and wrapping treatment method of the Fe-Si-Al soft magnetic alloy powder of the present invention is characterized in that it comprises the following steps:

[0033] S1. Pure iron, metal silicon and electrolytic aluminum ingots are smelted and homogenized to form sendust, and then the sendust is crushed and ball-milled to obtain unannealed soft magnetic silicon-aluminum powder;

[0034] S2. Mix the non-annealed soft magnetic silicon aluminum powder and insulating material in a solvent of 1%-8% of the weight of the soft magnetic alloy powder, and the insulating material must be able to withstand the annealing of the magnetic core stress above 700°C requirements;

[0035] S3. Stir the mixture in step 2 in an airtight container and let it stand for more than 30 minutes;

[0036] S4, complete the powder annealing treatment in the annealing furnace under the protection of the atmosphere with the stirred powder;

[0037] S5. The ir...

Embodiment 2

[0043] In Example 2, take 100 g of the soft magnetic alloy powder of the traditional ball milling process with an average particle size of 50 μm that has not been annealed, and mix it with 1.5 grams of aluminum dihydrogen phosphate + 1.0 grams of silicone resin + 5 grams of alcohol The solution is fully stirred evenly in a closed container. After standing for 30 minutes, it is spread out and placed in a high-temperature annealing medium. It is integrated with traditional powder annealing to complete powder annealing + insulation coating. The annealing temperature is 850°C. The obtained powder was uniformly mixed with 0.5 g of zinc stearate lubricant to form an insulating and coated soft magnetic alloy powder. Under a pressing pressure of 78 tons, the standard 270 ring was pressed.

[0044] The performance test results are: the weight of the magnetic ring is 26.01 grams, and the magnetic permeability is 61.3. Under the test conditions of 50Khz@100mT, the measured power loss is 2...

Embodiment 3

[0047] In Example 3, take 100 g of the soft magnetic alloy powder of the traditional ball milling process with an average particle size of 50 μm that has not been annealed, mix it with 1.5 grams of organic silicon resin + 5 grams of alcohol solution, and place it in a closed container Stir well and evenly. After standing for 30 minutes, spread it out and place it in a high-temperature annealing medium. It is integrated with traditional powder annealing to complete powder annealing + insulation coating. The annealing temperature is 850°C. The obtained powder was uniformly mixed with 0.5 g of zinc stearate lubricant to form an insulating and coated soft magnetic alloy powder. Under a pressing pressure of 78 tons, the standard 270 ring was pressed.

[0048] The performance test results are: the weight of the magnetic ring is 25.86 grams, and the magnetic permeability is 60.4. Under the test conditions of 50Khz@100mT, the measured power loss is 263mW / cm3, and the inductance drops t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com