Patents

Literature

38results about How to "Omit cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

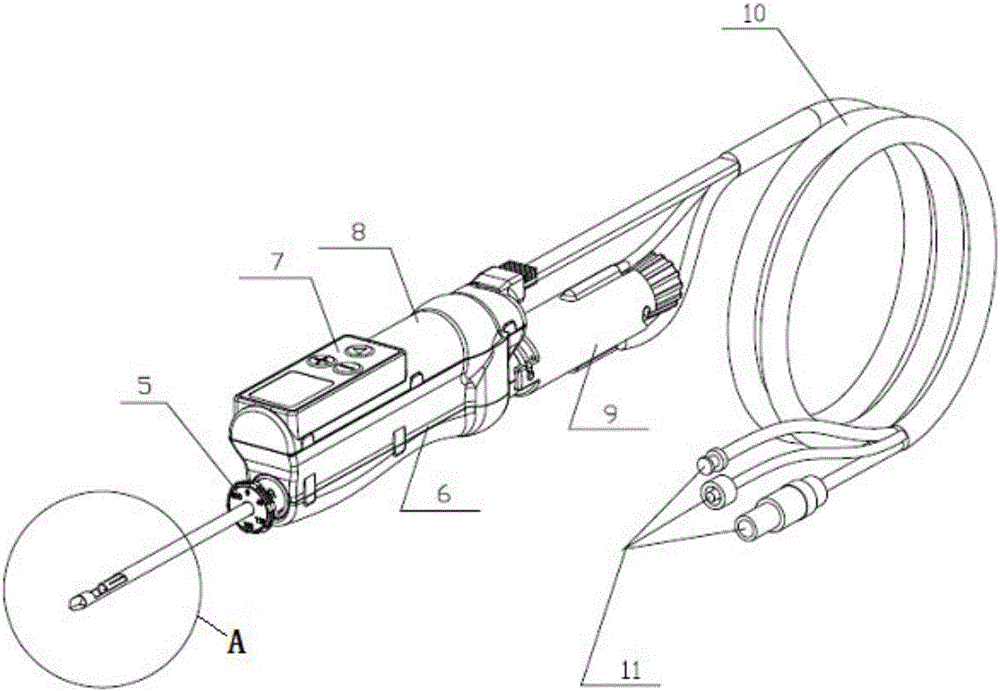

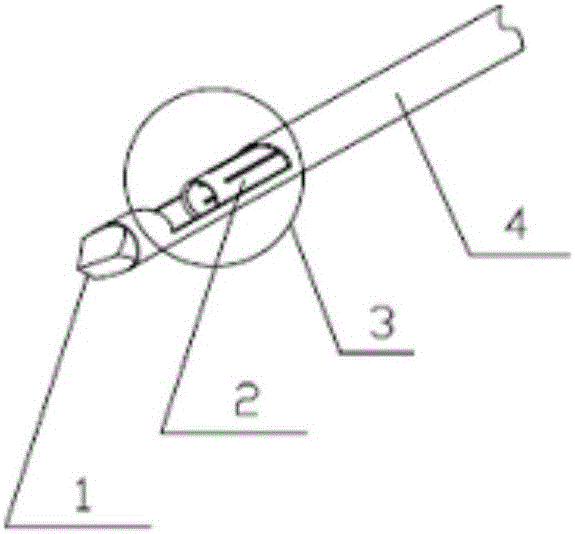

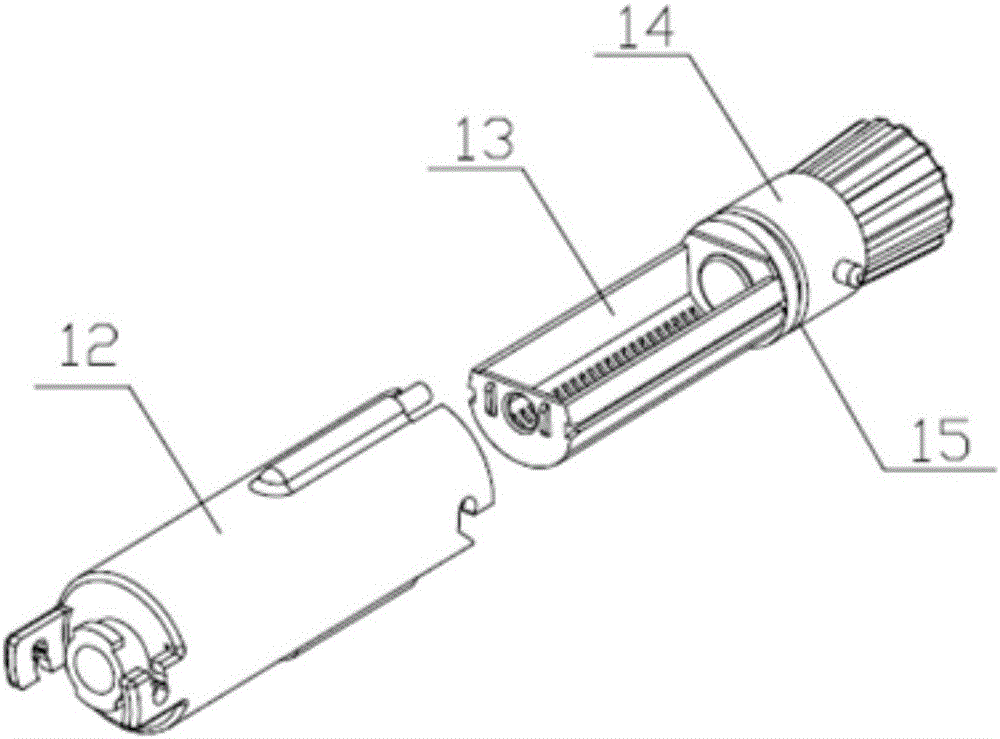

Vacuum-assisted mammary gland sample biopsy and rotary cutting system

InactiveCN105796135AProbes are compactCompact structureSurgical needlesVaccination/ovulation diagnosticsVacuum assistedBenign tumor

Owner:ACCUTARGET MEDIPHARMA (SHANGHAI) CO LTD

A copper adulterated aluminum complex flat line and its making method

ActiveCN101236798AImprove performanceEliminate processabilitySingle bars/rods/wires/strips conductorsCable/conductor manufactureCopperAluminum composites

The invention relates to a copper-clad aluminum composite flat wire and a preparation method thereof, relating to bimetal layered composite materials. The copper-clad aluminum composite flat wire is formed by composition of sandwich layer aluminum and clad copper, and the area ratio of the copper clad is 15 percent to 40 percent. The preparation steps are as follows: copper-clad aluminum composite blanks are directly compounded and formed by adoption of horizontal continuous casting; multi-pass groove rolling and / or multi-pass drawing is performed on the copper-clad aluminum blanks as required; the rolling speed of 3 to 60 meters per minute is adopted, and the single-pass relative percent reduction is 20 percent to 40 percent; or the drawing speed of 2 to 30 meters per minute is adopted, and the single-pass section scalage is 10 percent to 25 percent; under the condition of multi-pass processing and that the overall section scalage of the copper-clad aluminum composite materials reaches 75 percent to 95 percent, low-temperature intermediate annealing is performed on the copper-clad aluminum composite materials; the annealing temperature is 200 to 450 DEG C; the annealing time is 0.5 to 2 hours; the blanks after annealing are rolled or drawn further, and the copper-clad aluminum composite flat wire with required section shape and size is prepared. The invention not only can prepare the high performance copper-clad aluminum composite flat wire but also has high production efficiency.

Owner:UNIV OF SCI & TECH BEIJING

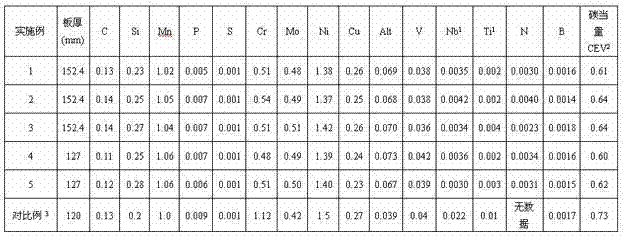

Low-carbon-equivalent low-temperature-usable high-thickness toothed rack steel and manufacturing method thereof

The invention relates to low-carbon-equivalent low-temperature-usable high-thickness toothed rack steel and a manufacturing method thereof. The toothed rack steel comprises the following chemical components: C, Si, Mn, P, S, Cr, Mo, Ni, Cu, Al, V, N, B and the balance of Fe and impurity elements, wherein the carbon equivalent CEV is less than 0.65. The manufacturing method sequentially comprises the steps of KR molten iron pretreatment, converter smelting, LF and RH refining, continuous casting, continuous casting blank heating, rolling, thermal refining and the like. The thickness of the toothed rack steel plate manufactured by the invention can be up to 152.4mm, the yield strength is above 690Mpa, the tensile strength is 790-930MPa, the elongation percentage is 319%, and the Charpy impact energy at -60 DEG C is more than 100J. Besides, the toothed rack steel is favorable in comprehensive mechanical property, convenient in production process and low in cost.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

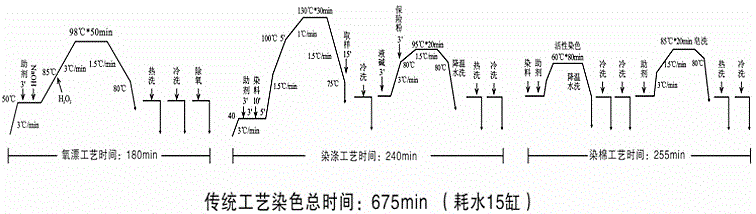

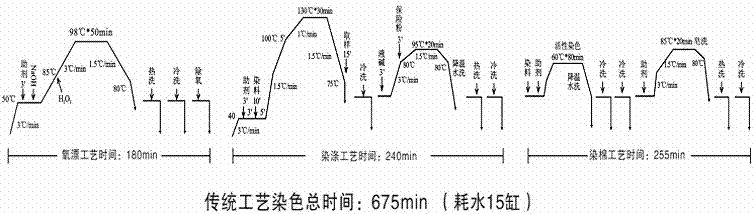

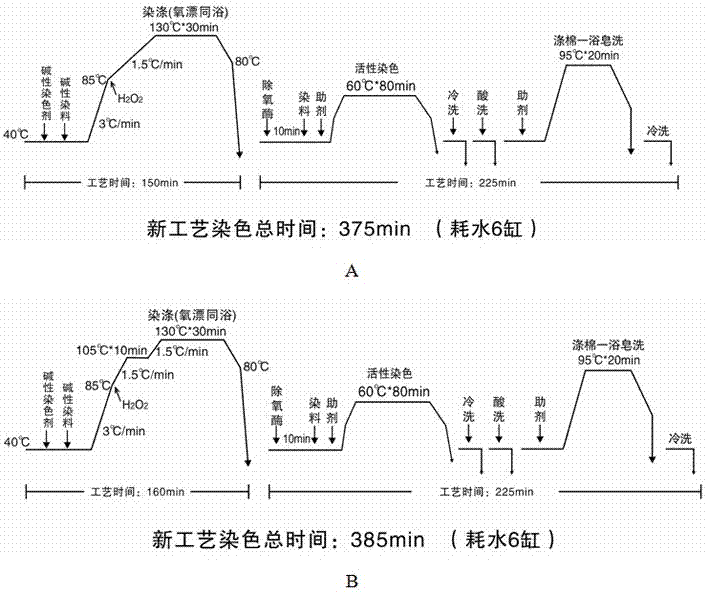

Dyeing method of polyester-cotton blended knitting fabric

ActiveCN106012610AAvoid scratchesAvoid rubbingBleaching apparatusDyeing processPolyesterPulp and paper industry

The invention discloses a dyeing method of polyester-cotton blended knitting fabric. The dyeing method comprises the steps of pre-treatment, dyeing of a polyester part and oxygen bleaching of a cotton part, dyeing of the cotton part and after-treatment. According to the dyeing method disclosed by the invention, dyeing is carried out by adopting a special alkaline polyester-cotton dyeing agent, the technologies of the oxygen bleaching of the cotton part and the dyeing of the polyester part are combined into one, washing of the polyester part can be omitted, and washing can be carried out only after the dyeing of the cotton part. Compared with traditional craftwork, the dyeing method disclosed by the invention has the advantages that the technological process is greatly simplified, the dyeing time is greatly shortened, the use of water, electricity and steam can be obviously reduced, the production cost is obviously reduced, and the pollution to the ecological environment, particularly the water resource, is reduced.

Owner:石狮市瑞鹰纺织科技有限公司

Alkaline aqueous solution composition for treating a substrate

InactiveCN101717939AAvoid adsorptionStrong coordination bondingDetergent mixture composition preparationSemiconductor/solid-state device manufacturingTetramethylammonium hydroxideMetal impurities

Owner:KANTO CHEM CO INC

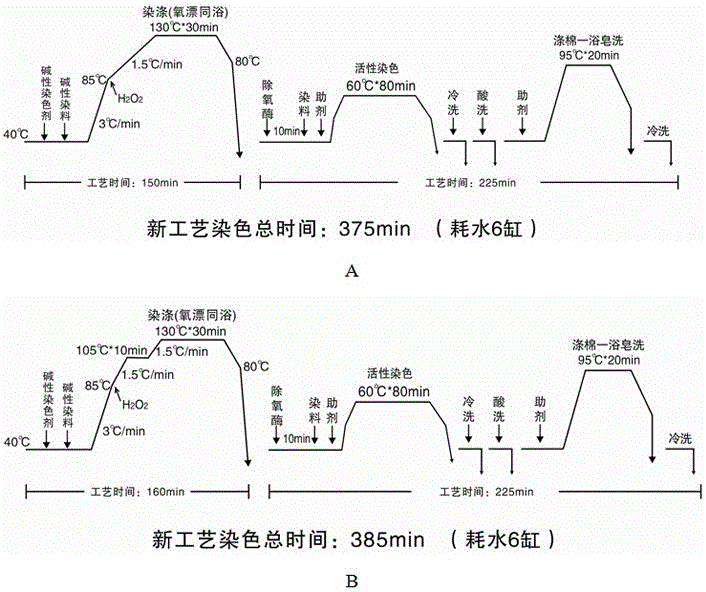

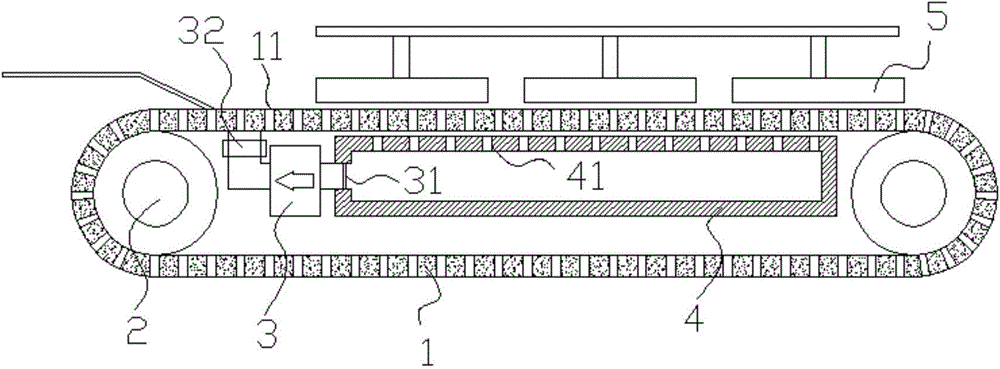

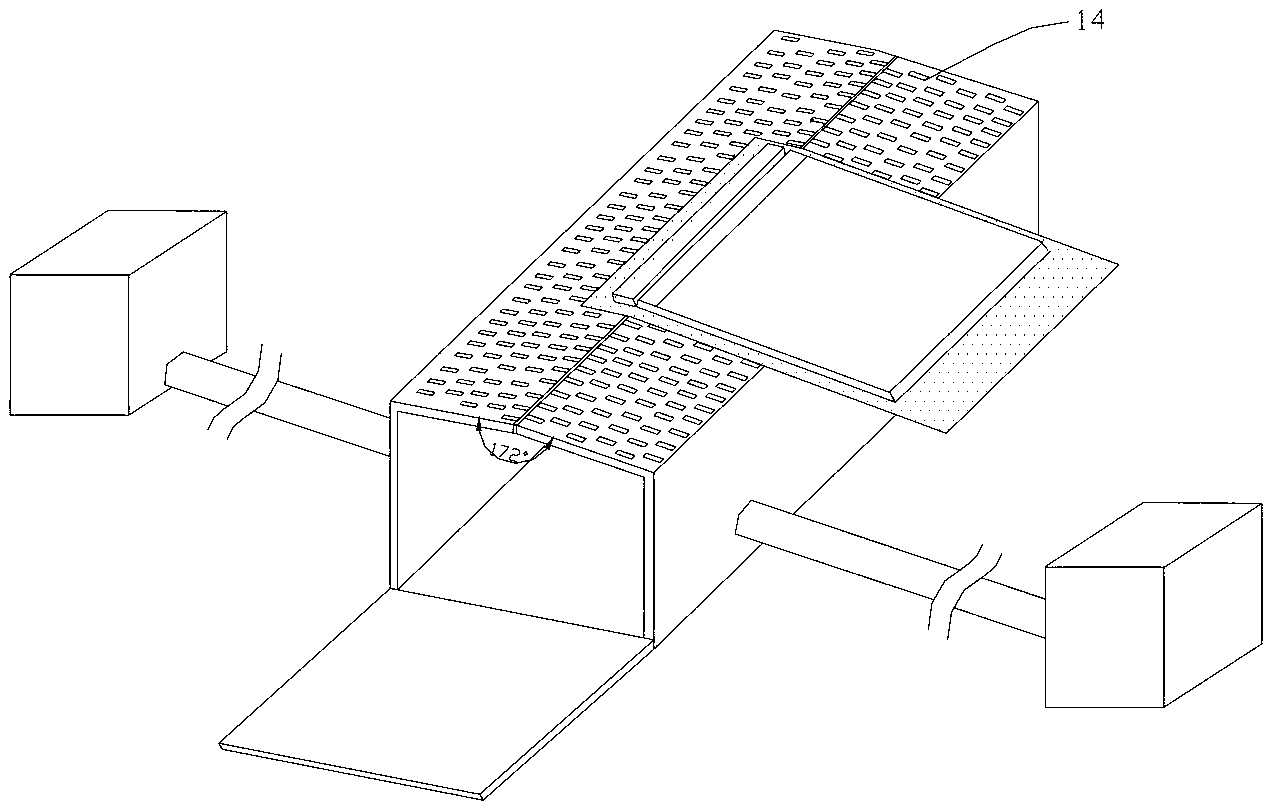

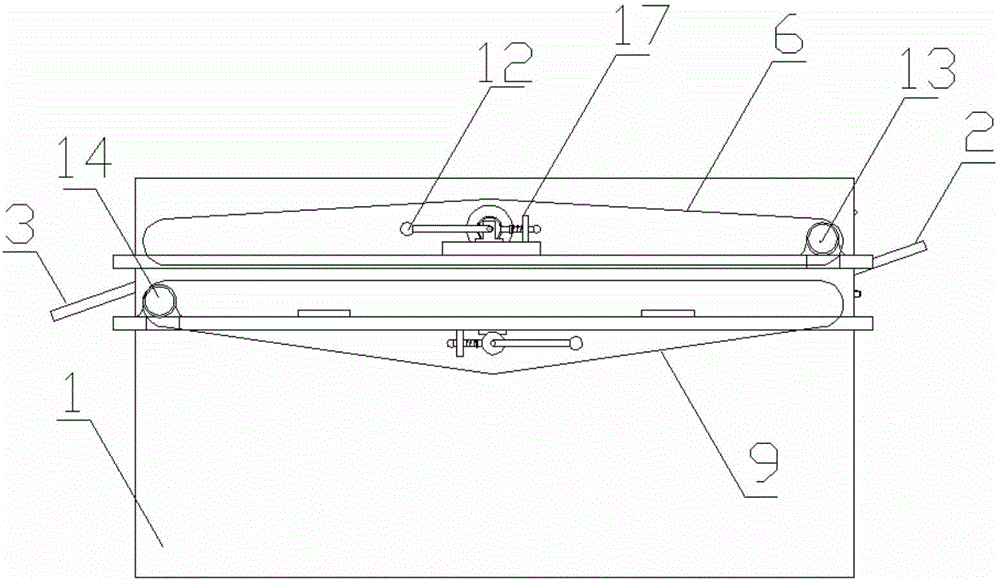

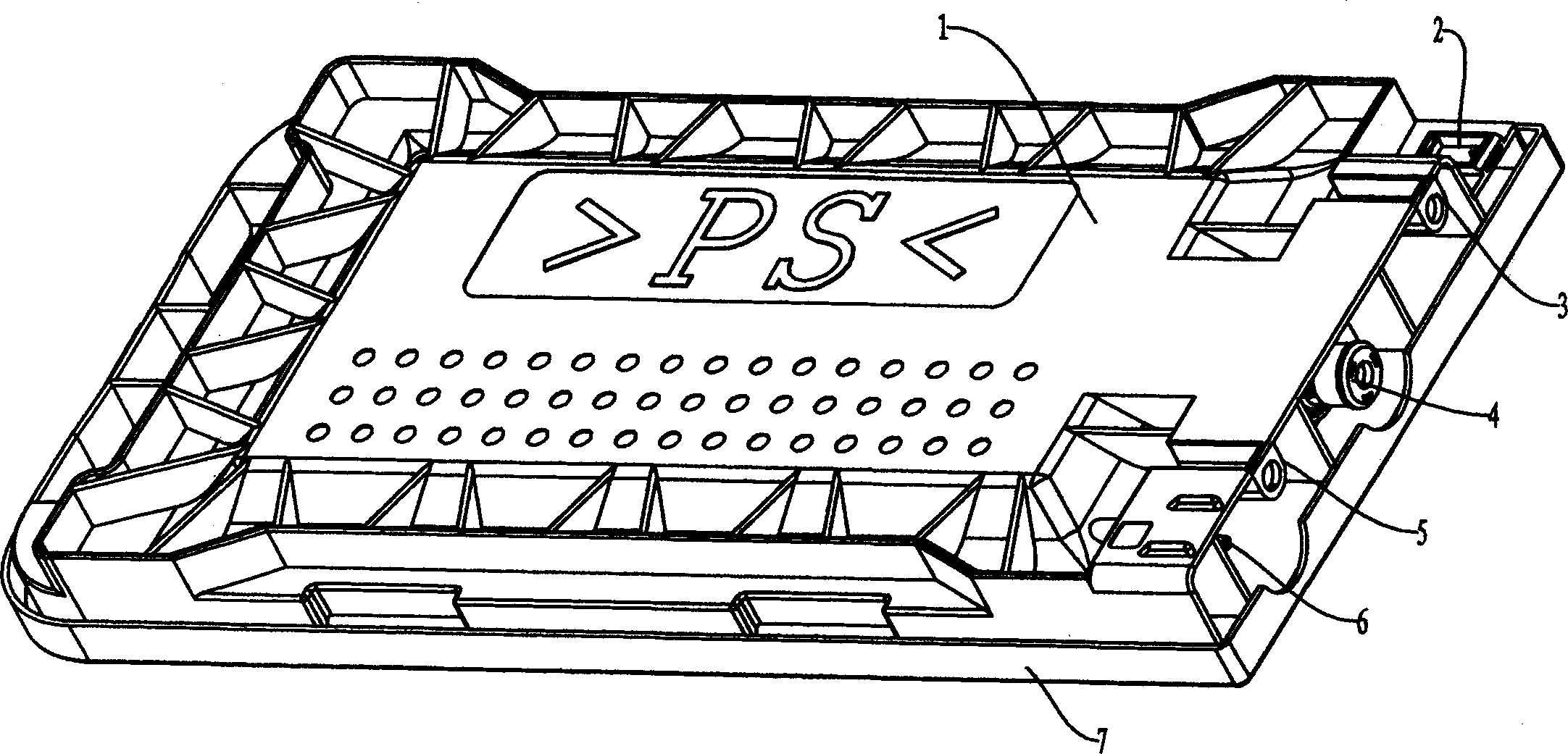

Cloth fixing device of printing machine

The invention relates to a cloth fixing device of a printing machine. The cloth fixing device of the printing machine comprises a conveying belt, wherein the conveying belt is arranged on two parallel rotating shafts in a sleeving manner; the surface of the entire conveying belt is uniformly provided with fine and dense adsorption holes penetrating through the conveying belt; an exhaust fan is assembled between the upper and lower layers of the conveying belt; an air inlet of the exhaust fan is provided with a flat cylinder-shaped air inlet box; the upper surface of the air inlet box is provided with fine and dense ventilation holes which are matched with the adsorption holes; particularly, the space between every two ventilation holes is different from the space between every two adsorption holes; an air outlet of the exhaust fan is formed in the tail end of the conveying belt and the opening direction directly faces the adsorption holes in the conveying belt. According to the device, cloth can be firmly fixed to the surface of the conveying belt, meanwhile processes are simplified, and the cloth is not polluted.

Owner:吴江市金都织造有限公司

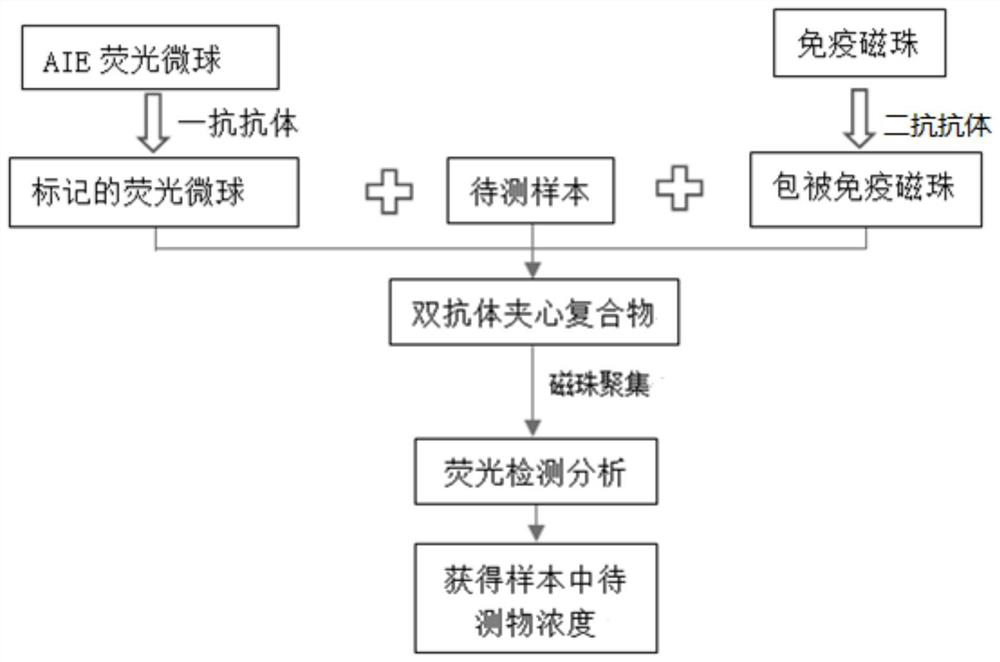

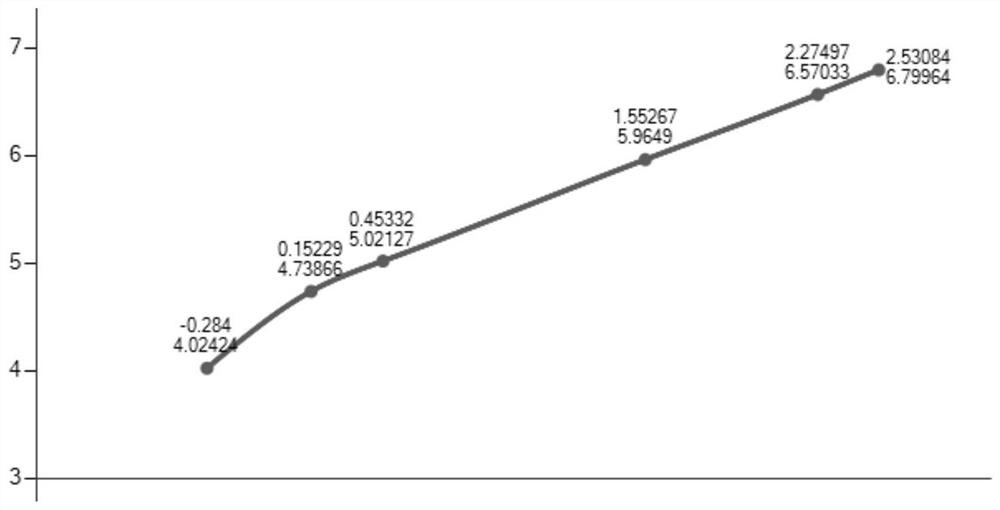

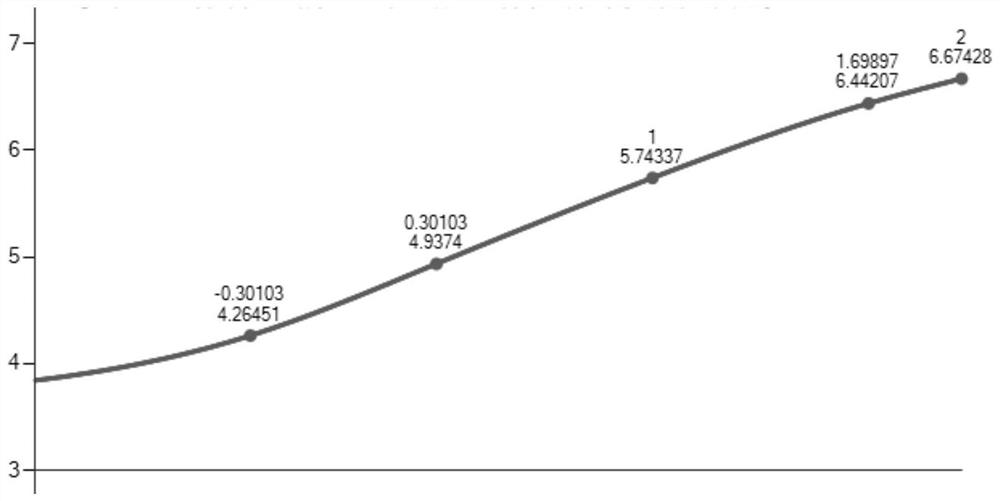

Method for detecting aggregation-induced emission combined with immunomagnetic beads and kit thereof

PendingCN112362867AOmit cleaningReduce pollutionMaterial analysis by observing effect on chemical indicatorFluorescence/phosphorescenceMicrobiologyBiochemistry

The invention provides a method for detecting aggregation-induced emission combined immunomagnetic beads. The method comprises the following steps: S1, respectively marking aggregation-induced fluorescent microspheres Y1, Y2... Yn by using primary antibodies of target objects X1, X2... Xn to be detected; S2, respectively coating immunomagnetic beads Z1, Z2... Zn with secondary antibodies of targetobjects X1, X2... Xn to be detected; S3, jointly incubating the fluorescent microspheres obtained in the step S1, the immunomagnetic beads obtained in the step S2 and a detection sample, and determining the content of a to-be-detected object according to a collected fluorescence value. The detection method disclosed by the invention not only can omit the cleaning of uncombined antigen / antibody, reduce the environmental pollution of cleaning waste liquid and greatly shorten the detection time, but also can improve the detection sensitivity and accuracy. In addition, due to the aggregation-induced emission molecules, aggregation-induced emission materials with different emission light can be obtained by designing different molecular structures according to detection requirements, so that multi-marker joint detection in the same detection system is more convenient to realize, the detection efficiency is higher, and the result is more accurate.

Owner:GUANGZHOU BIOKEY HEALTH TECH CO LTD

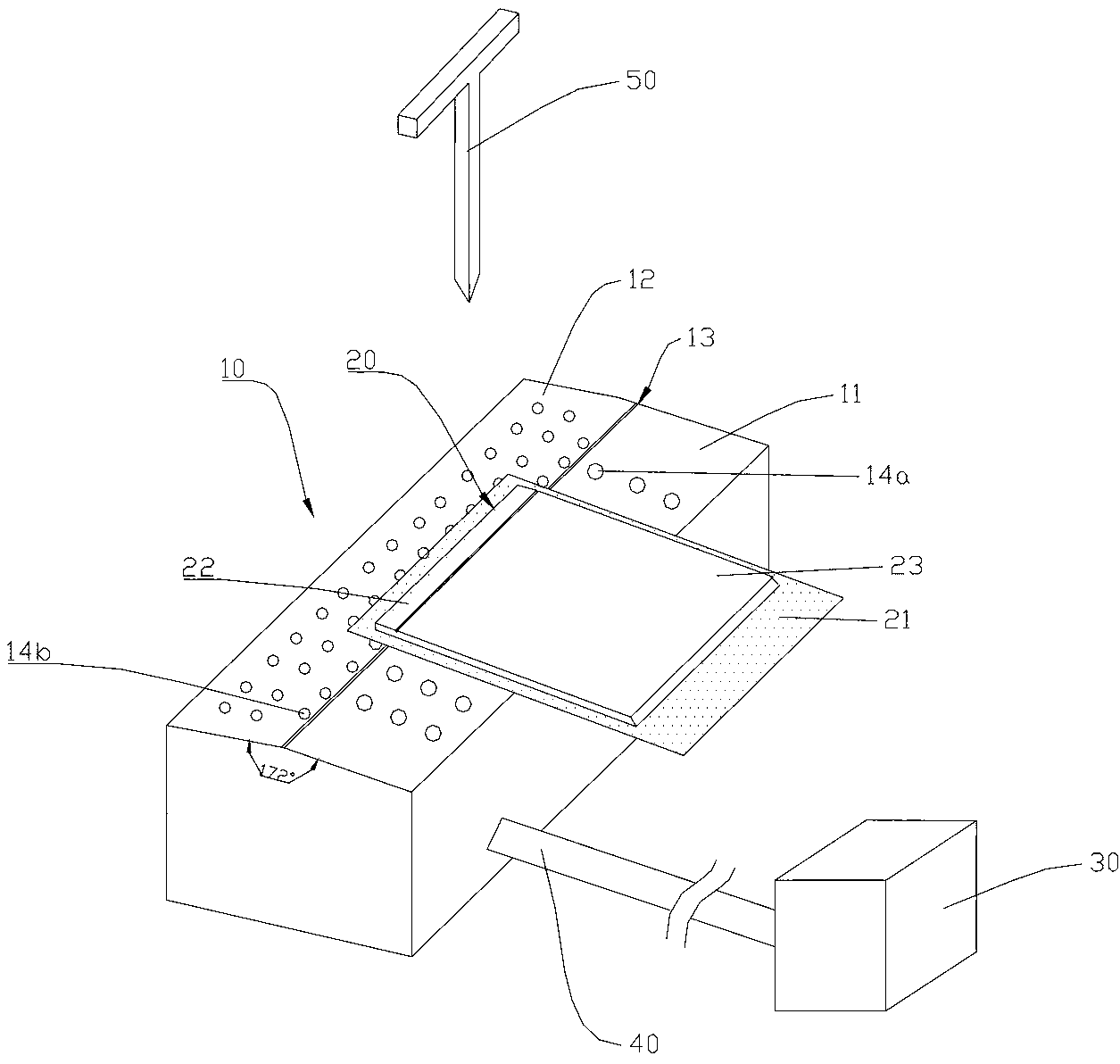

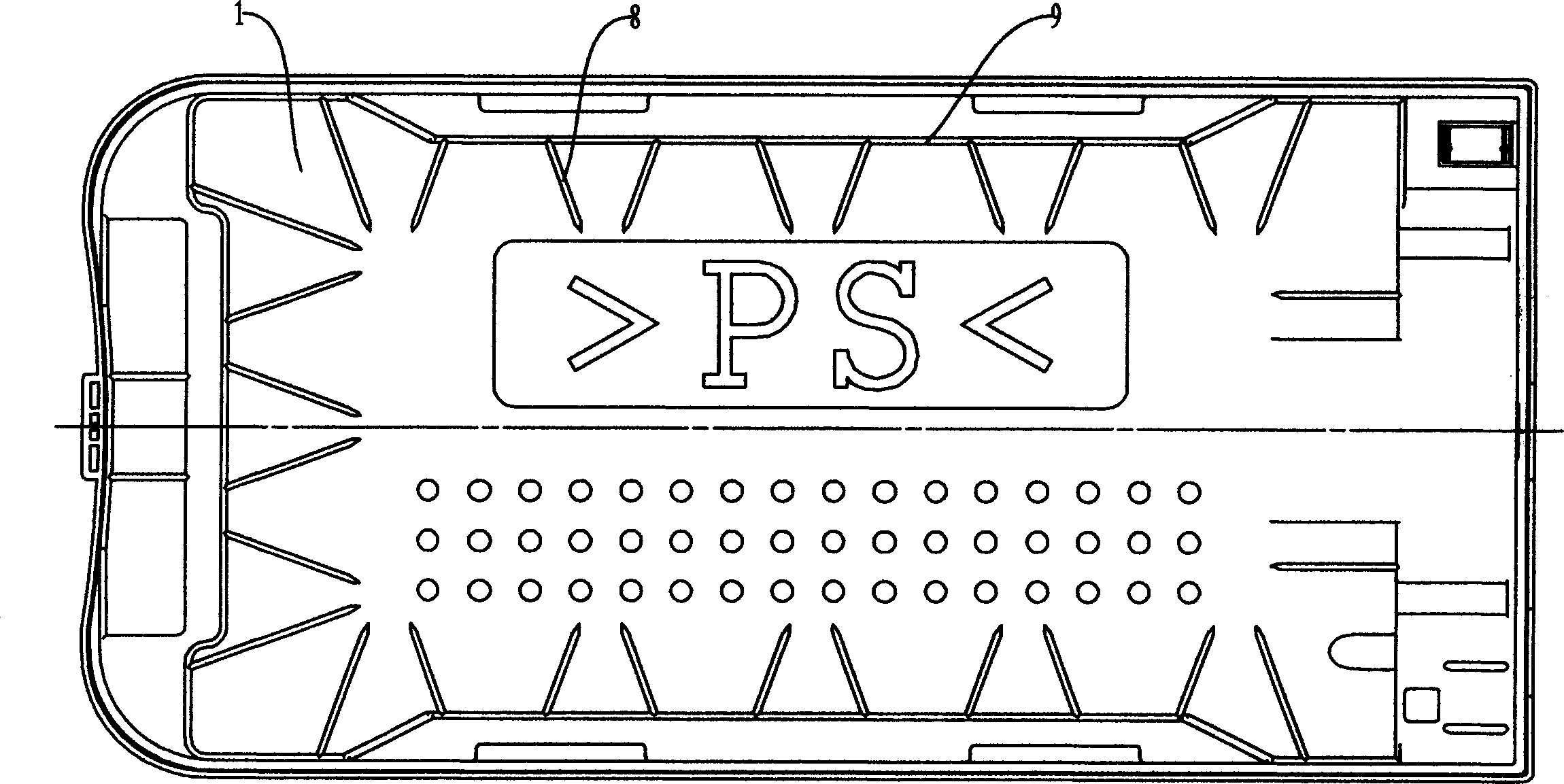

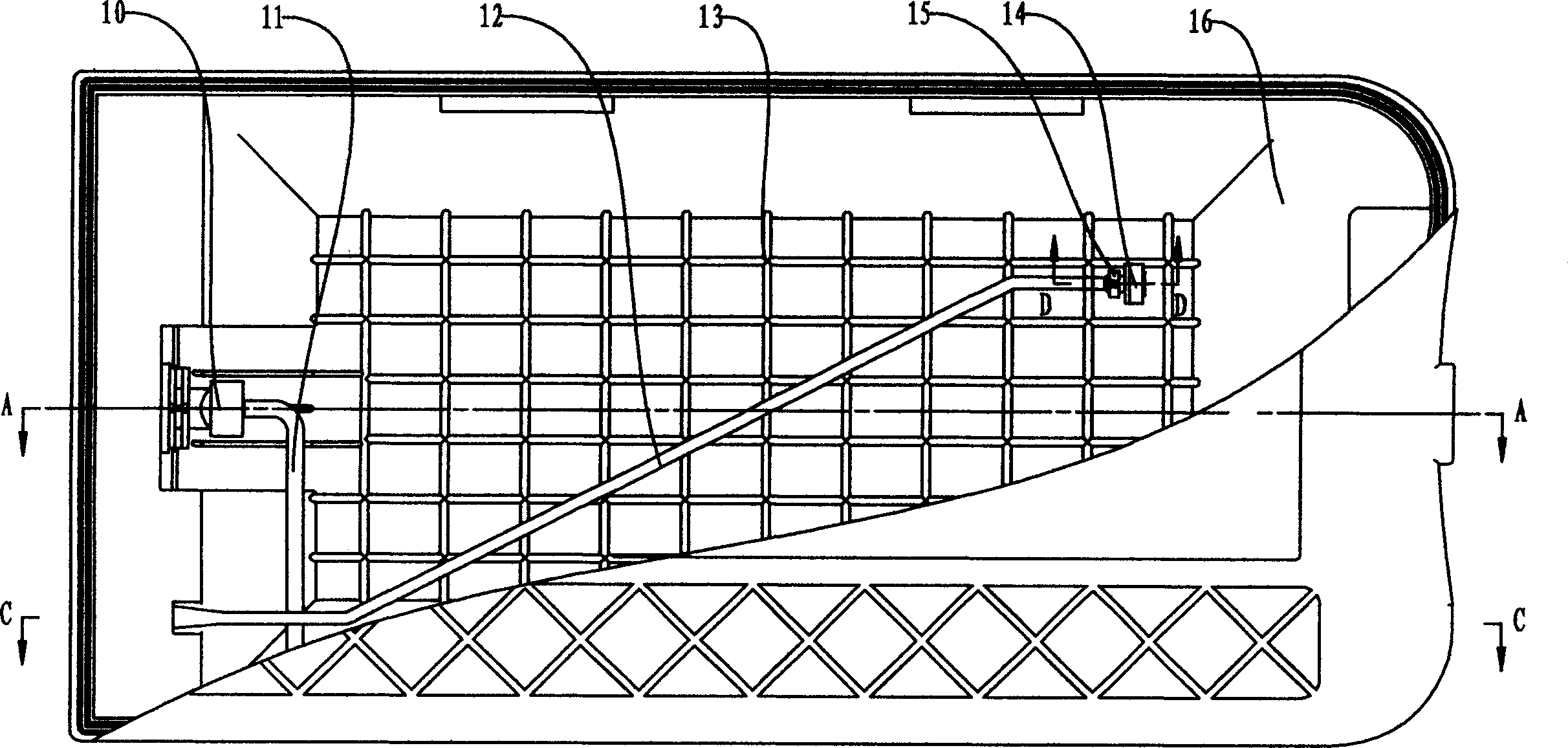

Splitting device

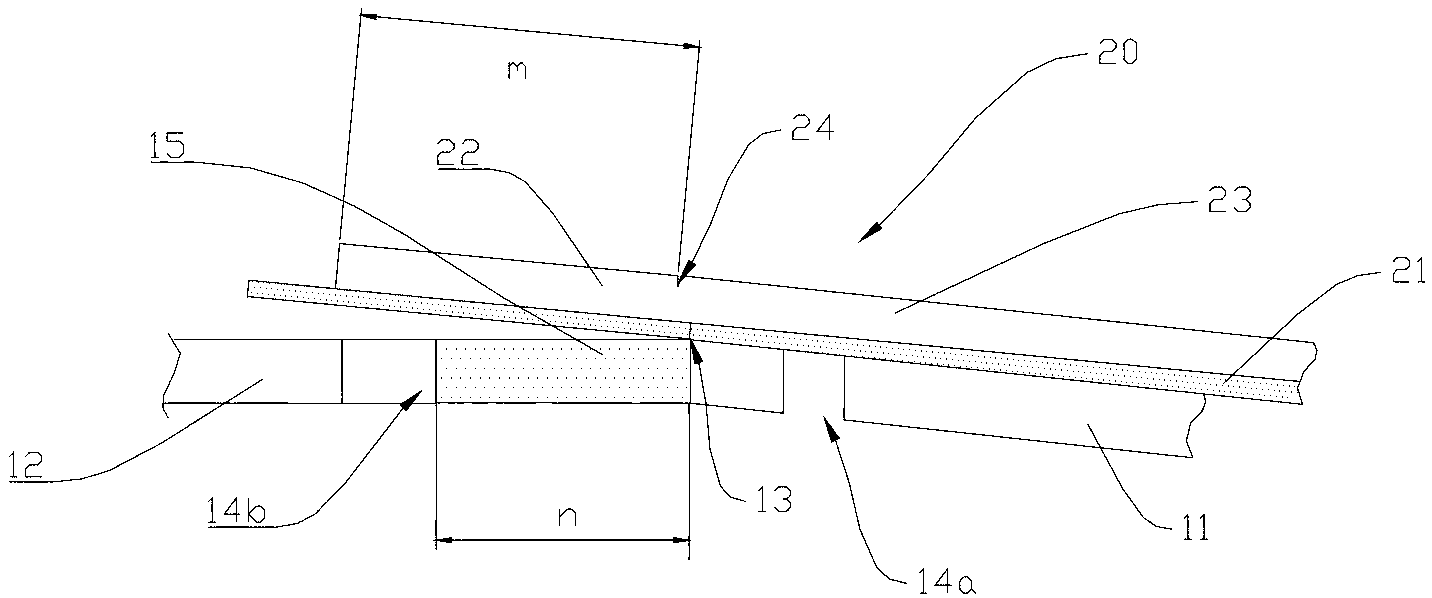

ActiveCN103296578AAvoid damageQuality improvementSemiconductor laser structural detailsEngineeringSupport point

The invention relates to the preparation technology of semiconductors, in particular to a splitting device. The splitting device is used for splitting a semiconductor bar into multiple chips. The splitting device comprises a negative pressure source and an absorbing cavity which is connected with the negative pressure source through a connecting pipe. The absorbing cavity comprises a first upper cover and a second upper cover. The first upper cover and the second upper cover are mutually supported in a way of an included angle to form a ridge. A plurality of through holes are formed in each of the first upper cover and the second upper cover. The through holes correspond to the bar spans on the first upper cover and the second upper cover. The bar is naturally split by using the ridge as a support point and through the absorbing force of the absorbing cavity to the bar. By the absorbing force, noncontact splitting of chip structural faces is achieved, sample surface structure can be protected from being damaged, and yield can be increased.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

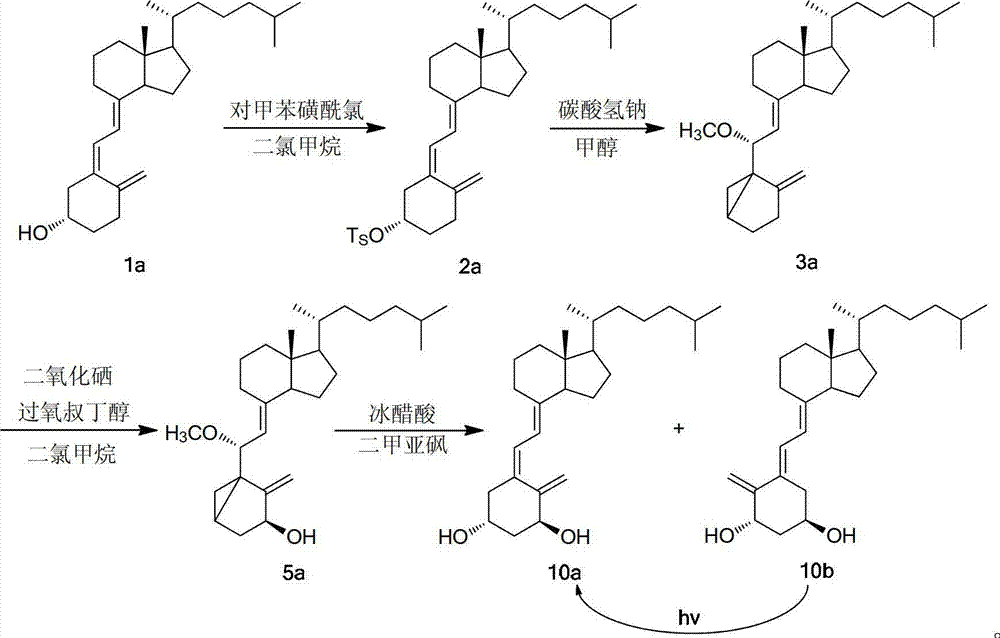

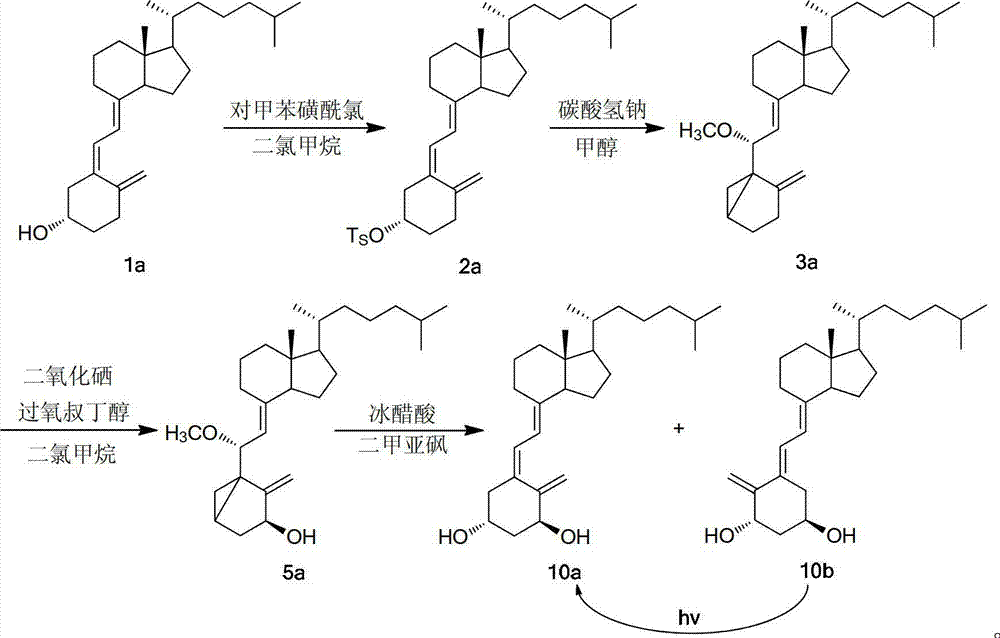

Synthetic method of osteoporosis treatment drug 1 alpha-hydroxyitamin D3

InactiveCN103073468AReduce usageShort reaction timeOrganic chemistrySkeletal disorderIsomerizationReaction temperature

The invention discloses a synthetic method of an osteoporosis treatment drug 1 alpha-hydroxyitamin D3, which comprises the following steps: 1) esterfying; 2) cyclizing; 3) oxidizing; 4) opening ring; and 5) performing photochemical isomerization: dissolving a mixture of 5,6-cis 1 alpha-hydroxyitamin D3 and 5,6-trans 1 alpha-hydroxyitamin D3 in methanol with 20-200 parts by weight, adding a photosensitizer, reacting for 0.5-10 hours under irradiation of ultraviolet light to obtain 5,6-cis 1 alpha-hydroxyitamin D3 which is 1 alpha-hydroxyitamin D3; and performing recrystallization to obtain the 1 alpha-hydroxyitamin D3 acicular crystal. According to the invention, a fat-soluble solvent substitutes pyridine, an organic alkalescence catalyst is used, under the analogous yield condition, the reaction temperature changes to normal temperature from low temperature, the reaction time is short, the energy consumption is low, toxic substance pyridine with mass usage can be avoided, the steps for extracting and cleaning pyridine can be omitted, and the technology economy is enhanced.

Owner:TIANJIN UNIV

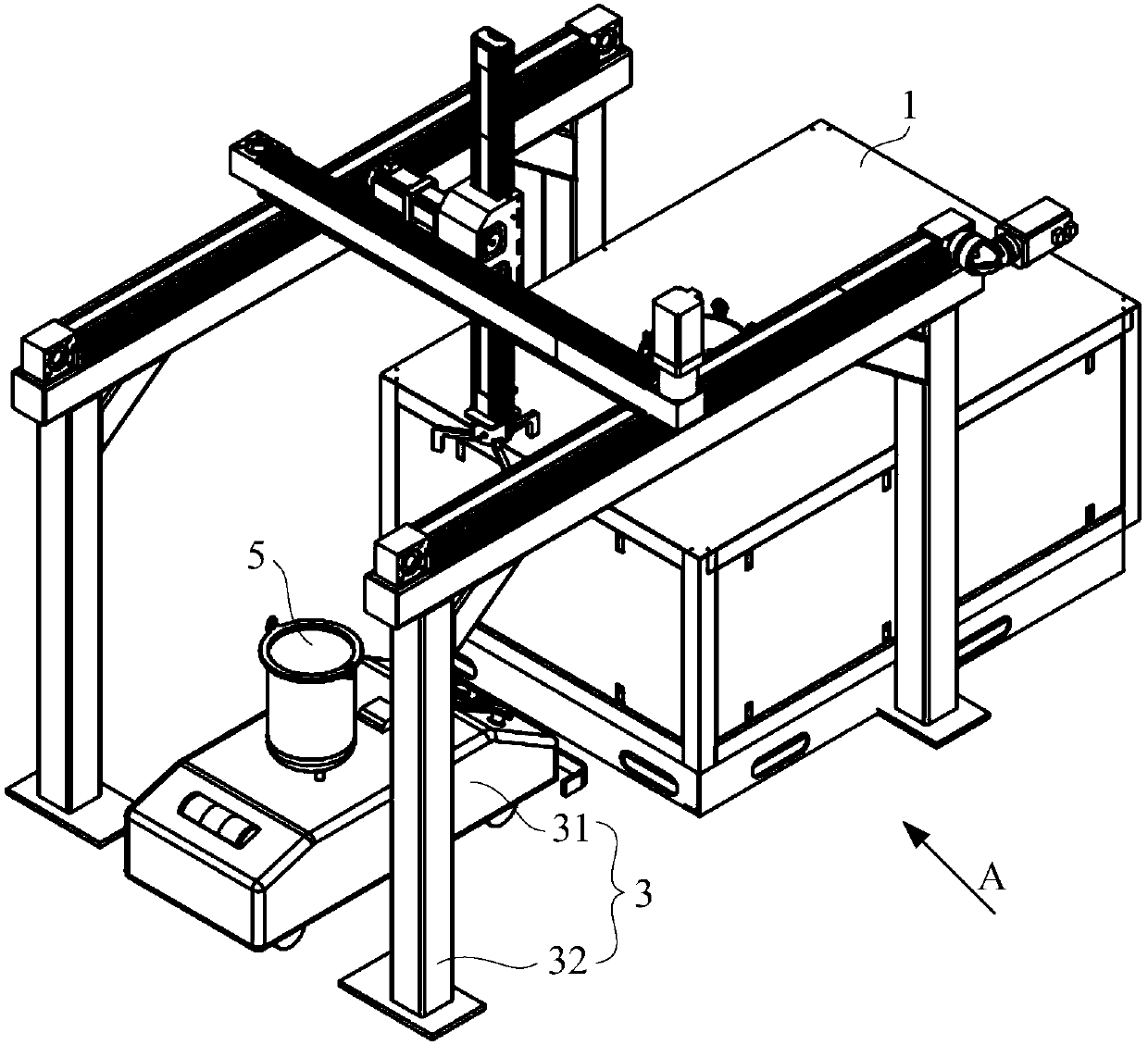

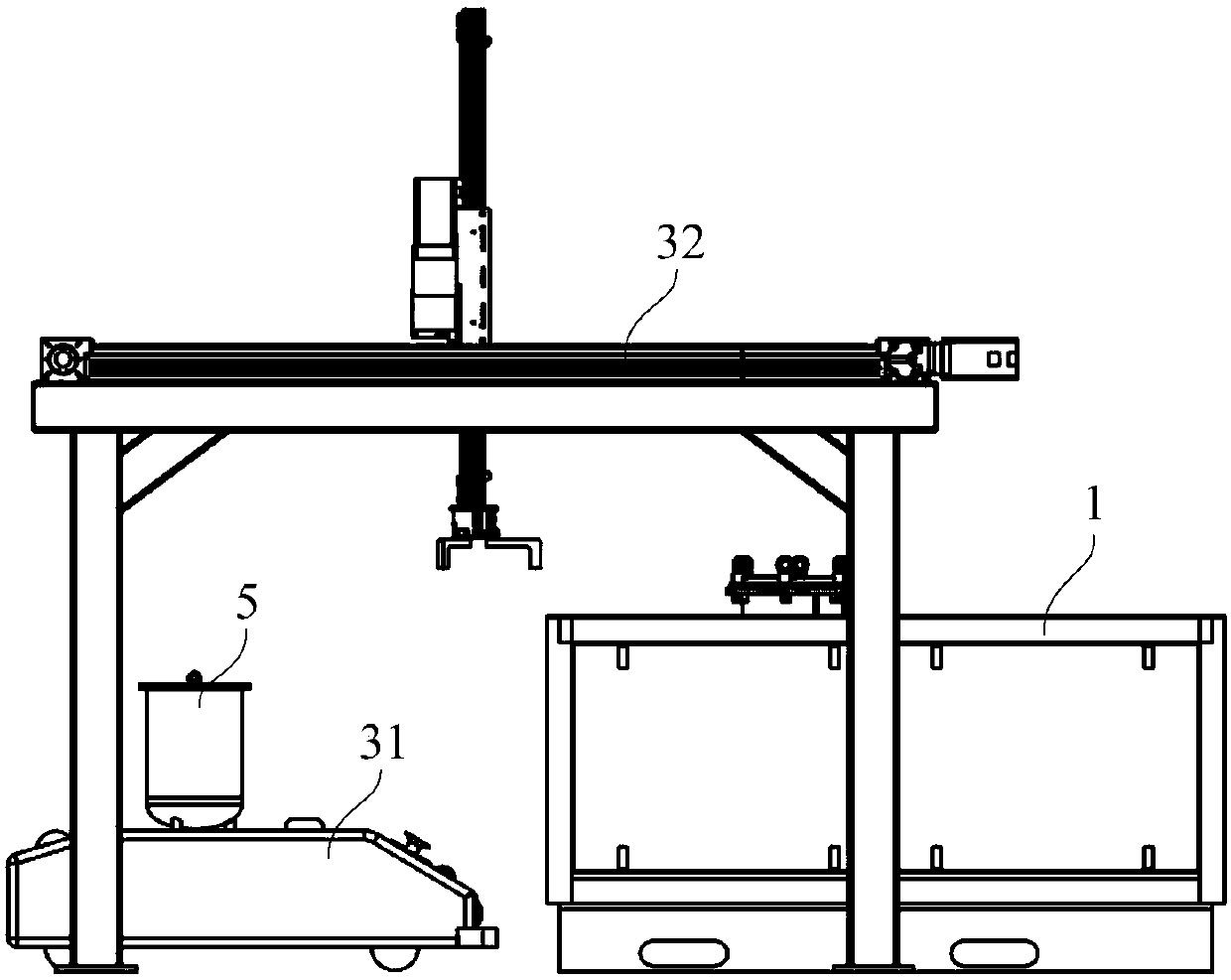

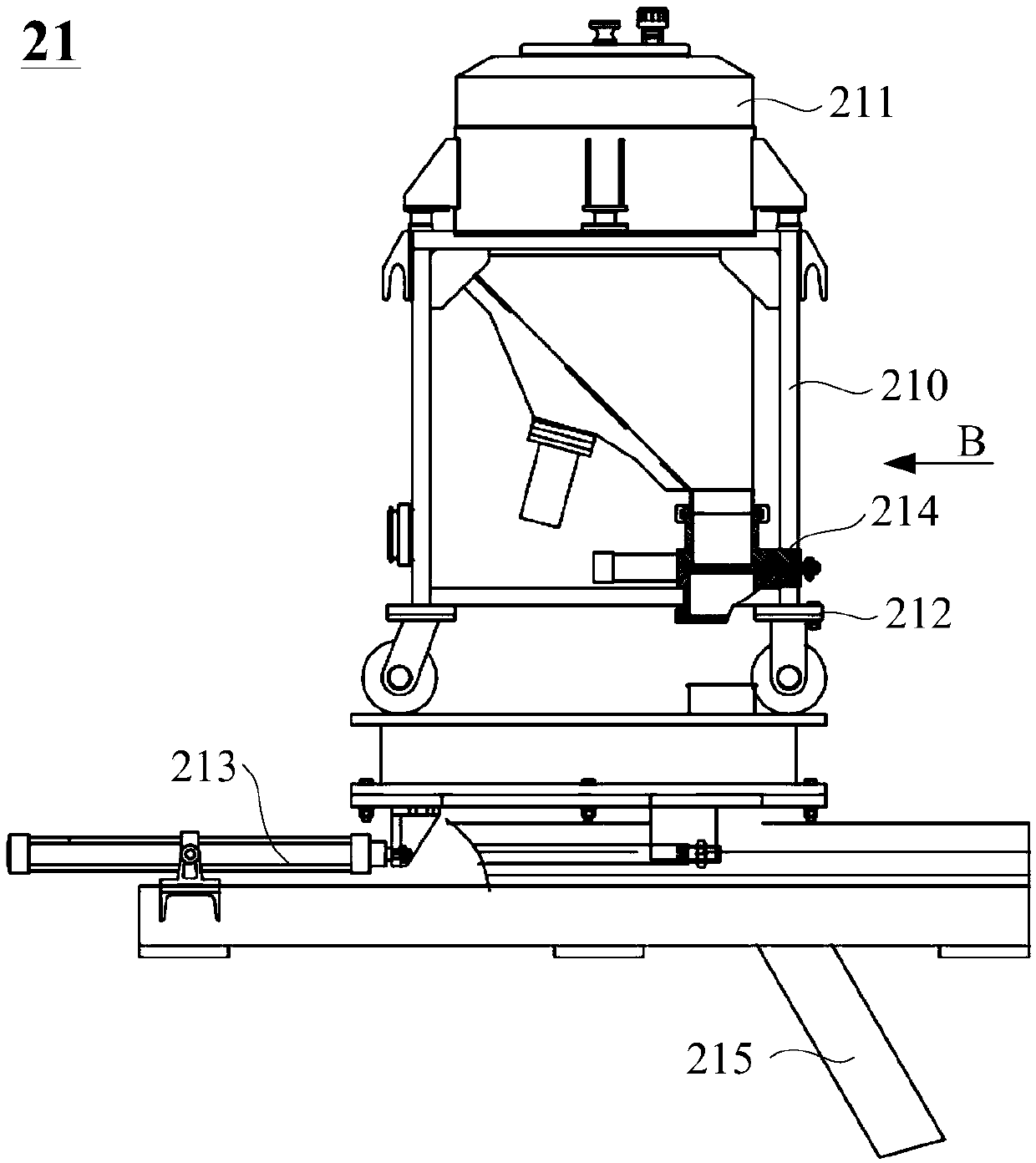

Explosive charging system and method

InactiveCN109092176AReduce lossesImprove mixing uniformityShaking/oscillating/vibrating mixersTransportation and packagingVibration accelerationMass ratio

An embodiment of the invention relates to the technical field of material mixing, in particular to an explosive charging system and method. the explosive charging system comprises a mixer, a mixing container, an automatic charging device, an automatic material transferring device and a control device, wherein the automatic charging device is used for charging a to-be-mixed material into the mixingcontainer in a preset mass ratio; the mixer is used for controlling the temperature, vacuum degree, vibration acceleration and mixing time of the mixing container containing the to-be-mixed material;the automatic material transferring device is used for conveying the mixing container among a charging station, a mixing station and a transfer station; the control device is in signal connection with the mixer, the automatic charging device and the automatic material transfer device and used for controlling actions of the mixer, the automatic charging device and the automatic material transferring device. The explosive charging system can solve the problems of long operation time and low production efficiency in the explosive charging process in the prior art.

Owner:HUBEI HANGPENG CHEM POWER TECH +1

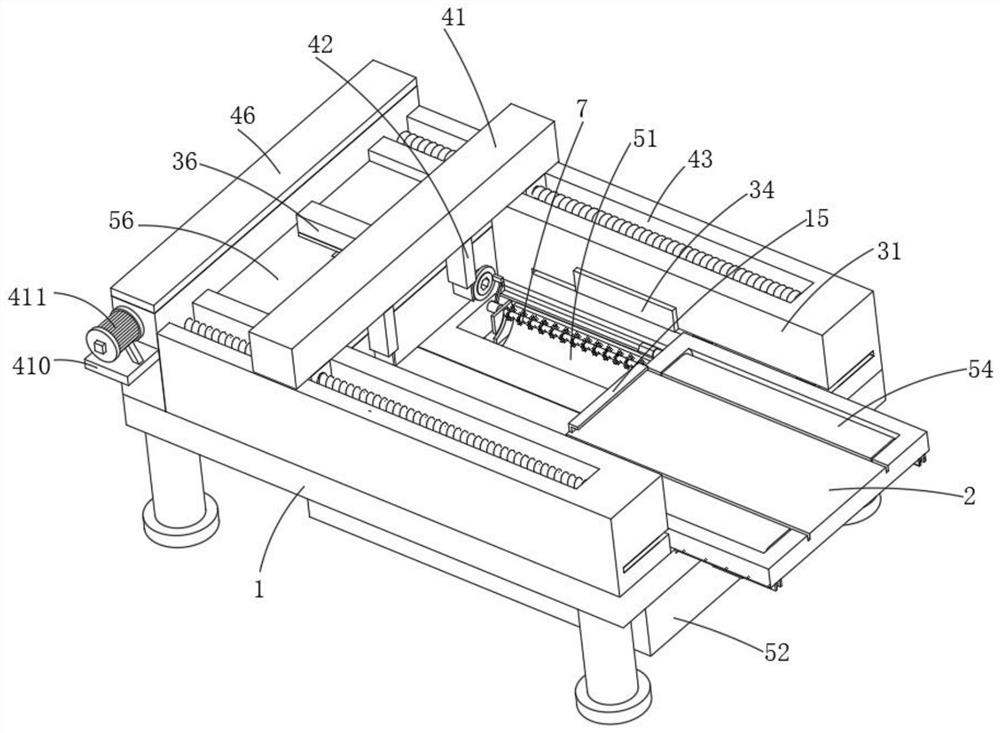

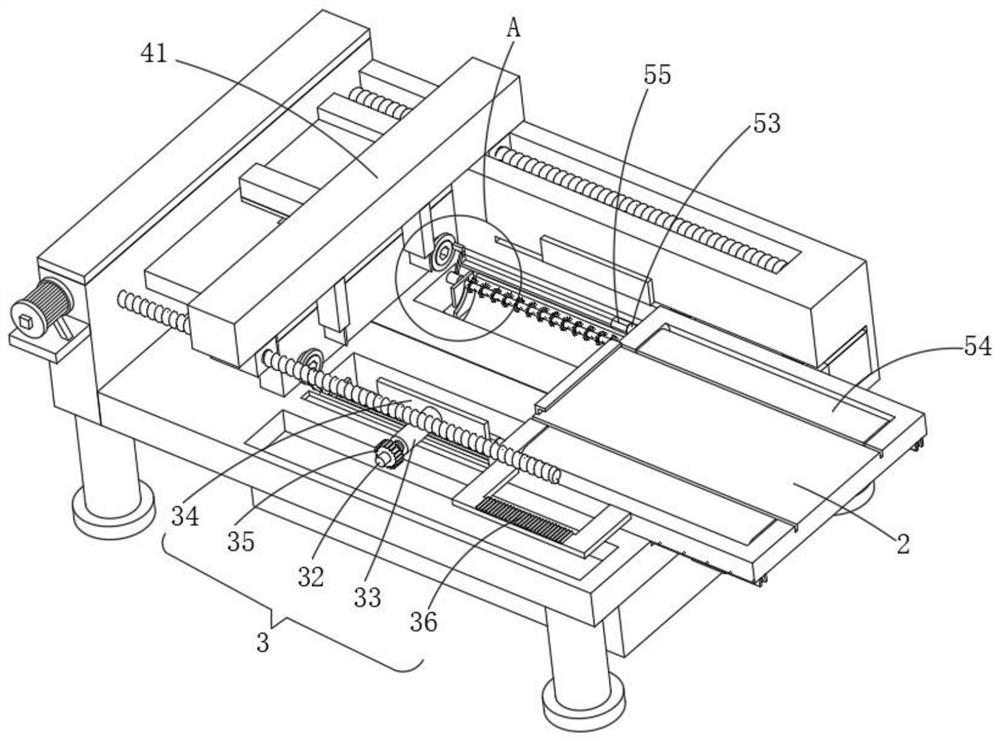

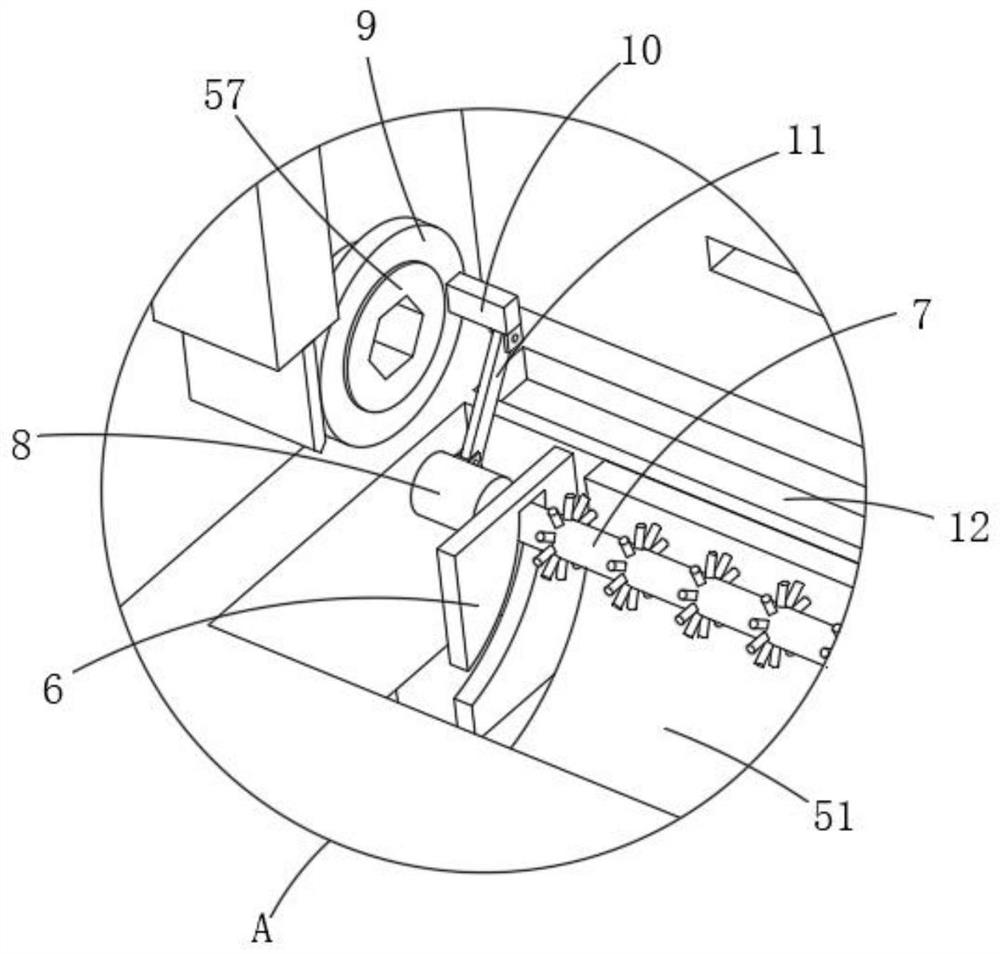

Trimming device for composite material based on aircraft production line

PendingCN113199516AAvoid accumulationConvenient for centralized collectionMetal working apparatusProduction lineGear wheel

The invention discloses a trimming device for a composite material based on an aircraft production line, and belongs to the technical field of aircraft composites. The trimming device comprises an operation table, a placing plate, fixing mechanisms and a cutting mechanism, wherein the operation table is used for trimming and trimming a resin-based composite material plate; the placing plate is in sliding connection with the side wall of the top end of the operation table; the number of the fixing mechanisms is two, the two fixing mechanisms are both fixedly connected to the operation table, and the two fixing mechanisms are located on the two sides of the top end of the operation table correspondingly; and the cutting mechanism is fixedly connected to the operation table, and the cutting mechanism is located over the placing plate. A tooth-shaped block and a driven gear are driven to be in meshing transmission through recycling of a moving frame, a baffle can be opened to enable waste to fall into a collecting box, meanwhile, a brush roller can be driven to clean the edge of a discharging opening, waste dust and the like are prevented from being accumulated to block the discharging opening, the convenience of the device for cleaning the waste in the trimming process is improved, and a good cleaning effect is achieved.

Owner:芜湖中科飞机制造有限公司

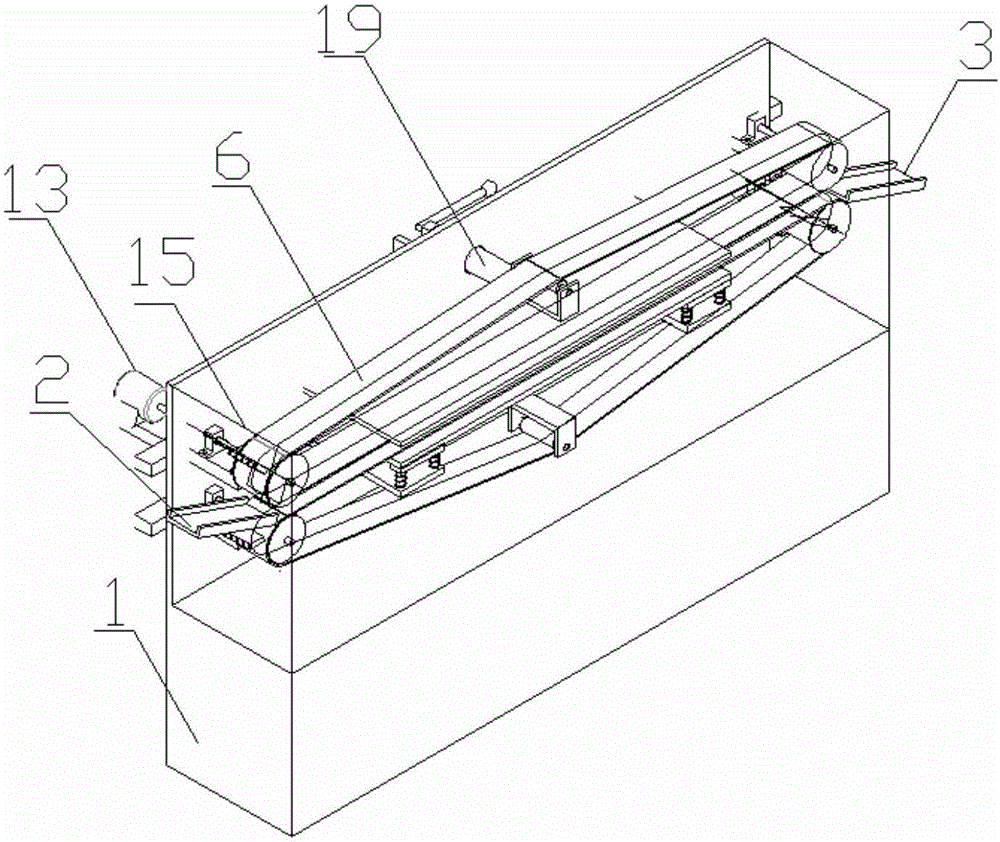

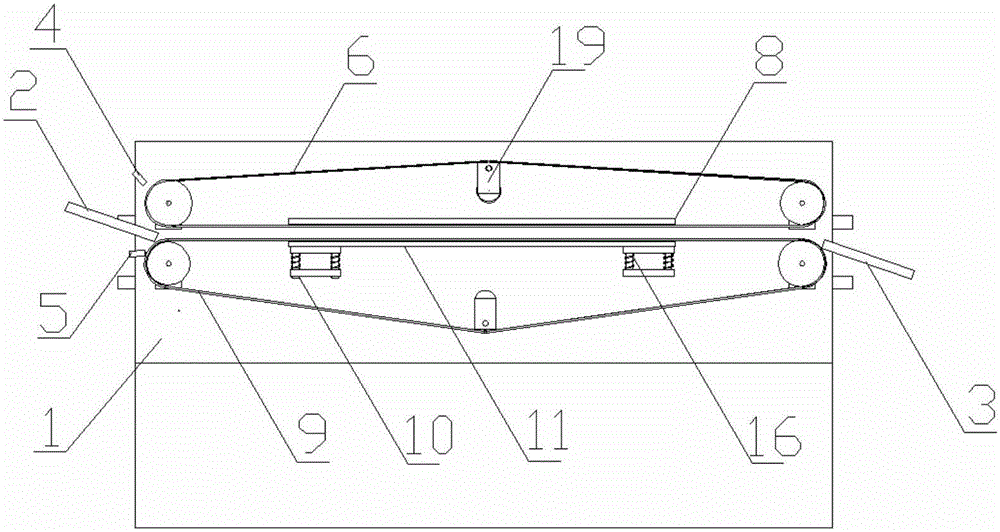

Gasket cleaning machine

InactiveCN106000927AQuick breakdownDecompose thoroughlyCleaning using toolsCleaning using liquidsSpray nozzleEngineering

The invention discloses a gasket cleaning machine. A gasket is manually cleaned, the efficiency is low, the cost is high, and the surface of the gasket is scratched. A cleaning device of the gasket cleaning machine is arranged in a cleaning machine body, and the cleaning device comprises an upper cleaning belt and a lower cleaning belt; a belt wheel mounted on the upper cleaning belt is driven by an upper stepping motor, a belt wheel mounted on the lower cleaning belt is driven by a lower stepping motor, an inlet groove is formed in each of the input end of the upper cleaning belt and the input end of the lower cleaning belt, and an outlet groove is formed in each of the output end of the upper cleaning belt and the output end of the lower cleaning belt; a spraying head device is fixed to the upper portion of the cleaning machine body and comprises an upper spraying head and a lower spraying head which are symmetrically distributed; a nozzle of the upper spraying head and a nozzle of the lower spraying head are both aligned with the opposite sides of the upper cleaning belt and the lower cleaning belt; and the upper cleaning belt and the lower cleaning belt are each provided with a tensioning device, and a gasket thickness adjusting device for adjusting the interval of the two cleaning belts is arranged on the opposite sides of the upper cleaning belt and the lower cleaning belt. According to the machine, the cleaning time is shortened, and meanwhile, the phenomenon that the surface of the gasket is scratched when other cleaning methods are used is avoided.

Owner:HANGZHOU DIANZI UNIV

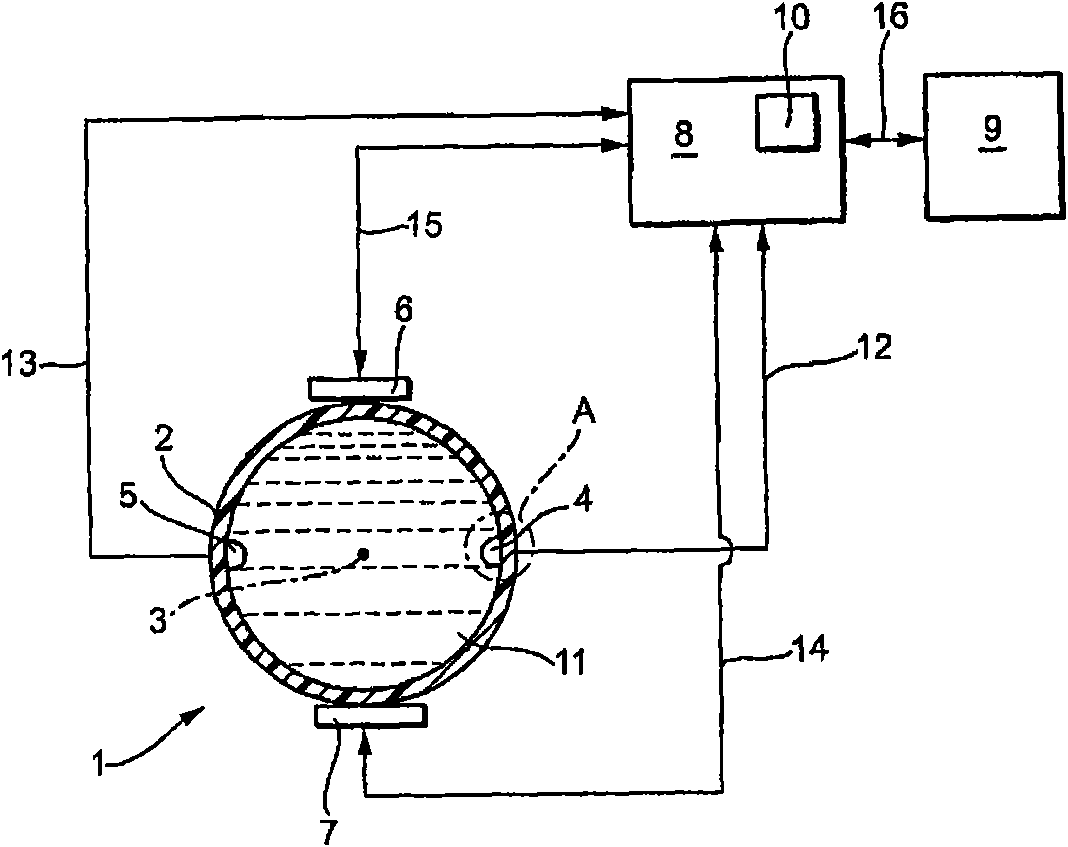

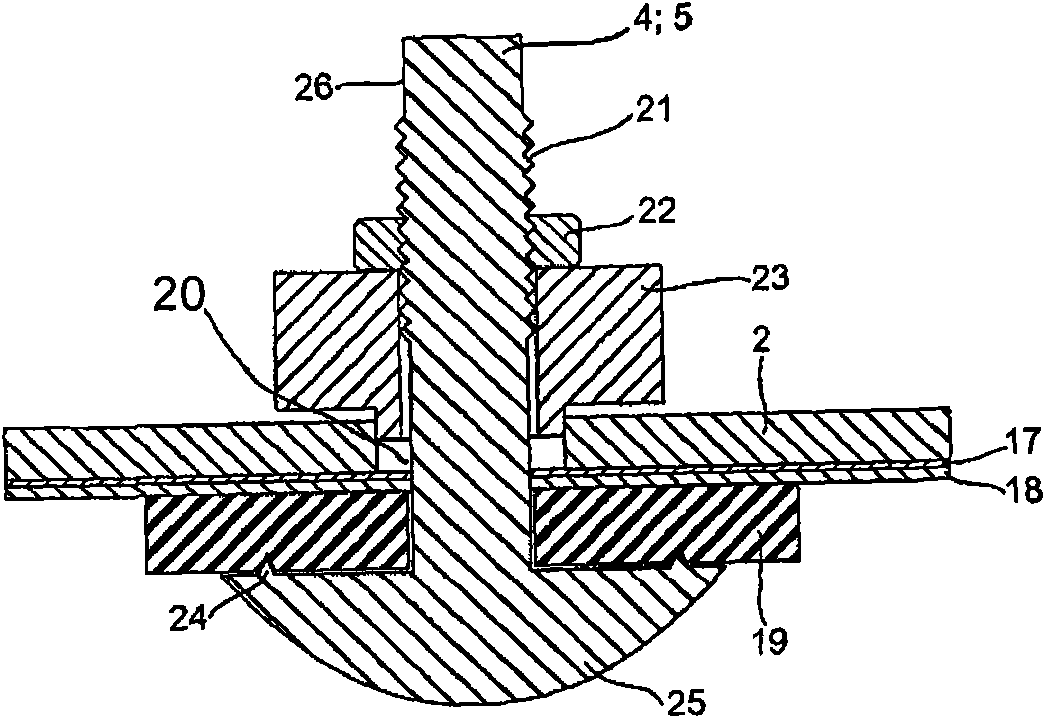

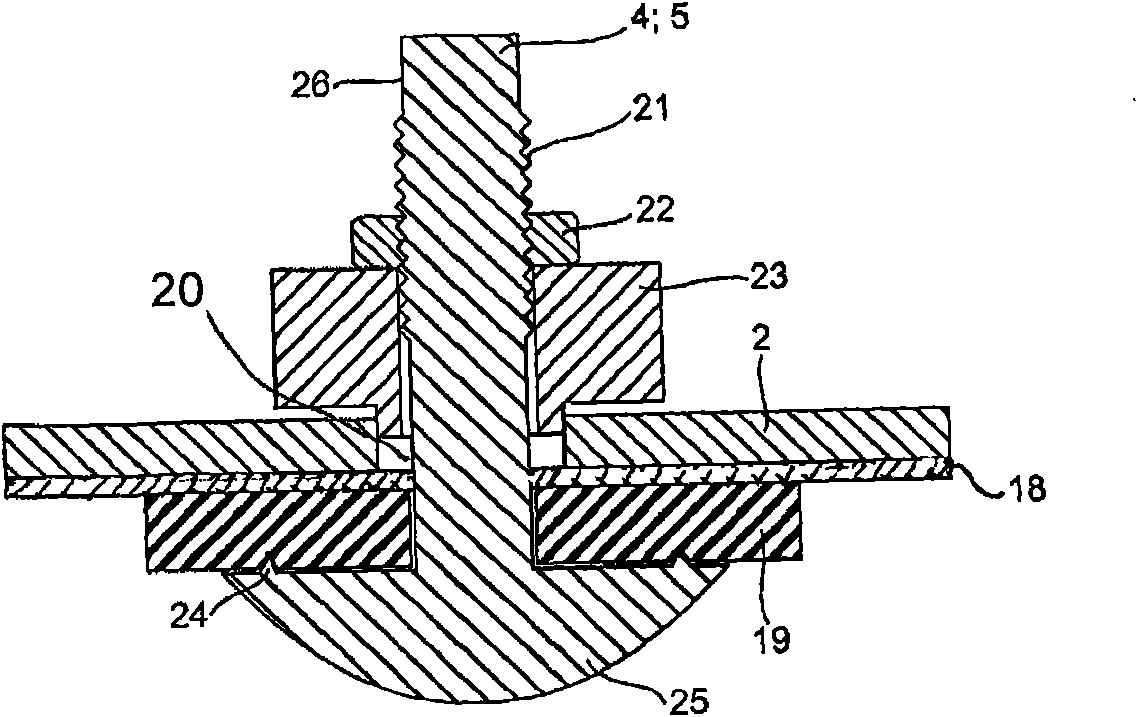

Device for measuring the volume or mass flow rate of a medium in a pipe

The invention relates to a measuring tube (2) for any flow meter (1) that determines or monitors the volume or mass flow rate of a medium (11) flowing in a pipe (33). A powder-coatable plastic is applied as a primer (17), liner (18), or protective layer (28) for a liner (18) at least in the area of the internal surface of the measuring tube (2) through which the medium (11) flows.

Owner:ENDRESS HAUSER FLOWTEC AG

Continuous polyester fabric padding and dyeing method free of boiling and washing process and polyester fabric

The invention discloses a continuous polyester fabric padding and dyeing method free of a boiling and washing process. The method includes steps: step one, proportionally and uniformly mixing dispersedyes, water-absorbent resin, a polyester repair agent, an anionic surfactant, a color fixing agent and a moisture absorbent in softened water to obtain dyeing working solution; step two, subjecting polyester fiber fabrics to padding in the dyeing working solution prepared in the step 1; step three, after padding in the dyeing working solution, subjecting the polyester fiber fabrics to drying, baking and cropping at 140-220 DEG C to complete continuous dyeing of the polyester fiber fabrics. Technical process shortening and remarkable production efficiency improvement are realized, energy saving, consumption reduction, environmental friendliness and freeness of dyeing sewage discharging are realized, production cost of dyeing and printing enterprises is reduced while economic benefits are increased, and discharging of dyeing sewage is avoided.

Owner:深圳天鼎新材料有限公司

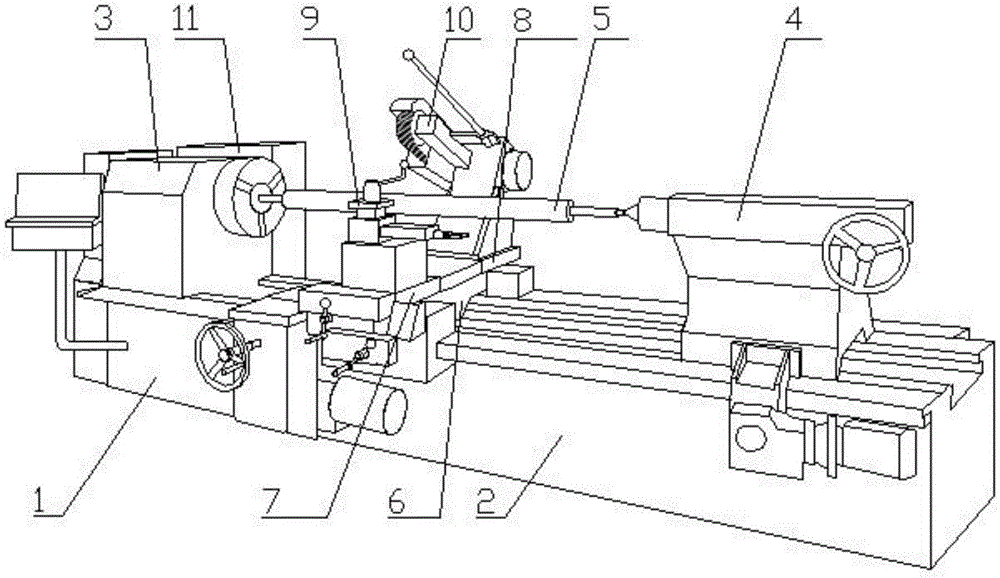

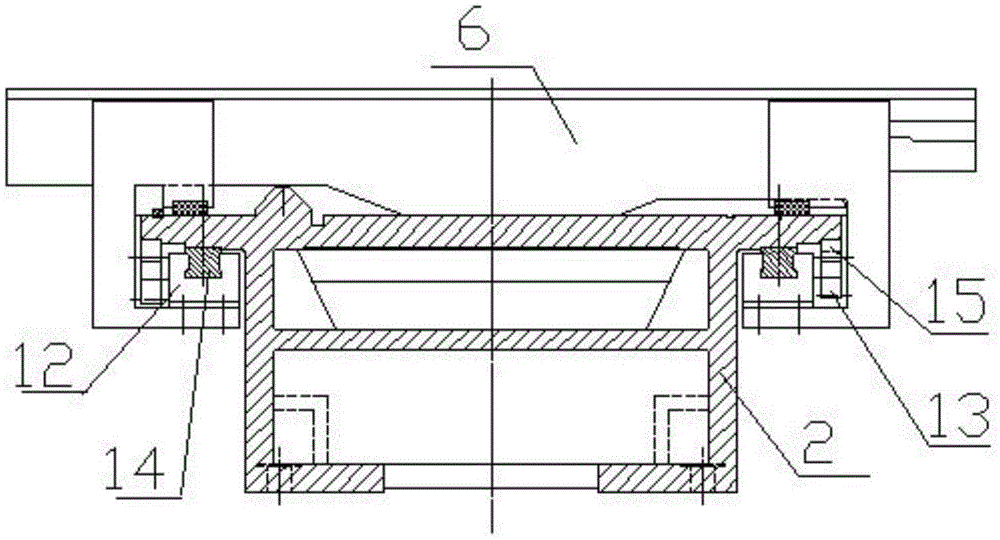

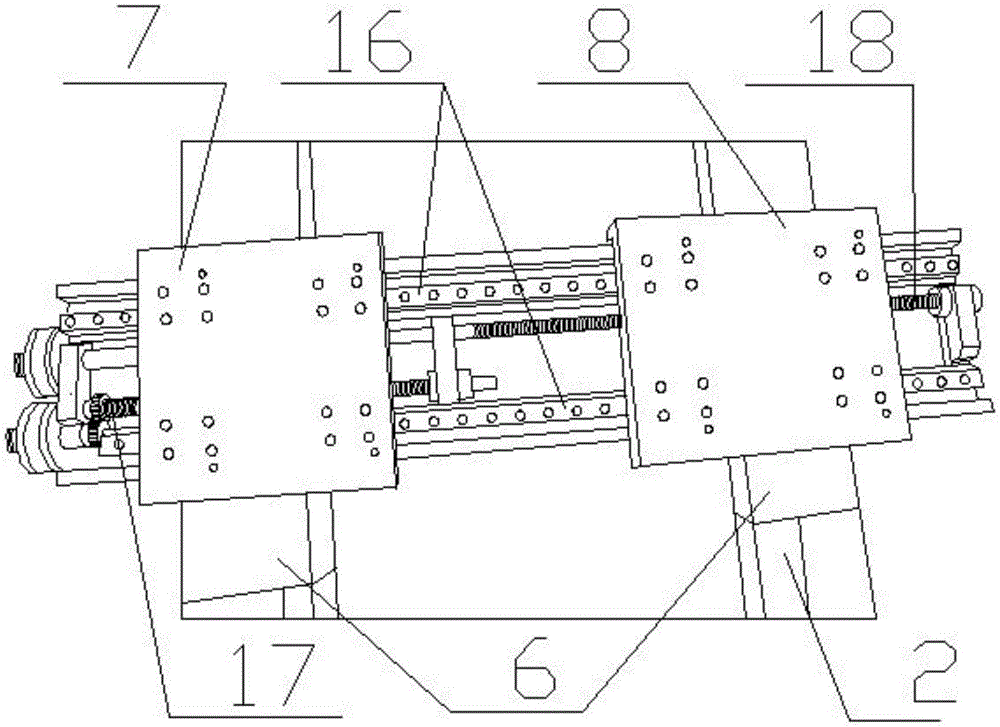

A rubber grinding machine for rubber rollers

ActiveCN103331614BExtended use timeExtend the life cycleTurning toolsOther manufacturing equipments/toolsSand blastingEngineering

The invention discloses a special automobile rubber grinding machine for a rubber covered roller. The special automobile rubber grinding machine comprises a lathe head and a lathe bed which are sequentially connected, wherein the lathe head is provided with a headstock, the lathe bed is provided with a tailstock, and a workpiece is fixed between the headstock and the tailstock; the lathe bed below the workpiece is provided with a large planker, a sliding block and a gear are arranged on the large planker, the lathe bed is provided with a linear guide rail and a rack, the sliding block is matched with the linear guide rail, and the gear is matched with the rack; the large planker is provided with a premedial planker and a postmedial planker which can move on the large planker, the premedial planker is provided with a knife rest, and the postmedial planker is provided with a belt sanding machine. According to the special automobile rubber grinding machine, the firmness between a bonding agent and a central spindle can be guaranteed, a traditional sand blasting technology can be replaced, and the surface is not needed to be washed by any solvent, so that the balance of the central spindle can not be damaged, the production efficiency can be improved, the cost is reduced and the labor force is saved, and the key is that the bonding between the rubber and the central spindle can be reliably guaranteed. According to the special automobile rubber grinding machine, the consumable materials can be saved and the environment pollution can be reduced.

Owner:JINAN POWER RUBBER ROLLER EQUIP

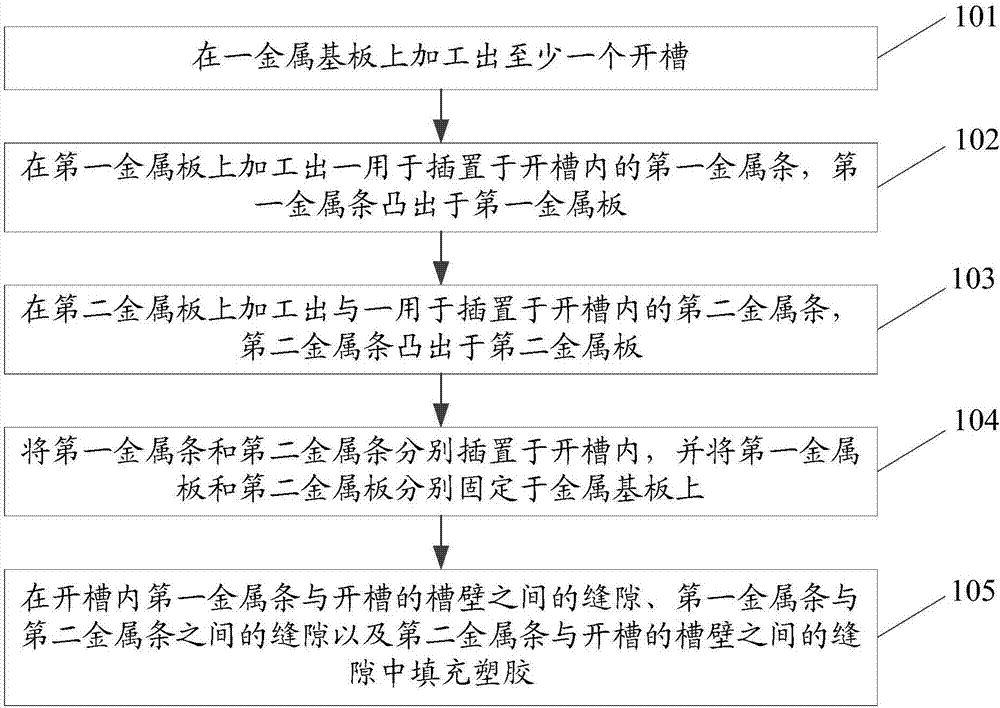

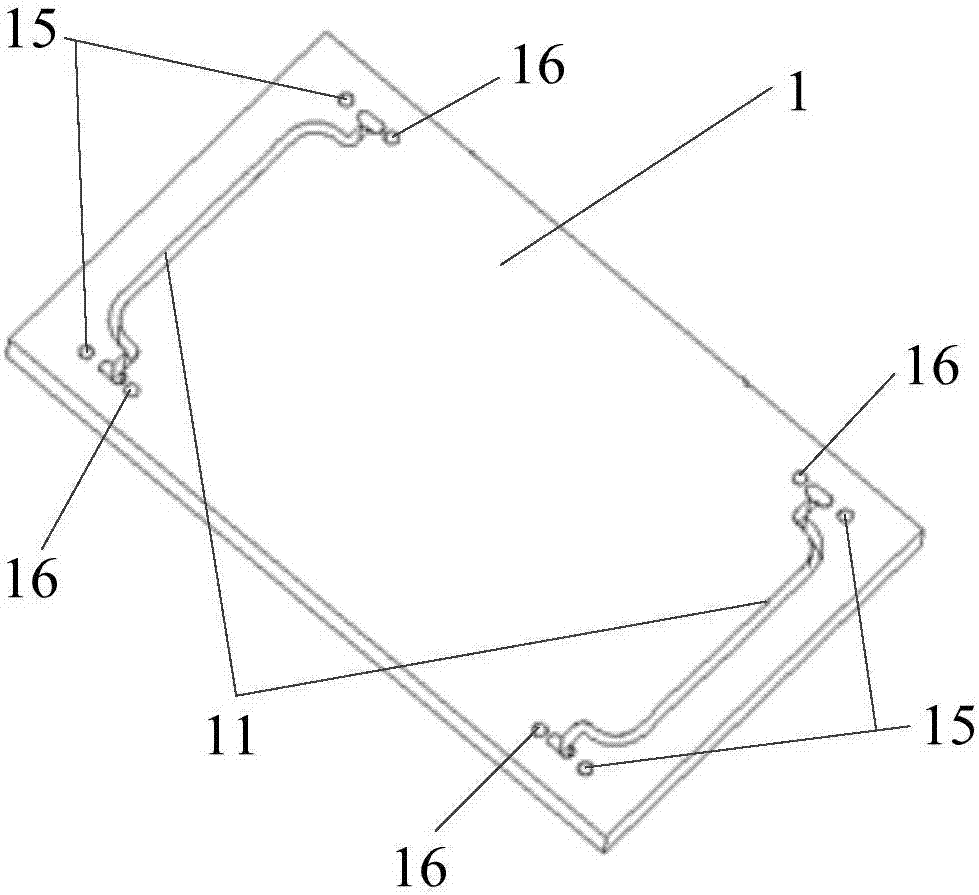

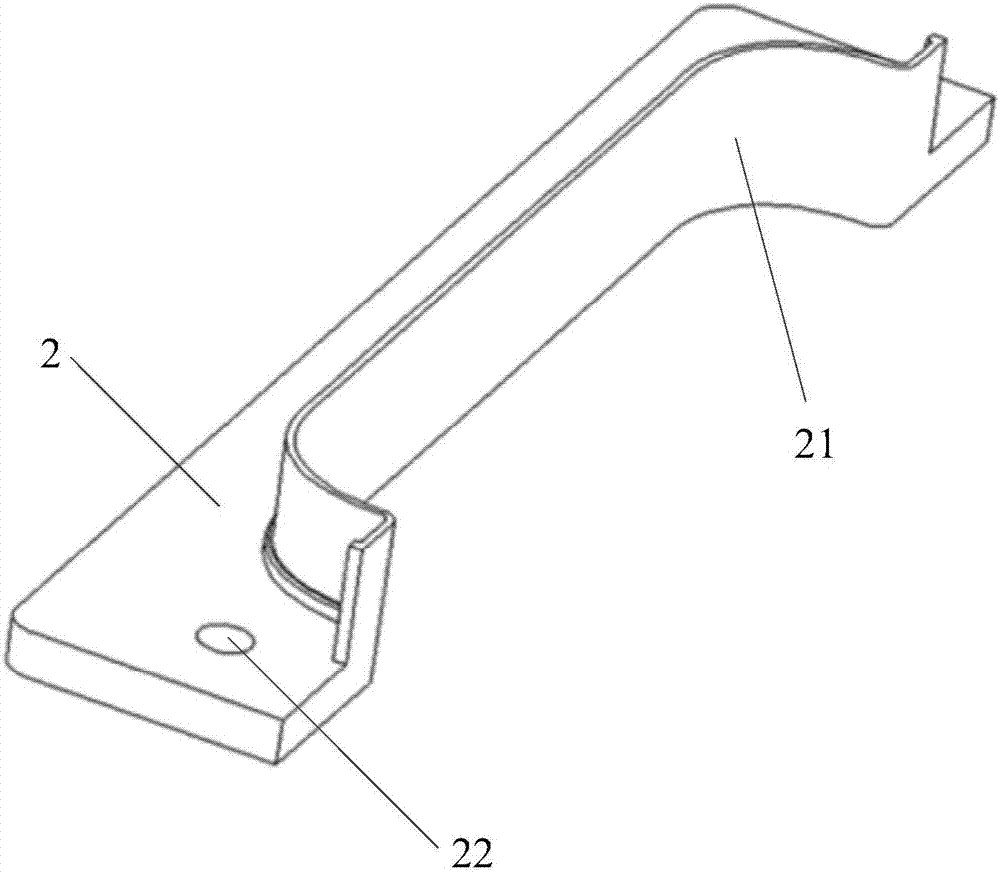

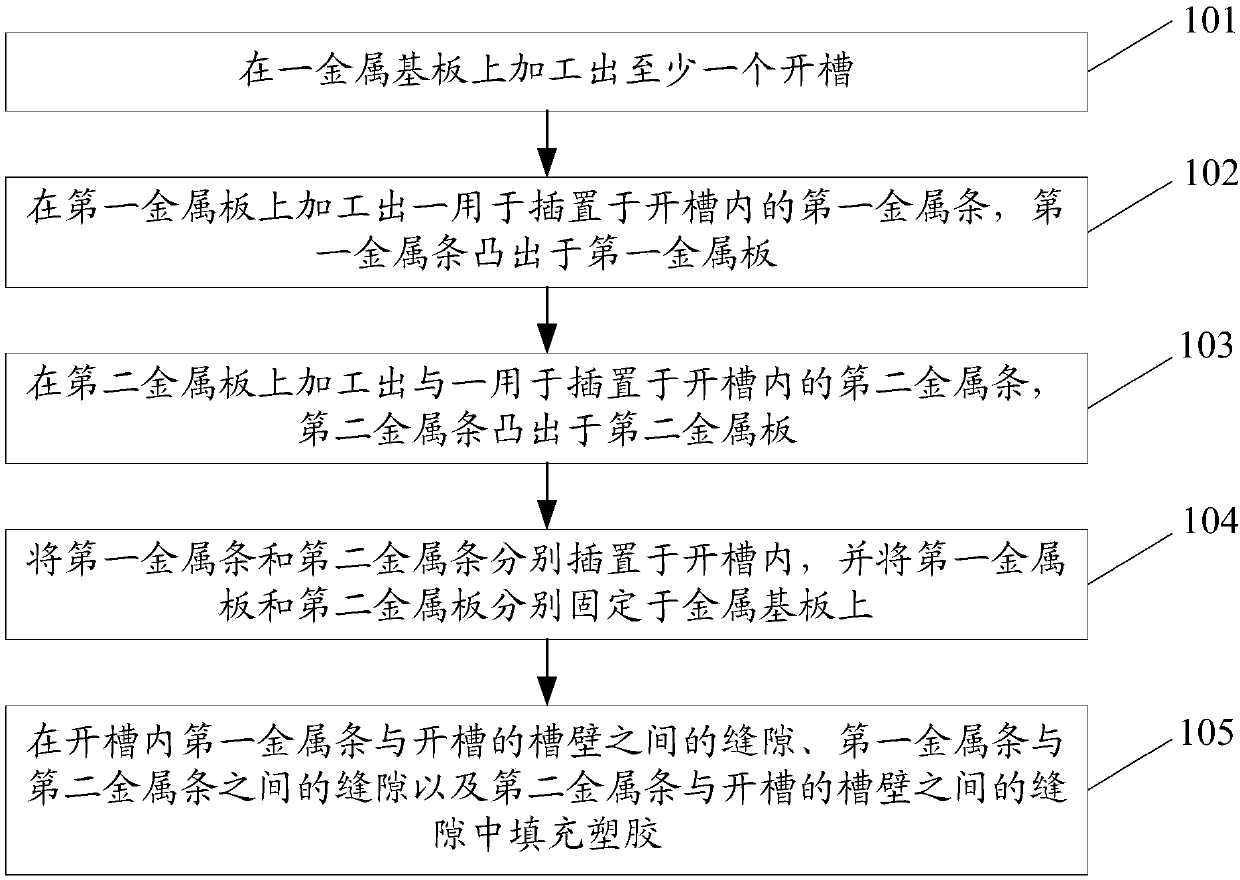

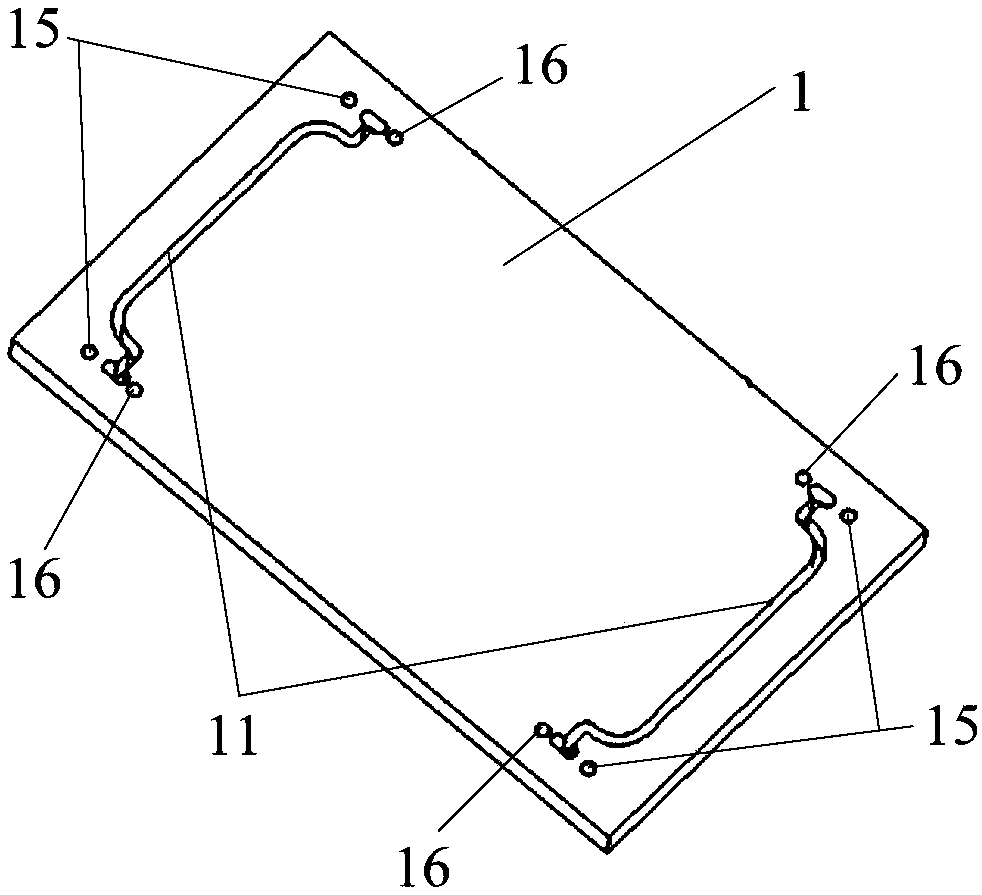

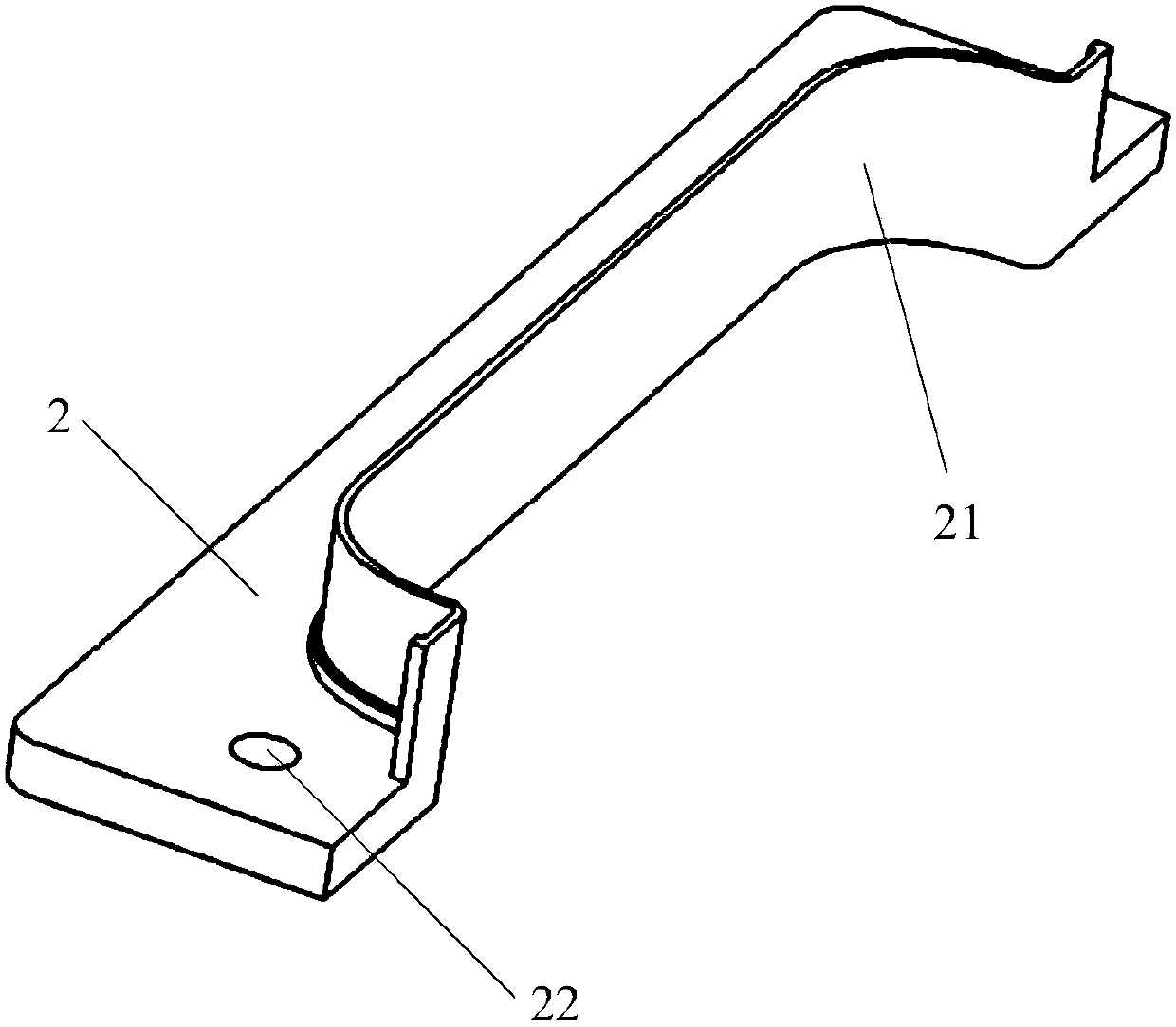

Method for processing slot antenna, slot antenna and mobile terminal

ActiveCN106898866AHigh strengthSimple processRadiating elements structural formsAntenna equipments with additional functionsMetal stripsMetal substrate

An embodiment of the invention provides a method for processing a slot antenna, a slot antenna and a mobile terminal. The method comprises the steps of forming at least one slot in a metal substrate; forming a first metal strip on a first metal plate; forming a second metal strip on a second metal plate; inserting the first metal strip and the second metal strip into the slot separately and fixing the first metal plate and the second metal plate separately onto the metal substrate separately, the first metal strip and the second metal strip being separated from the wall of the slot, and the first metal strip and the second metal strip being spaced apart by a predetermined distance; and filling a gap between the first metal strip and the wall of the slot, a gap between the first metal strip and the second metal strip, and a gap between the second metal strip and the wall of the slot with plastic. The embodiment solves the problems in the prior art that the process is complicated in the processing of a micro-slot antenna and a micro-slit with a curved appearance is difficult to realize.

Owner:VIVO MOBILE COMM CO LTD

A kind of dyeing method of polyester-cotton blended knitted fabric

The invention discloses a dyeing method of polyester-cotton blended knitting fabric. The dyeing method comprises the steps of pre-treatment, dyeing of a polyester part and oxygen bleaching of a cotton part, dyeing of the cotton part and after-treatment. According to the dyeing method disclosed by the invention, dyeing is carried out by adopting a special alkaline polyester-cotton dyeing agent, the technologies of the oxygen bleaching of the cotton part and the dyeing of the polyester part are combined into one, washing of the polyester part can be omitted, and washing can be carried out only after the dyeing of the cotton part. Compared with traditional craftwork, the dyeing method disclosed by the invention has the advantages that the technological process is greatly simplified, the dyeing time is greatly shortened, the use of water, electricity and steam can be obviously reduced, the production cost is obviously reduced, and the pollution to the ecological environment, particularly the water resource, is reduced.

Owner:石狮市瑞鹰纺织科技有限公司

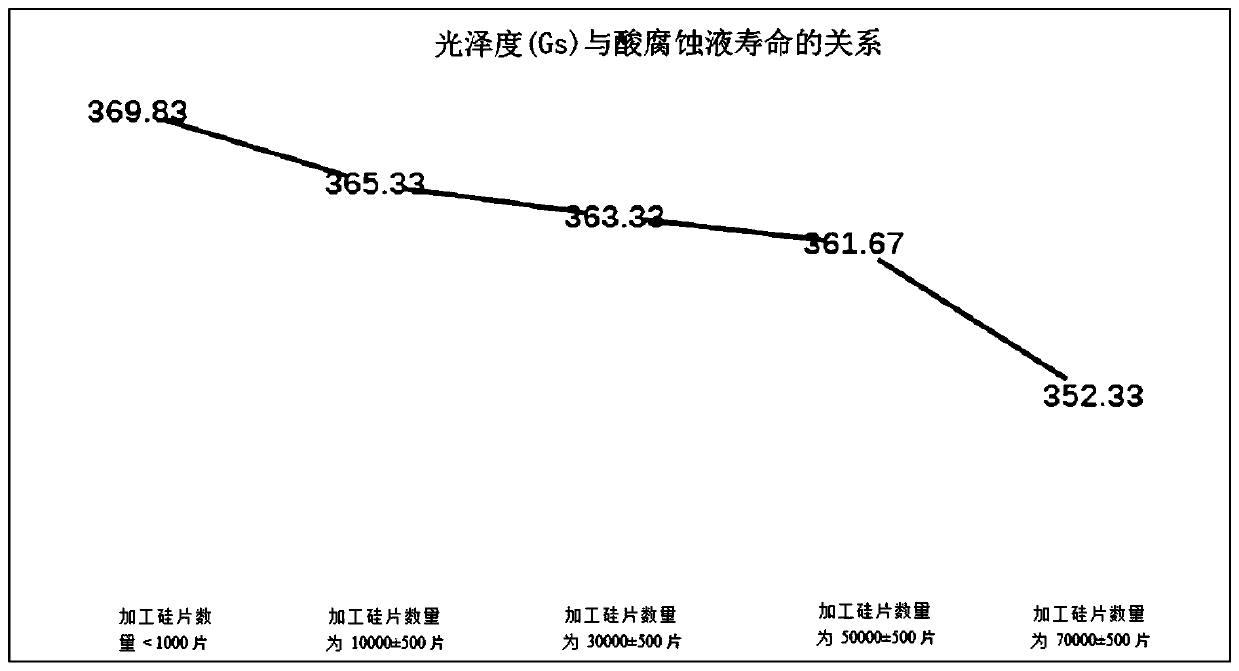

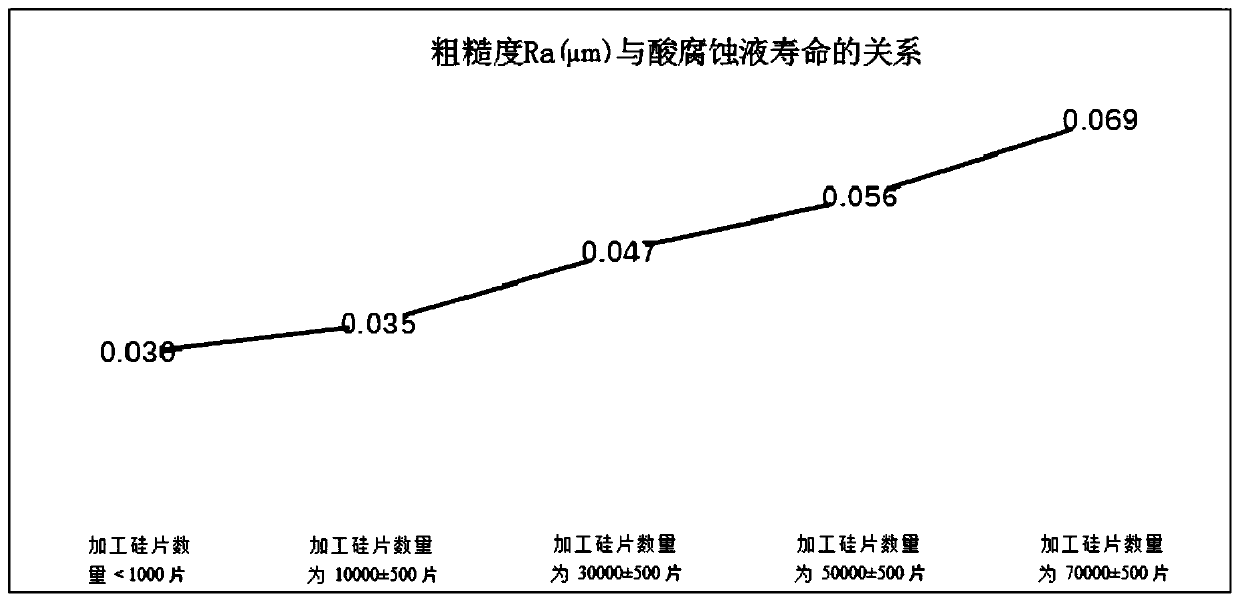

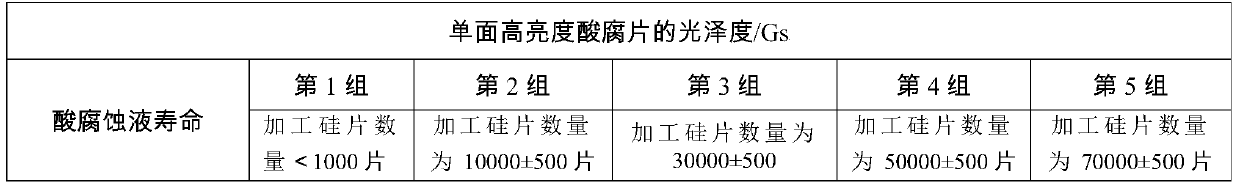

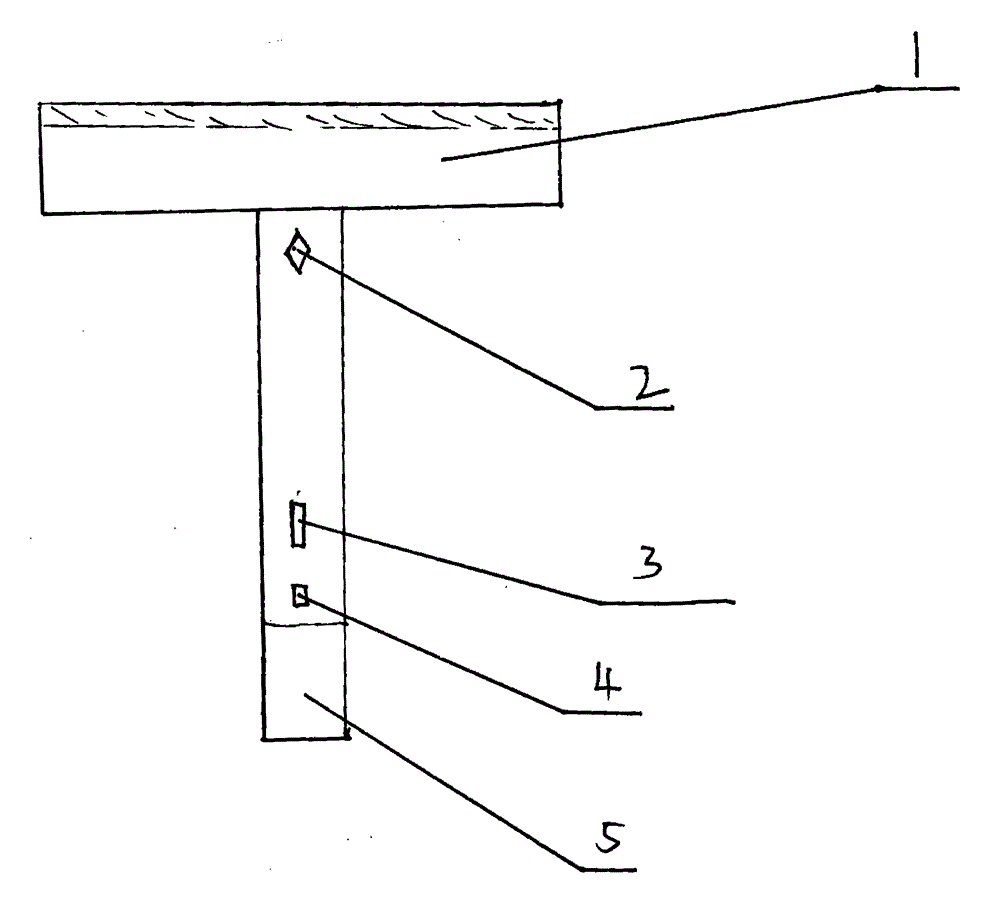

Process method for preparing acid corrosion wafer with high brightness at single side

ActiveCN110277307ASimple processOmit polishingSemiconductor/solid-state device manufacturingSemiconductor devicesMetallurgyAcid corrosion

The invention provides a process method for preparing an acid corrosion wafer with high brightness at the single side, which comprises the steps of (1) carrying out shearing and grinding on the single side, namely, performing shearing and grinding on one surface of a two-sided grinding wafer by adopting a grinding wheel, wherein the grinding removal amount is 10-20[mu]m to obtain a single-sided grinding wafer; and (2) carrying out acid corrosion, namely, performing acid corrosion on the single-sided grinding wafer obtained in the step (1) by using an acid corrosion solution to obtain an acid corrosion wafer with high brightness at the single side. Compared with the traditional process route, the process method of the invention adds a procedure of single-sided shearing and grinding, the front and the back of the acid corrosion wafer are enabled to be different in brightness by single-sided shearing and grinding, the acid corrosion wafer with the single-side glossiness being greater than 360Gs, the reflectivity being greater than 98% and less roughness is prepared after acid corrosion, the use requirement is ensured, the polished wafer is replaced, and the cost is saved.

Owner:TIANJIN ZHONGHUAN ADVANCED MATERIAL TECH +1

Window cleaner capable of spraying water

A window cleaner capable of spraying water is composed of a glass brush (1), a sprinkler head (2), a sprinkling button (3), a water storage opening (4) and a handle (5). The handle (5) is connected with the glass brush (1). The sprinkler head (2), the sprinkling button (3) and the water storage opening (4) are located on the handle (5). The window cleaner is provided with a water storage device, water is sprayed firstly, then, the glass brush is used for cleaning a window, in this way, the processes of wetting cleaning cloth and washing the cleaning cloth can be omitted, a great number of troubles are removed for people during cleaning, meanwhile, the window cleaning effect is good, and the window cleaner is a magical device for cleaning the window and is worthy of great popularization.

Owner:周雨

Manufacturing method of resistance strain gage based on ion beam technology

InactiveCN101614522BSimple processImprove yieldDecorative surface effectsPhotomechanical apparatusPolyimide substrateSputtering

The invention relates to a manufacturing method of a resistance strain gage based on an ion beam technology. The method comprises the following steps: coating polyimide glue solution on the surface of a high temperature silicon rubber substrate by adopting a DC plasma sputtering technology and a plasma etching technology, hot solidifying the polyimide glue solution to form a flexible polyimide substrate, then peeling off, solidifying to obtain a flexible substrate film with needed strain property requirement, sputtering a resistance alloy film on the polyimide surface of the flexible substrate and finally manufacturing the resistance strain gage by a photoengraving and etching process. The invention has simple process, high rate of finished products, controllable components of the resistance alloy film, adjustable alloy components as required, high image resolution, favorable property of manufactured material, and the like.

Owner:SHAANXI ELECTRICAL APPLIANCE RES INST

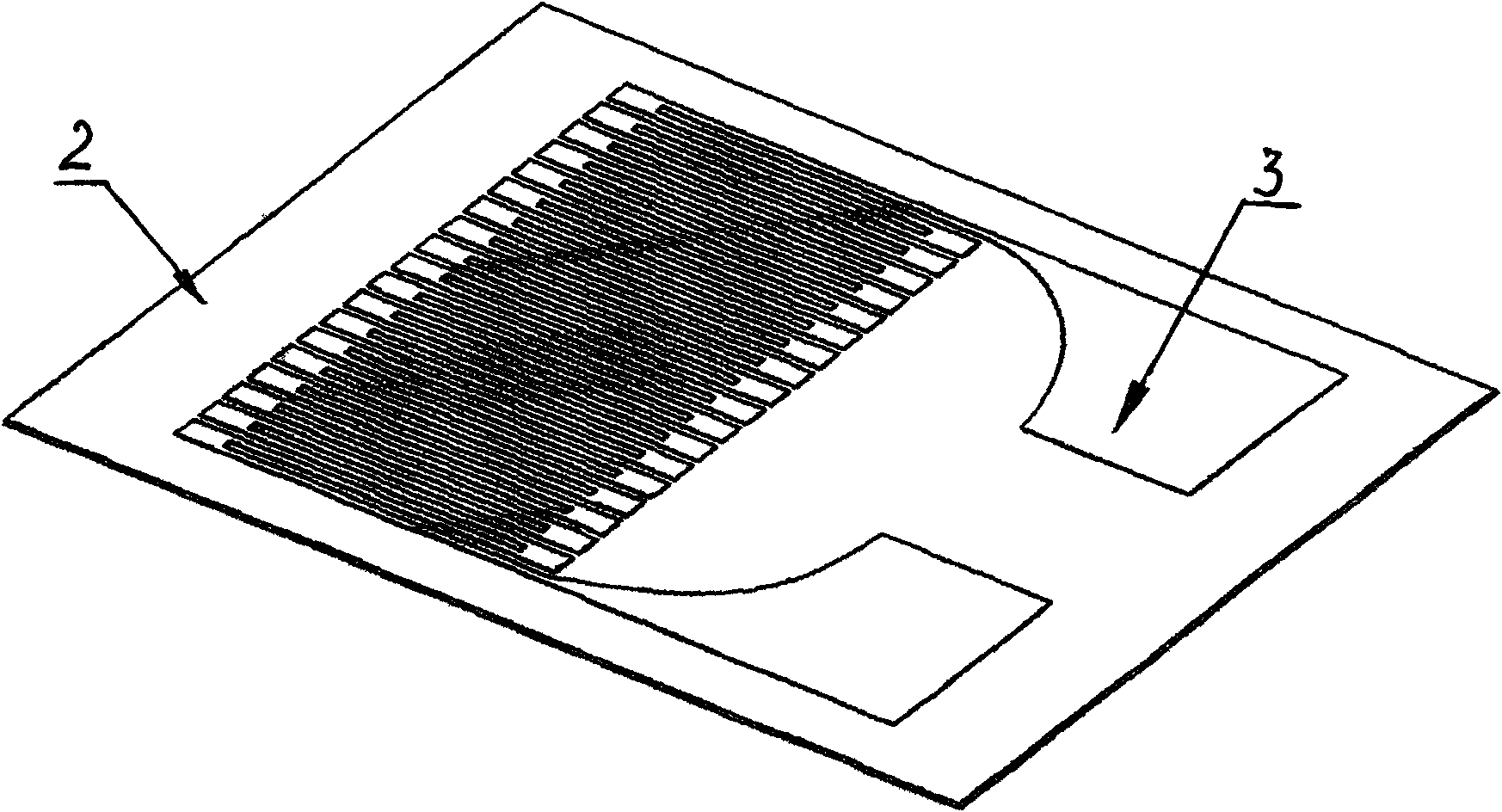

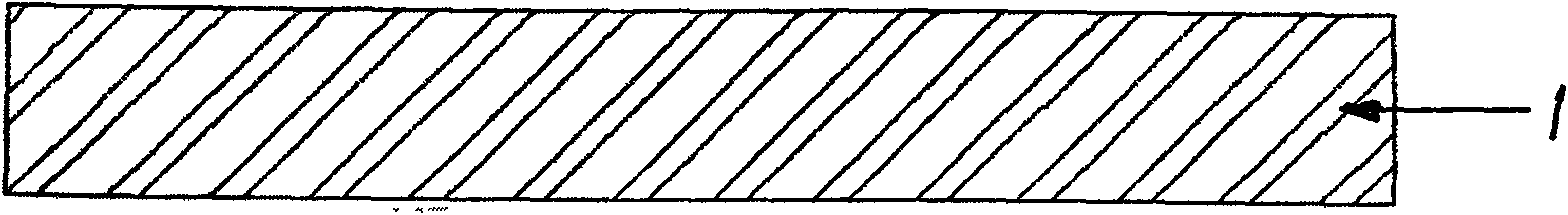

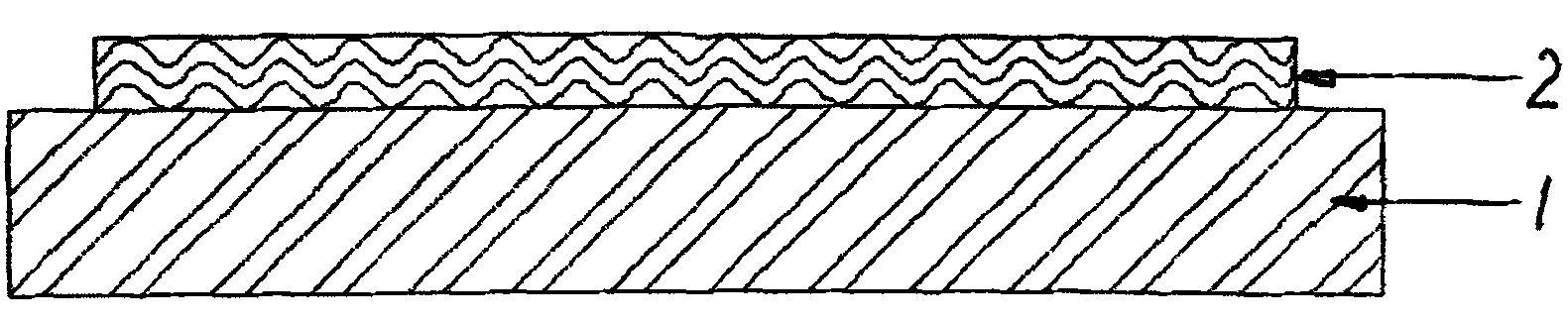

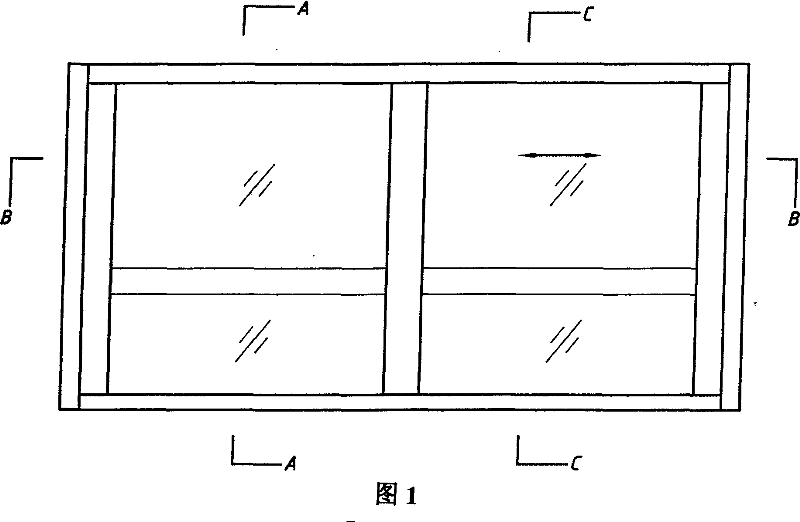

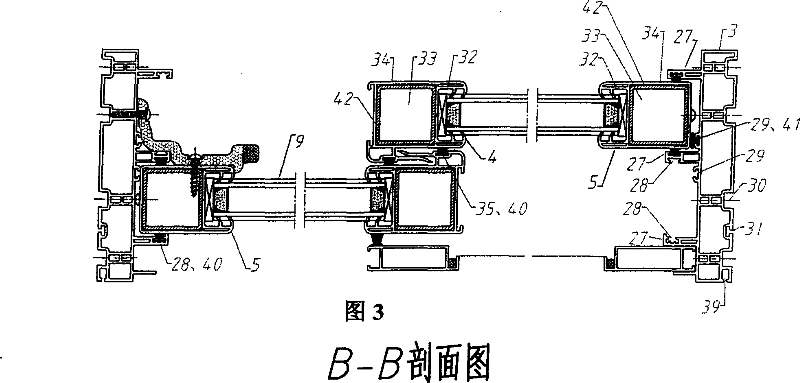

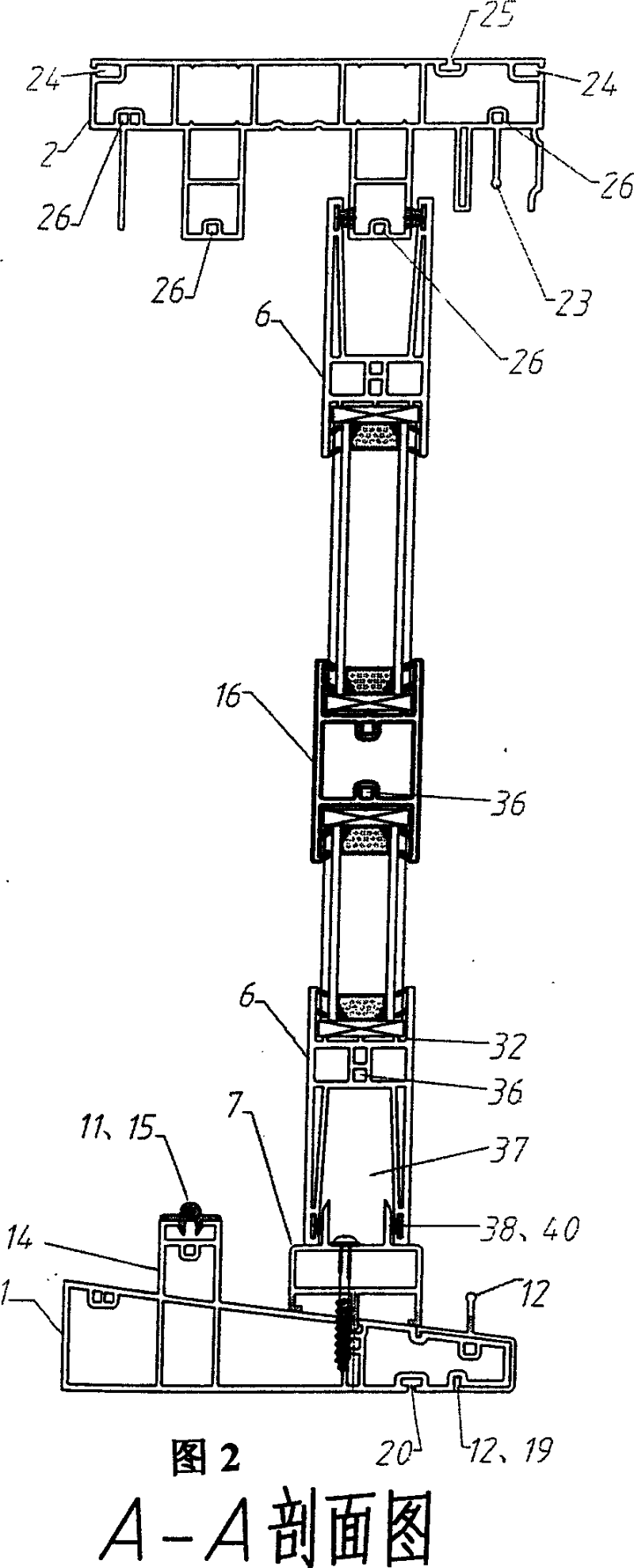

Outdoor plastics sliding doors no need welding molding

InactiveCN101037918AEliminate plastic welding processOmit cleaningCorner/edge jointsWing arrangementsMortise and tenonWeld seam

The invention belongs to plastic doors, particularly relates to a plastic outdoor sliding door without welding forming, comprising outer frame, door saddle, top frame, side frame, unlatching leaf, latching leaf, leaf stile plastic profiled bar for segregating facade and matched aluminum alloy sections. Characterized in that the outer frame section bars overlap at an angle of 90 degree, the overlapping portions are fastened by screw nuts; joint parts of the unlatching leaf, latching fan and leaf stile profiled bar for segregating facade mortice-tenon plug-connected and fastened by screw nuts at an angle of 90 degrees. Beneficial effects of the invention are: manufacture and assemble can be done by employing part of the present plastic door-window assembling apparatus; and pre-fabrication of frame leaf bar members, hollow glass and other elements can be accomplished in the factory; plastic welding procedure and welding seam cleaning procedure are overleaped; package, transportation and storage of the door are carried out in element form, assembly and installment are accomplished in subscriber's locale, which can effectively protect the products, transportation and storage cost are reduced.

Owner:TIANJIN DEV AREA JINPENG PLASTICS PROFILE MFG CO LTD

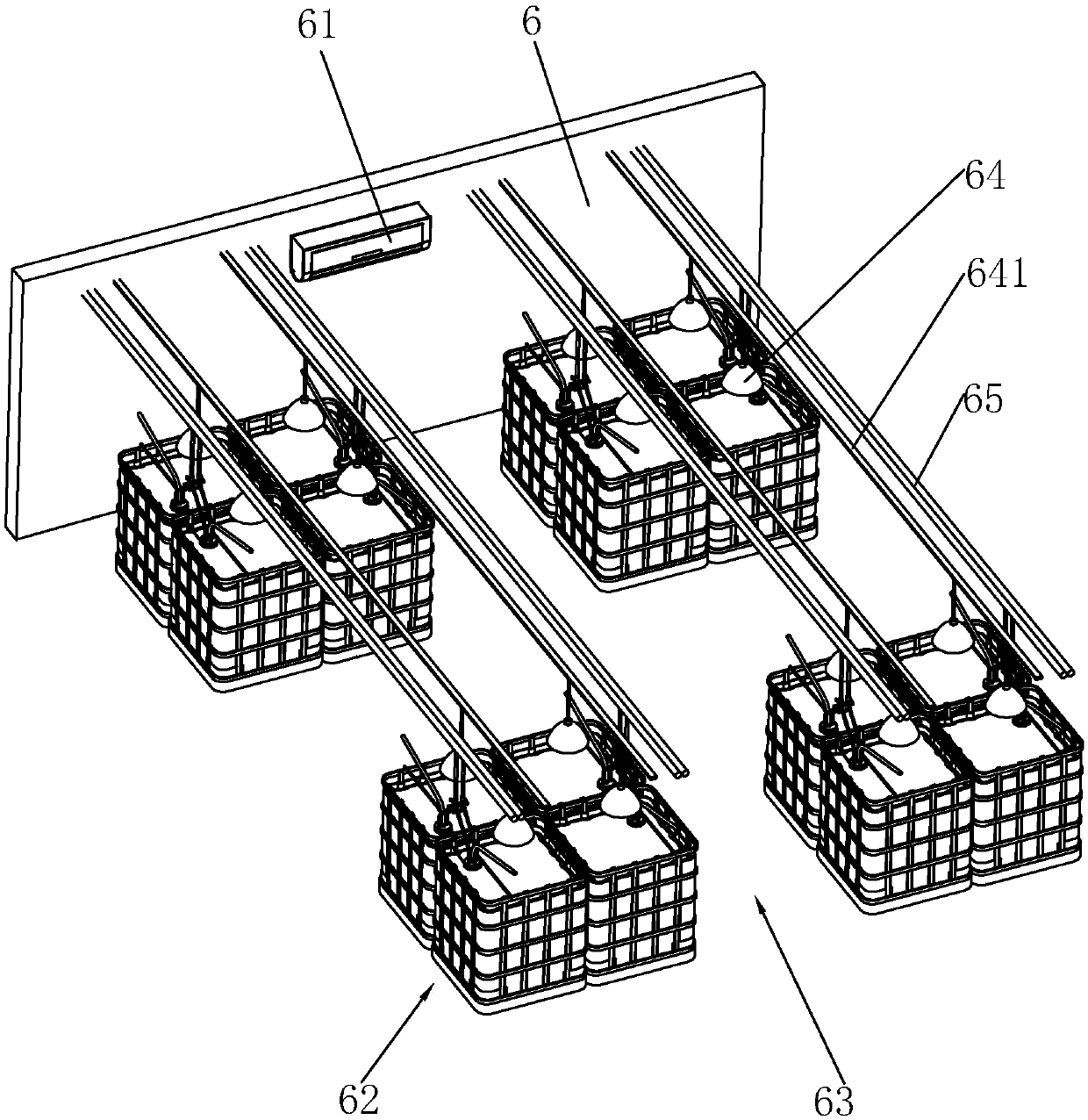

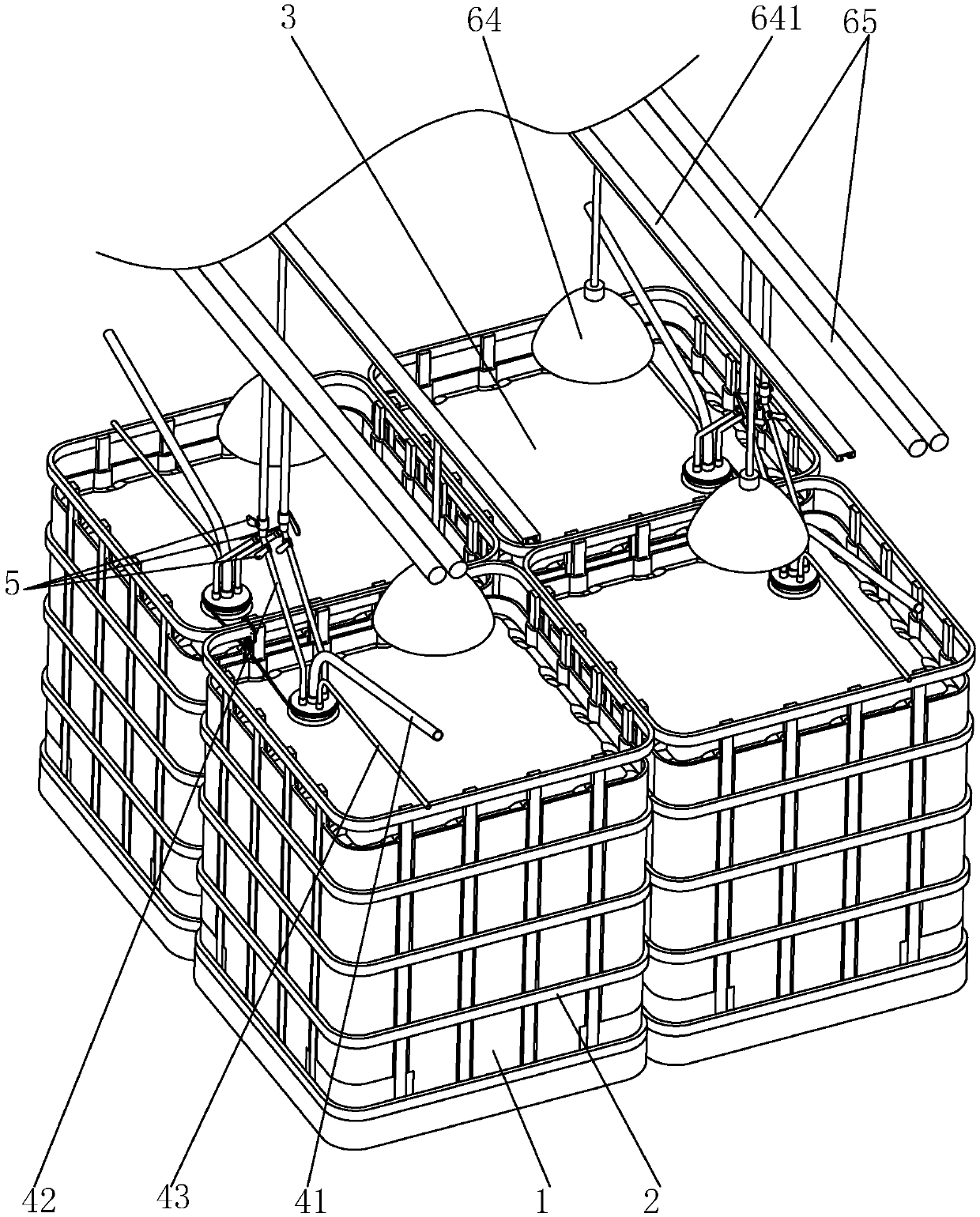

Production line for microalgae active cell nutritional repair liquid

InactiveCN109536383AOmit cleaningOmit aseptic processing stepsBioreactor/fermenter combinationsBiological substance pretreatmentsProduction lineCell selection

The invention discloses a production line for a microalgae active cell nutritional repair liquid and belongs to the technical field of microalgae production. The production line, according to the technical scheme, includes the following production zones: a single cell selection zone, an early stage amplifying culture zone, a final stage amplifying culture zone, and a mixing zone; wherein a plurality of culture sub-zones are arranged in the final stage amplifying culture zone, walking pathways being reserved between adjacent culture sub-zones; each culture sub-zone includes a plurality of culture apparatuses, each of which includes a culture bucket having an upward opening. A flexible transparent culture bag is placed in each culture bucket and is used for accommodating algae liquid. A topopening is formed in the top of each culture bag and communicates internal and external spaces of the culture bag. A top cover is detachably fixedly connected to each top opening. A gas inlet, a gas outlet and a liquid outlet are disposed on the top cover. The production line can improve efficiency of production operation and improve culture efficiency.

Owner:雷云飞

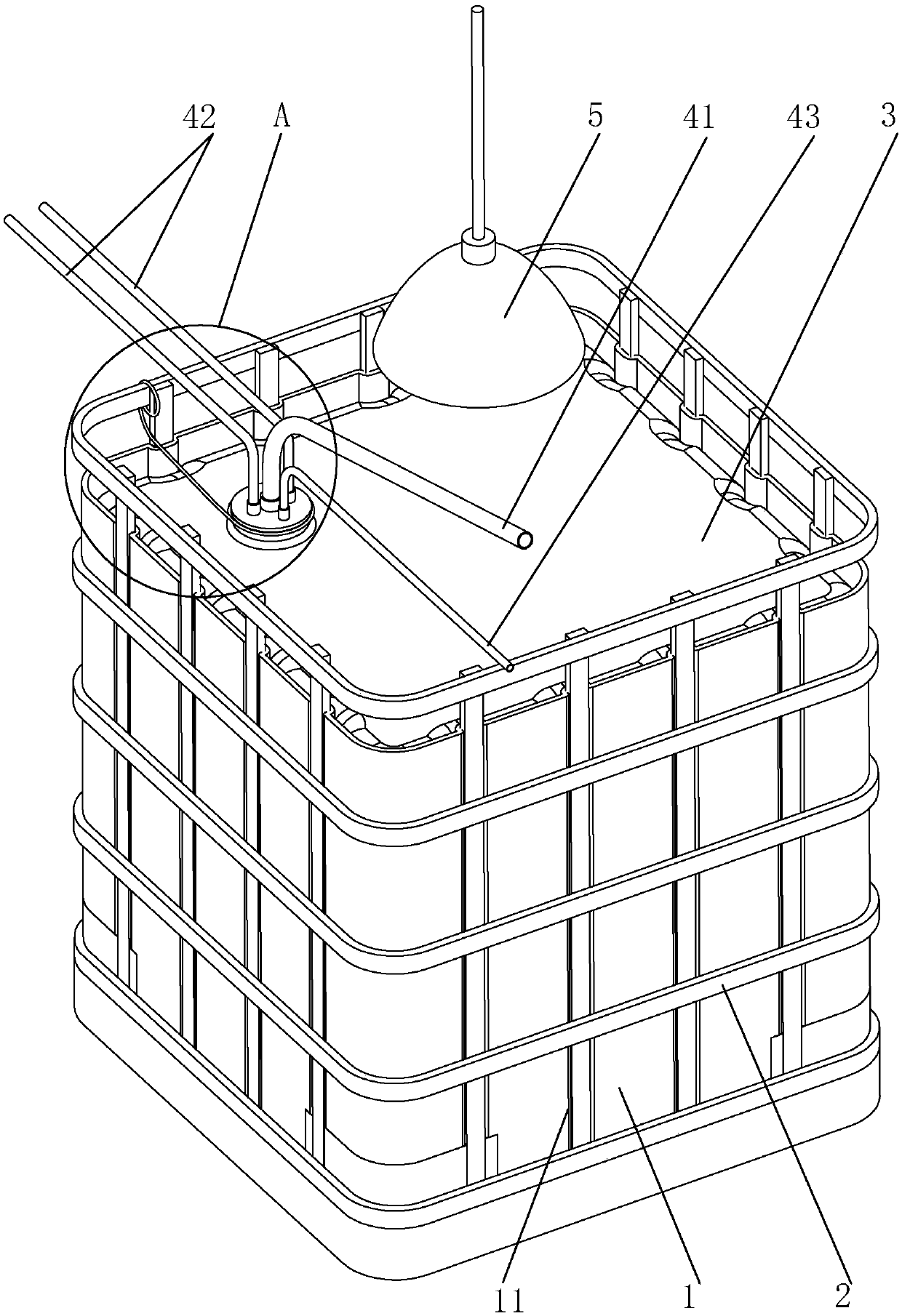

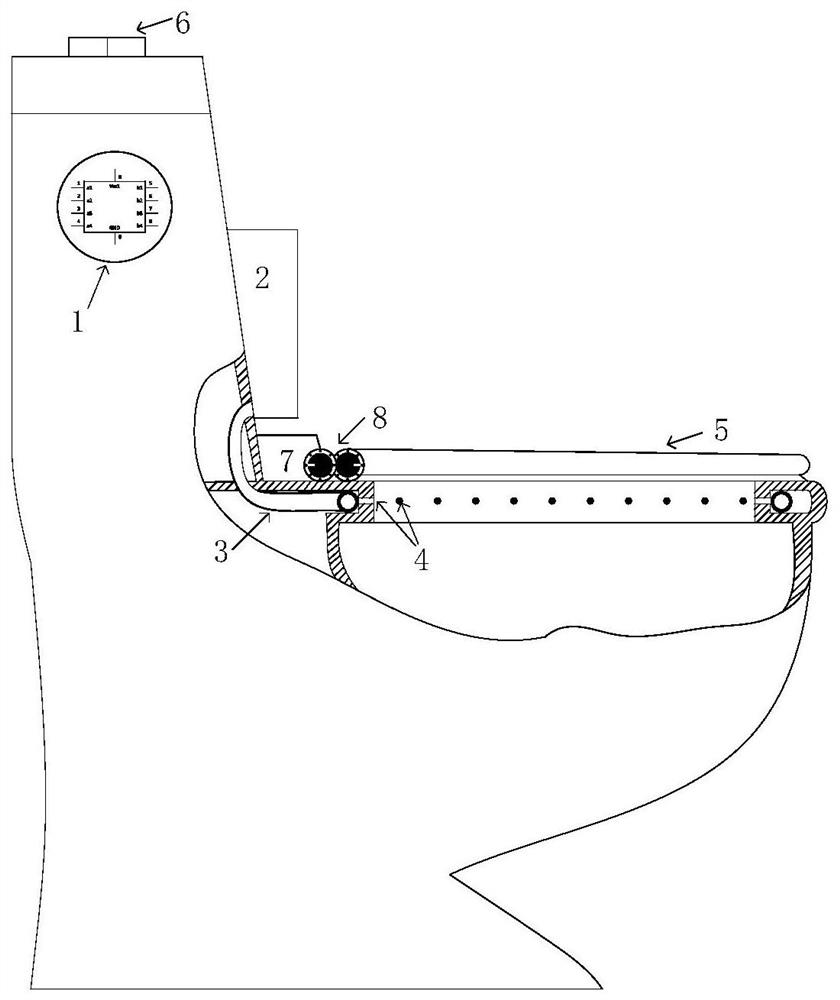

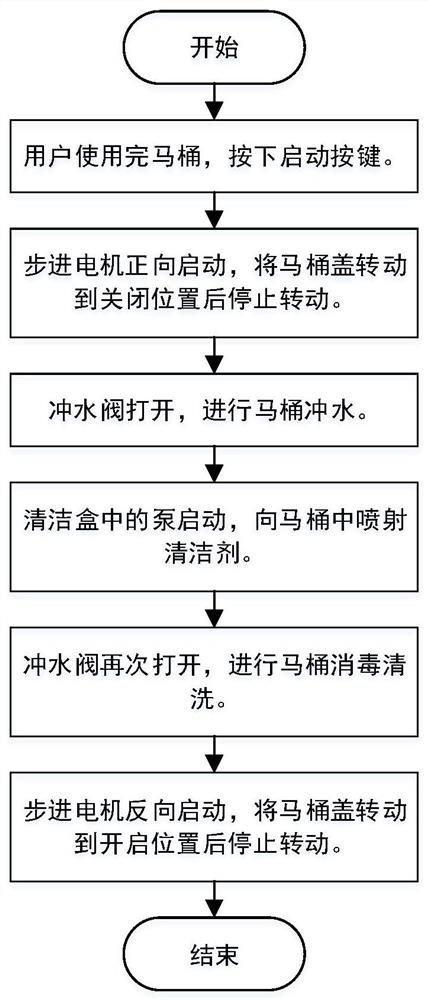

Intelligent closestool capable of automatically cleaning and preventing germ spreading and operation method thereof

InactiveCN111679624APrevent proliferationAvoid spreadingWater closetsFlushing devicesMicrocontrollerControl system

The invention discloses an intelligent closestool capable of automatically cleaning and preventing germ spreading and an operation method thereof, belonging to the technical field of smart home. The intelligent closestool is composed of a control system, a flushing system, a cleaning system and a closestool lid action system, wherein action instructions are sent to the control system, the flushingsystem, the cleaning system and a closetool lid through a programmable microcontroller, an operator presses down a starting key once, and the closestool can automatically complete a series of actionsof closing the closestool lid, flushing water, spraying a cleaning agent, flushing water and opening the toilet lid under the control of the programmable microcontroller. The intelligent closestool omits the trouble that the closestool operator manually opens and closes the closestool lid and cleans the closestool, and effectively prevents germs from diffusing and spreading indoors through excrement.

Owner:YANGZHOU UNIV

Ink-jet printer cartridge

The detachable ink cartridge for line printer includes one sealed casing to hold ink with air pipe, locating board and ink outlet on one side to be connected to the printer, self closing valve with outlet to be the said ink outlet and inlet in the lower part inside the ink cavity, non-return valve with inlet being the air pipe end and outlet in the high part inside the casing. The ink cartridge has relatively simple structure and this makes it possible to simplify the ink filling, cleaning and refilling. Without ink bag, the present invention has low cost and less environmental pollution.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

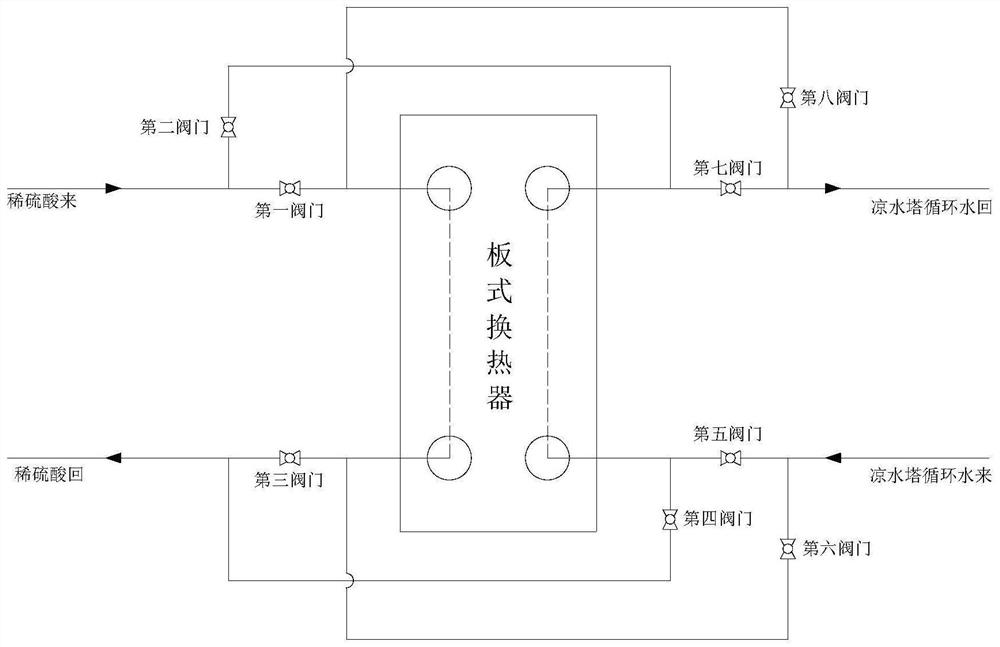

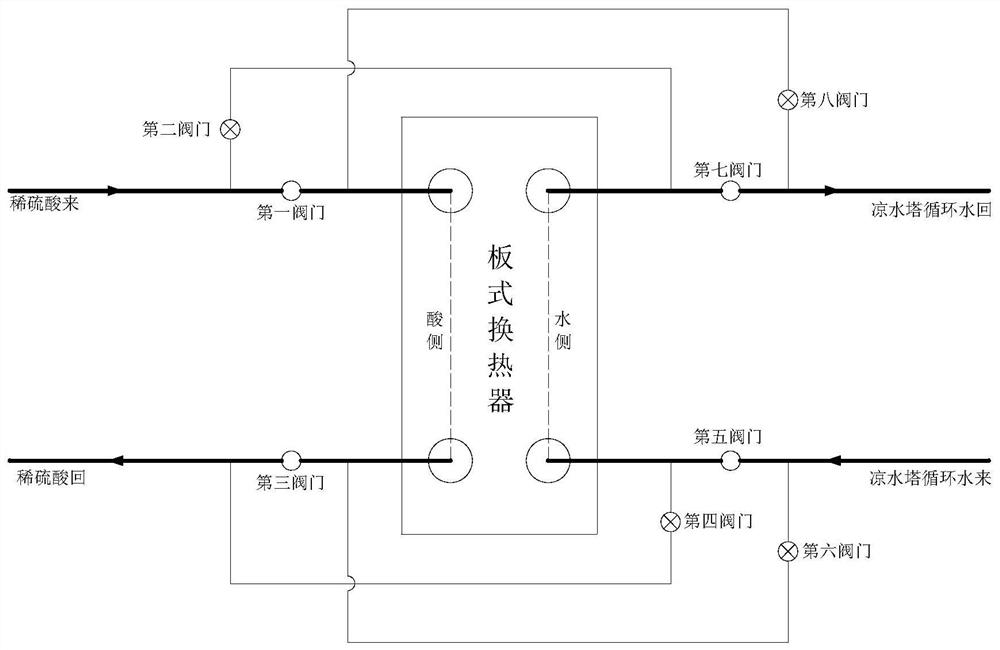

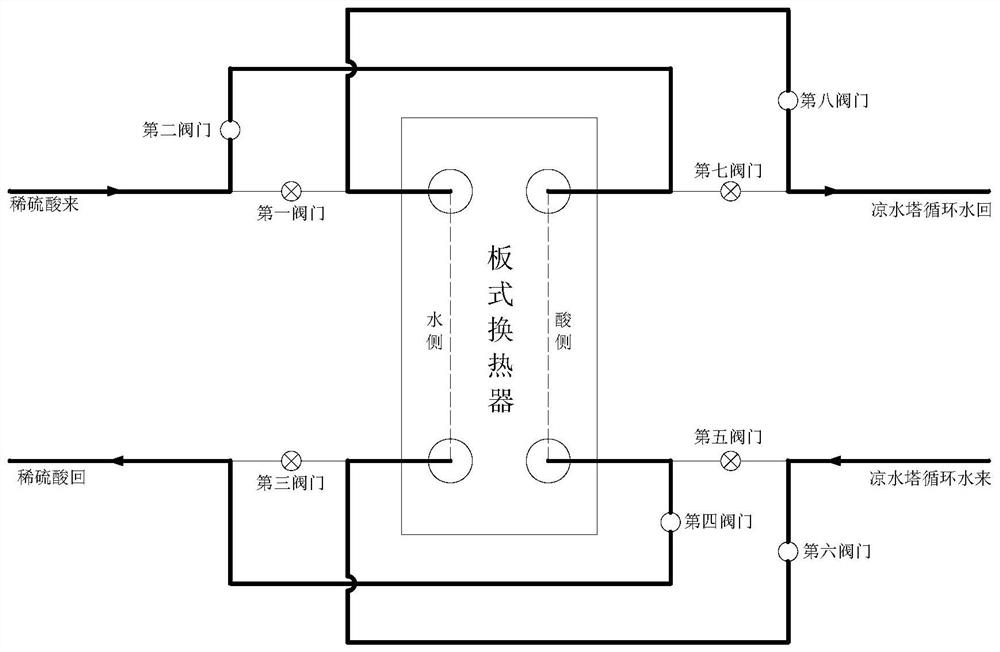

Sulfuric acid purification plate heat exchanger cleaning-free system and using method

PendingCN112797839AAchieve descaling effectImprove heat transfer effectFlush cleaningPlate heat exchangerEngineering

The invention discloses a sulfuric acid purification plate heat exchanger cleaning-free system and a using method, and belongs to the technical field of heat exchangers. The sulfuric acid purification plate heat exchanger cleaning-free system comprises a first production system and a second production system, wherein the first production system comprises a first dilute sulfuric acid injection pipe and a first water cooling tower circulating water injection pipe, the tail end of the first dilute sulfuric acid injection pipe is fixedly connected to a plate heat exchanger, a first valve is fixedly connected to the first dilute sulfuric acid injection pipe, a first dilute sulfuric acid discharging pipe is fixedly connected to the plate heat exchanger, and a third valve is fixedly connected to the first dilute sulfuric acid discharging pipe. According to the sulfuric acid purification plate heat exchanger cleaning-free system and the using method, the water side and the acid side of the plate heat exchanger can be exchanged through opening and closing of the valves, the heat exchange effect can reach normal within 15 minutes of exchange, the maintenance time is saved, a cleaning agent and manpower are saved, and the economic benefit is increased.

Owner:卢龙县双益磷化有限责任公司

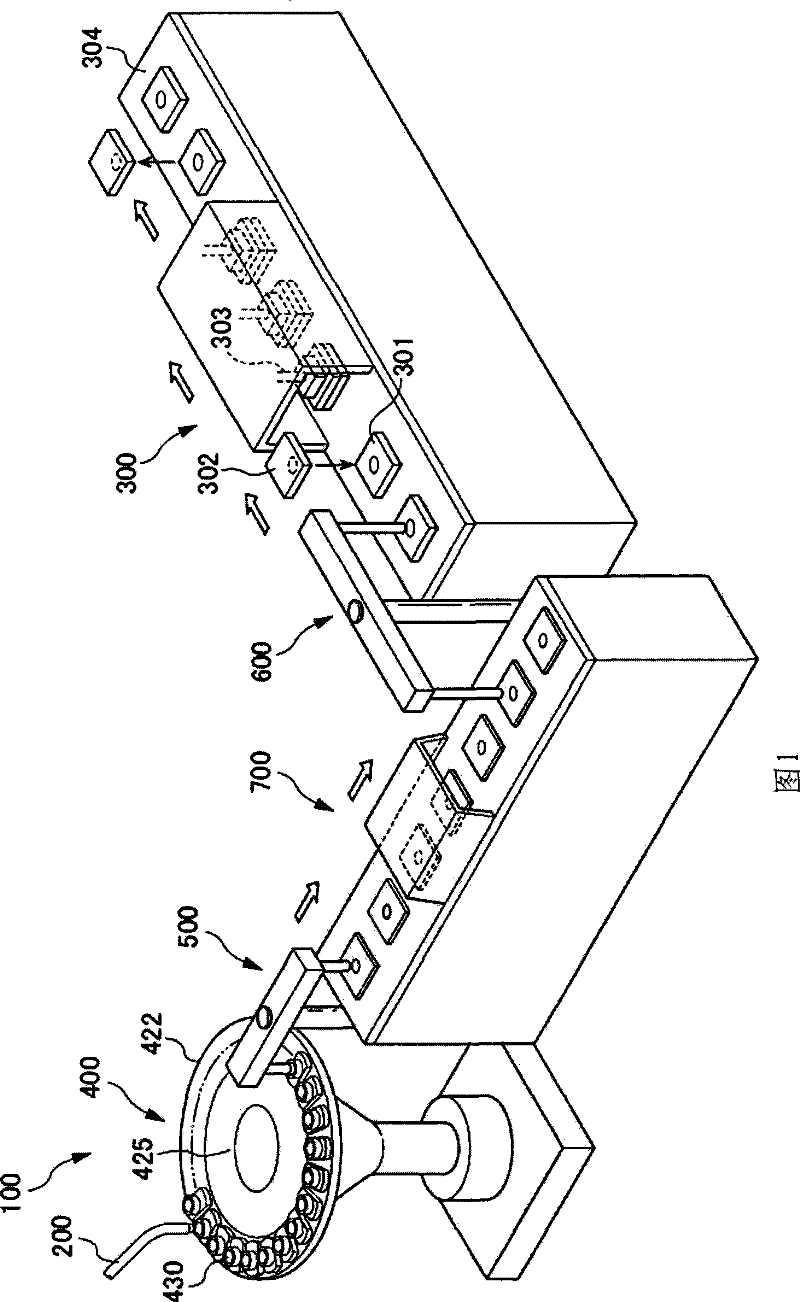

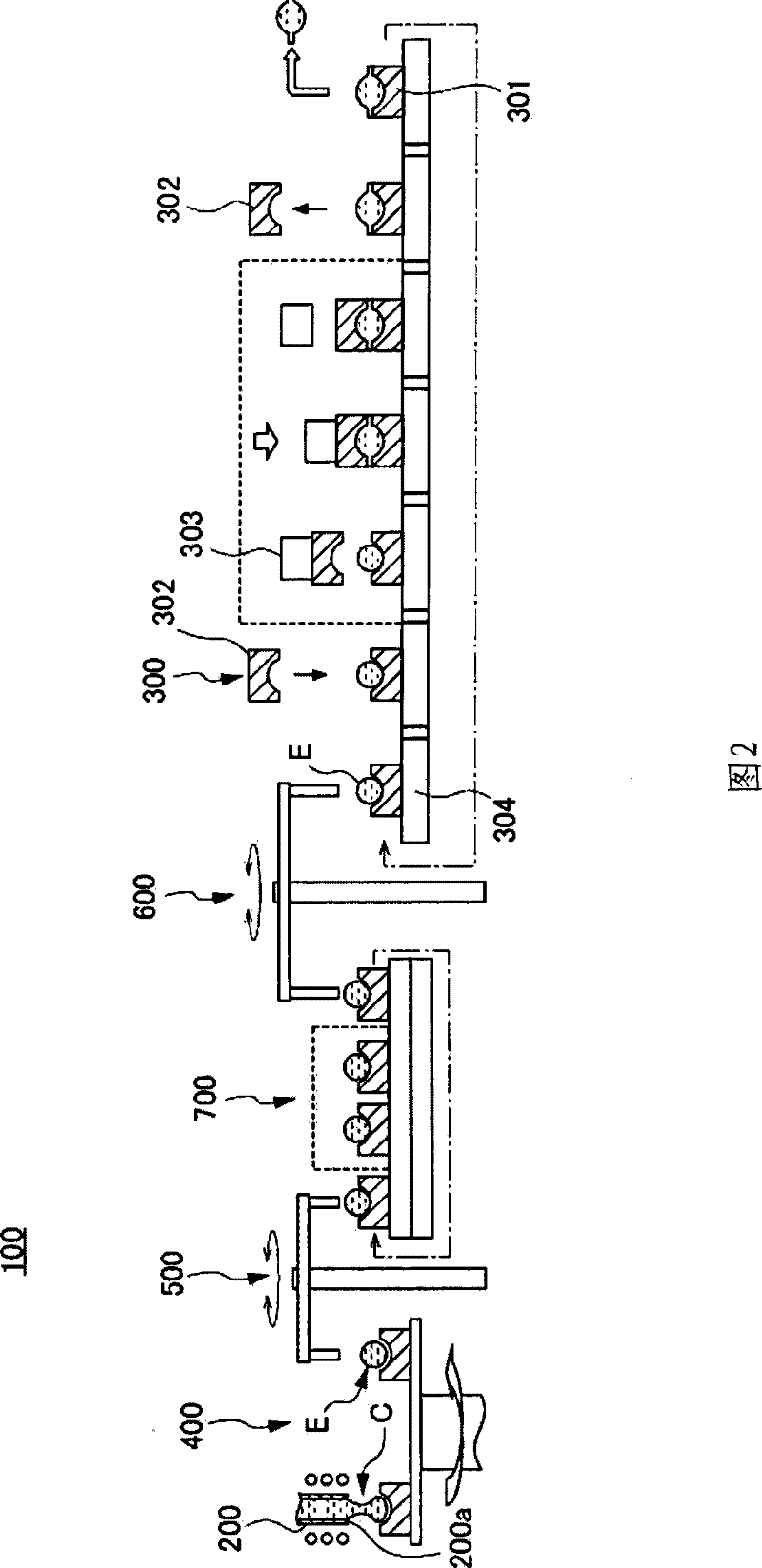

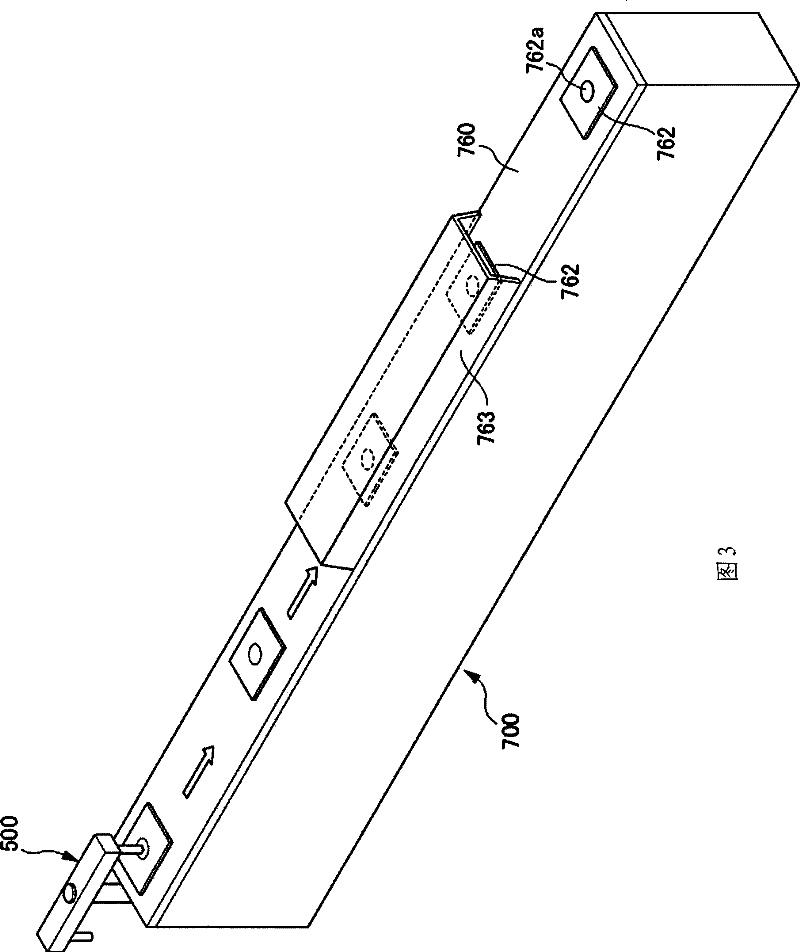

Device and method for manufacturing optical elements

InactiveCN101293728BEfficient preparationIncrease production capacityGlass pressing apparatusGlass productionFused glassEngineering

The invention provides a manufacturing apparatus which manufactures an optical element by fused glasses for manufacturing preformed body within a time consistent with the time for precise press forming, as well as a method for manufacturing an optical element by fused glasses. The manufacturing apparatus 100 of optical element in the invention comprises: (i) a glass block manufacturing apparatus 400 which fuses optical glasses and cuts the fused glasses into determined volume or mass to form glass blocks; (ii) a conveyor 700 for conveying glass blocks; and (iii) a precise press forming apparatus 300 for precisely press forming the conveyed glass blocks. The manufacturing apparatus 100 of optical element further comprises an adjusting mechanism. The average number of hours which the precise press forming takes in the precise press forming apparatus 300 is set to be a (second / piece); the number of precise press forming apparatus 300 is set to be b; the number of hours which forming of glass block takes in the glass block manufacturing apparatus 400 is set to be c (second / piece); the adjusting mechanism adjusts c to make a / b is not greater than c.

Owner:OHARA

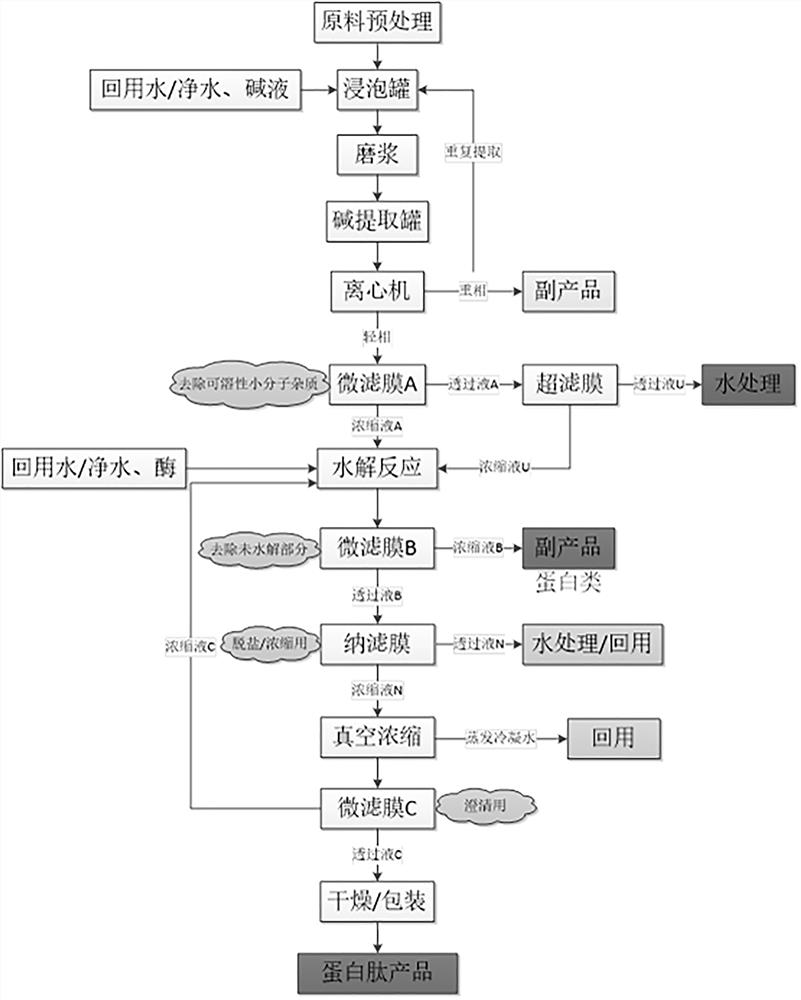

Clean production method for industrialized production of plant protein peptide

PendingCN111778306AAcid precipitationOmit cleaningPeptide preparation methodsFermentationBiotechnologyAlkaline water

The invention belongs to the field of deep processing of cereals, miscellaneous beans and tubers, and in particular relates to a clean production method for industrialized production of plant proteinpeptide. For the existing problems of being long in production period, not environmentally-friendly, high in salt content, high in wastewater treatment difficulty, high in operation cost and the like,the following scheme is provided: the method comprises the following steps of: S1, soaking and grinding: soaking by utilizing alkaline water for 1-3 h with the pH of 9-11, the temperature of 20-50 DEG C and the liquid-solid ratio of 1:(2-5), and, after the tissue is soft, performing wet grinding to 80-200 meshes; S2, performing alkali extraction: putting the slurry in the step S1 into a constant-temperature stirring tank, stirring to extract the protein component at 20-50 DEG C for 2-4 h; and S3, performing centrifugal separation. The clean production method in the invention can increase theprotein peptide extraction efficiency, increase the yield, reduce high organic wastewater discharge, reduce environmental pollution and reduce the enterprise production input cost, and has extremely wide market prospect.

Owner:无锡海思瑞科技有限公司

Processing method of slot antenna, slot antenna and mobile terminal

ActiveCN106898866BHigh strengthSimple processRadiating elements structural formsAntenna equipments with additional functionsMetal stripsMetallurgy

Owner:VIVO MOBILE COMM CO LTD

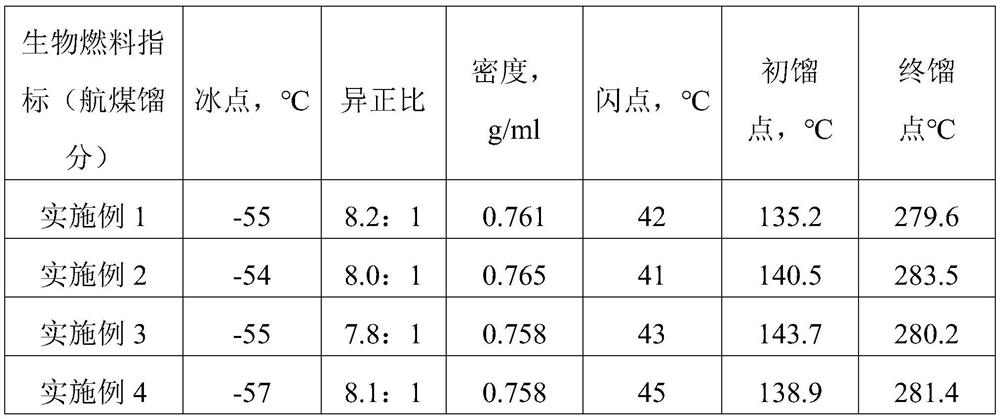

Method for preparing biofuel by taking elaeagnus angustifolia kernels as raw material and obtained biofuel

ActiveCN113061453AReduce process stepsShorten the time required for the processBiofuelsLiquid hydrocarbon mixture productionProcess engineeringCatalytic hydrogenation

The invention provides a method for preparing biofuel by taking elaeagnus angustifolia kernels as a raw material. The method comprises the following steps: step 1, drying and crushing elaeagnus angustifolia kernels, and adding the crushed kernels into a solvent for dipping to obtain extracted mixed oil; 2, mixing the extracted mixed oil with acid liquor, and performing layering to obtain refined mixed oil; and 3, under the action of a hydrogenation catalyst, carrying out catalytic hydrogenation on the refined mixed oil to generate the biofuel. The biofuel prepared by adopting the method is good in quality, high in calorific value and almost free of aromatic hydrocarbon, olefin, sulfur, nitrogen and the like, the production process flow is simple and easy to implement, the production cost is low, and large-scale production is facilitated.

Owner:PETROCHINA CO LTD

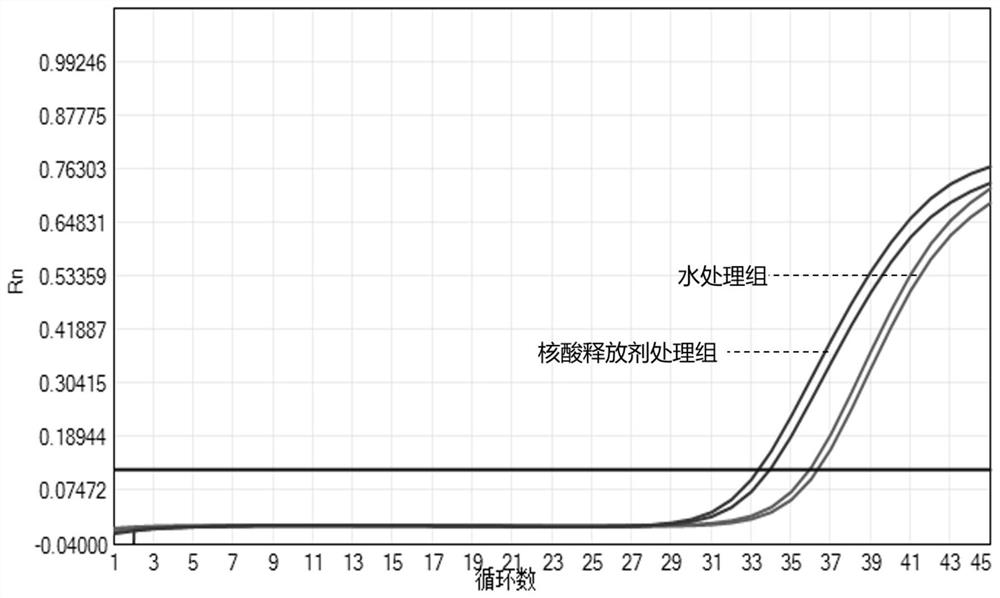

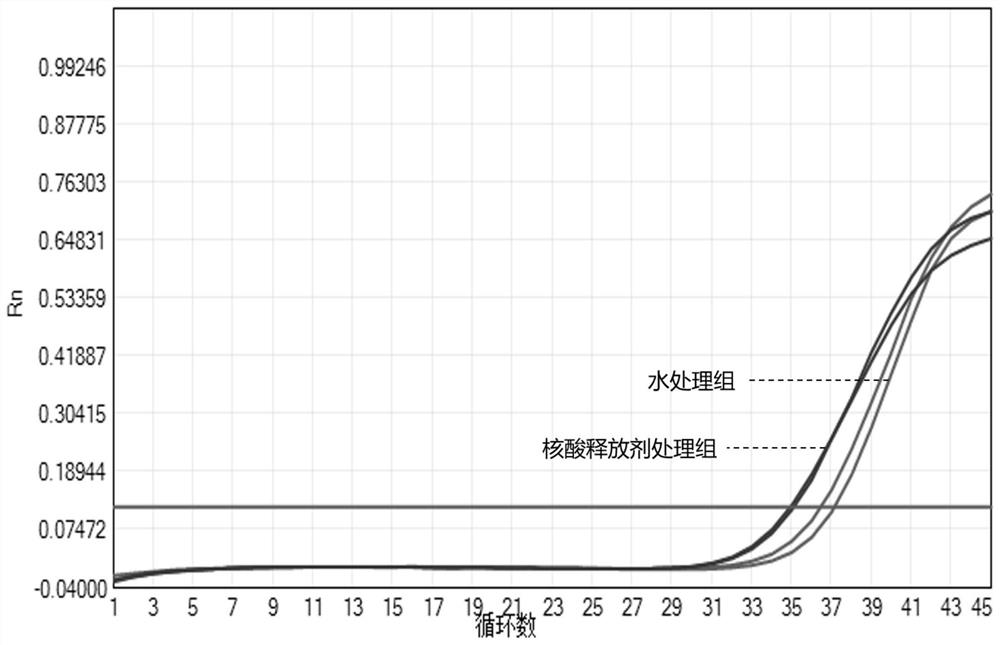

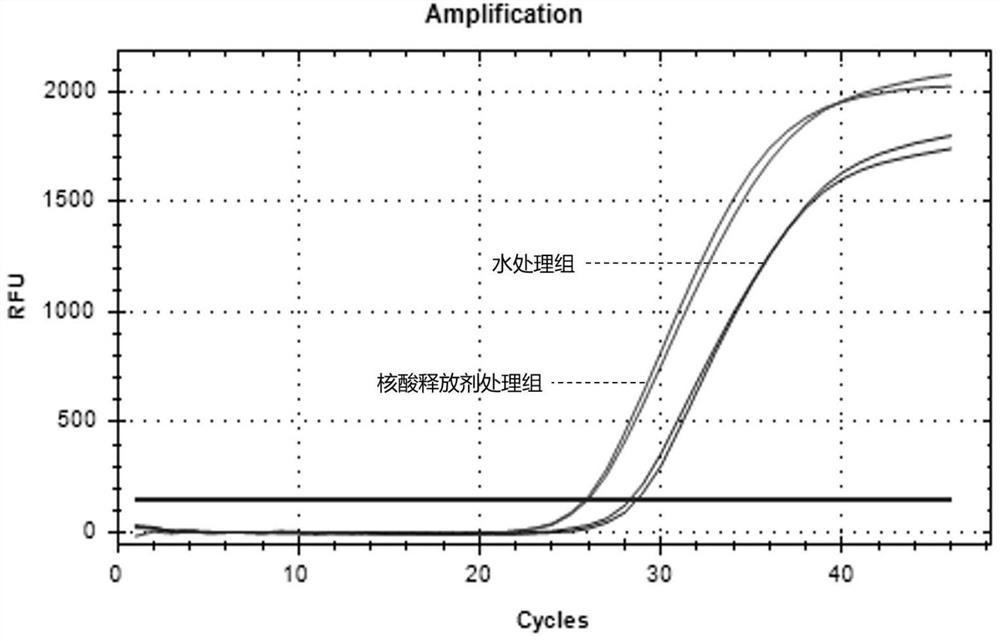

Solid-phase particle material for treating biological sample and biological sample treatment method

PendingCN113584128AInhibit enzyme activityHas hardnessMicrobiological testing/measurementMaterials scienceCell

The invention provides a solid-phase particle material for treating a biological sample, the solid-phase particle material takes a high-molecular polymeric material or a gel material as a core, magnetic particles can be contained in the core or on the surface of the core, a composite structure of the magnetic particles and the core is externally coated with a polymer coating, the surface of the coating is modified with weak cation exchange groups, the weak cation exchange groups can chelate metal ions and adsorb proteins. The invention further discloses a corresponding biological sample treatment method. The related raw materials comprise the solid-phase particle material and the nucleic acid releasing agent. The solid-phase particle material is a weak cation exchange material, and the nucleic acid releasing agent has the effects of splitting cells and viruses, inhibiting nucleic acid degradation and the like. According to the reagent and the method provided by the invention, the sample can be simply and quickly treated, nucleic acid is released, part of impurities are removed, a nucleic acid extraction and purification step is not needed, the time and the material cost are greatly saved, and the reagent and the method have a relatively good application value.

Owner:YEASEN BIOTECHNOLOGY (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com