Ink-jet printer cartridge

A technology of inkjet printers and ink cartridges, which is applied in printing and other fields, can solve the problems of ink cartridges with complex structure, complicated process, high manufacturing and use costs, and achieve the effects of simplifying cleaning and filling processes, reducing environmental pollution, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

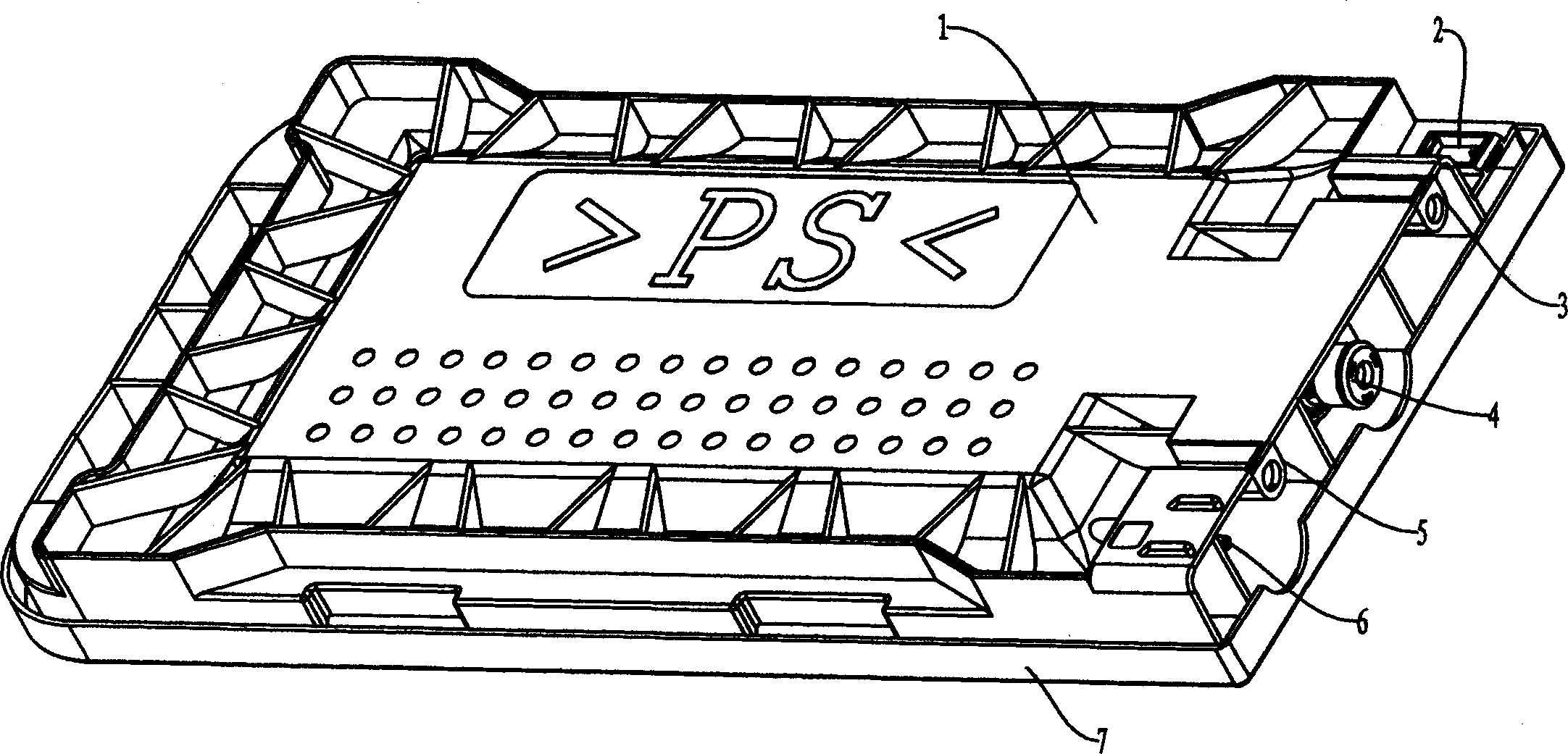

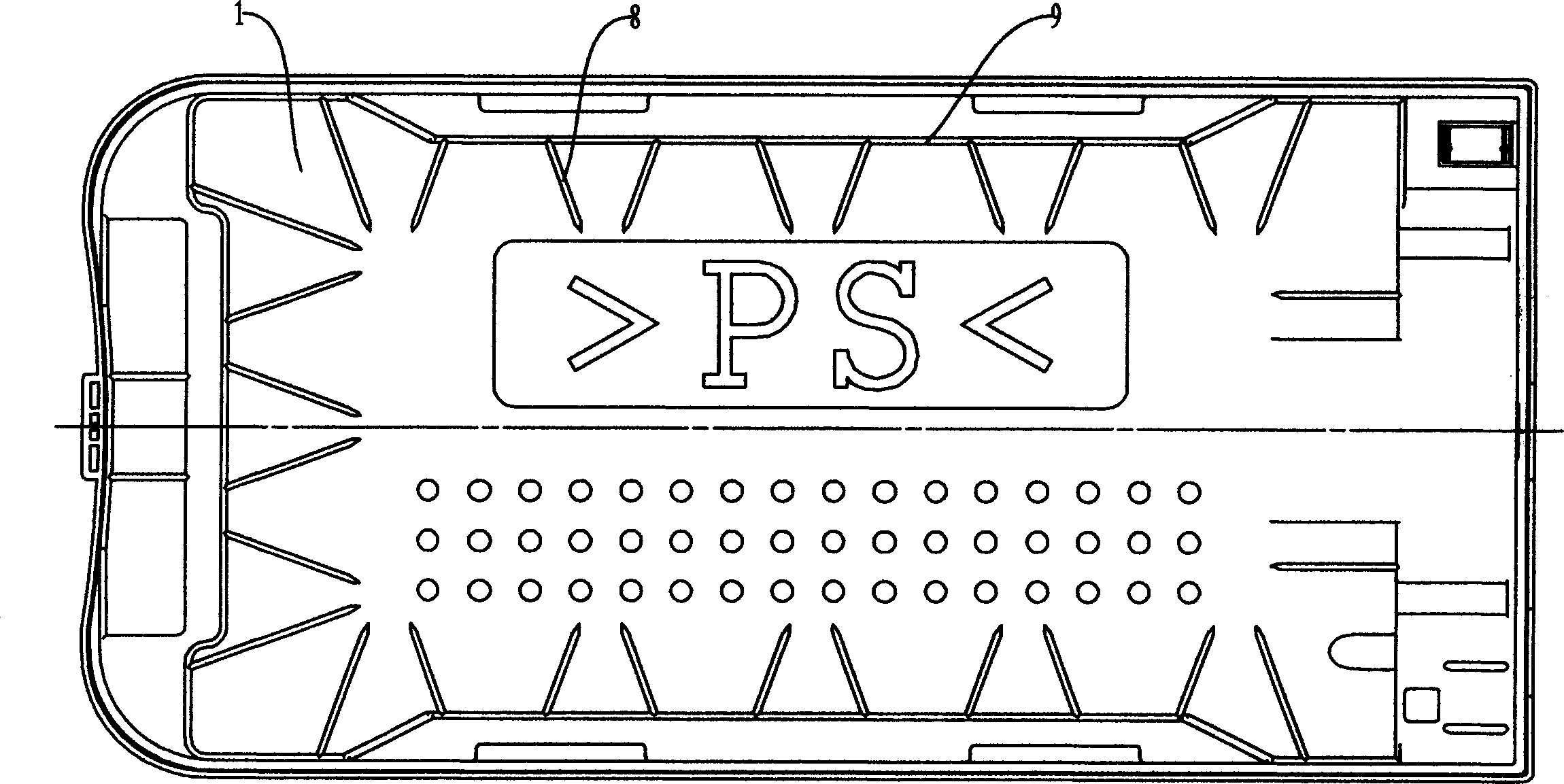

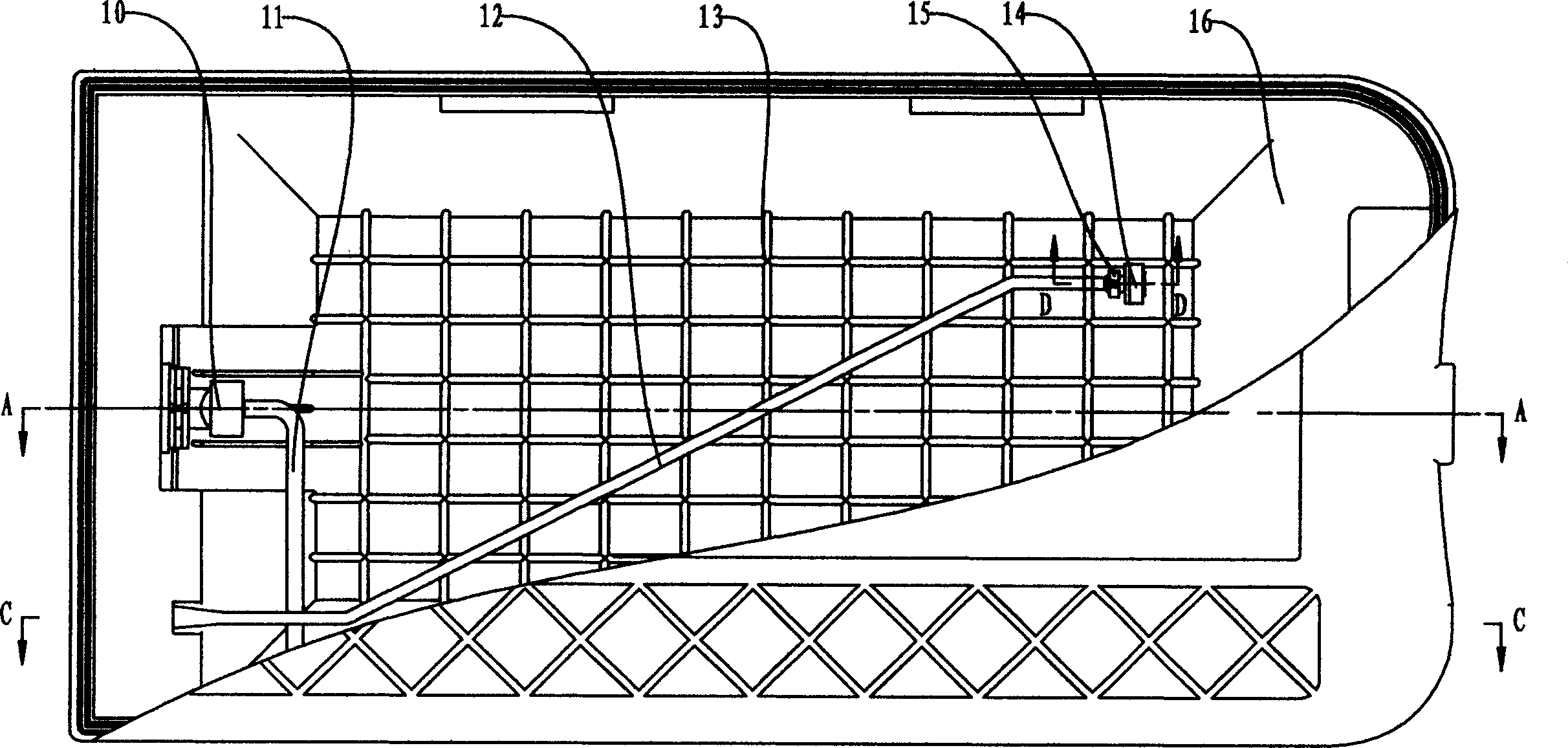

[0025] see figure 1 , The ink cartridge is composed of a housing 1 close to a cube and a cover 7 that seals its opening. The two can be sealed and connected by ultrasonic fusion welding, and the inside is an ink chamber. Seen from the position after installation, the front end has a circuit board base 2 for storing and reading out ink information from top to bottom, positioning plates 3 and 5 with positioning holes, ink outlet 4 and Trachea6. A circuit substrate that can maintain a good electrical connection with the relevant plug-in line in the printer box compartment can be fixed on the substrate seat 2. The ink outlet 4 and the air pipe 6 are also sealed and docked with the ink guide tube and the air pump tube in the box compartment respectively. The self-closing valve is immediately turned on, so that the ink outlet 4 is in the state of being able to supply ink to the ink pipe. When the print head needs to supply ink, the central processing unit of the printer will give a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com