Explosive charging system and method

A technology of a charging system and a transfer device, which is applied in chemical instruments and methods, transportation and packaging, dissolution, etc., can solve the problems of low production efficiency and long operation time, and achieve small energy loss, short mixing time, and mixing uniformity. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

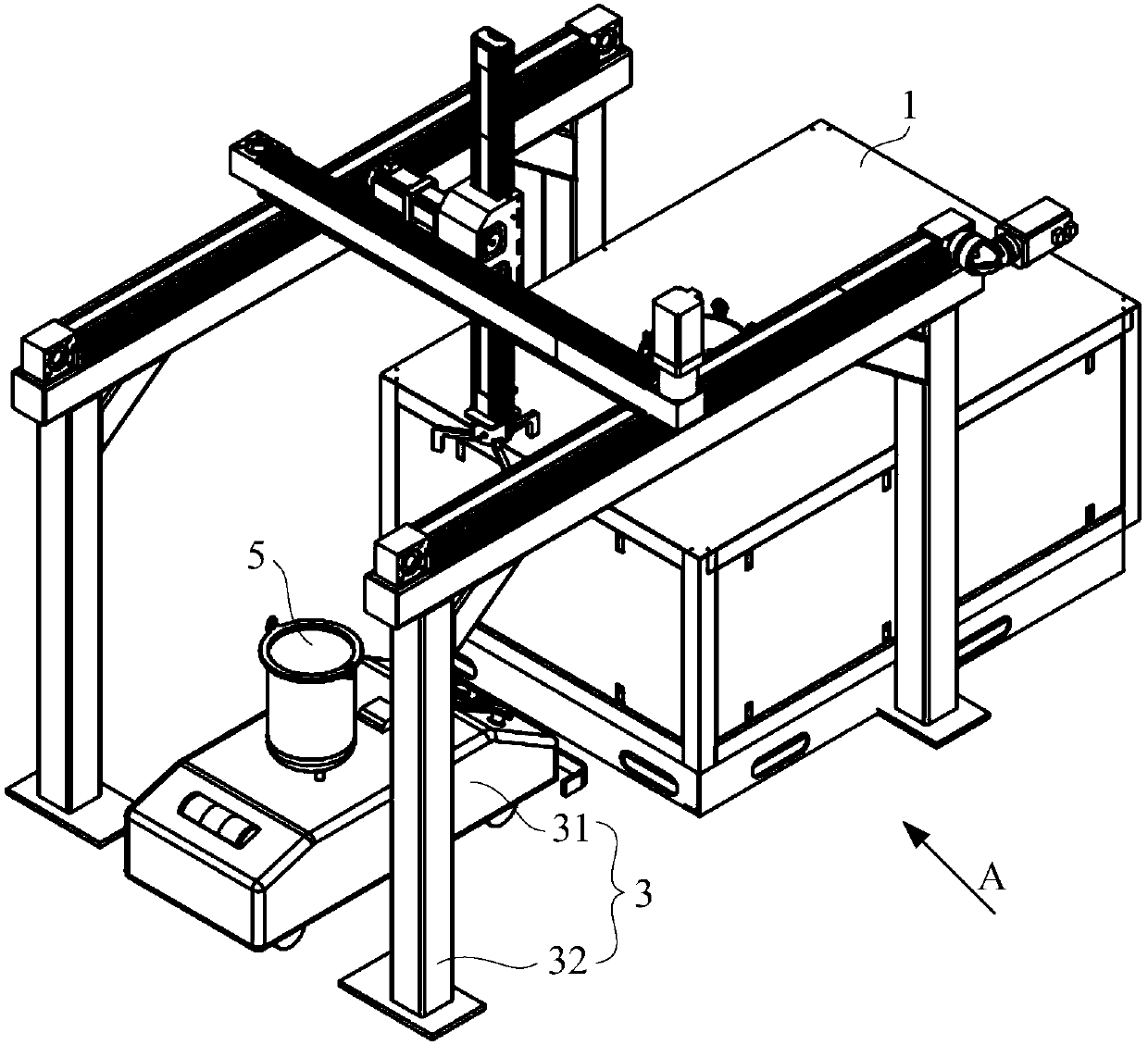

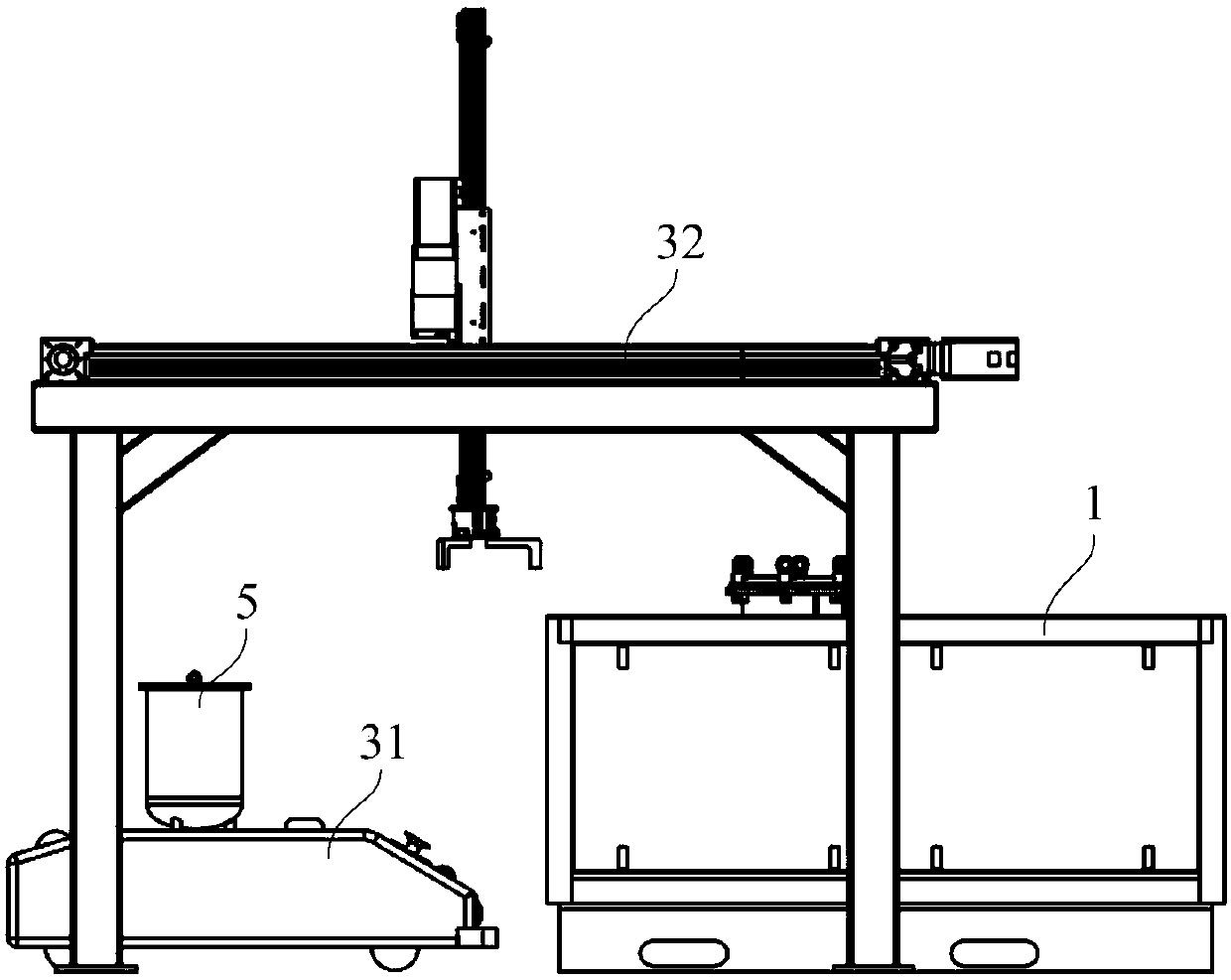

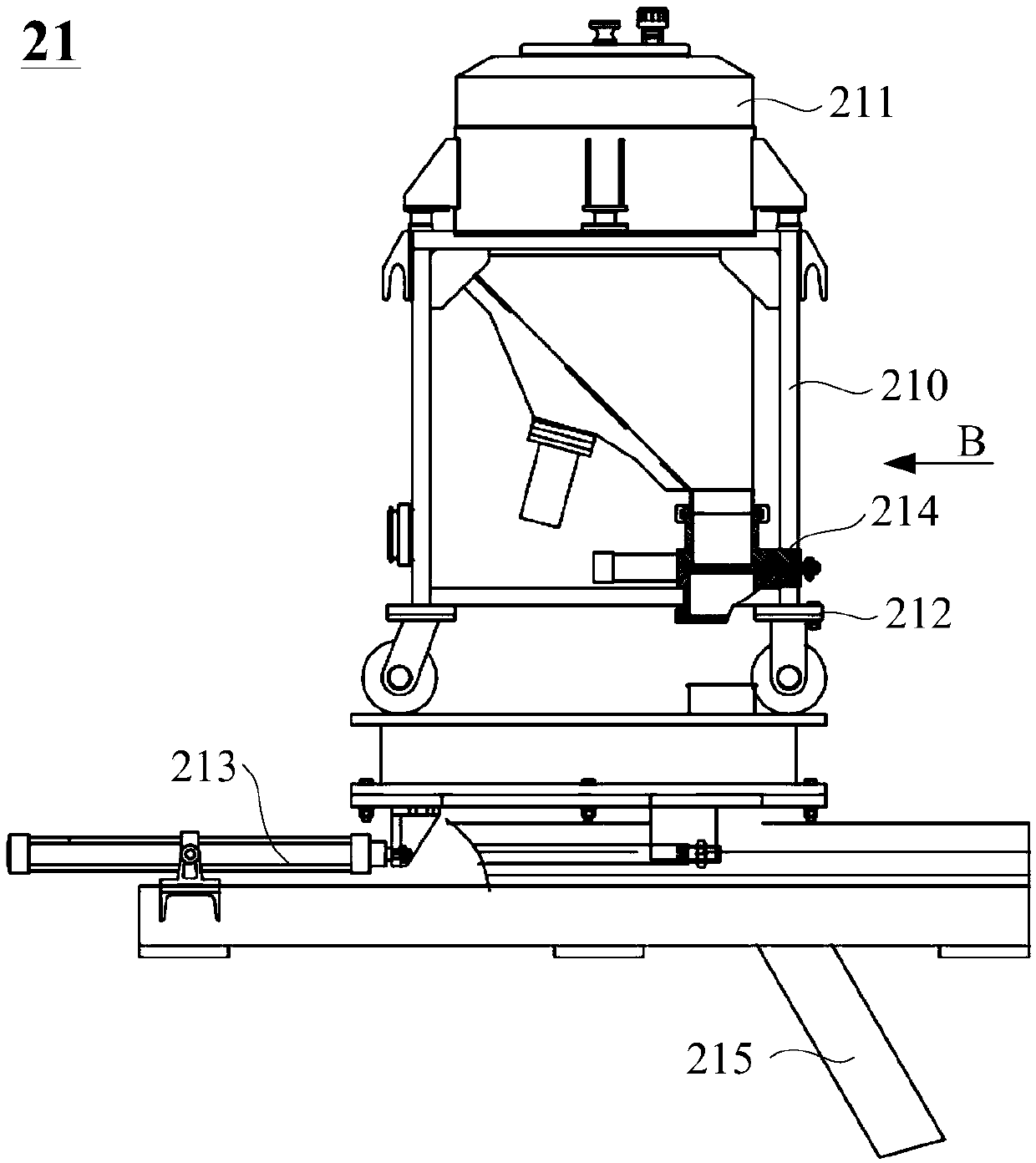

[0063] The embodiment of the present application provides a charging system of solid propellant slurry and PBX explosive, such as figure 1 , image 3 and Figure 4 As shown in the structure, the charging system includes a mixer 1, an automatic feeding device 2, an automatic material transfer device 3, a control device 4 and a mixing container 5; as Figure 7 As shown in the structure, the control device 4 is signal-connected with the mixer 1, the automatic feeding device 2 and the automatic material transfer device 3, and is used to control the actions of the mixer 1, the automatic feeding device 2 and the automatic material transfer device 3;

[0064] Mixer 1 is used to drive the mixing vessel 5 that the material to be mixed is housed to vibrate, and controls the temperature, vacuum degree, vibration acceleration and mixing time of mixing vessel 5; Mixing vessel 5 can be figure 1 and figure 2 Mixing pots, stainless steel or plastic containers as shown in the structure, ca...

Embodiment 2

[0088] The embodiment of the present application provides a charging method using the charging system described above, such as Figure 8 and Figure 9 Shown, charging method comprises the following steps:

[0089] Step S10, the automatic material transfer device 3 transports the mixing container 5 to the mixer 1;

[0090] Step S20, the automatic feeding device 2 adds the materials to be mixed into the mixing container 5 according to the preset mass ratio;

[0091] Step S30, using the mixer 1 to mix the materials to be mixed in the mixing container 5 according to preset parameters, and the preset parameters include resonance acceleration, temperature, vacuum degree and preset mixing time;

[0092] In step S40, the automatic material transfer device 3 transports the mixing container 5 to a designated location.

[0093] In the above charging method, the automatic material transfer device 3 transports the mixing container 5 to each device for corresponding operation. The automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com