Outdoor plastics sliding doors no need welding molding

A technology of welding forming and sliding doors, which is applied in the field of plastic doors, can solve the problems of large consumption of packaging materials, large space for storage and transportation, and high requirements for product protection, so as to reduce transportation and storage costs and save welding seam cleaning processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

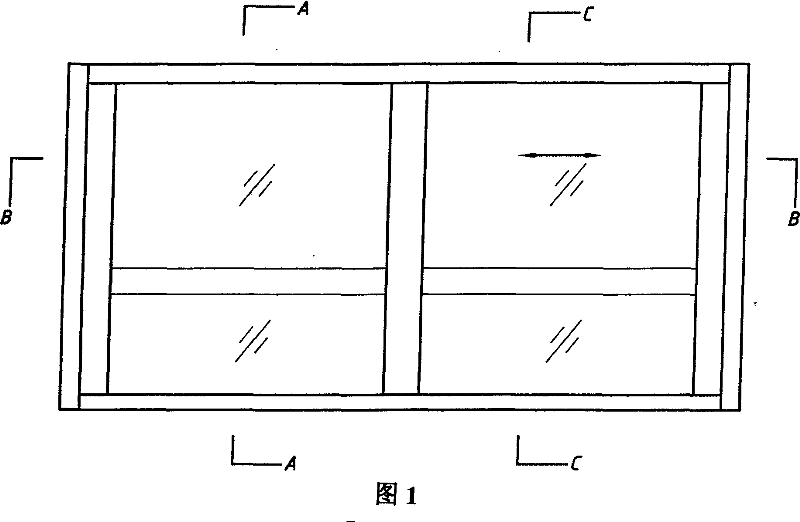

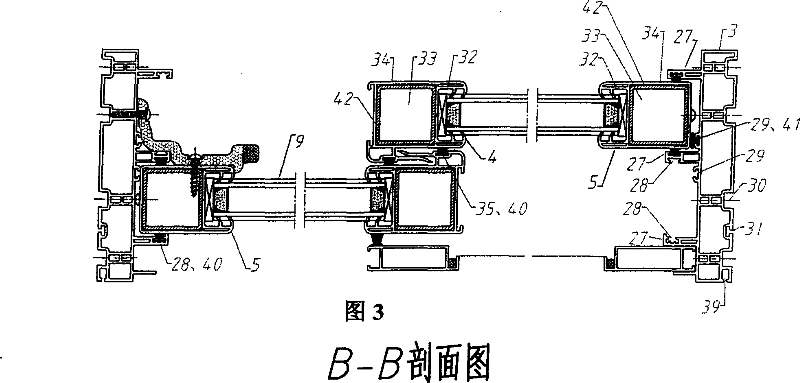

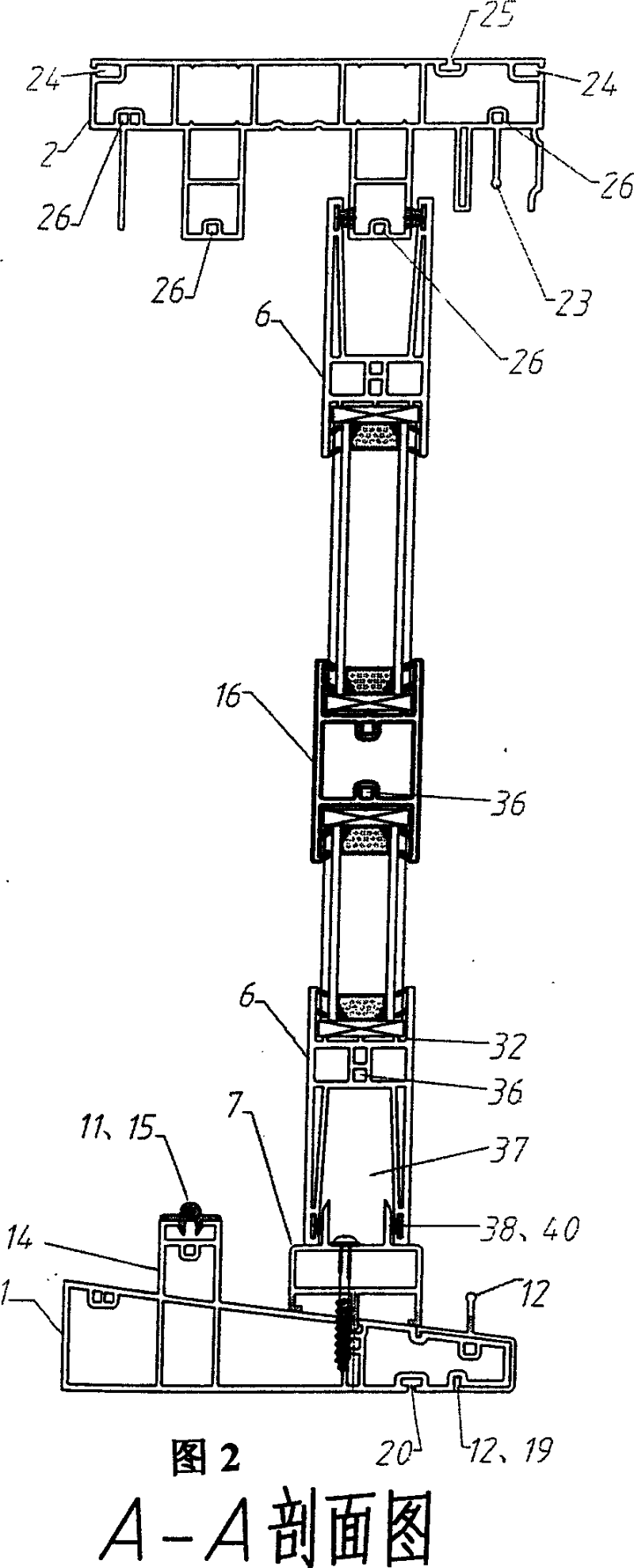

[0018] The accompanying drawings are embodiments of the present invention, and the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0019] See the attached figure for details, a plastic outdoor sliding door that does not need to be welded and formed, including an outer frame composed of a threshold 1, a top frame 2, and a side frame 3, and a middle vertical leaf 4, a side vertical leaf 5, and a top and bottom leaf 6. Plastic profiles such as stiles 16 for the opening fan, non-opening fan, and grid fan facade, and supporting aluminum alloy profiles 11 and 12, the outer frame profiles are 90° lapped, and the laps are fastened by screws , the joints of the stile profiles 16 for the sliding door to open, not open, and partition facade are 90°, and the mortise and tenon joints are inserted and fastened by screws 10.

[0020] The outer frame is composed of a threshold profile 1 for the lower p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com