Clean production method for industrialized production of plant protein peptide

A plant protein peptide and clean production technology, applied in the deep processing of miscellaneous beans, tubers, and grains, can solve the problems of difficult wastewater treatment, unfriendly environment, and high operating costs, so as to reduce production input costs and broaden market prospects , the effect of improving the extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

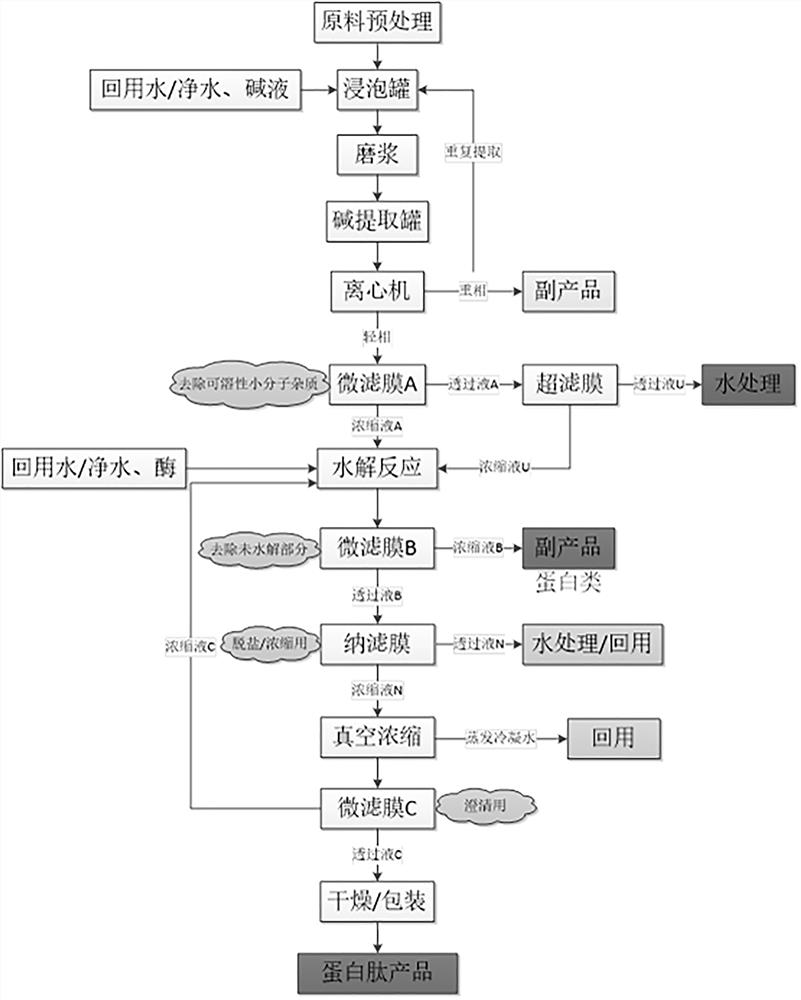

[0030] refer to figure 1 , a clean production method capable of industrially producing vegetable protein peptides, comprising the following steps:

[0031] S1: soaking and refining: raw materials (including but not limited to rice, wheat, oats, buckwheat, quinoa, barley, corn, potatoes, sweet potatoes, soybeans, chickpeas, peas, mung beans, etc.), utilization (sodium hydroxide or hydrogen (prepared with potassium oxide) alkaline water, pH=9, temperature 20°C, liquid-solid ratio 1:2, soak for 1 hour, after the tissue is soft, wet grinding, 80 mesh;

[0032] S2: Alkaline extraction: put the slurry in S1 in a constant temperature stirring tank at a temperature of 20°C, and stir to extract protein components for 2 hours;

[0033] S3: Centrifugal separation: The extraction liquid in S2 is separated from solid to liquid by a horizontal screw centrifuge, the heavy phase slag is returned to the wet refining step for repeated extraction, and the light phase liquid enters the next proc...

Embodiment 2

[0041] refer to figure 1 , a clean production method capable of industrially producing vegetable protein peptides, comprising the following steps:

[0042] S1: soaking and refining: raw materials (including but not limited to rice, wheat, oats, buckwheat, quinoa, barley, corn, potatoes, sweet potatoes, soybeans, chickpeas, peas, mung beans, etc.), utilization (sodium hydroxide or hydrogen (prepared with potassium oxide) alkaline water, pH=10, temperature 35°C, liquid-solid ratio 1:3, soak for 2 hours, after the tissue is soft, wet grinding, 150 mesh;

[0043] S2: Alkaline extraction: put the slurry in S1 in a constant temperature stirring tank at a temperature of 35°C, and stir to extract protein components for 3 hours;

[0044] S3: Centrifugal separation: The extraction liquid in S2 is separated from solid to liquid by a horizontal screw centrifuge, the heavy phase slag is returned to the wet refining step for repeated extraction, and the light phase liquid enters the next p...

Embodiment 3

[0052] refer to figure 1 , a clean production method capable of industrially producing vegetable protein peptides, comprising the following steps:

[0053] S1: soaking and refining: raw materials (including but not limited to rice, wheat, oats, buckwheat, quinoa, barley, corn, potatoes, sweet potatoes, soybeans, chickpeas, peas, mung beans, etc.), utilization (sodium hydroxide or hydrogen (prepared with potassium oxide) alkaline water, pH=11, temperature 50°C, liquid-solid ratio 1:5, soak for 3 hours, after the tissue is soft, wet grinding, 200 mesh;

[0054] S2: Alkaline extraction: put the slurry in S1 in a constant temperature stirring tank at a temperature of 50°C, and stir to extract protein components for 4 hours;

[0055] S3: Centrifugal separation: The extraction liquid in S2 is separated from solid to liquid by a horizontal screw centrifuge, the heavy phase slag is returned to the wet refining step for repeated extraction, and the light phase liquid enters the next p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com