Method for preparing biofuel by taking elaeagnus angustifolia kernels as raw material and obtained biofuel

A technology of biofuel and jujube seed, which is applied in the preparation of liquid hydrocarbon mixture, petroleum industry, hydrotreating process, etc., can solve the problems of large workload, complexity, poor industrial realization, etc., and achieves low production cost and high product quality. The effect of high oil and time saving process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

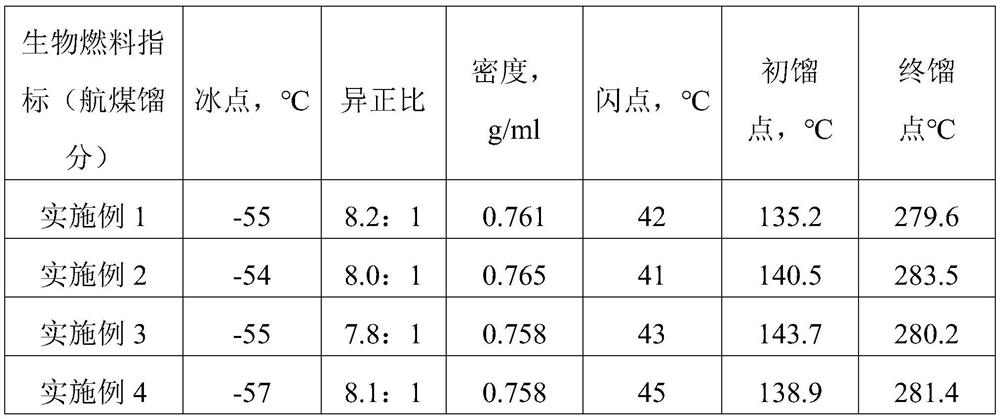

Examples

Embodiment 1

[0038] After drying the jujube, the pulverizer was pulverized into a small powder, spare.

[0039] Take 100 g of the sand jujube powder, 300 g of n-pentane, the temperature is maintained at about 30 ° C for 3 h; filtration, 0.5 g of 10% phosphate and 4g deionized water, the temperature is 50 ° C, the stirring time is 45min Pour the separatory funnel, stand the bottom layer of water, to obtain the mixed oil.

[0040] The purified mixed oil was catalytically hydrogenated with a Ni / Mo catalyst using a Ni / Mo catalyst, a reaction temperature of 330 ° C, a reaction pressure of 4 MPa, a hydrogen ratio of 800: 1, a liquid 3025 g, distillation to obtain carbon nine or more alkane biofuel 25g .

Embodiment 2

[0042] Take 100 g of sand jujube powder, 200 g of n-octane, the temperature is maintained at a temperature of about 120 ° C for 1 h; filter, 0.3 g of 10% phosphate and 3 g of deionized water, the temperature is 85 ° C, stirred after 15min Separation funnel, deposition separation of the underlying water liquid, resulting in a layer of purified mixed oil.

[0043]The Ni / W catalyst was used to catalyze hydrogenation on the fixed bed device, the reaction temperature was 370 ° C, the reaction pressure was 4 MPa, the hydrogen ratio was 800: 1, the liquid received 235 g, and the distillation was cut to obtain carbon nine alkane biofuel 35g. .

Embodiment 3

[0045] Take 100 g of the sand jujube powder, 500 g of n-hexane is added, and the temperature remains at 60 ° C for 1.5 h; filtration, 10% phosphoric acid and 6 g of deionized water in the filtrate, the temperature is 70 ° C, stirred after 25min Separation funnel, deposition separation of the underlying water liquid, resulting in a layer of purified mixed oil.

[0046] The CO / MO catalyst was used to catalyze hydrogenation on the fixed bed device, the reaction temperature was 350 ° C, the reaction pressure was 4 MPa, the hydrogen ratio was 800: 1, the liquid received by 638 g, and the distillation was cut to obtain carbon nine alkane biofuel 38g. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com