Device and method for manufacturing optical elements

A technology for optical components and manufacturing devices, used in manufacturing tools, glass pressing, glass manufacturing equipment, etc., can solve the problems of low material yield and high cold processing cost, and achieve the effect of improving productivity and omitting cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Hereinafter, embodiments of the manufacturing apparatus and manufacturing method of the optical element of the present invention will be described in detail, but the present invention is not limited to the following embodiments at all, and can be implemented with appropriate changes within the scope of the purpose of the present invention. In addition, description may be appropriately omitted for parts that are repeated in description, but this does not limit the gist of the invention.

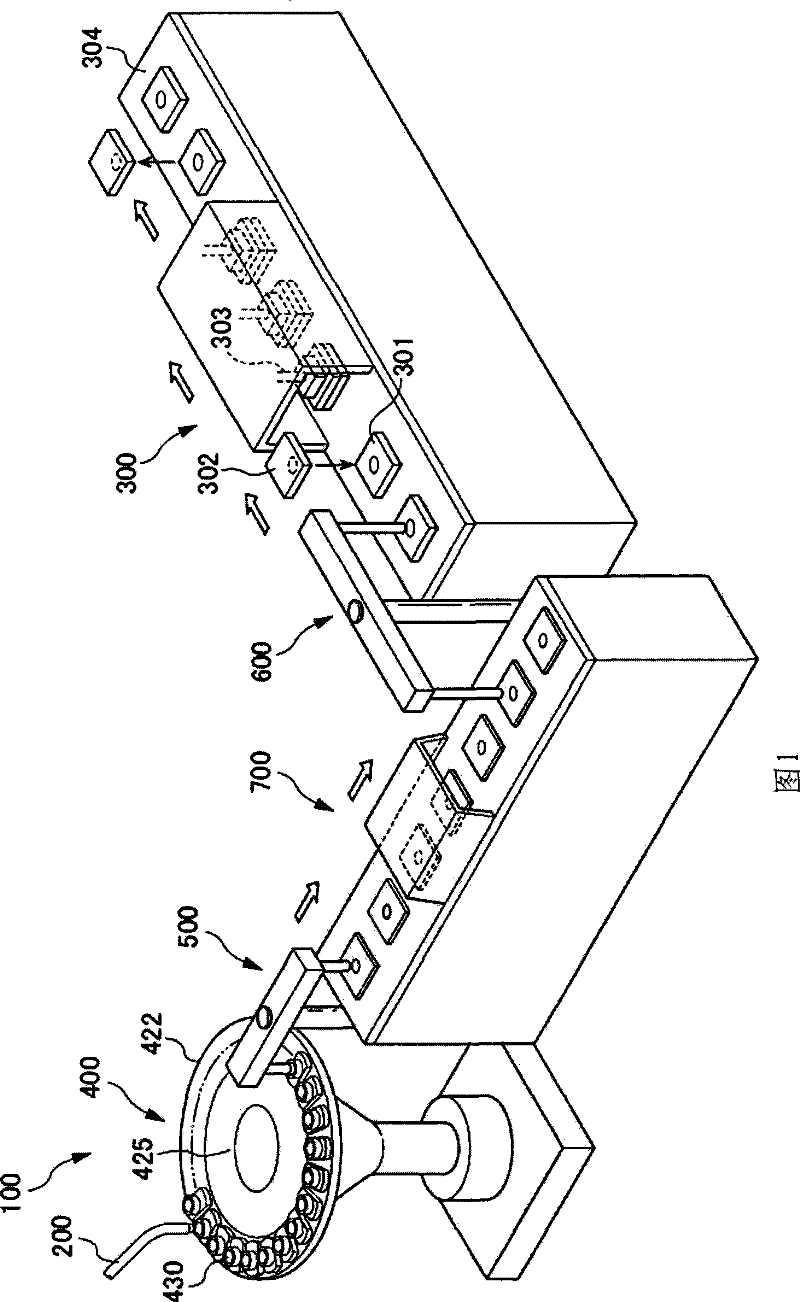

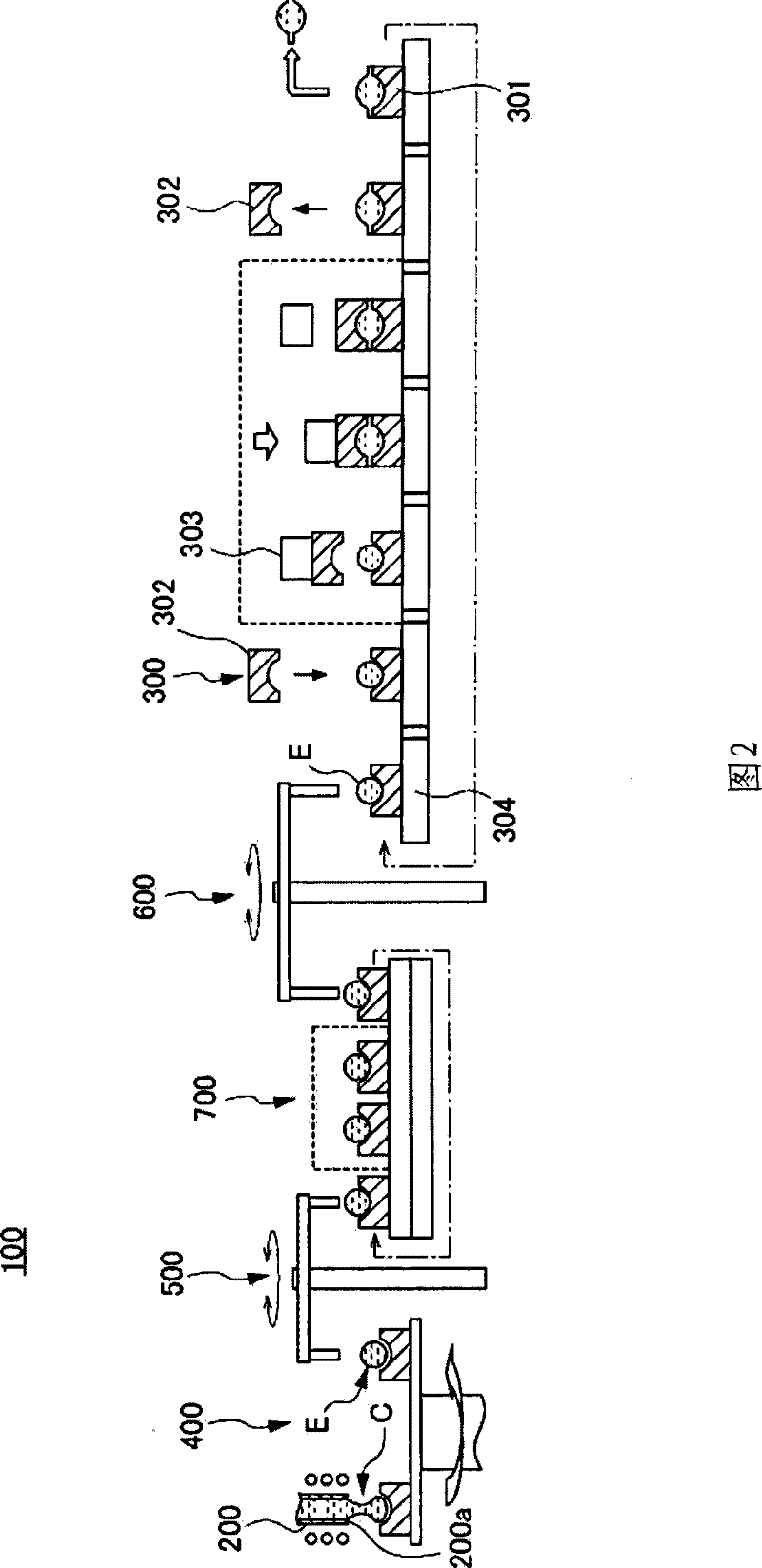

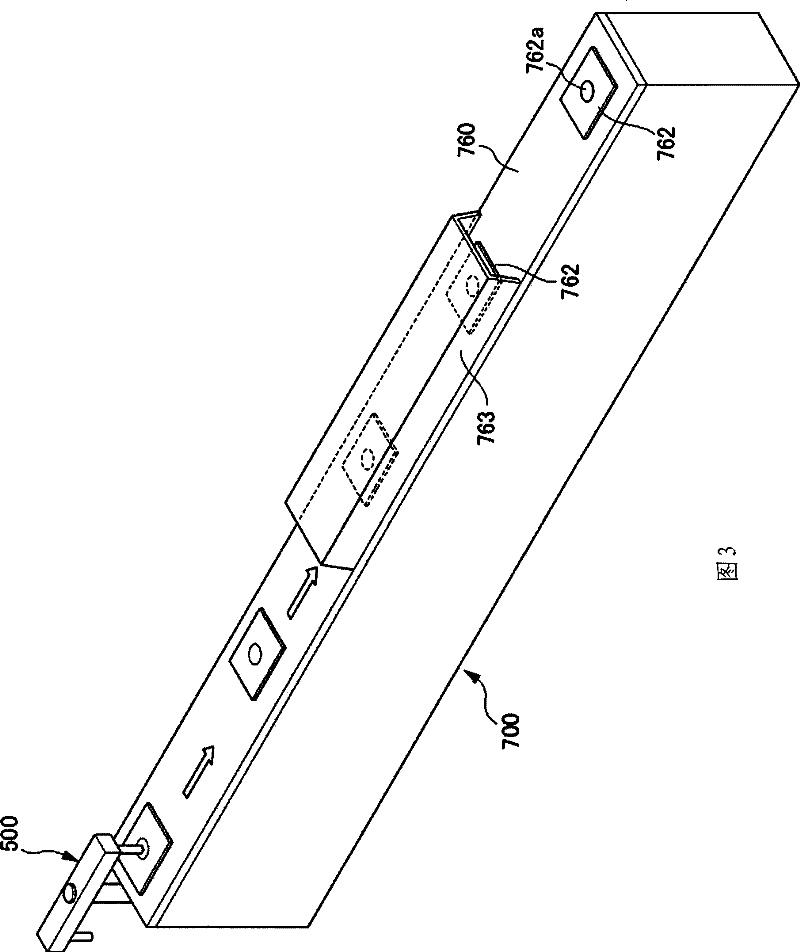

[0061] like figure 1 and figure 2 As shown, a manufacturing apparatus 100 (hereinafter referred to as manufacturing apparatus) for manufacturing optical elements from molten glass includes: a glass block manufacturing apparatus 400 , a precision press molding apparatus 300 , a conveying apparatus 700 , and transfer apparatuses 500 and 600 .

[0062] The glass gob manufacturing apparatus 400 shapes the molten glass C flowing down the channel 200 into a glass gob E using a molding die. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com