Sulfuric acid purification plate heat exchanger cleaning-free system and using method

A technology for plate heat exchangers and purification plates, which is applied in the direction of flushing, cleaning heat transfer devices, lighting and heating equipment, etc., can solve the problems of poor effect, long time for cleaning scale in plate heat exchangers, etc., so as to save cleaning agent and labor, saving maintenance time, good heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

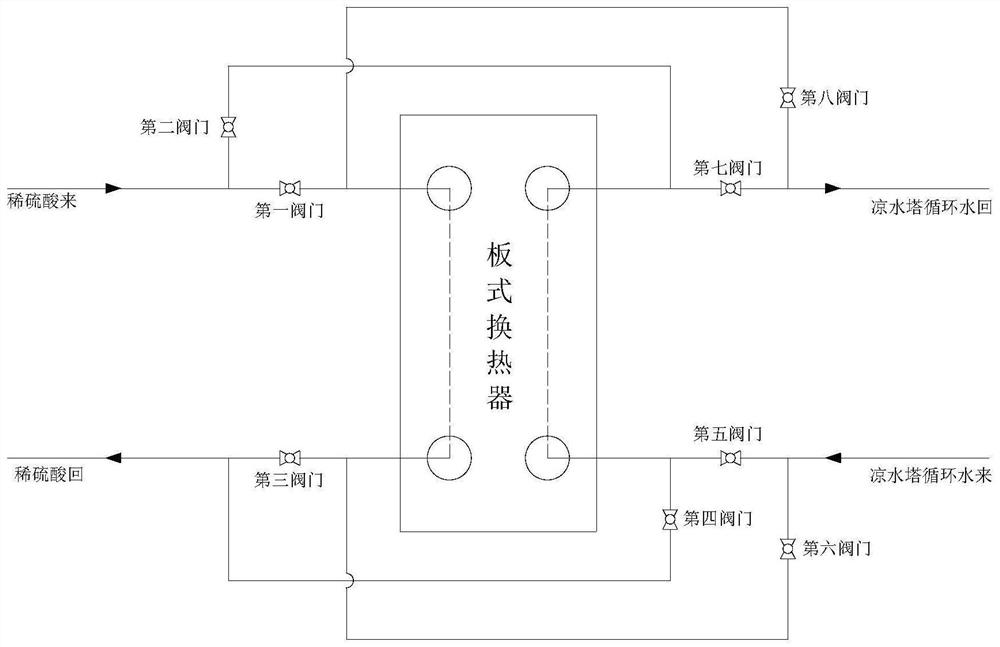

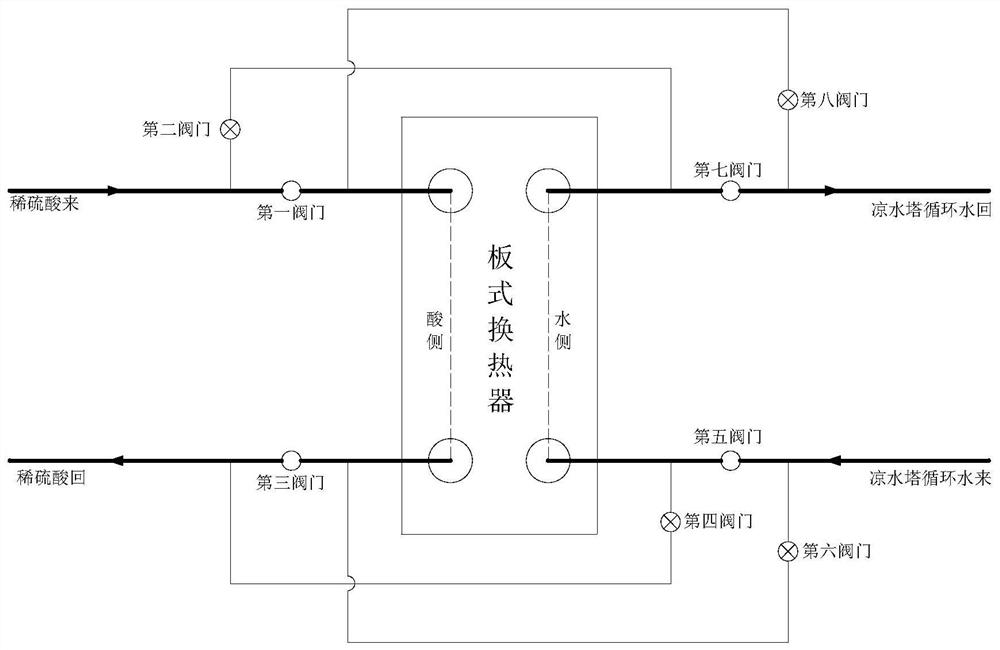

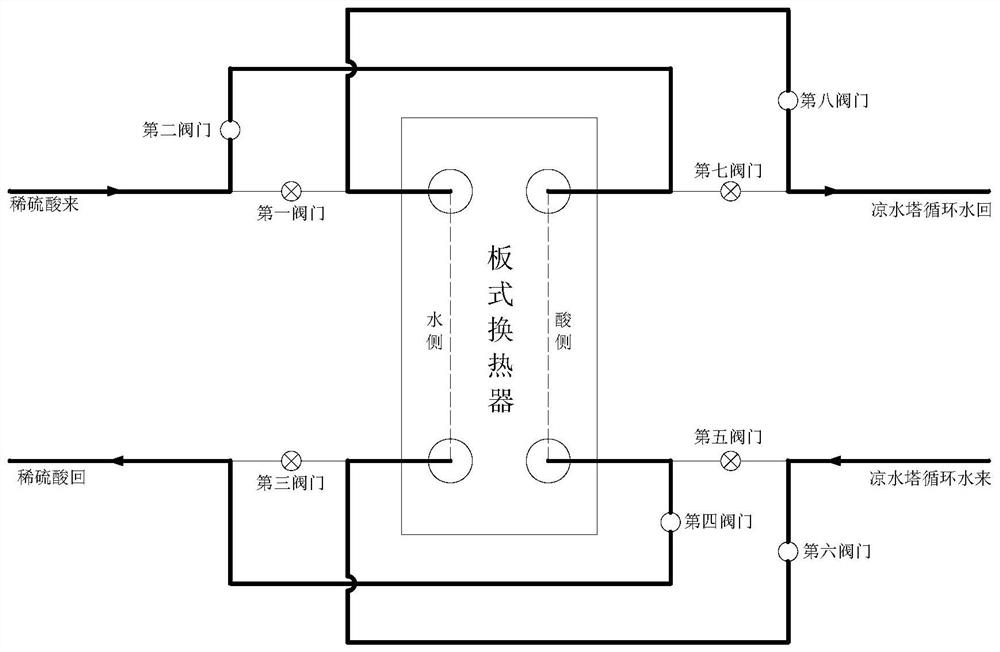

[0027] see Figure 1-3 , Sulfuric acid purification plate heat exchanger no-cleaning system, including the first production system and the second production system, the first production system includes the first dilute sulfuric acid injection pipe and the first cooling tower circulating water injection pipe, the first dilute sulfuric acid injection The end of the tube is fixedly connected to the plate heat exchanger, the first dilute sulfuric acid injection pipe is fixedly connected with the first valve, the plate heat exchanger is fixedly connected with the first dilute sulfuric acid discharge pipe, and the first dilute sulfuric acid discharge pipe is fixedly connected with the The third valve; the end of the circulating water injection pipe of the first cooling tower communicates with the plate heat exchanger, the fifth valve is fixedly connected to the circulating water injection pipe of the first cooling tower, and the first cooling water is also fixedly connected to the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com