Sewage heat exchange device capable of self-cleaning and scale inhibition

A heat exchange device and self-cleaning technology, which is applied in the direction of cleaning heat transfer devices, heat exchanger types, indirect heat exchangers, etc., can solve problems such as inability to achieve scaling self-cleaning, easy scaling, flow channel blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

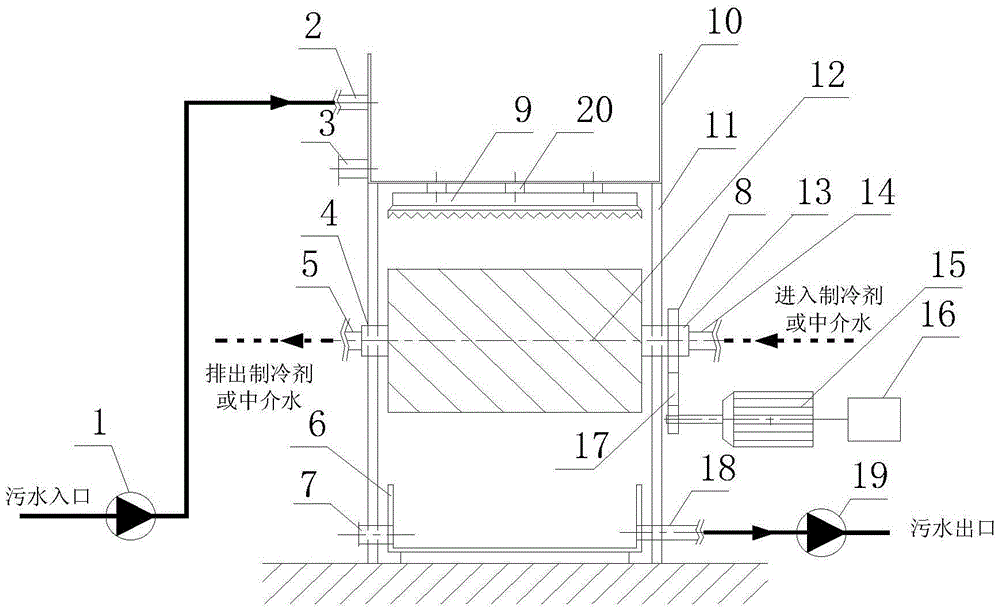

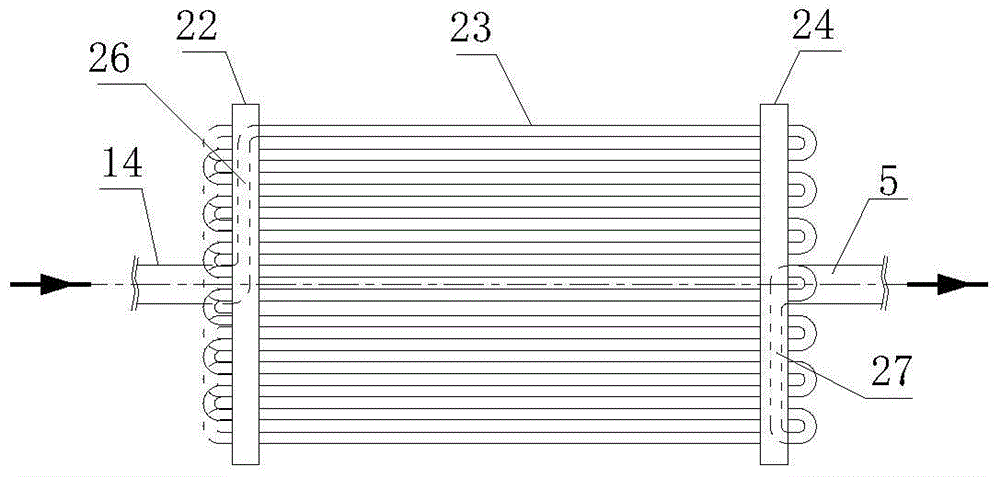

[0055] The structure of the sewage heat exchange device in this embodiment adopts the structure of the sewage heat exchange device given above, wherein the heat exchange coil tube row 23 is a circular straight tube made of copper. The heat exchange device is mainly suitable for heat exchange of sewage with less large-scale dirt and high water quality, such as sewage after primary treatment and sewage after secondary treatment in sewage treatment plants.

[0056] The operation process of the sewage heat exchange device is as follows:

[0057] (1) If figure 1 , Figure 2-a , Figure 2-b , Figure 2-cAs shown, the sewage is transported through the sewage lifting pump 1 to the sewage inlet 2 of the upper water supply tank through the pipeline, and the sewage enters the upper water supply tank 10, and the sewage passes through the water distributor 20 at the bottom of the upper water supply tank and flows into the water distributor 9 of the sawtooth overflow tank. Under the act...

Embodiment 2

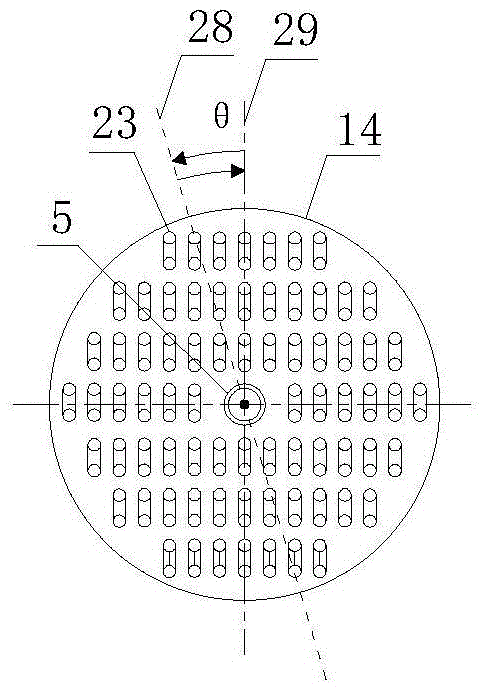

[0062] For sewage with more large-scale dirt and low water quality, such as raw sewage. The difference between this embodiment and Embodiment 1 is that during the operation process of the sewage heat exchange device, it runs continuously for 3 days or more, and takes the line connecting the frame centers of the wheel-type coil frames 22 and 24 as the axis to control the water flow through rotation. The device 16 controls the motor 15 to drive the wheel type heat exchange tube column 12 to rotate clockwise or counterclockwise, as Figure 2-b As shown, the vertical axis of symmetry of the wheel-type heat exchange tube row 12 turns from a vertical angle 29 to a θ angle 28. The θ angle is the rotation angle, and the rotation angle can vary from 170 to 190 degrees. Other steps are the same as in Embodiment 1.

Embodiment 3

[0064] For sewage containing more elongated pollutants, such as sewage containing hair. The difference between this embodiment and one of the first or second embodiments is that: during the operation of the self-cleaning and scale-inhibiting sewage heat exchange device, it operates continuously for 1 day or more, such as figure 1 As shown, taking the line connecting the frame centers of the wheel-type coil frames 22 and 24 as the axis, the motor 15 is controlled by the rotation controller 16 to drive the wheel-type heat exchange tube row 12 to rotate clockwise or counterclockwise, as shown in FIG. Figure 2-b As shown, the vertical axis of symmetry of the wheel-type heat exchange tube row 12 turns from a vertical angle 29 to a θ angle 28, where the θ angle is the rotation angle, and the rotation angle can vary from 80 to 100 degrees. Others are identical to embodiment one or two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com