A kind of dyeing method of polyester-cotton blended knitted fabric

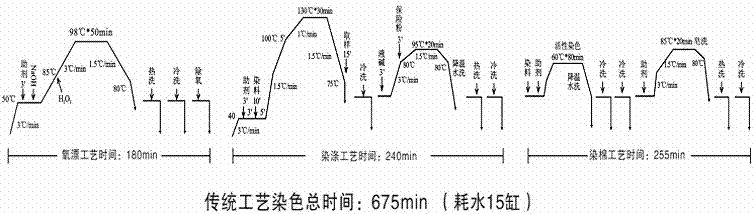

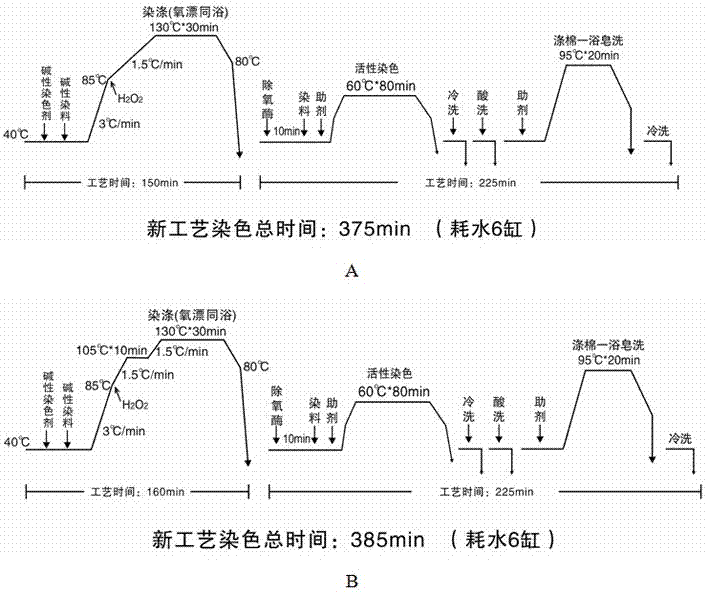

A technology of polyester-cotton blending and dyeing method, which is applied in the field of dyeing and finishing technology, can solve the problems of low production volume, long process time, and large labor load, and achieve the effects of improving fabric feel and style, shortening operation time, and preventing fabric scratches Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Pretreatment: put 10.00kg of polyester-cotton blended knitted gray fabric to be dyed into 40°C water for 10 minutes, take it out, and dehydrate;

[0024] 2) Dyeing of the polyester part and oxygen bleaching of the cotton part: put the water at a bath ratio of 1:10, add 0.15kg of alkaline polyester-cotton dyeing agent, and add 0.1kg of dye particles according to the desired color, mix well, and make alkaline dyeing Liquid; The raw material composition of basic polyester cotton dyeing agent used comprises by weight: 5 parts of NaOH, NaOH 2 CO 3 20 parts, 20 parts of solid organic buffer base (composed of KOH and triisopropanolamine in a weight ratio of 1:10), 15 parts of lignin; then soak the gray cloth pretreated in step 1) in the alkaline dyeing solution, Cover and seal, heat up to 85°C at a rate of 3°C / min, open the cover, add 0.4 kg of hydrogen peroxide with a volume concentration of 27.5%, cover and seal, heat up to 105°C at a rate of 1.5°C / min, keep warm for 10...

Embodiment 2

[0028] 1) Pretreatment: put 10.00kg of polyester-cotton blended knitted gray fabric to be dyed into 45°C water for 10 minutes, take it out, and dehydrate;

[0029] 2) Dyeing of the polyester part and oxygen bleaching of the cotton part: put the water at a bath ratio of 1:10, add 0.15kg of alkaline polyester-cotton dyeing agent, and add 0.1kg of dye particles according to the desired color, mix well, and make alkaline dyeing liquid; the raw material composition of alkaline polyester-cotton dyeing agent used comprises by weight: 15 parts of NaOH, NaOH 2 CO 3 25 parts, 30 parts of solid organic buffer base (composed of KOH and triisopropanolamine in a weight ratio of 1:15), 20 parts of lignin; then soak the gray cloth pretreated in step 1) in the alkaline dyeing solution, Cover and seal, heat up to 85°C at a rate of 3°C / min, open the cover, add 0.4 kg of hydrogen peroxide with a volume concentration of 27.5%, cover and seal, heat up to 105°C at a rate of 1.5°C / min, keep warm fo...

Embodiment 3

[0033] 1) Pretreatment: put 10.00kg of polyester-cotton blended knitted gray fabric to be dyed into 50°C water for 10 minutes, take it out, and dehydrate;

[0034] 2) Dyeing of the polyester part and oxygen bleaching of the cotton part: put the water at a bath ratio of 1:10, add 0.15kg of alkaline polyester-cotton dyeing agent, and add 0.1kg of dye particles according to the desired color, mix well, and make alkaline dyeing Liquid; The raw material composition of basic polyester cotton dyeing agent used comprises by weight: 18 parts of NaOH, NaOH 2 CO 3 35 parts, 45 parts of solid organic buffer base (composed of KOH and triisopropanolamine in a weight ratio of 1:20), 25 parts of lignin; then soak the gray cloth pretreated in step 1) in alkaline dyeing solution, Cover and seal, heat up to 85°C at a rate of 3°C / min, open the cover, add 0.4 kg of hydrogen peroxide with a volume concentration of 27.5%, cover and seal, heat up to 105°C at a rate of 1.5°C / min, keep warm for 10 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com