Gasket cleaning machine

A cleaning machine and gasket technology, applied in cleaning methods and utensils, cleaning methods using liquids, cleaning methods using tools, etc., can solve the problems of high cost, inability to guarantee cleaning quality, low efficiency, etc. Conducive to repeated use and simple mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

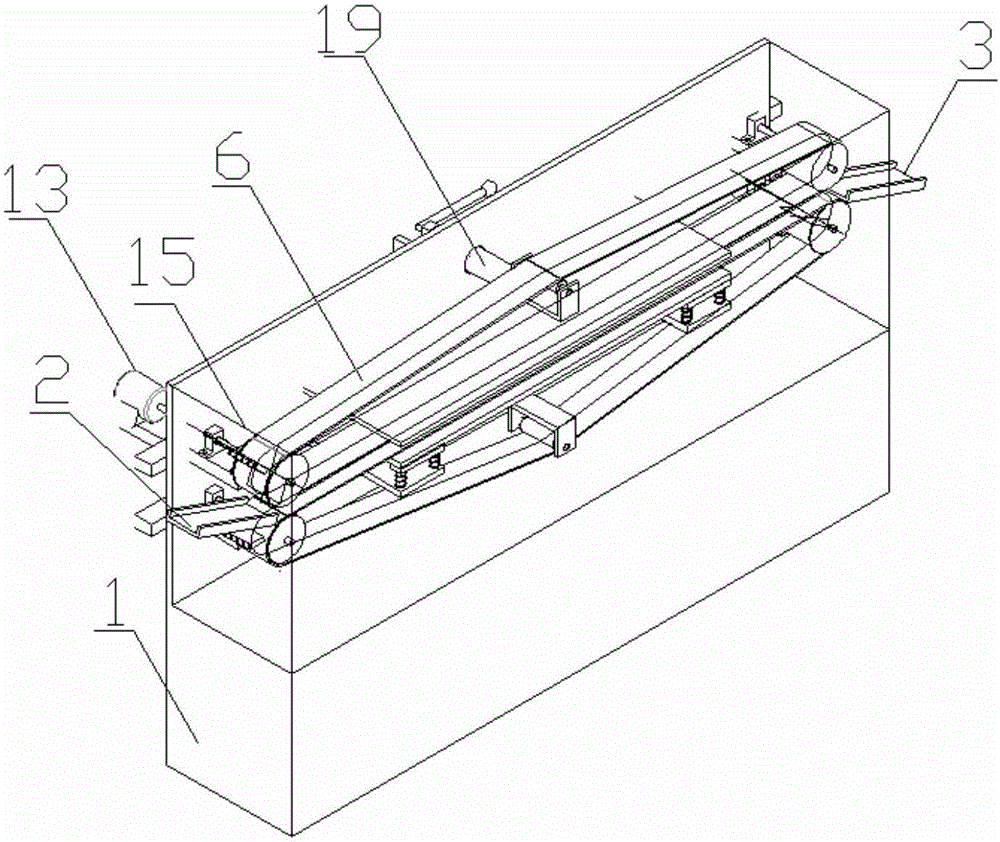

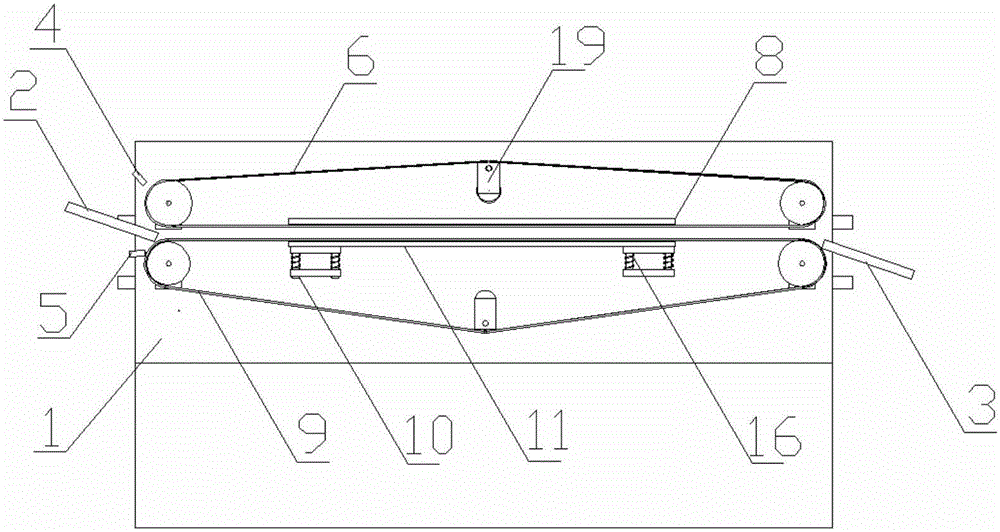

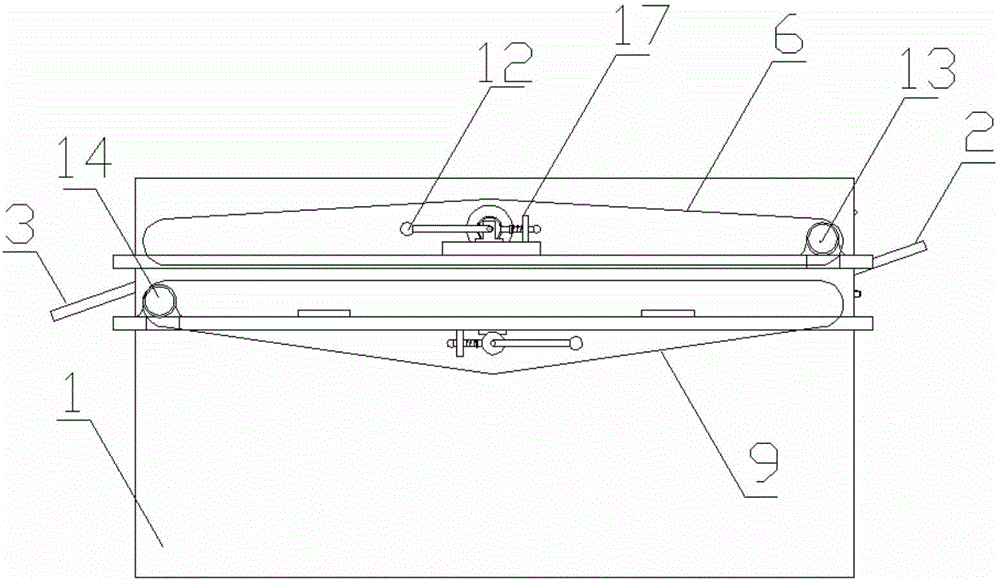

[0019] Further illustrate the present invention below in conjunction with accompanying drawing.

[0020] Such as figure 1 , 2 As shown in and 3, the gasket cleaning machine includes a cleaning machine main body 1, an inlet tank 2, an outlet tank 3, a protective cover 15, a cleaning device, a nozzle device, a tensioning device, a gasket thickness adjusting device, a single-chip microcomputer control module, and a pulse distributor and motor drive modules. The cleaning device is arranged in the cleaning machine main body 1, and is covered by a protective cover 15, and is isolated from the outside air; the cleaning device includes an upper cleaning belt 6 and a lower cleaning belt 9; Drive, install the pulley of lower cleaning belt 9 to be driven by lower stepper motor 14; Import groove 2 is arranged on the input end of upper cleaning belt 6 and lower cleaning belt 9, and outlet groove 3 is arranged on upper cleaning belt 6 and lower cleaning belt 9 The output end of the clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com