Splitting device

A technology of cleavage and dicing, which is applied in the field of cleavage devices for cleavage of semiconductors, which can solve the problems of time-consuming and labor-intensive operation, wear samples, cumbersome processes, etc., and achieve the effects of avoiding damage, improving quality, and improving process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment provides a cleavage device for realizing the natural cleavage of bars into chips. Wherein, in order to illustrate the feature of the present invention more clearly, define: each bar comprises two parts, and a part of dicing is the part to be cleaved as the quasi-chip, and the remaining part is the bar to be cleaved. The thickness of the bars in this embodiment is 70-150 μm, and the width of a cut chip is about 500 μm.

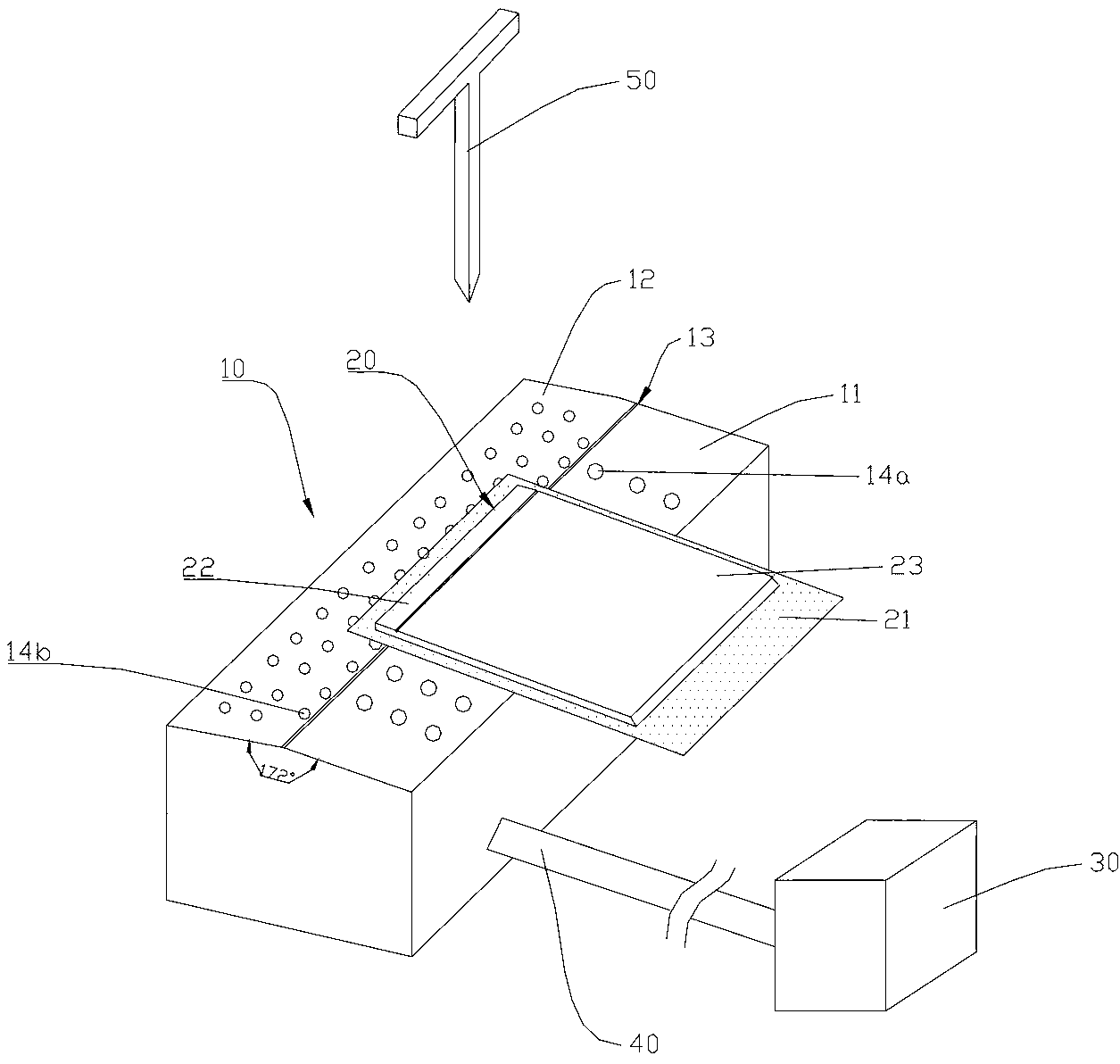

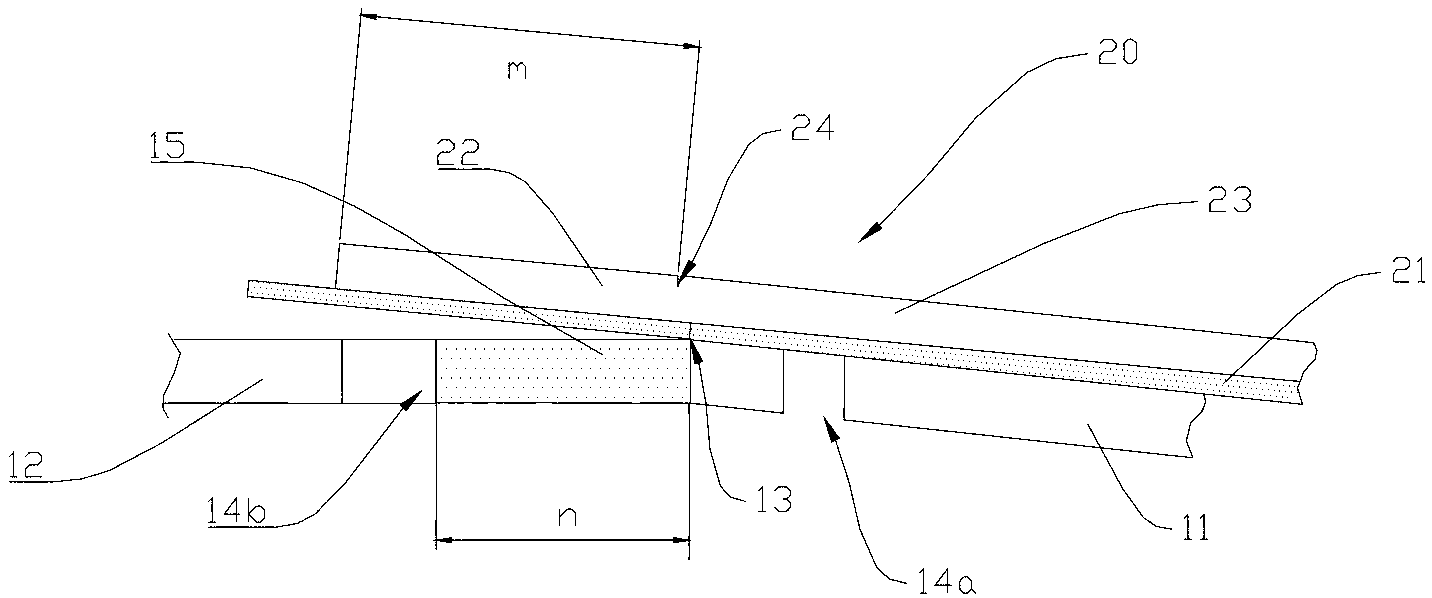

[0024] Such as figure 1 As shown, the cleavage device provided in this embodiment includes:

[0025] The cuboid adsorption cavity 10 is provided with a first upper cover 11 and a second upper cover 12 on its top. The second upper cover 12 is arranged horizontally parallel to the bottom of the adsorption cavity 10 , and the first upper cover 11 and the second upper cover 12 support each other at an included angle (172°) to form a ridge 13 after tilting. Wherein, the ridge 13 is used to straddle the bar 20 above it as a fulcrum for cleav...

Embodiment 2

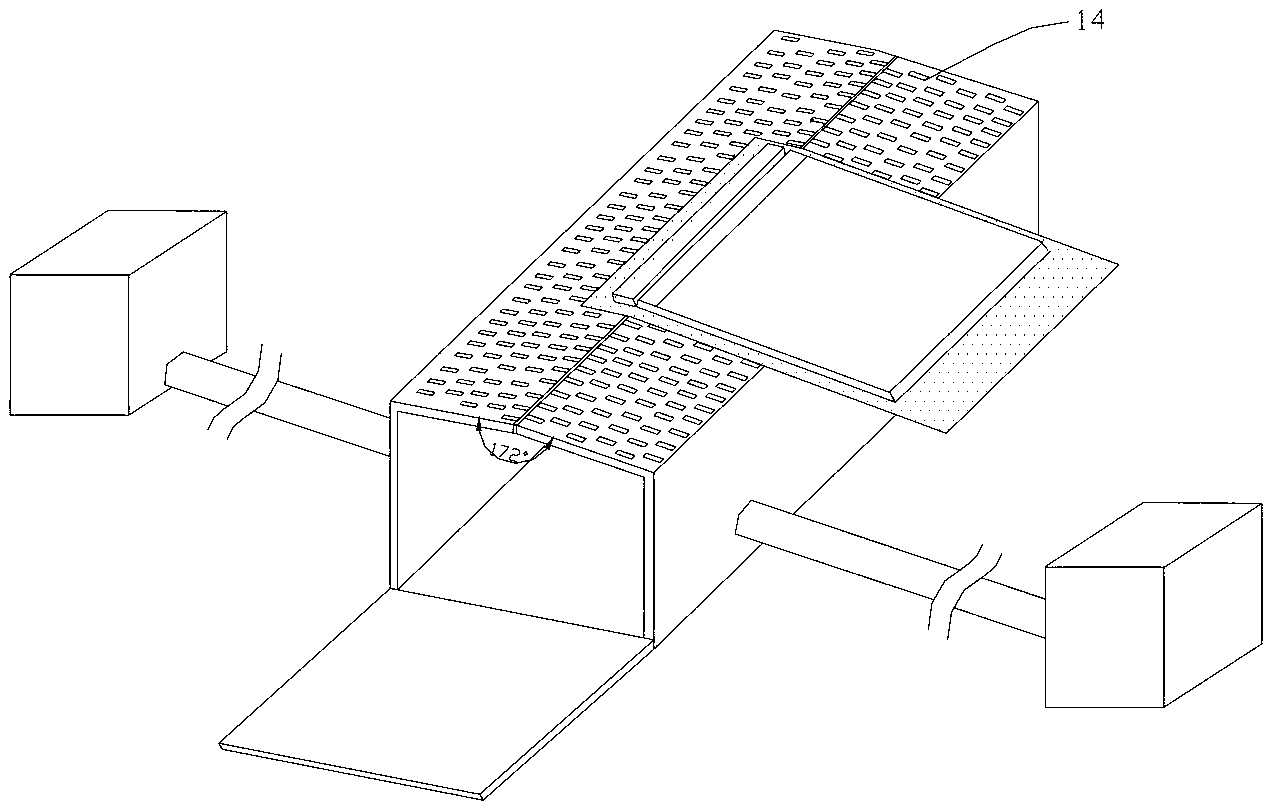

[0051] This embodiment is improved on the basis of Embodiment 1, especially for some bars with a larger thickness (150-400 μm), it can be better cleaved. like Figure 5 As shown in (a), the adsorption chamber 10 of this embodiment also has holes 16 on the scribing table 15 . Corresponding to the bottom of the scribing table 15, a support assembly 60 is provided in the adsorption cavity 10 for passing through the holes 16 opened on the scribing table 15 to apply the adsorption force to the bar 20 Support forces in the opposite direction. In order to avoid affecting the stability of dicing, the width of the hole groove 16 can be no more than 1 / 2 of the scribing table 15, for example, corresponding to a chip with a width of 500 μm, and the dicing table 15 is set to 400 μm, then the width of the hole groove 16 will be No more than 200μm. However, the width and shape of the hole 16 are not limited, and can be adjusted according to the shape of the actual support assembly 60 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com