Low-carbon-equivalent low-temperature-usable high-thickness toothed rack steel and manufacturing method thereof

A carbon equivalent and large thickness technology, applied in the field of large thickness rack steel and its manufacturing, can solve the problems of not being able to manufacture large thickness rack steel plates for offshore platforms, not being able to meet the requirements of easy welding, and high carbon equivalent of steel plates, so as to save the need for compounding Effects of processing, improved yield, and low carbon equivalent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

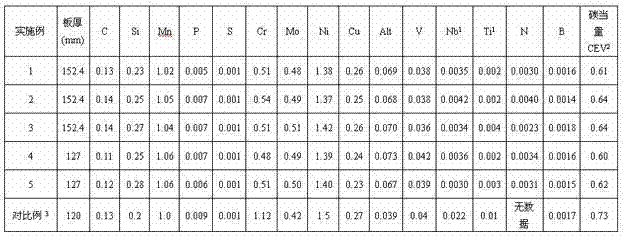

Embodiment 1

[0037] The rack steel plate involved in Embodiments 1-3 has a thickness of 152.4 mm.

[0038] The production process of these large thickness rack steel plates is as follows:

[0039] According to the chemical composition of the above-mentioned rack steel plate, the smelting raw materials are arranged in turn for KR molten iron pretreatment - converter smelting - LF refining - RH refining - continuous casting (thickness of continuous casting slab: 370mm) - continuous casting slab with cover and slow cooling - continuous casting slab cleaning - Heating (insulation treatment) - Descaling with high pressure water - Controlled rolling - Straightening - Slow cooling of batches or slow cooling under controlled conditions - Quenching and tempering.

[0040] Further, the specific process of the above-mentioned heating, controlled rolling, and cooling stages is: heating the continuous casting slab to 1250°C for 2.5 hours (Example 1 and 2) or 1200°C for 3 hours (Example 3), and then Af...

Embodiment 1

[0042] To embodiment 1: heating temperature 910 DEG C, in furnace time 1.8min / mm, use quenching machine water quenching;

Embodiment 2

[0043] To embodiment 2: heating temperature 900 ℃, in furnace time 1.8min / mm, use quenching machine water quenching;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com