Production line for microalgae active cell nutritional repair liquid

A technology for cell nutrition and remediation solution, applied in enzymology/microbiology devices, bioreactors/fermenters for specific purposes, biochemical instruments, etc. Activity, reducing plant stress resistance and other issues, to achieve the effect of improving space utilization, reducing contact, and rationally arranging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

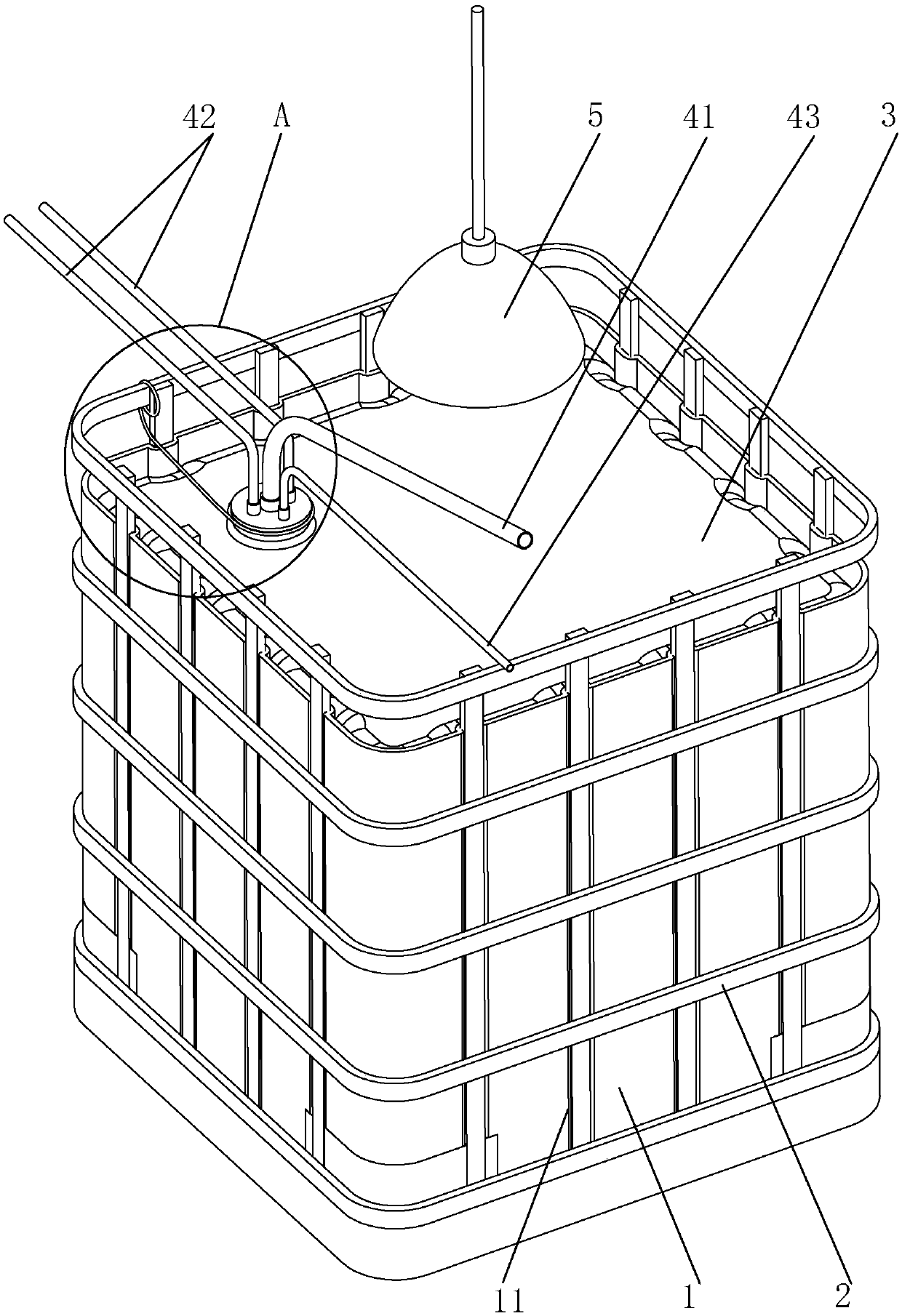

[0046] The present invention will be described in further detail below in conjunction with accompanying drawing, and the words " front ", " rear ", " left ", " right ", " upper " and " lower " used in the following description refer to the direction in the accompanying drawing, word "Bottom" and "top", "inner" and "outer" refer to directions toward and away from, respectively, the geometric center of a particular component.

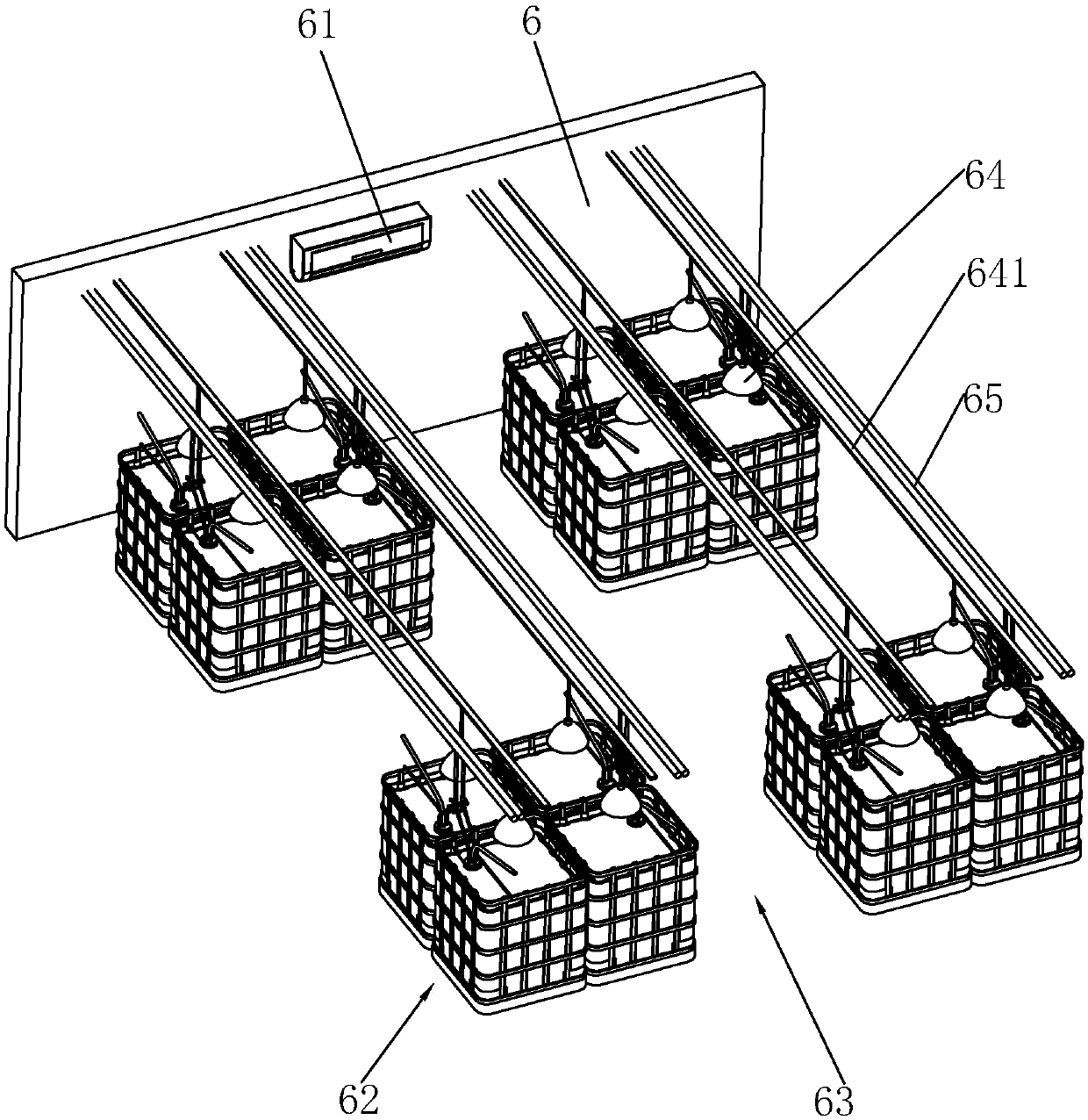

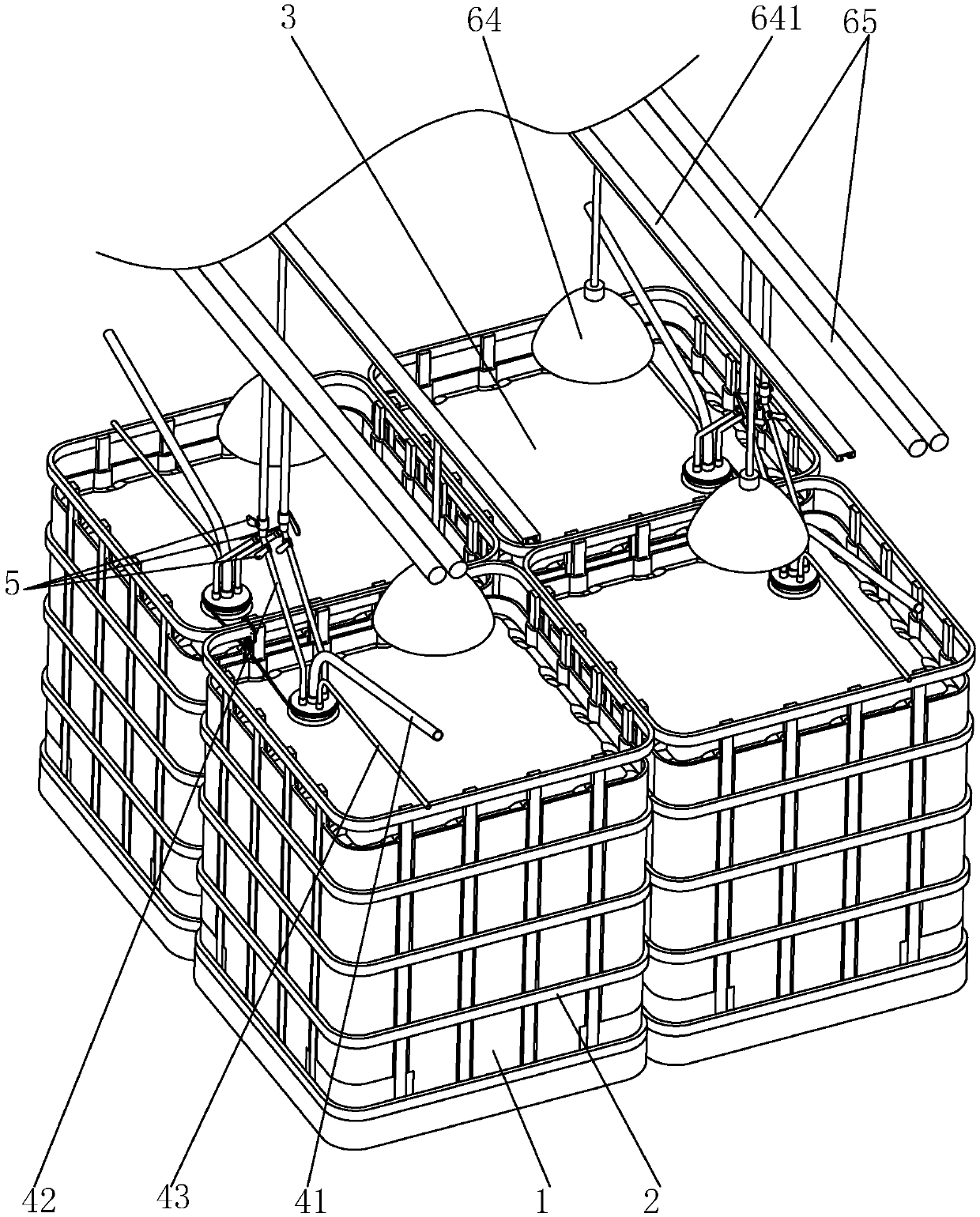

[0047] A production line for microalgae active cell nutrient repair liquid, which includes the following production areas in turn: a single cell selection area, an initial expansion cultivation area, and a final expansion cultivation area 6 (refer to figure 1 ), mixing area, filling area.

[0048]The monomer cell selection area includes an ultra-clean workbench, which is equipped with an electron microscope. The state of the monomer cells can be carefully observed through the electron microscope, providing guarantee for the selection of suitable monomer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com